DIY $1500 Metal Printer

Posted by PeteD

|

DIY $1500 Metal Printer December 03, 2013 03:34PM |

Registered: 11 years ago Posts: 102 |

I thought this was something people on this forum would get a kick out of, since the creators used some RepRap ideas and software to make it.

[www.mtu.edu]

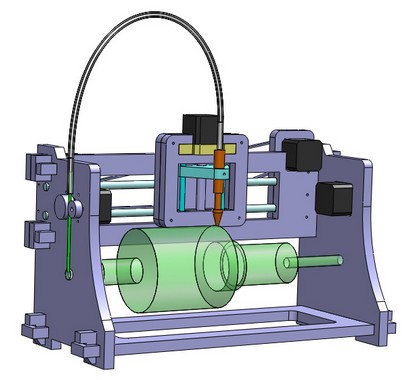

Engineers at MTU have published a DIY $1500.00 metal printer using MIG welding equipment and some RepRap Software and design ideas.

Edited 1 time(s). Last edit at 12/03/2013 03:34PM by PeteD.

[www.mtu.edu]

Engineers at MTU have published a DIY $1500.00 metal printer using MIG welding equipment and some RepRap Software and design ideas.

Edited 1 time(s). Last edit at 12/03/2013 03:34PM by PeteD.

|

Re: DIY $1500 Metal Printer December 03, 2013 07:19PM |

Registered: 11 years ago Posts: 112 |

|

Re: DIY $1500 Metal Printer December 04, 2013 02:58AM |

Registered: 10 years ago Posts: 1,381 |

Michigan Technological University (www.mtu.edu)

A link within the article:

Open-source metal 3-D printer

[www.appropedia.org]

The work is described in "A Low-Cost, Open-Source Metal 3-D Printer," to be published in IEEE Access (DOI: 10.1109/ACCESS.2013.2293018).

Edited 1 time(s). Last edit at 12/04/2013 03:04AM by A2.

A link within the article:

Open-source metal 3-D printer

[www.appropedia.org]

The work is described in "A Low-Cost, Open-Source Metal 3-D Printer," to be published in IEEE Access (DOI: 10.1109/ACCESS.2013.2293018).

Edited 1 time(s). Last edit at 12/04/2013 03:04AM by A2.

|

Re: DIY $1500 Metal Printer December 04, 2013 03:25AM |

Registered: 10 years ago Posts: 1,381 |

Substrate: an article that is placed on top of the platen (build table/platform) which supports, and facilitates metal welding of a 3d objects.

The instruction doesn't mention what type of substrate it's printing on.

Reusable substrate:

It would be beneficial to identify a substrate that conducts electricity (i.e. a ground),

prevent's or reduces warping, and easily releases the printed object with out destroying it self,

and doesn't require a secondary machining operation to the printed object.

Substrate ideas:

Graphite.

Copper.

Clay with a high iron content.

Clay with a high iron, and graphite content.

Refractory cement, perlite, iron particles, graphite.

Calcium aluminate cements.

Fire clay.

Ganister.

Minerals high in aluminum.

The substrate, and preheating will be of importance:

If you weld on a thin sheet of metal it will warp.

If you preheat the metal it reduces the amount it will warp.

If you print on a surface that the metal can't adhere too (a non conductor), then welding won't be initiated.

Edited 4 time(s). Last edit at 12/04/2013 03:52AM by A2.

The instruction doesn't mention what type of substrate it's printing on.

Reusable substrate:

It would be beneficial to identify a substrate that conducts electricity (i.e. a ground),

prevent's or reduces warping, and easily releases the printed object with out destroying it self,

and doesn't require a secondary machining operation to the printed object.

Substrate ideas:

Graphite.

Copper.

Clay with a high iron content.

Clay with a high iron, and graphite content.

Refractory cement, perlite, iron particles, graphite.

Calcium aluminate cements.

Fire clay.

