mechanical engineering

Posted by maniygandan.t

|

mechanical engineering September 08, 2009 09:45AM |

|

Re: mechanical engineering September 08, 2009 10:14AM |

Admin Registered: 16 years ago Posts: 13,886 |

|

Re: mechanical engineering September 08, 2009 10:19AM |

Admin Registered: 17 years ago Posts: 1,915 |

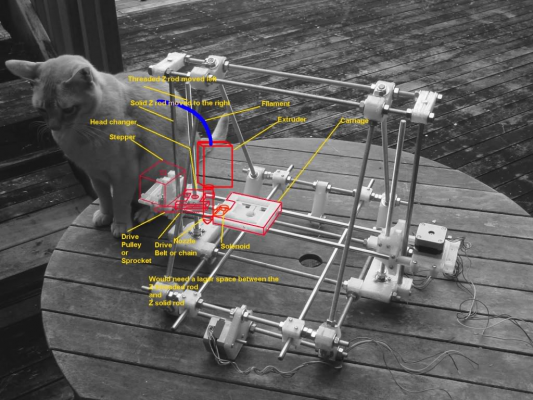

A cheap, small capacity filament extruder for 3 mm feedstock.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: mechanical engineering September 08, 2009 02:36PM |

Registered: 14 years ago Posts: 458 |

|

Re: mechanical engineering September 08, 2009 03:37PM |

Admin Registered: 17 years ago Posts: 1,915 |

Grogyan Wrote:

-------------------------------------------------------

> How about an Auto head changer, able to change

> between 2 or 3 heads.

Yeah, but for Darwin {which is relatively easy} or Mendel{which isn't}?

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

> How about an Auto head changer, able to change

> between 2 or 3 heads.

Yeah, but for Darwin {which is relatively easy} or Mendel{which isn't}?

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: mechanical engineering September 08, 2009 05:06PM |

Registered: 14 years ago Posts: 458 |

|

Re: mechanical engineering September 08, 2009 05:24PM |

Admin Registered: 17 years ago Posts: 1,915 |

Be interesting to see how you kept the filament untangled in a rotary head changer.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: mechanical engineering September 08, 2009 10:51PM |

Registered: 14 years ago Posts: 458 |

Simple, the rotary head changer notes in memory where the heads are, and so no two heads will be more than 270 degrees out of alignment before having to reverse in the other direction to select the next nozzle.

Of course i'm suggesting a 4 nozzle head changer, but the principle is till the same for a 3 nozzle head changer or even a 2 nozzle head changer.

I'll do a sketch if I can to show what i'm suggesting.

Anyone is more than welcome to tackle it, I was, after building my printer so that I have something to print parts with

Of course i'm suggesting a 4 nozzle head changer, but the principle is till the same for a 3 nozzle head changer or even a 2 nozzle head changer.

I'll do a sketch if I can to show what i'm suggesting.

Anyone is more than welcome to tackle it, I was, after building my printer so that I have something to print parts with

|

Re: mechanical engineering September 09, 2009 12:43AM |

Registered: 14 years ago Posts: 458 |

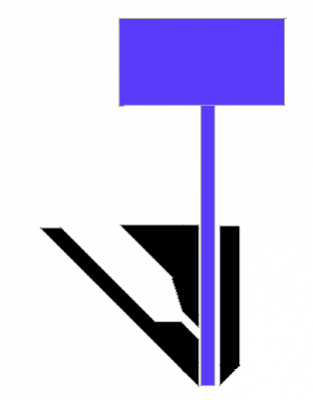

Here is a very rough sketch. My apologies to Vik for using his photo

The Sketch shows a possible 2 head changer, just changing the geometry of the head changer would allow a 3 or even a 4 head changer

I've shown the extruder raised up a bit to see a proposed geometry for an extruder to slot into

As for a Darwin head changer, I personally wouldn't even waste my time on something so simple anyway, that is if I was doing a BE Mech degree

