2 Extruders, 1 Hotend

Posted by uGen

|

2 Extruders, 1 Hotend October 18, 2013 06:05PM |

Registered: 11 years ago Posts: 490 |

Hey folks,

some time ago I had the idea to use one hotend for dual extrusion. Basically, the filament change would be performed by retracting the old filament to a Y-junction and pushing the new one in. Thinking that this might not work reliably because of the plug of molten plastic needing to fit through the whole length of the hotend, this idea was abandoned after a short while.

However, it turns out that someone thought of exactly the same and got the whole contraption to work. I think he might have posted his results in this forum with accompanying YouTube videos, but no matter how hard I search, all traces about this dual extrusion method seem to have vanished. Even my YouTube history doesn't seem to remember the videos.

With my E3D v4.1 hotend, I noticed rather short zones of molten plastic after pulling out the filament, so when I insert new filament, only 1 or 2 cm of old and mixed plastic extrudate exits the nozzle. Which is totally contrary to what I have experienced with the GRRF hotend where there is a much bigger pool of molten plastic that has to be purged first. This leads me to think that with the right hotend (all metal?), dual extrusion can be done without much additional cost and infrastructure especially when you have got a bowden system installed.

To list what major issues I could think of:

Advantages:

- one hotend: reduces oozing, saves space, weight and cost

- no leveling of second hotend necessary -> easy implementation

- support material extrudes at roughly the same temperature as build material (PLA - PVA / ABS - HIPS)

Disadvantages:

- some material is lost due to mixture zone between both filaments - either blemishes in print or extruded into a waste container

- the filament change takes time, with long hotends, this might become more and more troublesome

- the molten plug MIGHT get stuck somewhere along the way

Unknowns:

- what alterations have to be made to the standard Marlin firmware?

- what happens if one heater + thermistor is paired to two extruders? Will the settings for both extruder temperatures interfere in the standard firmware scenario?

Here is a little animation to illustrate dual extrusion with one hotend:

Sorry about the quality, it was a little bit difficult to squeeze in enough to make sense.

Also, if anyone can remember the thread I am talking about, please link me to it.

some time ago I had the idea to use one hotend for dual extrusion. Basically, the filament change would be performed by retracting the old filament to a Y-junction and pushing the new one in. Thinking that this might not work reliably because of the plug of molten plastic needing to fit through the whole length of the hotend, this idea was abandoned after a short while.

However, it turns out that someone thought of exactly the same and got the whole contraption to work. I think he might have posted his results in this forum with accompanying YouTube videos, but no matter how hard I search, all traces about this dual extrusion method seem to have vanished. Even my YouTube history doesn't seem to remember the videos.

With my E3D v4.1 hotend, I noticed rather short zones of molten plastic after pulling out the filament, so when I insert new filament, only 1 or 2 cm of old and mixed plastic extrudate exits the nozzle. Which is totally contrary to what I have experienced with the GRRF hotend where there is a much bigger pool of molten plastic that has to be purged first. This leads me to think that with the right hotend (all metal?), dual extrusion can be done without much additional cost and infrastructure especially when you have got a bowden system installed.

To list what major issues I could think of:

Advantages:

- one hotend: reduces oozing, saves space, weight and cost

- no leveling of second hotend necessary -> easy implementation

- support material extrudes at roughly the same temperature as build material (PLA - PVA / ABS - HIPS)

Disadvantages:

- some material is lost due to mixture zone between both filaments - either blemishes in print or extruded into a waste container

- the filament change takes time, with long hotends, this might become more and more troublesome

- the molten plug MIGHT get stuck somewhere along the way

Unknowns:

- what alterations have to be made to the standard Marlin firmware?

- what happens if one heater + thermistor is paired to two extruders? Will the settings for both extruder temperatures interfere in the standard firmware scenario?

Here is a little animation to illustrate dual extrusion with one hotend:

Sorry about the quality, it was a little bit difficult to squeeze in enough to make sense.

