my extruder is bottlenecking my machine speed!

Posted by aduy

|

my extruder is bottlenecking my machine speed! October 20, 2013 04:26AM |

Registered: 11 years ago Posts: 544 |

ok so now that Ive switched to 24v my steppers are running great, no more stalling at random times. however now that its running so smoothly my extruder feed rates have gone up, and because I have 1.75mm filament it needs to feed very quickly to keep up. Ive done my research and found that a dual hobbed bolt setup will work to correct the random slippage of the filament by being redundant and still pushing the filament through even if one slips. Ive seen the kracken or whatever but theres no way im going to pay 300 dollars for an extruder that may or may not work correctly. has anyone used this [www.thingiverse.com]. or improved on the idea? One issue is you would need to have identical hobbed bolts to make it work.

Redundancy on 3d printers is very important because it can save you hours of wasted work. I recently printed half of a full size boba fett helmet.... the print time was about 32 hours at 30mm/s using .25 external 0.5 internal using a 0.6mm nozzle. the max feed was 14mm/s going into the hot end, but it would randomly slip.

Edited 1 time(s). Last edit at 10/20/2013 04:29AM by aduy.

Redundancy on 3d printers is very important because it can save you hours of wasted work. I recently printed half of a full size boba fett helmet.... the print time was about 32 hours at 30mm/s using .25 external 0.5 internal using a 0.6mm nozzle. the max feed was 14mm/s going into the hot end, but it would randomly slip.

Edited 1 time(s). Last edit at 10/20/2013 04:29AM by aduy.

|

Re: my extruder is bottlenecking my machine speed! October 20, 2013 05:13AM |

Admin Registered: 11 years ago Posts: 1,063 |

which hotend and extruder have you currently got?

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: my extruder is bottlenecking my machine speed! October 20, 2013 06:16AM |

Registered: 11 years ago Posts: 544 |

the hot end is a europa, its water cooled and is probably the best hot end on the market, no issues with it at all. the extruder is the issue, sort of. its a wades reloaded with a grooved bearing and the airwolf hobbed bolt. Its a fine setup i just need more speed out of it. the issue is that it chews up the filament every once and a while while feeding at high speed.

|

Re: my extruder is bottlenecking my machine speed! October 20, 2013 06:30AM |

Registered: 11 years ago Posts: 173 |

You can try and replace your hobbed bolt with something similar to

[www.tridimake.com]

I am using it in my filament feeder with great results.

No slipping of filament - the motor will skip.

You only learn when you change your mind.

[www.deltaprinter.co.za]

[www.tridimake.com]

I am using it in my filament feeder with great results.

No slipping of filament - the motor will skip.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: my extruder is bottlenecking my machine speed! October 20, 2013 06:45AM |

Registered: 13 years ago Posts: 1,797 |

reduce flow rate and do the unthinkable. disable extruder stepper when not in use in firmware . have 0.1mm lift with retraction enabled for about 5mm distance.

what this does allows back pressure to build up and to escape springing back your motor a couple of steps. it compensates for non linear and imperfect adjustment of build up of pressure. with current hardware and firmware it is not possible to correctly compensate for pressure build up correctly.

also turn down stepper power on e axis, you want the stepper to skip rather than chew feedstock! if it skips you are ok! it means that there is so much pressure it cant push anymore. stuff will still flow! (except for wide base layer. this layer you should do slow enough that motor never skips.

thinner layers. put down thinner layers like 0.2 or 0.15 mm

if you do the above the worst that will happen is the walls will become thinner, but feed stock will still flow.

another note. take out hobbed bolt and wash with soap. then apply soap and dry it off. the decrease action of the soap will stay on for months, and prevent loose plastic from sticking and building up in the teeth of the hobbed groove.

don't be afraid to lower travel speed. this is the fastest the machine can normally move great distances, but you don't know what it may drag over. better safe than sorry. my prusa normally runs 60-90mm a second and travel runs at 70-80mm/s

know your infill direction. diagonal infills can go 1.4 times faster if at 45deg. why because x/y motor run at 1/1.4 speed to create the line!

now start printing 90mm to 120mm a second. if your machine will not skip.

have issues with layer sinusoidal wobble. reduce z axis firmware setting to 4-5 digits precision. that is as accurate as a single precision float can be anyways for practical use. it gets multiplied and compared to other floats. it is guess game anyway. better ensure every step is a real step.