Ganister.

Minerals high in aluminum.

The substrate, and preheating will be of importance:

If you weld on a thin sheet of metal it will warp.

If you preheat the metal it reduces the amount it will warp.

If you print on a surface that the metal can't adhere too (a non conductor), then welding won't be initiated.

Edited 4 time(s). Last edit at 12/04/2013 03:52AM by A2.

|

Re: DIY $1500 Metal Printer December 04, 2013 05:07AM |

Registered: 11 years ago Posts: 74 |

Wow! That is very cool news, especially that it's using RepRap components!! There is a picture of their printed sprocket here: [www.metalbot.org]

If anyone has not seen it yet, be sure to check out the "mini metal maker", a $750 printer that prints with metal clay.

3D Metal Printing and more - visit [www.metalbot.org] !

If anyone has not seen it yet, be sure to check out the "mini metal maker", a $750 printer that prints with metal clay.

3D Metal Printing and more - visit [www.metalbot.org] !

|

Re: DIY $1500 Metal Printer December 04, 2013 06:03AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: DIY $1500 Metal Printer December 04, 2013 06:39AM |

Registered: 12 years ago Posts: 206 |

I've worked on a Irepa machine that was actually set up to do FGM (unlike what is advertised..).

I can tell you that cladding machines, powder projection or fused "filament", are really far from doing anything worth using in commercial products.

There are some inherent design flaws this such technologies. The overhang is really low with that technology, you could reduce it with a 5-axis machine. The thermal gradient in the part creates a lot of wrapping. Did you think the wrapping with ABS was bad? Wait until you try cladding metal. Most metals need some type of controlled atmosphere if you don't want oxidation.

Unlike the current polymer extruder that take a 1.75 mm (or 3 mm) and reduce it to 0.30 mm. The current "filament" in mig/tig is much bigger, the droplets of molten metal are going to be bigger making a crude part.

Next question, do you care about the porosity of your part?

I invite you to check out Karunakaran's work:

[www.sciencedirect.com]

I can tell you that cladding machines, powder projection or fused "filament", are really far from doing anything worth using in commercial products.

There are some inherent design flaws this such technologies. The overhang is really low with that technology, you could reduce it with a 5-axis machine. The thermal gradient in the part creates a lot of wrapping. Did you think the wrapping with ABS was bad? Wait until you try cladding metal. Most metals need some type of controlled atmosphere if you don't want oxidation.

Unlike the current polymer extruder that take a 1.75 mm (or 3 mm) and reduce it to 0.30 mm. The current "filament" in mig/tig is much bigger, the droplets of molten metal are going to be bigger making a crude part.

Next question, do you care about the porosity of your part?

I invite you to check out Karunakaran's work:

[www.sciencedirect.com]

|

Re: DIY $1500 Metal Printer December 04, 2013 07:40AM |

Registered: 11 years ago Posts: 74 |

The machine is basically good for printing a rough billet that will need to be subtractively milled to produce the finial part. Sand casting would be much more practical and affordable and get you the same results. So, as stated, the real challenges facing 3D Metal printing are - resolution (hence highly focused lasers ~ 100um) and warping. It is the resolution that opens up amazing possibilities, just check out some of EOS's work:[www.metalbot.org]

3D Metal Printing and more - visit [www.metalbot.org] !

3D Metal Printing and more - visit [www.metalbot.org] !

|

Re: DIY $1500 Metal Printer December 04, 2013 07:46AM |

Registered: 10 years ago Posts: 1,381 |

This is exciting, we now have Globular Deposition Modeling of metal (GDMm)

I can't wait to see the first organic frames for cars, motorcycles, scooters, bikes, wheelchairs, hospital devices, and the like!

You can make hardware for the home, farm implements, cookware, sporting goods, the list goes on...

I bet there will be some cool steampunk art/costume that could be made with it too.

There's all kinds of different welding metals to explore.

