Copper jhead nozzle

Posted by Mogal

|

Copper jhead nozzle October 27, 2013 12:55PM |

Registered: 11 years ago Posts: 250 |

Besides cost, why aren't there more copper nozzles?

Its thermal conductivity is nearly 3 times greater.

Would there be any performance gains? Heating up faster? Better temperature control?

I have some scraps in the shop and thinking of milling a couple to try out.

Before I get too far into this, is brass really the better option?

Thoughts?

P.S. my current nozzle is a 0.5mm brass nozzle.

I was going to make a 0.4mm, 0.35mm and 0.3mm nozzles.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Its thermal conductivity is nearly 3 times greater.

Would there be any performance gains? Heating up faster? Better temperature control?

I have some scraps in the shop and thinking of milling a couple to try out.

Before I get too far into this, is brass really the better option?

Thoughts?

P.S. my current nozzle is a 0.5mm brass nozzle.

I was going to make a 0.4mm, 0.35mm and 0.3mm nozzles.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Copper jhead nozzle October 27, 2013 01:41PM |

Registered: 10 years ago Posts: 162 |

It is superior for thermal conductivity/uniformity. There are other factors to consider as well though... like do melted PLA and ABS stick to it. Is it easy to machine a 0.5mm or smaller hole in it? Someone here might have the answer to these. I know it can be difficult to drill pores into brass and its the easiest metal to machine. Copper is a "gummy" metal, so it might put up a fight.

On another note, I have seen aluminum hot ends -- nearly as good for thermal conductivity, but less thermal capacity.

On another note, I have seen aluminum hot ends -- nearly as good for thermal conductivity, but less thermal capacity.

|

Re: Copper jhead nozzle October 27, 2013 02:19PM |

Registered: 11 years ago Posts: 250 |

Yea, I thought about the 'stickiness' of copper...

I have worked with copper before, I know the machining characteristics of it, but nothing this small.

I guess there's only one way to find out!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I have worked with copper before, I know the machining characteristics of it, but nothing this small.

I guess there's only one way to find out!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Copper jhead nozzle October 27, 2013 02:25PM |

Registered: 11 years ago Posts: 560 |

I've been using only copper nozzles since I started printing about a year ago at 0.25mm without issue.

I'm running a modified Wildseyed hotend that uses a MIG welder tip. The tips have a manufactured size of .6mm but they can be hand hammered down to .25mm. I've gone smaller but the properties of ABS and the extreme increase in print times makes it impractical.

A MIG tip does need drilled to accept 1.75mm or 3mm filament, and does require a lot of oil to drill out. You want to drill slowly and clear the cuttings out of the bit to keep from breaking off the bit in the copper. I've snapped off 3 or 4 bits even going slow.

If you have the means, I do encourage you to make a few and try them out.

PLA and ABS do not stick to the copper any more than brass, probably about the same in that aspect.

I'm running a modified Wildseyed hotend that uses a MIG welder tip. The tips have a manufactured size of .6mm but they can be hand hammered down to .25mm. I've gone smaller but the properties of ABS and the extreme increase in print times makes it impractical.

A MIG tip does need drilled to accept 1.75mm or 3mm filament, and does require a lot of oil to drill out. You want to drill slowly and clear the cuttings out of the bit to keep from breaking off the bit in the copper. I've snapped off 3 or 4 bits even going slow.

If you have the means, I do encourage you to make a few and try them out.

PLA and ABS do not stick to the copper any more than brass, probably about the same in that aspect.

|

Re: Copper jhead nozzle October 27, 2013 02:35PM |

Registered: 11 years ago Posts: 250 |

Thanks Steve, good to know it works well.

I'll get into the shop and mill out a couple!

LOL... now to start milling the 1" diam round stock to 1/2" square!!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I'll get into the shop and mill out a couple!