The Sketch shows a possible 2 head changer, just changing the geometry of the head changer would allow a 3 or even a 4 head changer

I've shown the extruder raised up a bit to see a proposed geometry for an extruder to slot into

As for a Darwin head changer, I personally wouldn't even waste my time on something so simple anyway, that is if I was doing a BE Mech degree

|

Re: mechanical engineering September 09, 2009 02:42AM |

Registered: 14 years ago Posts: 177 |

|

Re: mechanical engineering September 09, 2009 04:35AM |

Registered: 15 years ago Posts: 110 |

I second Sam's idea of the hopper. I would love to be able to reuse our plastic milk bottles, as we produce (waste) piles of this plastic. They take up so much space, too. We get through 3 to 4 large bottles a week, and there are only 2 of us. We don't currently have kerbside collection of these for recycling, and we have no car, so we have to take them in rucksacks on the bus up to the supermarket for recycling.

It is an environmental issue, a convenience issue, and a potential cost-saving issue.

Hazel

It is an environmental issue, a convenience issue, and a potential cost-saving issue.

Hazel

|

Re: mechanical engineering September 09, 2009 08:28AM |

Registered: 14 years ago Posts: 12 |

sam0737 Wrote:

-------------------------------------------------------

> A hopper extruder that accepts plastic in granule

> form! Not necessary in one part, could be

> hopper/extruder that produce 3mm filament than

> feed into the existing extruder.

>

> I think this would reduce the running cost a whole

> lot...! Especially for those who can't get

> filament cheaply.

This might be able to be done with a preheat chamber with a small airpump attached to force the molten granules directly in to the normal head.

-------------------------------------------------------

> A hopper extruder that accepts plastic in granule

> form! Not necessary in one part, could be

> hopper/extruder that produce 3mm filament than

> feed into the existing extruder.

>

> I think this would reduce the running cost a whole

> lot...! Especially for those who can't get

> filament cheaply.

This might be able to be done with a preheat chamber with a small airpump attached to force the molten granules directly in to the normal head.

|

Re: mechanical engineering September 10, 2009 03:15AM |

Registered: 14 years ago Posts: 458 |

jpcw Wrote:

-------------------------------------------------------

> sam0737 Wrote:

> --------------------------------------------------

> -----

> > A hopper extruder that accepts plastic in

> granule

> > form! Not necessary in one part, could be

> > hopper/extruder that produce 3mm filament than

> > feed into the existing extruder.

> >

> > I think this would reduce the running cost a

> whole

> > lot...! Especially for those who can't get

> > filament cheaply.

> This might be able to be done with a preheat

> chamber with a small airpump attached to force the

> molten granules directly in to the normal head.

I think you'll need a LOT more force than that to push granules into the extruder.

It depends on how challenging of a project this guy wants, the more challenge, the better his marks

-------------------------------------------------------

> sam0737 Wrote:

> --------------------------------------------------

> -----

> > A hopper extruder that accepts plastic in

> granule

> > form! Not necessary in one part, could be

> > hopper/extruder that produce 3mm filament than

> > feed into the existing extruder.

> >

> > I think this would reduce the running cost a

> whole

> > lot...! Especially for those who can't get

> > filament cheaply.

> This might be able to be done with a preheat

> chamber with a small airpump attached to force the

> molten granules directly in to the normal head.

I think you'll need a LOT more force than that to push granules into the extruder.

It depends on how challenging of a project this guy wants, the more challenge, the better his marks

|

Re: mechanical engineering September 10, 2009 04:14AM |

Registered: 14 years ago Posts: 12 |

Grogyan Wrote:

-------------------------------------------------------

> jpcw Wrote:

> --------------------------------------------------

> -----

> > sam0737 Wrote:

> >

> --------------------------------------------------

>

> > -----

> > > A hopper extruder that accepts plastic in

> > granule

> > > form! Not necessary in one part, could be

> > > hopper/extruder that produce 3mm filament

> than

> > > feed into the existing extruder.