Also, if anyone can remember the thread I am talking about, please link me to it.

|

Re: 2 Extruders, 1 Hotend October 18, 2013 07:26PM |

Registered: 11 years ago Posts: 544 |

|

Re: 2 Extruders, 1 Hotend October 18, 2013 07:28PM |

Registered: 10 years ago Posts: 34 |

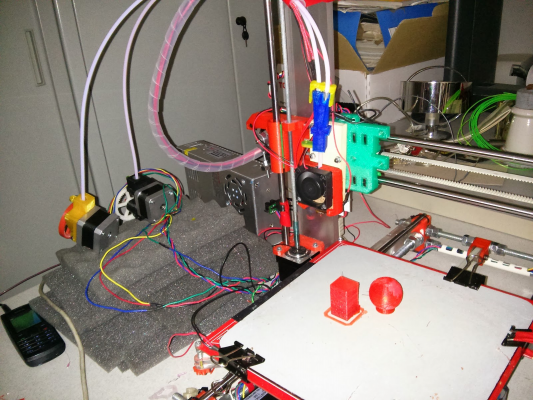

What a coincidence! I have been scratching my head with how this strange extruder worked because it has two motors and one hot end:

[3dita.falaschi.com]

Is that it and can you elaborate on it if so?

Now that I get it the implications are amazing. You could mix up to 4 this way and if you want a blended color you just do the colors in succession and if not you extrude the blended section over the infill! The tricky part seems the firmware.

Edited 1 time(s). Last edit at 10/18/2013 07:32PM by Coherent.

[3dita.falaschi.com]

Is that it and can you elaborate on it if so?

Now that I get it the implications are amazing. You could mix up to 4 this way and if you want a blended color you just do the colors in succession and if not you extrude the blended section over the infill! The tricky part seems the firmware.

Edited 1 time(s). Last edit at 10/18/2013 07:32PM by Coherent.

|

Re: 2 Extruders, 1 Hotend October 20, 2013 03:05AM |

Registered: 11 years ago Posts: 490 |

@aduy: You are right. I mainly considered bowden designs because I wanted to keep X carriage weight to a minimum. However, I am unsure about how reliable feeding filament into an extruder without decreasing tension on the idler first will be. Given that the idler doesn't have to sit absolutely tight against the hobbed bolt when no filament is in the extruder, though, I can imagine that this might be a non-issue.

@Coherent: Thank you! I have given up all hope on finding this design again.

The principle is fairly easy: just like when you manually change filament and yank the old one out of the hotend, this design pulls the old filament out via a very long retraction. The new filament is fed into the hotend by its own extruder and off we go again. I am not sure whether the person had to change anything at all in the firmware, but judging from what I read on his blog via Google Translate, he just implemented some clever G-Code hackery.

Blending colors wouldn't be so simple with this design, at least not in a reasonable timeframe. As you can see on his blog, the filament change took some time (although this can be optimized with better hotend design, I guess). For me, it's more about being able to extrude support material and build material from the same nozzle as it will be completely OK to have some imperfect support structures as long as the length of extruded old filament remains short. So, when changing from build material to support, a nozzle purge may not be necessary, while the other way round, it would make sense to have consistent filament quality.

@Coherent: Thank you! I have given up all hope on finding this design again.

The principle is fairly easy: just like when you manually change filament and yank the old one out of the hotend, this design pulls the old filament out via a very long retraction. The new filament is fed into the hotend by its own extruder and off we go again. I am not sure whether the person had to change anything at all in the firmware, but judging from what I read on his blog via Google Translate, he just implemented some clever G-Code hackery.

Blending colors wouldn't be so simple with this design, at least not in a reasonable timeframe. As you can see on his blog, the filament change took some time (although this can be optimized with better hotend design, I guess). For me, it's more about being able to extrude support material and build material from the same nozzle as it will be completely OK to have some imperfect support structures as long as the length of extruded old filament remains short. So, when changing from build material to support, a nozzle purge may not be necessary, while the other way round, it would make sense to have consistent filament quality.

|

Re: 2 Extruders, 1 Hotend October 20, 2013 05:05PM |

Registered: 10 years ago Posts: 23 |

This is something I was thinking about a few days back after I had a blockage in my hotend with nylon (I had to give the weed eater line ago), after I finished messing about with the nylon I changed back to yellow PLA, did a print or two and then suddenly got a blockage, after working the hotend to remove the blockage a bit of nylon started to come out, then it started to blend with the yellow PLA in the print in a gradient fashion, the nylon is red and so I got a red to yellow gradient(orange) that looked pretty cool and surprisingly the amalgamated nylon/PLA seems to be strong.