LOL... now to start milling the 1" diam round stock to 1/2" square!!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Copper jhead nozzle October 27, 2013 02:56PM |

Registered: 13 years ago Posts: 2,947 |

I have two copper j-heads made by tlalexander and they perform "exactly" the same as the brass ones. You can read the old thread form the beginning of the process here [forums.reprap.org] . I never updated the thread because the hotend did not perform any better or worse than the brass one. The difference with the mig welder tip hotends (which I also used a few of [geometricobjectdepositiontool.blogspot.ca] ) is the orifice length and melt zone length. The J-head has a medium length melt zone and a medium to long orifice length which increase the back pressure which limits the max print speed.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Copper jhead nozzle October 27, 2013 02:59PM |

Registered: 11 years ago Posts: 560 |

I could stand to have a mill and a lathe for sure! I had to hand work a very rough chunk of aluminum scrap to make my heater block. At least I do have a half way decent drill press. I also turned my thermal barrier out of PEEK. Used it kind of like a vertical lathe with a tool rest c-clamped to the table.

|

Re: Copper jhead nozzle October 27, 2013 04:39PM |

Registered: 11 years ago Posts: 560 |

|

Re: Copper jhead nozzle October 27, 2013 04:41PM |

Registered: 11 years ago Posts: 250 |

LOL, I've done my fair share of hand finishing

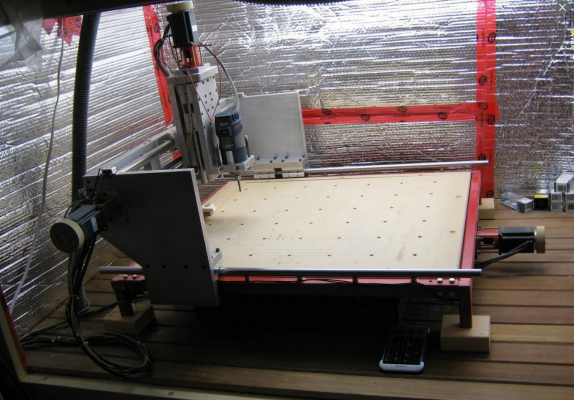

But now I have these

not this clean anymore. these were taken after a complete rebuild (lathe and mill)

then when the CNC was first built and setup

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

But now I have these

not this clean anymore. these were taken after a complete rebuild (lathe and mill)

then when the CNC was first built and setup

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Copper jhead nozzle October 27, 2013 04:53PM |

Registered: 11 years ago Posts: 250 |

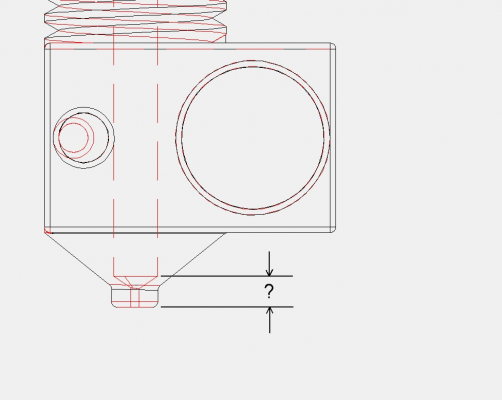

I think this has been brought up, but I couldn't find it.

What should the distance be in the pic?

Does this directly contribute to the back-pressure?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

What should the distance be in the pic?

Does this directly contribute to the back-pressure?

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Copper jhead nozzle October 27, 2013 06:03PM |

Registered: 13 years ago Posts: 2,947 |

Here are a bunch of blog posts from Brian at hotends.com about the nozzle orifice.

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

[jheadnozzle.blogspot.ca]

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Copper jhead nozzle October 27, 2013 07:30PM |

Registered: 11 years ago Posts: 250 |

|

Re: Copper jhead nozzle October 28, 2013 03:01AM |

Registered: 10 years ago Posts: 580 |

Hi Mogal,

You might want to try Tellurium copper. It has 85% manageability as brass, where regular copper has about 20%. Tellurium copper is what they make welding nozzles from.

It has almost the same thermal characteristics as regular copper.

I found some at Onlinemetals (I'm planning on making a few hot ends myself). It's not expensive. FYI: I have no connection to them.

Here's the link: [www.onlinemetals.com]

You might want to try Tellurium copper. It has 85% manageability as brass, where regular copper has about 20%. Tellurium copper is what they make welding nozzles from.

It has almost the same thermal characteristics as regular copper.

I found some at Onlinemetals (I'm planning on making a few hot ends myself). It's not expensive. FYI: I have no connection to them.

Here's the link: [www.onlinemetals.com]

|

Re: Copper jhead nozzle October 28, 2013 02:21PM |

Admin Registered: 17 years ago Posts: 7,879 |

The length of the orifice only has a linear effect on the pressure but the diameter has an inverse fourth power effect.

