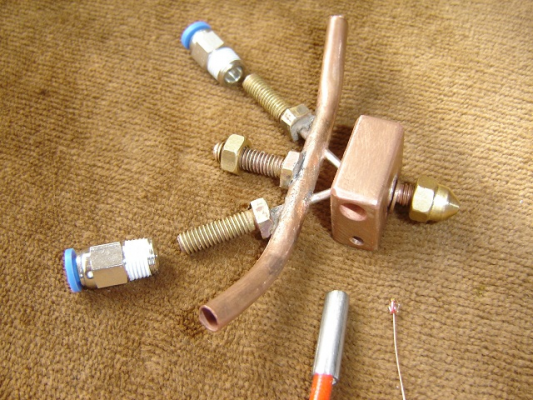

Water cooled all metal hotend with 2 Bowdens and one heaterblock

Posted by Xabbax

|

Water cooled all metal hotend with 2 Bowdens and one heaterblock November 27, 2013 10:54AM |

Registered: 11 years ago Posts: 173 |

Stainless tubes converge halfway down in the heater block.

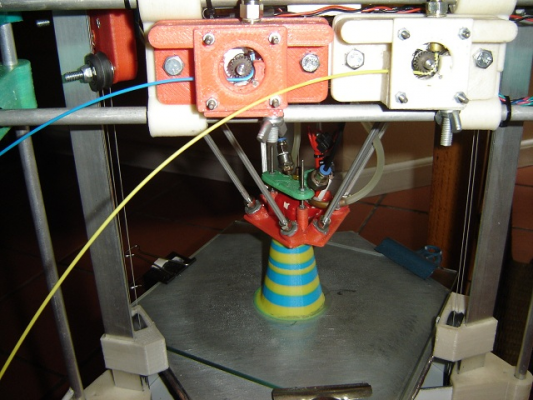

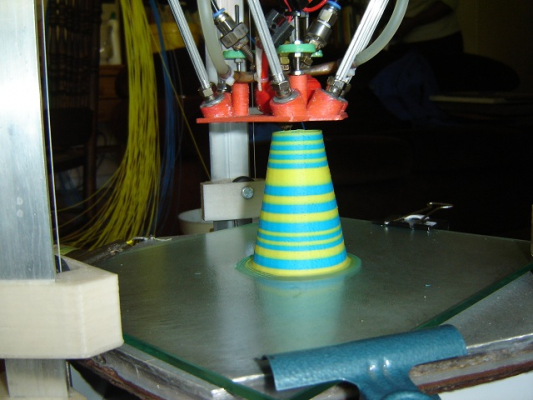

Started off with a .75 mm nozzle (prints attached)

Colour change on a layer change without any retraction

Will change to .5 and then .35 nozzle size and give feedback.

It may well be that the back pressure on the lower nozzle sizes will lead to blockages - will see.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock November 28, 2013 06:02AM |

Registered: 11 years ago Posts: 173 |

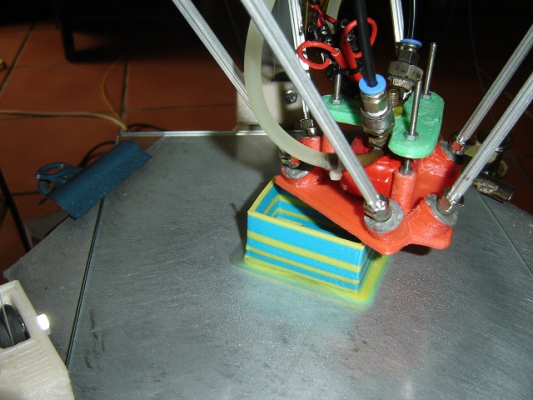

Used a .5 mm nozzle and did not experience any problems

I sliced the tube with slic3r and then manually added the colour changes in wordpad

Edited 1 time(s). Last edit at 11/28/2013 09:36AM by Xabbax.

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock November 28, 2013 09:17AM |

Registered: 11 years ago Posts: 544 |

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock November 28, 2013 12:09PM |

Registered: 11 years ago Posts: 177 |

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock November 28, 2013 12:20PM |

Registered: 11 years ago Posts: 490 |

Looks interesting, but one thing I am not sure about is how filament in the hotend will react to being exposed to heat for a long time, for example when you print a long time with one color and then switch to the other color or when you only print with one color in a print.

Did you notice any effects like thermal degradation of the filament?

Did you notice any effects like thermal degradation of the filament?

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock November 28, 2013 12:43PM |

Registered: 11 years ago Posts: 173 |

Quote

aduy

i couldnt help but notice that your extruders are actually wrapping the filament around the drive gear

Have only used ABS with the feeders and it's working fine with the better grip.

Quote

Evil Monkey

Do you have some sort of radiator to remove heat from the circulating water? What kind of pump do you use?

No pumping - water in 100 ml plastic torus tank open to atmosphere with natural circulation

Quote

uGen

Looks interesting, but one thing I am not sure about is how filament in the hotend will react to being exposed to heat for a long time, for example when you print a long time with one color and then switch to the other color or when you only print with one color in a print.

Did you notice any effects like thermal degradation of the filament?

That is certainly a concern. I have not noticed any degradation but did not do any long prints.Only been printing for a few hours and with colour changes close to each other.

Will print some longer prints with a single colour and then after 30 minutes or longer change to another colour to see the results.

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock November 28, 2013 03:57PM |

Registered: 11 years ago Posts: 490 |

Having had some uncolored ABS on a heated bed (80-90°C) get brown during long prints made me a little sensitive about thermal degradation. But maybe the discoloration had no detrimental effect to the mechanical properties at all. I can't know for sure as I have no means of measuring those.

|

Re: Water cooled all metal hotend with 2 Bowdens and one heaterblock December 14, 2013 07:35AM |

Registered: 11 years ago Posts: 173 |

I had some longer prints with the hotend - 2.5 hours and manually changed the colours halfway throug the print with the LCD smart controller.

Pressed the T1 hotend and it stopped the T0 and proceeded with the T1 hotend without stopping the movement of the hotend and without any problems. Very easy to change the colours wherever you want to - no need to change the g-code to swap the colours. I did the switch with infill.

I also did prints longer than 2.5 hours with one colour and when the print finished I swapped the colours and extruded in the air. I did not find any noticeable degredation of the plastic. The reason I think is that the stationary colour plastic is slowly eroded by the other colour during printing and then added to again with pullbacks. Seems like there is no buildup of overheated brown plastic. Just a thought.

Next in line will be to add another colour - the hotend will be ready in a day or three. As soon as Repetier's new firmware version is available I will post more.

Pressed the T1 hotend and it stopped the T0 and proceeded with the T1 hotend without stopping the movement of the hotend and without any problems. Very easy to change the colours wherever you want to - no need to change the g-code to swap the colours. I did the switch with infill.

I also did prints longer than 2.5 hours with one colour and when the print finished I swapped the colours and extruded in the air. I did not find any noticeable degredation of the plastic. The reason I think is that the stationary colour plastic is slowly eroded by the other colour during printing and then added to again with pullbacks. Seems like there is no buildup of overheated brown plastic. Just a thought.

Next in line will be to add another colour - the hotend will be ready in a day or three. As soon as Repetier's new firmware version is available I will post more.

Sorry, only registered users may post in this forum.