This got me thinking, I would like to construct a three filament hotend with each filament coming together in the melt zone. If red, green and blue filament is used then I should be able to get a near full color spectrum and have a full color printer, however the electronics would be the problem as I am not sure if any boards available could be used in a way to control the amount of each color at any given time. making such a hotend won't be a big deal but building the electronics would be too much

This got me thinking, I would like to construct a three filament hotend with each filament coming together in the melt zone. If red, green and blue filament is used then I should be able to get a near full color spectrum and have a full color printer, however the electronics would be the problem as I am not sure if any boards available could be used in a way to control the amount of each color at any given time. making such a hotend won't be a big deal but building the electronics would be too much

|

Re: 2 Extruders, 1 Hotend October 20, 2013 05:14PM |

Registered: 11 years ago Posts: 195 |

|

Re: 2 Extruders, 1 Hotend October 20, 2013 05:38PM |

Registered: 11 years ago Posts: 490 |

@psilocin: Do you mean something similar to what RichRap has built? 3 Color Extruder

Again, this is NOT about mixing the colors, but extruding multiple materials from the same nozzle instead of using several nozzles.

Again, this is NOT about mixing the colors, but extruding multiple materials from the same nozzle instead of using several nozzles.

|

Re: 2 Extruders, 1 Hotend October 20, 2013 06:06PM |

Registered: 10 years ago Posts: 23 |

Yeah, thats basically what I am thinking, thanks for the link.

I see what you are saying and I agree that one nozzle used instead of several is a plus, but if you go so far as this I think the next step of blending wouldn't be far off

I have been thinking about my next printer having multiple hotends, but now I think I am going to go this route of a color blending nozzle instead, it's the next level

I see what you are saying and I agree that one nozzle used instead of several is a plus, but if you go so far as this I think the next step of blending wouldn't be far off

I have been thinking about my next printer having multiple hotends, but now I think I am going to go this route of a color blending nozzle instead, it's the next level

|

Re: 2 Extruders, 1 Hotend October 21, 2013 04:15PM |

Registered: 11 years ago Posts: 490 |

|

Re: 2 Extruders, 1 Hotend October 24, 2013 12:10PM |

Registered: 11 years ago Posts: 301 |

Hi folks!

I'm at the update 5... look the improvments...

( i hope to start a little campaign in indiegogo for develop a 4 colour model...)

aaaaand... @uGen ...I write on developer page about this project... on 29 august

and you have reply-me that:

uGen [ PM ]

Re: Botobjects color printer - hoax?

August 30, 2013 03:24AM Registered: 11 months ago

Posts: 385

This looks like an idea that I also shortly thought about.

I pretty much discarded the idea because I thought that the plug from the melted plastic would be a pain to push in again...

but seeing it work makes me want to try it out, too.

Really nice idea because you save costs and weight with only 1 hot end!

Extruding filament with widely different melting temperatures could be a little bit tricky, though.

Edited 1 time(s). Last edit at 08/30/2013 03:25AM by uGen.

---------

and now...YOU have an idea??????? you write that.... "some time ago I had the idea to use one hotend for dual extrusion."

if you have tested it ... publish the results of the research you've done... or some photo...

---------

but ... don't worry.... all of Advantages - Disadvantages - Unknowns

are now solved and published on my blog..

thanks to @Coherent ...

Forgive my arrogance, but I do not like this kind of thing, because if Ugen had published the results of his research, I would not have had to start the work from scratch!!!

and... some time ago I had the idea.... I have design IT I have make/tested IT I have improved IT.....!

[www.falla3d.com]

[3dita.blogspot.it]

I'm at the update 5... look the improvments...

