Dual extruder for faster fillings

Posted by Zazza

|

Dual extruder for faster fillings January 05, 2014 02:37PM |

Registered: 10 years ago Posts: 10 |

I don't know if i'm saying the obvious and someone already tested it ,a "dual extruder" search here gives back too many results to check them all.

Everybody knows these printers can be really slow to print objects, and scaling them bigger affects time to the third power, and this is probabily one of the main reasons because they haven't still reached a real mass diffusion (not considering price); so find a way to print objects faster should be mandatory.

If the speed achievable by the motors isn't the limiting factor the main other one would be the thickness of the extrusion (influenced by the nozzle geometry) since the smaller it is the slower the print is. Though we can't increase the nozzle orifice area without decreasing resolution and finish of the object.The bigger amount of time during print apparently is lost when printing filling of every plane.

So this is the idea: why not use a smaller diameter nozzle only to print perimeters and have a good surface finish and a bigger nozzle to print plane fillings faster, keeping your usual filling setup (honeycomb, crossed, in the % you like). As much as i have looked, most of the dual printers use this feature only to print different colours. For example using a 1 mm nozzle with same z height would roughly save half of the time in filling printing compared to a 0.5 and two third compared to a 0.3.

Some things that should be tested would be how low one can go in z layer thickness for the different nozzle sections, and there would be the need of an appropriate software support (i don't know if this feature would be supported by actual slicers/firmwares, since it consists of printing with completely different settings a "print inside another").

Going further in the developement of this technique one wouldn't neither need two motor extruders to run two nozzles if he would use the same filament, maybe there could be a way to mount a solenoid valve that could switch the plastic flow from one nozzle to the other.

Edited 1 time(s). Last edit at 01/05/2014 02:39PM by Zazza.

Everybody knows these printers can be really slow to print objects, and scaling them bigger affects time to the third power, and this is probabily one of the main reasons because they haven't still reached a real mass diffusion (not considering price); so find a way to print objects faster should be mandatory.

If the speed achievable by the motors isn't the limiting factor the main other one would be the thickness of the extrusion (influenced by the nozzle geometry) since the smaller it is the slower the print is. Though we can't increase the nozzle orifice area without decreasing resolution and finish of the object.The bigger amount of time during print apparently is lost when printing filling of every plane.

So this is the idea: why not use a smaller diameter nozzle only to print perimeters and have a good surface finish and a bigger nozzle to print plane fillings faster, keeping your usual filling setup (honeycomb, crossed, in the % you like). As much as i have looked, most of the dual printers use this feature only to print different colours. For example using a 1 mm nozzle with same z height would roughly save half of the time in filling printing compared to a 0.5 and two third compared to a 0.3.

Some things that should be tested would be how low one can go in z layer thickness for the different nozzle sections, and there would be the need of an appropriate software support (i don't know if this feature would be supported by actual slicers/firmwares, since it consists of printing with completely different settings a "print inside another").

Going further in the developement of this technique one wouldn't neither need two motor extruders to run two nozzles if he would use the same filament, maybe there could be a way to mount a solenoid valve that could switch the plastic flow from one nozzle to the other.

Edited 1 time(s). Last edit at 01/05/2014 02:39PM by Zazza.

|

Re: Dual extruder for faster fillings January 05, 2014 05:20PM |

Registered: 10 years ago Posts: 153 |

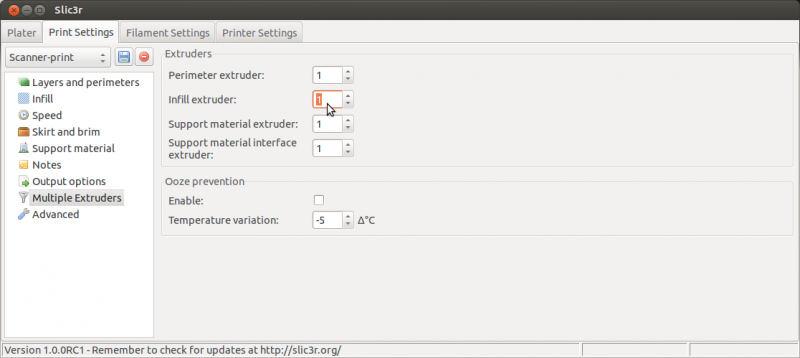

Slic3r has software support for this. So you define one extruder as extruder 1 and the other as 2. Then you define which extruder to use for infill and which to use for perimeters. So yes it can be done, and it looks like it will be fairly straight forward to setup

|

Re: Dual extruder for faster fillings January 05, 2014 06:00PM |

Registered: 10 years ago Posts: 10 |

Thanks for tip! Didn't really look much deep in slic3r, this exactly looks like what i've been asking for. If this feature has been implemented already than most probably someone should have tried the fast infill method....Now would really like to know how much thin in layer height you can go with the different nozzle sizes. Obtaining 0.1mm layer height with 1 mm nozzle would be perfect but 1:10 looks a pretty extreme ratio considering most printers use 1:2-1:5 ratios.

|

Re: Dual extruder for faster fillings January 05, 2014 08:30PM |

Registered: 11 years ago Posts: 544 |

|

Re: Dual extruder for faster fillings January 05, 2014 11:09PM |

Registered: 10 years ago Posts: 153 |

I have a 0.5 mm nozzle and I have succesfully printed things in nylon with 0.1mm layer height. I have read about other people doing prints in .1mm layer heights. Just try it on something small and see what works.  EDIT: I haven't tried PLA or ABS because I don't have any yet.

EDIT: I haven't tried PLA or ABS because I don't have any yet.

Edited 1 time(s). Last edit at 01/05/2014 11:10PM by TheTechnicalNoob.

EDIT: I haven't tried PLA or ABS because I don't have any yet.

EDIT: I haven't tried PLA or ABS because I don't have any yet.Edited 1 time(s). Last edit at 01/05/2014 11:10PM by TheTechnicalNoob.

|

Re: Dual extruder for faster fillings January 06, 2014 09:06AM |

Registered: 10 years ago Posts: 10 |

Quote

aduy

you can set the infill as a multiple of the perimeter extrusion

just setting multiples with same nozzle size wouldn't speed up the process, since it would be like just changing the infill pattern.

It's a matter of printed area per second, which is only dependent on extrusion speed, movement speed and nozzle size.

|

Re: Dual extruder for faster fillings January 06, 2014 09:15AM |

Registered: 11 years ago Posts: 544 |

|

Re: Dual extruder for faster fillings January 06, 2014 09:33AM |

Registered: 10 years ago Posts: 10 |

Quote

aduy

well not exactly, you would still be limited by max extrusion speed, however the infill would be say .3mm layer height and the perimeters would be .1mm, so assuming no extrusion bottleneck you could print the infill 3 times faster than the perimeters.

Oh sorry so, i thought you were referring to infill "stripes" width while you were talking about layer height.

Yes, that should definetly work, in fact if used with a bigger nozzle would speed the filling process by a factor of (r*l) where r is the ratio of the two nozzle sizes and l is the ratio of the two layer heights.

So supposing we're using a 0.2 nozzle for perimeters with 0.1 layer height , printing the infill with 0.5 nozzle and 0.3 layer height would be 7.5 times faster than using the same nozzle and same layer height (i think a bottleneck would come from temperature rather than motor power , the plastic would have for the same reason 7.5 less time to get to the proper temperature, so a longer hot end for more even heating would prolly be needed).

Sorry, only registered users may post in this forum.