Edited 1 time(s). Last edit at 10/20/2013 06:48AM by jamesdanielv.

what this does allows back pressure to build up and to escape springing back your motor a couple of steps. it compensates for non linear and imperfect adjustment of build up of pressure. with current hardware and firmware it is not possible to correctly compensate for pressure build up correctly.

also turn down stepper power on e axis, you want the stepper to skip rather than chew feedstock! if it skips you are ok! it means that there is so much pressure it cant push anymore. stuff will still flow! (except for wide base layer. this layer you should do slow enough that motor never skips.

thinner layers. put down thinner layers like 0.2 or 0.15 mm

if you do the above the worst that will happen is the walls will become thinner, but feed stock will still flow.

another note. take out hobbed bolt and wash with soap. then apply soap and dry it off. the decrease action of the soap will stay on for months, and prevent loose plastic from sticking and building up in the teeth of the hobbed groove.

don't be afraid to lower travel speed. this is the fastest the machine can normally move great distances, but you don't know what it may drag over. better safe than sorry. my prusa normally runs 60-90mm a second and travel runs at 70-80mm/s

know your infill direction. diagonal infills can go 1.4 times faster if at 45deg. why because x/y motor run at 1/1.4 speed to create the line!

now start printing 90mm to 120mm a second. if your machine will not skip.

have issues with layer sinusoidal wobble. reduce z axis firmware setting to 4-5 digits precision. that is as accurate as a single precision float can be anyways for practical use. it gets multiplied and compared to other floats. it is guess game anyway. better ensure every step is a real step.

Edited 1 time(s). Last edit at 10/20/2013 06:48AM by jamesdanielv.

|

Re: my extruder is bottlenecking my machine speed! October 20, 2013 11:14AM |

Registered: 11 years ago Posts: 374 |

I've run 1.75mm filament on a bowden extruder at flow rates exceeding 150mm^3/s with a 2:1 gear reduction. I have not run into issues with the extruder limiting how fast I can print. I know other people have run similar setups at nearly 300mm^3/s with fairly conventional extruders.

Based on this I think you should look at optimizing the extruder you have before trying to design some exotic dual hobbed bolt setup. You may need to increase the clamping force the idler exerts on the filament to keep it against the hobbed bolt. Or you may need to check that the filament path is smooth and aligned properly to prevent excessive friction.

Based on this I think you should look at optimizing the extruder you have before trying to design some exotic dual hobbed bolt setup. You may need to increase the clamping force the idler exerts on the filament to keep it against the hobbed bolt. Or you may need to check that the filament path is smooth and aligned properly to prevent excessive friction.

|

Re: my extruder is bottlenecking my machine speed! October 20, 2013 10:53PM |

Registered: 11 years ago Posts: 544 |

hmmm, I think im going to reduce the amount of current, because Its better to have the motor stall than have the filament strip, the other thing I noticed was that the gear was actually slipping on the motor.

@crispy: do you have any videos of these fast extrusions, the only one ive seen that was faster than mine was the cracken. also I know its exactly 14mm/s because I limited it in the firmaware and saw it slow down.

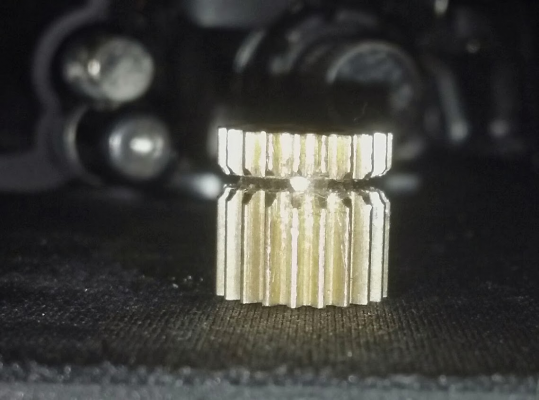

edit: I was doing some more research on hobbed bolts and found this [www.tridimake.com], then I thought that it sort of looked like the qu-bd grooved gear. I have one sitting around and the only difference is that central goove, I think if you cut that into the qu-bd gear it would be perfect, ill give it a try.

Edited 1 time(s). Last edit at 10/21/2013 12:29AM by aduy.

@crispy: do you have any videos of these fast extrusions, the only one ive seen that was faster than mine was the cracken. also I know its exactly 14mm/s because I limited it in the firmaware and saw it slow down.

edit: I was doing some more research on hobbed bolts and found this [www.tridimake.com], then I thought that it sort of looked like the qu-bd grooved gear. I have one sitting around and the only difference is that central goove, I think if you cut that into the qu-bd gear it would be perfect, ill give it a try.

Edited 1 time(s). Last edit at 10/21/2013 12:29AM by aduy.

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 01:48AM |

Registered: 11 years ago Posts: 173 |

aduy Wrote:

> edit: I was doing some more research on hobbed

> bolts and found this

> [www.tridimake.com]

> -for-filament-feeder.html, then I thought that it

> sort of looked like the qu-bd grooved gear. I have

> one sitting around and the only difference is that

> central goove, I think if you cut that into the

> qu-bd gear it would be perfect, ill give it a try.