( i hope to start a little campaign in indiegogo for develop a 4 colour model...)

aaaaand... @uGen ...I write on developer page about this project... on 29 august

and you have reply-me that:

uGen [ PM ]

Re: Botobjects color printer - hoax?

August 30, 2013 03:24AM Registered: 11 months ago

Posts: 385

This looks like an idea that I also shortly thought about.

I pretty much discarded the idea because I thought that the plug from the melted plastic would be a pain to push in again...

but seeing it work makes me want to try it out, too.

Really nice idea because you save costs and weight with only 1 hot end!

Extruding filament with widely different melting temperatures could be a little bit tricky, though.

Edited 1 time(s). Last edit at 08/30/2013 03:25AM by uGen.

---------

and now...YOU have an idea??????? you write that.... "some time ago I had the idea to use one hotend for dual extrusion."

if you have tested it ... publish the results of the research you've done... or some photo...

---------

but ... don't worry.... all of Advantages - Disadvantages - Unknowns

are now solved and published on my blog..

thanks to @Coherent ...

Forgive my arrogance, but I do not like this kind of thing, because if Ugen had published the results of his research, I would not have had to start the work from scratch!!!

and... some time ago I had the idea.... I have design IT I have make/tested IT I have improved IT.....!

[www.falla3d.com]

[3dita.blogspot.it]

|

Re: 2 Extruders, 1 Hotend October 24, 2013 04:27PM |

Registered: 11 years ago Posts: 490 |

Well, I thought about using two extruders to feed one hotend, but the idea never left the "thinking about" phase because I thought this method would have too many drawbacks. And then you came along to prove that it is indeed fully possible with good results. So I kept that in mind, but couldn't find the post again where you published your results and opened this thread in hopes to find it again.

By the way, there is a group discussing the same thing in the German sub-forum...

EDIT: Ah, I see you already found it.

Edited 1 time(s). Last edit at 10/24/2013 04:29PM by uGen.

By the way, there is a group discussing the same thing in the German sub-forum...

EDIT: Ah, I see you already found it.

Edited 1 time(s). Last edit at 10/24/2013 04:29PM by uGen.

|

Re: 2 Extruders, 1 Hotend October 24, 2013 05:14PM |

Registered: 11 years ago Posts: 301 |

well, it was just to clarify that if YOU found an answers to the questions that YOU place yourself ... on MY BLOG You found all the answers to your questions..

(in the update7 , because the update6 is dedicated to you uGen... you can find a new design of the extruder, more compact and more fast, with the plug-in magic-hole , the basket and many others improvments)

so...MAKE and TEST before declaring that a thing is not possible!

[www.falla3d.com]

[3dita.blogspot.it]

(in the update7 , because the update6 is dedicated to you uGen... you can find a new design of the extruder, more compact and more fast, with the plug-in magic-hole , the basket and many others improvments)

so...MAKE and TEST before declaring that a thing is not possible!

[www.falla3d.com]

[3dita.blogspot.it]

|

Re: 2 Extruders, 1 Hotend October 24, 2013 06:18PM |

Registered: 11 years ago Posts: 490 |

|

Re: 2 Extruders, 1 Hotend October 25, 2013 03:26AM |

Registered: 11 years ago Posts: 301 |

Point To Point REPLY.

uGen Wrote:

-------------------------------------------------------

> Hey folks,

>

> some time ago I had the idea to use one hotend for

> dual extrusion. Basically, the filament change

> would be performed by retracting the old filament

> to a Y-junction and pushing the new one in.

here is a description of YOURS fantastic IDEA (19 august)

> Thinking that this might not work reliably because

> of the plug of molten plastic needing to fit

> through the whole length of the hotend, this idea

> was abandoned after a short while.

the system works ! (23 august)

> However, it turns out that someone thought of

> exactly the same and got the whole contraption to

> work. I think he might have posted his results in

> this forum with accompanying YouTube videos, but

> no matter how hard I search, all traces about this

> dual extrusion method seem to have vanished. Even

> my YouTube history doesn't seem to remember the

> videos.

> <just needed to do a search on the forum, in the previous post you have demonstrated the ability to use the forum.