The thermal conductivity of brass is already three orders of magnitude better than the the plastic it is melting, so I don't think using copper makes much difference there.

I think the reason welding nozzles extrude so easily is mainly due to them being oversized. I.e. if you buy a 0.6mm one (which is pretty big to start with) then that is for 0.6mm wire, but the aperture is actually bigger than that to have some clearance, maybe 0.8mm. That would reduce the pressure by more than 6 times all other things being equal.

[www.hydraraptor.blogspot.com]

The thermal conductivity of brass is already three orders of magnitude better than the the plastic it is melting, so I don't think using copper makes much difference there.

I think the reason welding nozzles extrude so easily is mainly due to them being oversized. I.e. if you buy a 0.6mm one (which is pretty big to start with) then that is for 0.6mm wire, but the aperture is actually bigger than that to have some clearance, maybe 0.8mm. That would reduce the pressure by more than 6 times all other things being equal.

[www.hydraraptor.blogspot.com]

|

Re: Copper jhead nozzle October 29, 2013 10:39AM |

Registered: 13 years ago Posts: 1,797 |

I think the more thermally conductive the hot end the better the temp equilibrium is between the hot end heater and the thermister. temp readings are more accurate and temp is more consistent through the hot end of copper than brass or aluminum. different parts of a brass block read temp differences of up to 10 degrees.

what would be interesting is for someone to include 2 thermisters in a hot end. one near the nozzle and one on the other side near the thermal break to see what the temp variation actually is on average.

what would be interesting is for someone to include 2 thermisters in a hot end. one near the nozzle and one on the other side near the thermal break to see what the temp variation actually is on average.

|

Re: Copper jhead nozzle October 29, 2013 11:21AM |

Registered: 12 years ago Posts: 80 |

I don't know if this is of interest to anyone, but it's nearly on topic, so here goes:

I modded my brass J-head to take an aluminium inset (m4 nut rivet iircc). Mainly because the replacement heater resistors I got hold of were way too small. I then drilled the threaded part out to fit the resistor (I got lucky and got a very snug fit). After this mod I believe my heating response has got way better. Don't have any figures at hand, but I think I'm well under a minute from room to printing temp.

/Andreas

I modded my brass J-head to take an aluminium inset (m4 nut rivet iircc). Mainly because the replacement heater resistors I got hold of were way too small. I then drilled the threaded part out to fit the resistor (I got lucky and got a very snug fit). After this mod I believe my heating response has got way better. Don't have any figures at hand, but I think I'm well under a minute from room to printing temp.

/Andreas

|

Anonymous User

Re: Copper jhead nozzle October 31, 2013 12:15AM |

|

Re: Copper jhead nozzle October 31, 2013 12:49AM |

Registered: 13 years ago Posts: 2,947 |

ohioplastics Wrote:

-------------------------------------------------------

> LOL Sublime. I can drill a .2mm nozzle in my

> sleep. I hope to go down as low as .05mm one day.

> All thanks to Brass.

Huh?

-------------------------------------------------------

> LOL Sublime. I can drill a .2mm nozzle in my

> sleep. I hope to go down as low as .05mm one day.

> All thanks to Brass.

Huh?

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Anonymous User

Re: Copper jhead nozzle October 31, 2013 01:12AM |

|

Re: Copper jhead nozzle October 31, 2013 01:42AM |

Registered: 13 years ago Posts: 2,947 |

ohioplastics Wrote:

-------------------------------------------------------

> Copper is more expensive and harder to work with.

And what does this have to do with me? I just don't understand why your comment was directed at me.

-------------------------------------------------------

> Copper is more expensive and harder to work with.

And what does this have to do with me? I just don't understand why your comment was directed at me.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Anonymous User

Re: Copper jhead nozzle October 31, 2013 01:46AM |

|

Re: Copper jhead nozzle October 31, 2013 01:55AM |

Registered: 13 years ago Posts: 2,947 |

ohioplastics Wrote:

-------------------------------------------------------

> No offense bro. I was simply illustrating the

> machinability of brass vs. copper.

I wasn't taking offence I was just confused to what was going on. I thought you were replying to me in some way and I did not understand why or how.

-------------------------------------------------------

> No offense bro. I was simply illustrating the

> machinability of brass vs. copper.

I wasn't taking offence I was just confused to what was going on. I thought you were replying to me in some way and I did not understand why or how.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.