It will be interesting to see if bridging can be achieved.

You could make a graphite mold and fill it with melted metal, a pseudo kiln.

I used to hand forge medical devices. This tool would be useful to construct a rough profile for further refinement by hand and machine.

@tleneel

Sounds like you have some experience, as you know this technology has been around for awhile, it's mature in some arenas.

For an example, back in the late 1980's at a university, I made a single arm robot griper for a mig welding machine. Welding students have been doing this for decades.

Lower your expectations a little, this isn't a precision 5 axis CNC machining center.

This is the first step, I expect that there will be a lot of naive knee jerk responses, and ignorance to this introduction from the mainstream chattel.

Tks Michigan Tech, you rock!

Edited 4 time(s). Last edit at 12/04/2013 11:53AM by A2.

I can't wait to see the first organic frames for cars, motorcycles, scooters, bikes, wheelchairs, hospital devices, and the like!

You can make hardware for the home, farm implements, cookware, sporting goods, the list goes on...

I bet there will be some cool steampunk art/costume that could be made with it too.

There's all kinds of different welding metals to explore.

It will be interesting to see if bridging can be achieved.

You could make a graphite mold and fill it with melted metal, a pseudo kiln.

I used to hand forge medical devices. This tool would be useful to construct a rough profile for further refinement by hand and machine.

@tleneel

Sounds like you have some experience, as you know this technology has been around for awhile, it's mature in some arenas.

For an example, back in the late 1980's at a university, I made a single arm robot griper for a mig welding machine. Welding students have been doing this for decades.

Lower your expectations a little, this isn't a precision 5 axis CNC machining center.

This is the first step, I expect that there will be a lot of naive knee jerk responses, and ignorance to this introduction from the mainstream chattel.

Tks Michigan Tech, you rock!

Edited 4 time(s). Last edit at 12/04/2013 11:53AM by A2.

|

Re: DIY $1500 Metal Printer December 04, 2013 12:23PM |

Registered: 12 years ago Posts: 206 |

@A2

This is what I am saying, it is not me that has to lower my expectation (because I somewhat have seen what can be done or can't be done?) but the journalists!

I hope some day those type of machines can perform as well as expected. But I see this type of threads every week, it just frustrates me that people can't do a simple search instead of jumping to conclusions. Metallurgy is complicated ^^

This is what I am saying, it is not me that has to lower my expectation (because I somewhat have seen what can be done or can't be done?) but the journalists!

I hope some day those type of machines can perform as well as expected. But I see this type of threads every week, it just frustrates me that people can't do a simple search instead of jumping to conclusions. Metallurgy is complicated ^^

|

Re: DIY $1500 Metal Printer December 04, 2013 01:35PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: DIY $1500 Metal Printer December 04, 2013 02:02PM |

Registered: 10 years ago Posts: 106 |

|

Re: DIY $1500 Metal Printer December 04, 2013 02:16PM |

Registered: 12 years ago Posts: 206 |

Well... If you manage to lose or gain some electrons in the process you can  EBM anybody ?!?

EBM anybody ?!?

Gold is subjective, if you manage to build a part for $10 and sell it for $1000 then you are making gold son.

PS: Cookson "prints" gold, but I am not even going to go into details on how much gold powder is.

EBM anybody ?!?

EBM anybody ?!?Gold is subjective, if you manage to build a part for $10 and sell it for $1000 then you are making gold son.

PS: Cookson "prints" gold, but I am not even going to go into details on how much gold powder is.

Quote

ddseeker

Quote

tleneel

Metallurgy is complicated ^^

Wait, so what you are saying is, when I melt it and 3D print it, it will not turn to gold?