<just needed to do a search on the forum, in the previous post you have demonstrated the ability to use the forum.

but I want to help you, for the umpteenth time

here is the link to the article and the video you tube

>

> With my E3D v4.1 hotend, I noticed rather short

> zones of molten plastic after pulling out the

> filament, so when I insert new filament, only 1 or

> 2 cm of old and mixed plastic extrudate exits the

> nozzle. Which is totally contrary to what I have

> experienced with the GRRF hotend where there is a

> much bigger pool of molten plastic that has to be

> purged first. This leads me to think that with the

> right hotend (all metal?), dual extrusion can be

> done without much additional cost and

> infrastructure especially when you have got a

> bowden system installed.

>

> To list what major issues I could think of:

>

and now...the I reply at all ADVANTAGES/DISAVANTAGES/UNKNOWNS

> Advantages:

> - one hotend: reduces oozing, saves space, weight

> and cost

> - no leveling of second hotend necessary -> easy

> implementation

> - support material extrudes at roughly the same

true and obvious.

> temperature as build material (PLA - PVA / ABS -

> HIPS)

you can use only one material at a time

I test:

( PLA - PLA)

( ABS - ABS)

(NYLON - NYLON)

>

> Disadvantages:

> - some material is lost due to mixture zone

> between both filaments - either blemishes in print

> or extruded into a waste container

SOLVED and IMPROVE.I speak of this on august 19

SOLVED and IMPROVE.I speak of this on august 19

My solution is here

I create a "basket" were if you want,

with only adding a few lines of gcode on slic3r,

you can use a single color or shaded.

> - the filament change takes time, with long

> hotends, this might become more and more

> troublesome

> - the molten plug MIGHT get stuck somewhere along

> the way

SOLVED. ...in the next update....soon...

SOLVED. ...in the next update....soon...

>

> Unknowns:

> - what alterations have to be made to the standard

> Marlin firmware?

SOLVED but.....

SOLVED but.....

I prefer to let you study a bit of time, even if my extruder works just for the changes made to the firmware, I want to see that you will find solution

> - what happens if one heater + thermistor is

> paired to two extruders? Will the settings for

> both extruder temperatures interfere in the

> standard firmware scenario?

SOLVED.. hehehe

SOLVED.. hehehe

the same...

I prefer to let you study a bit of time, even if my extruder works just for the changes made to the firmware, I want to see that you will find solution

>

> Here is a little animation to illustrate dual

> extrusion with one hotend:

>

> [attachment 20089 2e1h.gif]

> Sorry about the quality, it was a little bit

> difficult to squeeze in enough to make sense.

>

> Also, if anyone can remember the thread I am

> talking about, please link me to it.

... here is my blog...

on right top you can translate (google) in all language...

is not very accurate but I am sure that you are able to understand very well, since you've written everything I have talked about for months.

since you've written everything I have talked about for months.

In conclusion...

FalaUnion Mono system works perfectly.

now I'm developing the latest improvements, and........ SECRET...

you tube

[www.falla3d.com]

[3dita.blogspot.it]

uGen Wrote:

-------------------------------------------------------

> Hey folks,

>

> some time ago I had the idea to use one hotend for

> dual extrusion. Basically, the filament change

> would be performed by retracting the old filament

> to a Y-junction and pushing the new one in.

here is a description of YOURS fantastic IDEA (19 august)

> Thinking that this might not work reliably because

> of the plug of molten plastic needing to fit

> through the whole length of the hotend, this idea

> was abandoned after a short while.

the system works ! (23 august)

> However, it turns out that someone thought of

> exactly the same and got the whole contraption to

> work. I think he might have posted his results in

> this forum with accompanying YouTube videos, but

> no matter how hard I search, all traces about this

> dual extrusion method seem to have vanished. Even

> my YouTube history doesn't seem to remember the

> videos.

>

<just needed to do a search on the forum, in the previous post you have demonstrated the ability to use the forum.