> > >

> > > I think this would reduce the running cost a

> > whole

> > > lot...! Especially for those who can't get

> > > filament cheaply.

> > This might be able to be done with a preheat

> > chamber with a small airpump attached to force

> the

> > molten granules directly in to the normal head.

>

> I think you'll need a LOT more force than that to

> push granules into the extruder.

>

> It depends on how challenging of a project this

> guy wants, the more challenge, the better his

> marks

Rather than pushing the granules in to the extruder chamber, melt them in a preheat chamber first and use air pressure to force the molten plastic through. You would need to put a valve of some type in the nozzle. I’ve been working on a couple of ideas for this that might work for liquids and also molten plastics and give a cleaner “switch off” on the extruded output.

-------------------------------------------------------

> jpcw Wrote:

> --------------------------------------------------

> -----

> > sam0737 Wrote:

> >

> --------------------------------------------------

>

> > -----

> > > A hopper extruder that accepts plastic in

> > granule

> > > form! Not necessary in one part, could be

> > > hopper/extruder that produce 3mm filament

> than

> > > feed into the existing extruder.

> > >

> > > I think this would reduce the running cost a

> > whole

> > > lot...! Especially for those who can't get

> > > filament cheaply.

> > This might be able to be done with a preheat

> > chamber with a small airpump attached to force

> the

> > molten granules directly in to the normal head.

>

> I think you'll need a LOT more force than that to

> push granules into the extruder.

>

> It depends on how challenging of a project this

> guy wants, the more challenge, the better his

> marks

Rather than pushing the granules in to the extruder chamber, melt them in a preheat chamber first and use air pressure to force the molten plastic through. You would need to put a valve of some type in the nozzle. I’ve been working on a couple of ideas for this that might work for liquids and also molten plastics and give a cleaner “switch off” on the extruded output.

|

Re: mechanical engineering September 10, 2009 06:44AM |

Registered: 14 years ago Posts: 12 |

|

Re: mechanical engineering September 10, 2009 03:03PM |

Registered: 15 years ago Posts: 216 |

Something like this has been successfully tested by Adrian, it was working the other way around with the solenoid wire going in from the side.

[blog.reprap.org]

[blog.reprap.org]

|

Re: mechanical engineering September 11, 2009 09:18AM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: mechanical engineering September 11, 2009 04:57PM |

Registered: 15 years ago Posts: 216 |

|

Re: mechanical engineering September 12, 2009 01:36PM |

Registered: 16 years ago Posts: 101 |

|

Re: mechanical engineering September 12, 2009 06:45PM |

Registered: 14 years ago Posts: 248 |

letsburn00 Wrote:

-------------------------------------------------------

> From what I understand, the problem with all the

> granual extruders is that they work perfectly the

> first time you start them up, but the second time

> they can't be started because the melted plastic

> mixes with the granuals and you can't start the

> drive again.

How do they deal with this in injection molding machines?

Edited 1 time(s). Last edit at 09/12/2009 06:45PM by annodomini2.

-------------------------------------------------------

> From what I understand, the problem with all the

> granual extruders is that they work perfectly the

> first time you start them up, but the second time

> they can't be started because the melted plastic

> mixes with the granuals and you can't start the

> drive again.

How do they deal with this in injection molding machines?

Edited 1 time(s). Last edit at 09/12/2009 06:45PM by annodomini2.

|

Re: mechanical engineering September 12, 2009 09:13PM |

Registered: 14 years ago Posts: 458 |

As normal, they heat up the plastic normally, then turn on the screw

[en.wikipedia.org]

Except we will not be having the worm drive reciprocate as they are in injection moulding.

The system for a RepRap will also mean that the system will operate vertically instead of horizontally as in injecting moulding

[en.wikipedia.org]

Except we will not be having the worm drive reciprocate as they are in injection moulding.

The system for a RepRap will also mean that the system will operate vertically instead of horizontally as in injecting moulding

Sorry, only registered users may post in this forum.