* losses all interest *

|

Re: DIY $1500 Metal Printer December 04, 2013 03:45PM |

Registered: 11 years ago Posts: 544 |

Im a goldsmith, I know a thing or two about the properties of gold and a few of its alloys, 14k, 18k, 22k. I could get some 24k gold casting grain, then cast it into an ingot, then mill it down into 1.75mm wire, probably about 2 feet per ounce, then use a very high temp hot end to print it out in the air. however 24k gold melts at something like 1200c, and you would need to heat the chamber to about 1100c to get proper fusing and prevent warping. so your entire mechanism would need to be made from titanium if you wanted to use fdm. using metal for fdm is not really useful because it tends to ball up because of its low viscousity when its liquid and it higher specific gravity. when I make granules i just cut equal lengths of thin wire and heat them up on a piece of graphite, they turn into prefect balls. if you were to use 24k gold it might work, howver any other alloy of gold forms an oxide layer because of the other elements in it, copper and silver, which do oxidize. also for everyones information there is no such this as white gold, gold is yellow.

sorry for the rant but in a nutshell fdm and metal are not really a good mix because hot metal basically forms drops and is not easy to control, the minimum detail size would be the size of a drop of rain, so useless for any sort of fine or accurate details.

sorry for the rant but in a nutshell fdm and metal are not really a good mix because hot metal basically forms drops and is not easy to control, the minimum detail size would be the size of a drop of rain, so useless for any sort of fine or accurate details.

|

Re: DIY $1500 Metal Printer December 04, 2013 06:02PM |

Admin Registered: 13 years ago Posts: 730 |

In many cases this is true, but careful design of an alloy can result in a metal that has a "slushy phase" which can be easier to control. For examples, seeQuote

aduy

in a nutshell fdm and metal are not really a good mix because hot metal basically forms drops and is not easy to control

this paper by Mireles et. al.: Fused Deposition Modeling of Metals

and this RepRap blog post: a new approach to printing metals

True in many cases, but these guys (who got a lot of publicity a few months ago) were able to make things out of tiny - about 0.01 inch (0.25 mm) - drops of metal:Quote

aduy

the minimum detail size would be the size of a drop of rain

3D Printing of Liquid Metals at Room Temperature.

|

Re: DIY $1500 Metal Printer December 05, 2013 01:59AM |

Registered: 10 years ago Posts: 1,381 |

The LISA 3d Delta Printer would be a good platform to further develop GDMm,

as it uses steel threaded rods, which can support a lot of weight.

Consider making the arms out of metal (aluminum, steel), or epoxy/glass/carbon fiber.

Add a worm gear drive to give it an added measure of safety (anti-reversing),

and the ability to move a heavy mass.

LISA Simpson

[forums.reprap.org]

Worm Drive Grounded Delta Printer

[forums.reprap.org]

Edited 4 time(s). Last edit at 12/05/2013 02:06AM by A2.

as it uses steel threaded rods, which can support a lot of weight.

Consider making the arms out of metal (aluminum, steel), or epoxy/glass/carbon fiber.

Add a worm gear drive to give it an added measure of safety (anti-reversing),

and the ability to move a heavy mass.

LISA Simpson

[forums.reprap.org]

Worm Drive Grounded Delta Printer

[forums.reprap.org]

Edited 4 time(s). Last edit at 12/05/2013 02:06AM by A2.

|

Re: DIY $1500 Metal Printer December 05, 2013 03:59AM |

Registered: 11 years ago Posts: 74 |

Quote

sorry for the rant but in a nutshell fdm and metal are not really a good mix because hot metal basically forms drops and is not easy to control, the minimum detail size would be the size of a drop of rain, so useless for any sort of fine or accurate details.

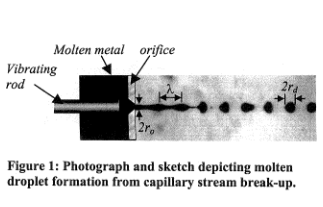

Direct Droplet Deposition has used the balling effect with good results, just look at the pictures of prints using an alloy that melts at 350C. The PDF is attached here... [www.metalbot.org]

Amazing!