<just needed to do a search on the forum, in the previous post you have demonstrated the ability to use the forum.but I want to help you, for the umpteenth time

here is the link to the article and the video you tube

>

> With my E3D v4.1 hotend, I noticed rather short

> zones of molten plastic after pulling out the

> filament, so when I insert new filament, only 1 or

> 2 cm of old and mixed plastic extrudate exits the

> nozzle. Which is totally contrary to what I have

> experienced with the GRRF hotend where there is a

> much bigger pool of molten plastic that has to be

> purged first. This leads me to think that with the

> right hotend (all metal?), dual extrusion can be

> done without much additional cost and

> infrastructure especially when you have got a

> bowden system installed.

>

> To list what major issues I could think of:

>

and now...the I reply at all ADVANTAGES/DISAVANTAGES/UNKNOWNS

> Advantages:

> - one hotend: reduces oozing, saves space, weight

> and cost

> - no leveling of second hotend necessary -> easy

> implementation

> - support material extrudes at roughly the same

true and obvious.

> temperature as build material (PLA - PVA / ABS -

> HIPS)

you can use only one material at a time

I test:

( PLA - PLA)

( ABS - ABS)

(NYLON - NYLON)

>

> Disadvantages:

> - some material is lost due to mixture zone

> between both filaments - either blemishes in print

> or extruded into a waste container

SOLVED and IMPROVE.I speak of this on august 19

SOLVED and IMPROVE.I speak of this on august 19My solution is here

I create a "basket" were if you want,

with only adding a few lines of gcode on slic3r,

you can use a single color or shaded.

> - the filament change takes time, with long

> hotends, this might become more and more

> troublesome

> - the molten plug MIGHT get stuck somewhere along

> the way

SOLVED. ...in the next update....soon...

SOLVED. ...in the next update....soon...>

> Unknowns:

> - what alterations have to be made to the standard

> Marlin firmware?

SOLVED but.....

SOLVED but.....I prefer to let you study a bit of time, even if my extruder works just for the changes made to the firmware, I want to see that you will find solution

> - what happens if one heater + thermistor is

> paired to two extruders? Will the settings for

> both extruder temperatures interfere in the

> standard firmware scenario?

SOLVED.. hehehe

SOLVED.. hehehethe same...

I prefer to let you study a bit of time, even if my extruder works just for the changes made to the firmware, I want to see that you will find solution

>

> Here is a little animation to illustrate dual

> extrusion with one hotend:

>

> [attachment 20089 2e1h.gif]

> Sorry about the quality, it was a little bit

> difficult to squeeze in enough to make sense.

>

> Also, if anyone can remember the thread I am

> talking about, please link me to it.

... here is my blog...

on right top you can translate (google) in all language...

is not very accurate but I am sure that you are able to understand very well,

since you've written everything I have talked about for months.

since you've written everything I have talked about for months.In conclusion...

FalaUnion Mono system works perfectly.

now I'm developing the latest improvements, and........ SECRET...

you tube

[www.falla3d.com]

[3dita.blogspot.it]

|

Re: 2 Extruders, 1 Hotend October 25, 2013 05:05AM |

Registered: 12 years ago Posts: 1,236 |

ifala writes:

---------------

> ... here is my blog...

Hmm, I used Google translate on your blog:

Now, I am sure the translation must be wrong, because it makes the author sound like a complete jerk.

---------------

> ... here is my blog...

Hmm, I used Google translate on your blog:

Quote

this is what happens to "hang" the forum.

[RepRap logo]

While I gave an eye on the RepRap forum,

usually check the posts that I have left to figure out if someone had, already gone down this road. I tried to post it a bit everywhere to see if there were even just people interested and wanted to participate in the implementation unfortunately I did not find it a similar project that I wanted to help people interested in the past or who had helped with some tests. (apart richrap but that 'mixed colors .... pushing them even simultaneously) The fact that they found no one has pushed me to continue to develop and test ... test development until the first results are seen coming ... but today ... just today ... I'm going to see on the forum RepRap if I had answered some Christian or interested ... and here's what I found ...! Mugen I found a user who says he has had a revolutionary idea ... and explains how a system like the one tested many times by me ... (I have a new design in Serbia more reduced and functional) and explains the pros and cons ... (Obviously copying everything I have written in previous posts) and even illustrating a schemino fucking what I designed with fatigue in recent months .. here is these things make me alter. Luckily there are people CONSISTENT ... in fact already in His post a user had told him that he had probably got all the information from my blog ... GUARDATEEEE! Coherent @ BIG! besides I wrote him too ... I was just so pissed off like a beast! reminding him that he months ago I had responded to my post saying that he had abandoned this solution ... in fact doing almost lose hope of a successful front of other users .... ! COUNTY TO THESE PEOPLE CALL YOU .... only one way ... BASTXXDI!

