Extruder Drive Design Ideas for Inexpensive Oval Welding Rod

Posted by A2

|

Extruder Drive Design Ideas for Inexpensive Oval Welding Rod December 14, 2013 05:11AM |

Registered: 10 years ago Posts: 1,381 |

It's so cheap.

What hot end design ideas do you have to process an oval profile?

I read complaints of feeding issues with slightly out of round filament.

The hob has a round profile, and this filament has an oval profile.

I'm wondering if there will be significant feeding challenges

with an oval profile in a typical hobbed bolt drive?

The second potential issues, because the oval profile doesn't plug-seal the bore of the barrel,

would the melted plastic tend to back up and out the top of the extruder barrel?

My first thought is that once that the rod is inside the barrel, and is pressed firmly

into the melt zone of the hot end, the profile of the filament doesn't matter anymore.

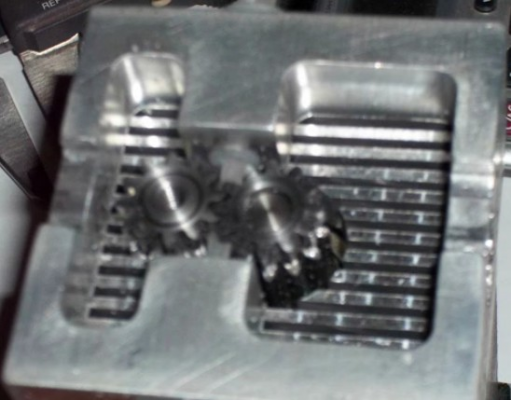

Looking at this gear on gear filament driver that takes advantage of the inexpensive

plastic welding rod, I think that the oval profile is a challenge to feed.

Improved 3D printer extruder allows more plastic options

[www.kickstarter.com]

A third potential problem of an oval profile, would twisting ahead of

feeding the filament into the barrel of the extruder cause feeding problems?

$8 to $16 / lbs

1/8" HDPE Oval Welding Rod

1/8" LDPE Oval Welding Rod

1/8" White ABS Welding Rod

1/8" Natural Polypropylene Oval Welding Rod

5/32" Marine Grade HDPE Black Welding Rod

[www.usplastic.com]

Edited 4 time(s). Last edit at 12/15/2013 09:53AM by A2.

What hot end design ideas do you have to process an oval profile?

I read complaints of feeding issues with slightly out of round filament.

The hob has a round profile, and this filament has an oval profile.

I'm wondering if there will be significant feeding challenges

with an oval profile in a typical hobbed bolt drive?

The second potential issues, because the oval profile doesn't plug-seal the bore of the barrel,

would the melted plastic tend to back up and out the top of the extruder barrel?

My first thought is that once that the rod is inside the barrel, and is pressed firmly

into the melt zone of the hot end, the profile of the filament doesn't matter anymore.

Looking at this gear on gear filament driver that takes advantage of the inexpensive

plastic welding rod, I think that the oval profile is a challenge to feed.

Improved 3D printer extruder allows more plastic options

[www.kickstarter.com]

A third potential problem of an oval profile, would twisting ahead of

feeding the filament into the barrel of the extruder cause feeding problems?

$8 to $16 / lbs

1/8" HDPE Oval Welding Rod

1/8" LDPE Oval Welding Rod

1/8" White ABS Welding Rod

1/8" Natural Polypropylene Oval Welding Rod

5/32" Marine Grade HDPE Black Welding Rod

[www.usplastic.com]

Edited 4 time(s). Last edit at 12/15/2013 09:53AM by A2.

|

Re: Design Ideas for Cheap 1/8" HDPE Oval Welding Rod December 15, 2013 05:39AM |

Registered: 11 years ago Posts: 544 |

|

Re: Design Ideas for Cheap 1/8" HDPE Oval Welding Rod December 15, 2013 08:48AM |

Admin Registered: 17 years ago Posts: 1,915 |

It is true that HDPE is inexpensive and polypropylene is even cheaper. Printing successfully with them, however, requires quite a bit of experience because of the high heat shrinkage rate of both polymers. It is quite difficult to make larger objects with these plastics. It can be done, mind, but it is quite an art. I know from first hand experience.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Design Ideas for Cheap 1/8" HDPE Oval Welding Rod December 15, 2013 09:46AM |

Registered: 10 years ago Posts: 1,381 |

I'm looking for a workaround to the gear-to-gear drive.

A tractor feed might work. Is there an example of a tractor feed extruder?

Whatever you get to work with an oval filament, I believe will work for a round filament.

I used to teach hand welding PP/PE, and I can attest that it's challenging for some people to master (it's an art).

But after watching Luminar Products video of a 3d printer laying down an extrudate, I'm encouraged by what I see.

It looks like it prints well.

The Luminar Super Extruder EX001 might be pricey for some budgets,

but I think it's valuated fairly, as there is lot of machining to it.

A tractor feed might work. Is there an example of a tractor feed extruder?

Whatever you get to work with an oval filament, I believe will work for a round filament.

I used to teach hand welding PP/PE, and I can attest that it's challenging for some people to master (it's an art).

But after watching Luminar Products video of a 3d printer laying down an extrudate, I'm encouraged by what I see.

It looks like it prints well.

The Luminar Super Extruder EX001 might be pricey for some budgets,

but I think it's valuated fairly, as there is lot of machining to it.

|

Re: Design Ideas for Cheap 1/8" HDPE Oval Welding Rod December 23, 2013 04:39PM |

Registered: 10 years ago Posts: 1,381 |

Quote

Forrest Higgs

Printing successfully with them [HDPE, PP], however, requires quite a bit of experience because of the high heat shrinkage rate of both polymers.

It is quite difficult to make larger objects with these plastics.

It can be done, mind, but it is quite an art. I know from first hand experience.

Please share your experience of how to best go about printing HDPE/PP.

If you have any photos to share it would be helpful.

Tks!

|

Re: Extruder Drive Design Ideas for Inexpensive Oval Welding Rod December 25, 2013 06:59PM |

Registered: 10 years ago Posts: 64 |

|

Re: Extruder Drive Design Ideas for Inexpensive Oval Welding Rod December 25, 2013 09:10PM |

Admin Registered: 13 years ago Posts: 730 |

Quote

A2

Please share your experience of how to best go about printing HDPE/PP.

Some of Forrest's experiments with HDPE:

Revisiting HDPE

No-sweat HDPE printing

Some of nophead's experiments with HDPE:

Scaling new heights

Sorry, only registered users may post in this forum.