They use a melt pool of metal and a silicone chip with a 50um nozzle. The rod positioned above the nozzle is vibrated up and down to let the tiny droplets through. The whole apparatus is stationary while the build platform moves in Cartesian coordinates.

Edited 1 time(s). Last edit at 12/05/2013 04:00AM by Hazel1919.

3D Metal Printing and more - visit [www.metalbot.org] !

|

Re: DIY $1500 Metal Printer December 05, 2013 04:58AM |

Registered: 10 years ago Posts: 1,381 |

That's called the StarJet, I like that design, and from what I have read they are pursuing a patent.

The design solves the problem of leaking, but I think it's prone to clogging from particulate and oxidation due to the small orifice diameter.

They have made some changes though to improve it some.

The groves allow an inert gas to bathe the liquid metal.

The land length of the groves, and the small orifice diameter provide for capillary action, which helps prevent leaks.

From my survey of the literature, it appears that most of the high temperature droplet dispensers utilize a continuous stream, which waste material.

The StarJet design allows you to pause, and move to a new section without spraying all over your object, and build platform.

The continuous stream of inert gas at the orifice interface helps to prevent oxidation.

I have friends that can make that type of orifice, but due to the patents, I'm avoiding any development that infringes StarJets IP.

The continuous stream droplet dispensers move the head off to the side when they are not printing, over a basin to catch the liquid.

I think they typically run for about 15 minutes, then you need to, purge, clean, refill, and then start over, a time consuming, and very technical process.

High pressure droplet dispensers can be very dangerous if you don't understand the dynamics that surround it.

Don't put your body parts near that stream of liquid metal!

The design solves the problem of leaking, but I think it's prone to clogging from particulate and oxidation due to the small orifice diameter.

They have made some changes though to improve it some.

The groves allow an inert gas to bathe the liquid metal.

The land length of the groves, and the small orifice diameter provide for capillary action, which helps prevent leaks.

From my survey of the literature, it appears that most of the high temperature droplet dispensers utilize a continuous stream, which waste material.

The StarJet design allows you to pause, and move to a new section without spraying all over your object, and build platform.

The continuous stream of inert gas at the orifice interface helps to prevent oxidation.

I have friends that can make that type of orifice, but due to the patents, I'm avoiding any development that infringes StarJets IP.

The continuous stream droplet dispensers move the head off to the side when they are not printing, over a basin to catch the liquid.

I think they typically run for about 15 minutes, then you need to, purge, clean, refill, and then start over, a time consuming, and very technical process.

High pressure droplet dispensers can be very dangerous if you don't understand the dynamics that surround it.

Don't put your body parts near that stream of liquid metal!

|

Re: DIY $1500 Metal Printer December 05, 2013 06:51AM |

Registered: 11 years ago Posts: 74 |

Thanks for sharing that A2! A major advantage with a system like this is that you could use an array of nozzles to deposit the metal very fast, sort of like a souped up inkjet printer.

Issues inherent to the process would be the inability to print overhangs...

Any ideas as to how they heat the melt pool? I think an induction heater would work very well in this case...

3D Metal Printing and more - visit [www.metalbot.org] !

Issues inherent to the process would be the inability to print overhangs...

Any ideas as to how they heat the melt pool? I think an induction heater would work very well in this case...

3D Metal Printing and more - visit [www.metalbot.org] !

|

Re: DIY $1500 Metal Printer December 05, 2013 07:43AM |

Registered: 10 years ago Posts: 1,381 |

From my readings, the biggest challenge to printing an overhanging profile is caused by the varying heat flux.

That is as you move away (up) from the build platform the temperature gradient of the object is not consistent.

It can be done, and there are examples.

Example of an overhanging profile:

My notes are incomplete for this image, but I think it's an example of varying heat flux for low melt temp solder?

For high temp metals like aluminum:

Induction heating is the most common method of controlling the melt temp,

as you can envelope the crucible, and avoid cool/hot spots.