A groove cut with a .5 mm dremel cutting blade 1mm deep is all thats needed for a 1.75 mm filament. I used a steel gear from aliexpress (http://www.aliexpress.com/item/45-steel-gear-20T-0-5-Modulus-4mm-Aperture-metal-gear-variety-rc-hobby/1009769353.html )

> edit: I was doing some more research on hobbed

> bolts and found this

> [www.tridimake.com]

> -for-filament-feeder.html, then I thought that it

> sort of looked like the qu-bd grooved gear. I have

> one sitting around and the only difference is that

> central goove, I think if you cut that into the

> qu-bd gear it would be perfect, ill give it a try.

A groove cut with a .5 mm dremel cutting blade 1mm deep is all thats needed for a 1.75 mm filament. I used a steel gear from aliexpress (http://www.aliexpress.com/item/45-steel-gear-20T-0-5-Modulus-4mm-Aperture-metal-gear-variety-rc-hobby/1009769353.html )

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 02:27AM |

Registered: 11 years ago Posts: 544 |

I will try this and get back to you all. I may even convert back to direct drive, with a grooved idler and other improvement of course.

it seems grippier and it also looks a lot better than the cut up bolt, also its got 20 teeth so it falls in the range suggested.

Edited 3 time(s). Last edit at 10/21/2013 03:00AM by aduy.

it seems grippier and it also looks a lot better than the cut up bolt, also its got 20 teeth so it falls in the range suggested.

Edited 3 time(s). Last edit at 10/21/2013 03:00AM by aduy.

|

Anonymous User

Re: my extruder is bottlenecking my machine speed! October 21, 2013 04:35AM |

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 05:02AM |

Registered: 11 years ago Posts: 173 |

aduy Wrote:

-------------------------------------------------------

This may be to deep and wide and will deform the filament without the extra grip - only the small groove is needed and a guide at the back in the form of a grooved idler.

-------------------------------------------------------

This may be to deep and wide and will deform the filament without the extra grip - only the small groove is needed and a guide at the back in the form of a grooved idler.

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 05:15AM |

Registered: 11 years ago Posts: 173 |

winwalk Wrote:

-------------------------------------------------------

> the issue is that it chews up the filament every

> once and a while while feeding at high speed.

A way to avoid the chewing is to increase the contact area of the filament with the drive gear - instead of a straight filament you curve it around the gear. Successfully done with 1.75 mm ABS filament.

You only learn when you change your mind.

[www.deltaprinter.co.za]

-------------------------------------------------------

> the issue is that it chews up the filament every

> once and a while while feeding at high speed.

A way to avoid the chewing is to increase the contact area of the filament with the drive gear - instead of a straight filament you curve it around the gear. Successfully done with 1.75 mm ABS filament.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 06:23AM |

Registered: 13 years ago Posts: 1,797 |

teeth are still too far apart for this to really work well with every type of feed stock. i see it working ok with abs, but tearing apart pla. it is the surface area grip as well as the teeth that grip the area. don't be fooled. this won't really work on all types of pla.

the answer to faster flow is not just the bolt type.

the answer to faster flow is not just the bolt type.

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 12:08PM |

Admin Registered: 15 years ago Posts: 1,470 |

You could just decrease the gear reduction on your extruder. Print a larger small gear and a smaller large gear. The OpenSCAD files should allow you to do that to some extent. This will give you more speed at the expense of less torque.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: my extruder is bottlenecking my machine speed! October 21, 2013 02:51PM |

Registered: 11 years ago Posts: 544 |

jamesdanielv Wrote:

-------------------------------------------------------

> teeth are still too far apart for this to really

> work well with every type of feed stock. i see it

> working ok with abs, but tearing apart pla. it is

> the surface area grip as well as the teeth that

> grip the area. don't be fooled. this won't really

> work on all types of pla.

>

> the answer to faster flow is not just the bolt

> type.

It is inthis case because it works fine until it slips then it grinds the filament, ive also noticed the abs im using for the print is very brittle, never had abs that was brittle like it before though.

Edited 1 time(s). Last edit at 10/21/2013 03:59PM by aduy.

-------------------------------------------------------

> teeth are still too far apart for this to really

> work well with every type of feed stock. i see it

> working ok with abs, but tearing apart pla. it is

> the surface area grip as well as the teeth that

> grip the area. don't be fooled. this won't really

> work on all types of pla.

>

> the answer to faster flow is not just the bolt

> type.

It is inthis case because it works fine until it slips then it grinds the filament, ive also noticed the abs im using for the print is very brittle, never had abs that was brittle like it before though.

Edited 1 time(s). Last edit at 10/21/2013 03:59PM by aduy.

|

Re: my extruder is bottlenecking my machine speed! October 25, 2013 07:27PM |

Registered: 11 years ago Posts: 544 |

I just need to make the transfer gears and i should be going, i have to say it looks a lot more substantial than the regular wades reloaded. maybe ill call it the wades reloaded double barrel.

[www.thingiverse.com]

[www.thingiverse.com]

Sorry, only registered users may post in this forum.