Now, I am sure the translation must be wrong, because it makes the author sound like a complete jerk.

|

Re: 2 Extruders, 1 Hotend October 25, 2013 10:10AM |

Registered: 11 years ago Posts: 301 |

Hahaha

Thanks for "complete jerk" @bobc

From the next update...

Only for the people "completely jerk"

I write in english...

[www.falla3d.com]

[3dita.blogspot.it]

Thanks for "complete jerk" @bobc

From the next update...

Only for the people "completely jerk"

I write in english...

[www.falla3d.com]

[3dita.blogspot.it]

|

Re: 2 Extruders, 1 Hotend October 25, 2013 07:27PM |

Registered: 11 years ago Posts: 490 |

@bobc: yeah, unfortunately...I first attributed everything to language barrier miscommunication as I am not a native speaker either and might have caused misunderstandings in some of my posts myself.

@ifala: look, you quoted this:

where I said that I remember someone (turns out to be you) posting his success in something I thought would be too problematic to bother. Unfortunately, after searching every resource I had, I just couldn't find your post again because I didn't expect it to be in the botobjects thread. Because I saw that you succeeded, I kept thinking about this method of dual extrusion and put my thoughts down here along with asking others who might remember where exactly you posted your results to point me to them:

By the way, the guys in the German forum also independently succeeded in exactly the same method. Multiple people can have the same idea at the same time.

Edited 2 time(s). Last edit at 10/25/2013 08:25PM by uGen.

@ifala: look, you quoted this:

Quote

excerpt from the starting post of this thread

> However, it turns out that someone thought of

> exactly the same and got the whole contraption to

> work. I think he might have posted his results in

> this forum with accompanying YouTube videos, but

> no matter how hard I search, all traces about this

> dual extrusion method seem to have vanished. Even

> my YouTube history doesn't seem to remember the

> videos.

where I said that I remember someone (turns out to be you) posting his success in something I thought would be too problematic to bother. Unfortunately, after searching every resource I had, I just couldn't find your post again because I didn't expect it to be in the botobjects thread. Because I saw that you succeeded, I kept thinking about this method of dual extrusion and put my thoughts down here along with asking others who might remember where exactly you posted your results to point me to them:

Quote

last line of the starting post

Also, if anyone can remember the thread I am talking about, please link me to it.

By the way, the guys in the German forum also independently succeeded in exactly the same method. Multiple people can have the same idea at the same time.

Edited 2 time(s). Last edit at 10/25/2013 08:25PM by uGen.

|

Re: 2 Extruders, 1 Hotend November 04, 2013 08:10AM |

Registered: 11 years ago Posts: 301 |

|

Re: 2 Extruders, 1 Hotend November 04, 2013 03:10PM |

Registered: 11 years ago Posts: 544 |

you know what i was thinking about? this would be cool if you could have it change the feedstock before it actually needed to change colors, since some of the plastic will build up in the hot end and need to be extruded still. you just need to figure out how far before the color change you would need to change it.

|

Re: 2 Extruders, 1 Hotend November 05, 2013 05:02AM |

Registered: 11 years ago Posts: 301 |

yes MAn ! I think and I develop a new extruder with a low melt zone... with 1.75 filament.

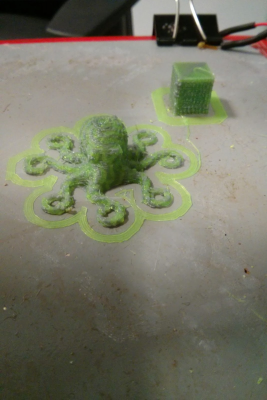

fibonacciVase 1-13

I was able to mix the color in a 1.75 hot end, with a "change clean" of 4 - 6 mm ... so ... I develop a new hotend .. hehe! with rumba actually I can use 3 color..