Heater cartridges are probably the second most popular.

I believe in the lab they have tested multihead jetting for low melt temp solder, but I couldn't find it in my notes.

Edited 3 time(s). Last edit at 12/05/2013 07:52AM by A2.

That is as you move away (up) from the build platform the temperature gradient of the object is not consistent.

It can be done, and there are examples.

Example of an overhanging profile:

My notes are incomplete for this image, but I think it's an example of varying heat flux for low melt temp solder?

For high temp metals like aluminum:

Induction heating is the most common method of controlling the melt temp,

as you can envelope the crucible, and avoid cool/hot spots.

Heater cartridges are probably the second most popular.

I believe in the lab they have tested multihead jetting for low melt temp solder, but I couldn't find it in my notes.

Edited 3 time(s). Last edit at 12/05/2013 07:52AM by A2.

|

Re: DIY $1500 Metal Printer December 06, 2013 11:16PM |

Registered: 10 years ago Posts: 1,381 |

Iron Screw Drive Delta Printer for GDMm!

It's easy to invision the end effector as the MIG welding nozzle

A few ideas:

Replace the NEMA 17 stepper motor with a larger NEMA 23, 34, or 42 stepper motor to lift more weight.

Or add a worm drive, or a gear reduction, or a belt drive.

Shield the iron screws with a flexible fire proof covering from spraying molten droplets of liquid metal, and sparks.

Make the arms out of metal, or a composite to resist softening, and to eliminate a fire hazard, heat rises.

Make sure electronics are isolated, and shielded from the welders ground circuit.

If the arm stalls and the wire continues to feed it could create a pool of molten metal.

You need to figure out a way to deal with over flowing liquid metal, and from starting a fire, etc.

Many safety concerns besides these, weld safe!

Video: LISA

[www.youtube.com]

LISA Simpson

[forums.reprap.org]

threaded rod instead of belts

[forums.reprap.org]

Edited 4 time(s). Last edit at 12/07/2013 05:20AM by A2.

|

Re: DIY $1500 Metal Printer December 07, 2013 02:16AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: DIY $1500 Metal Printer December 07, 2013 02:21AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: DIY $1500 Metal Printer December 07, 2013 02:26AM |

Registered: 10 years ago Posts: 1,381 |

A Low-Cost Open-Source Metal 3-D Printer

GERALD C. ANZALONE

CHENLONG ZHANG

BAS WIJNEN

PAUL G. SANDERS

JOSHUA M. PEARCE

Department of Materials Science and Engineering, Michigan Technological University, Houghton, MI 49931, USA

Department of Materials Science and Engineering and the Department of Electrical and Computer Engineering, Michigan Technological University, Houghton,MI 49931, USA

Corresponding author: G. C. Anzalone ([email protected])

[www.academia.edu]

Edited 1 time(s). Last edit at 12/07/2013 02:27AM by A2.

|

Re: DIY $1500 Metal Printer December 07, 2013 02:30AM |

Registered: 10 years ago Posts: 1,381 |

Metal 3-D Printer v1.0

by jpearce, published Dec 6, 2013

[www.thingiverse.com]

Edited 1 time(s). Last edit at 12/07/2013 02:31AM by A2.

|

Re: DIY $1500 Metal Printer December 07, 2013 10:57AM |

Registered: 11 years ago Posts: 74 |

|

Re: DIY $1500 Metal Printer December 09, 2013 05:04AM |

Registered: 10 years ago Posts: 1,381 |

Additive lathe

Fabricate custom medical devices, wheel chair components, prosthetic components, springs,

rebuild shafts with a hard surface, engine cylinder, sprockets, gears, transmission, farm equipment, and art!

It would be interesting also to fabricate boxes, cones, torus, toroidal polyhedrons, etc.

I think there is a heat dissipation advantage to spin weld verse platen weld.

Yoav Sterman, additive lathe

[web.media.mit.edu]

The Multi Processes Lathe - 3D copy machine

[fab.cba.mit.edu]

files to download

[mtm.cba.mit.edu]

Fabricate custom medical devices, wheel chair components, prosthetic components, springs,

rebuild shafts with a hard surface, engine cylinder, sprockets, gears, transmission, farm equipment, and art!

It would be interesting also to fabricate boxes, cones, torus, toroidal polyhedrons, etc.

I think there is a heat dissipation advantage to spin weld verse platen weld.

Yoav Sterman, additive lathe

[web.media.mit.edu]

The Multi Processes Lathe - 3D copy machine

[fab.cba.mit.edu]

files to download

[mtm.cba.mit.edu]

|

Re: DIY $1500 Metal Printer December 09, 2013 08:41AM |

Registered: 10 years ago Posts: 1,381 |

Found on Reddit

[www.reddit.com]

An enclosed chamber will save you money on bottled inert gas.

Quote

Desolationism

Depending on the mig wire; argon for stainless, carbon mix for mild steel usually. 90 bucks for us to get our bottles filled.

300 cf bottles usually last for 15 -20 hours of welding in open air.

I agree with you, sealed build chamber with a positive inlet pressure of shield gas is the way to go.

MIG welding wire cost per cm3?

Edited 1 time(s). Last edit at 12/09/2013 08:42AM by A2.

|

Re: DIY $1500 Metal Printer December 09, 2013 09:35AM |

Registered: 10 years ago Posts: 1,381 |

Welding robots have been around for a long time.

I recall back in 1985 single arm welding robots doing similar welds, at a university, I even made an end effector gripper for one.

I'm surprised that this hasn't been picked up by the students long ago.

Possibly it's because students enter the work force have access to production grade robots.

I know I did, and there was no incentive for me to make my own 3d welding bot at that time.

A good presentation showing the capabilities of 3d welding.

High deposition rate high quality metal additive manufacture using wire + arc technology

Dr. Paul Colegrove

Professor Stewart Williams

[www.norsktitanium.no]

Found the link on Reddit

"Scientists build a low-cost, open-source 3-D metal printer."

[www.reddit.com]

Edited 3 time(s). Last edit at 12/09/2013 09:39AM by A2.

I recall back in 1985 single arm welding robots doing similar welds, at a university, I even made an end effector gripper for one.

I'm surprised that this hasn't been picked up by the students long ago.

Possibly it's because students enter the work force have access to production grade robots.

I know I did, and there was no incentive for me to make my own 3d welding bot at that time.

A good presentation showing the capabilities of 3d welding.

High deposition rate high quality metal additive manufacture using wire + arc technology

Dr. Paul Colegrove

Professor Stewart Williams

[www.norsktitanium.no]

Found the link on Reddit

"Scientists build a low-cost, open-source 3-D metal printer."

[www.reddit.com]

Edited 3 time(s). Last edit at 12/09/2013 09:39AM by A2.

|

Re: DIY $1500 Metal Printer December 28, 2013 04:38PM |

Registered: 10 years ago Posts: 1,381 |

Sigma Labs & Michigan Tech to develop low cost 3D metal printer

[www.3ders.org]

Video of Low-Cost Open-Source 3D Metal Printing v.1 2013

Joshua Pearce

Published on Dec 16, 2013

[www.youtube.com]

Open-source metal 3-D printer

[www.appropedia.org]

SIGMA LABS, INC. LOW-COST 3D METAL PRINTER TECHNOLOGY DEVELOPMENT

The enabling technology for Sigma Labs' new, low-cost 3D Printer would be based on our proprietary and

patent-protected PrintRite3D® quality control and sensing technologies.

[sigmalabsinc.com]

Edited 2 time(s). Last edit at 12/28/2013 04:41PM by A2.

Sorry, only registered users may post in this forum.