If you don't want wasting time in a clean change, yes, you can calculate how much is the time of next filament delay, and insert in a gcode... but .... there are a lot of variables such a temperature speed etc etc.. that increase or decreased the melt zone!

so the best is have a Basket ! to purge away the old color before restart with a new color...

excuse my english..

[www.falla3d.com]

[3dita.blogspot.it]

fibonacciVase 1-13

I was able to mix the color in a 1.75 hot end, with a "change clean" of 4 - 6 mm ... so ... I develop a new hotend .. hehe! with rumba actually I can use 3 color..

If you don't want wasting time in a clean change, yes, you can calculate how much is the time of next filament delay, and insert in a gcode... but .... there are a lot of variables such a temperature speed etc etc.. that increase or decreased the melt zone!

so the best is have a Basket ! to purge away the old color before restart with a new color...

excuse my english..

[www.falla3d.com]

[3dita.blogspot.it]

|

Re: 2 Extruders, 1 Hotend November 05, 2013 05:09PM |

Registered: 11 years ago Posts: 490 |

In my experience, the E3D v4.1 hotend for 1.75mm filament keeps only a small plug of molten plastic when you pull the filament out (although the melt zone is supposed to be long).

The hotend itself is rather long, though. So to make the filament change more efficient, replacing the long heat sink with a water cooled solution might be an option worth considering.

The hotend itself is rather long, though. So to make the filament change more efficient, replacing the long heat sink with a water cooled solution might be an option worth considering.

|

Re: 2 Extruders, 1 Hotend November 06, 2013 10:11AM |

Registered: 11 years ago Posts: 301 |

I have discarded the option of liquid cooling, too bulky.

In the configuration of FalaUnionMono the change of filament occurs at all speeds regardless of the amount of melt zones or molten plastic when you pull the filament out ..

I consider the option of having lower melt areas by increasing and improving the cooling of the body extruder.. without using water, I could use a small peltier cell...maybe..

[www.falla3d.com]

[3dita.blogspot.it]

In the configuration of FalaUnionMono the change of filament occurs at all speeds regardless of the amount of melt zones or molten plastic when you pull the filament out ..

I consider the option of having lower melt areas by increasing and improving the cooling of the body extruder.. without using water, I could use a small peltier cell...maybe..

[www.falla3d.com]

[3dita.blogspot.it]

|

Re: 2 Extruders, 1 Hotend November 07, 2013 04:57AM |

Registered: 11 years ago Posts: 544 |

|

Re: 2 Extruders, 1 Hotend November 07, 2013 06:10AM |

Registered: 11 years ago Posts: 301 |

|

Re: 2 Extruders, 1 Hotend November 07, 2013 02:42PM |

Registered: 11 years ago Posts: 544 |

this is a picture of my hot end, its called the europa, and its made by bradley fudge. He makes some really great things, but after working with him for a while on research for his new hot end, the mercury he decided that he didnt need my help anymore and cut me out. anyways the watercooling actually weighs less than the equivalent fan and heatsink. and the plus is that you can control the temperature of the filament before it enters the melt zone, so it can give you more speed or more control over the filament.

|

Re: 2 Extruders, 1 Hotend December 23, 2013 03:30PM |

Registered: 11 years ago Posts: 301 |

|

Re: 2 Extruders, 1 Hotend February 07, 2014 07:20AM |

Registered: 11 years ago Posts: 301 |

|

Re: 2 Extruders, 1 Hotend February 07, 2014 10:25PM |

Registered: 11 years ago Posts: 471 |

|

Re: 2 Extruders, 1 Hotend February 19, 2014 10:52AM |

Registered: 11 years ago Posts: 301 |

|

Re: 2 Extruders, 1 Hotend February 19, 2014 10:56AM |

Registered: 11 years ago Posts: 490 |

Sorry, only registered users may post in this forum.