Bed modification question

Posted by roontoon

|

Bed modification question January 09, 2014 09:27AM |

Registered: 10 years ago Posts: 36 |

I am about to start a build of a Pursa i3 and there is a modification that I am considering but I have a question. I would like to double the y axis and include 2 bed heaters, is there any problems that you see that I may encounter with the operation of the printer as well as the electronics which is my main concern. Thanks for any help or advise.

d

d

|

Re: Bed modification question January 09, 2014 09:59AM |

Registered: 11 years ago Posts: 544 |

well it depends, what are your electronics, and how big is your power supply? if you are not using the fan mosfet you might be able to use it to power the second bed, however you would need to reprogram the firmware for that, which im sure someone could help you out with.

as far as frame rigidity, it should be fine, because the weight will be low on the frame and the y axis on the prusa is fairly sturdy, however you will need to lower the acceleration on the y axis to account for the added weight.

one more question, how many amps is your stepper motor? if its lower than 0.75, you might actually consider using two stepper motors in parallel, one at each end to drive the bed, this will negate the added weight of the second bed. I actually use two steppers on my x and y axis, mostly just for kicks and giggles.

as far as frame rigidity, it should be fine, because the weight will be low on the frame and the y axis on the prusa is fairly sturdy, however you will need to lower the acceleration on the y axis to account for the added weight.

one more question, how many amps is your stepper motor? if its lower than 0.75, you might actually consider using two stepper motors in parallel, one at each end to drive the bed, this will negate the added weight of the second bed. I actually use two steppers on my x and y axis, mostly just for kicks and giggles.

|

Re: Bed modification question January 09, 2014 11:54AM |

Registered: 10 years ago Posts: 36 |

Quote

aduy

what are your electronics, and how big is your power supply?

Arduino RAMPS. Currently using a server 600w power supply but I could get a dedicated unit.

Quote

aduy

if you are not using the fan mosfet you might be able to use it to power the second bed.

Attached is the Fan schematic. I plan on the extruder fan and the electronics fan but not sure about the print fan but would like the option if needed. In terms of my stepper motors the specs are: Voltage: 12V

Amps: 0.4A Step/Degree 1.8deg/step Holding Torque 260nm-m/ 36oz-in

Thanks for your reply.

Edited 1 time(s). Last edit at 01/09/2014 11:56AM by roontoon.

|

Re: Bed modification question January 09, 2014 02:39PM |

Registered: 11 years ago Posts: 544 |

there are a couple options, you could use the print fan as the bed and get an external driver(or make one, someone has done it before). external fan driver

hmm you could easily use two of those motors on one driver and double your torque, although you might as well just get a 1.2amp stepper with about twice the torque. Lets figure out the bed situation first though.

hmm you could easily use two of those motors on one driver and double your torque, although you might as well just get a 1.2amp stepper with about twice the torque. Lets figure out the bed situation first though.

|

Re: Bed modification question January 09, 2014 03:49PM |

Registered: 12 years ago Posts: 809 |

First off, do not connect two beds to RAMPS1.4. The fan port isn't designed to handle that much current - you'll blow that 5A PTC fuse in short order. You really should use an external driver to safely run a bed that large. Look at the sevenswitch.

As far as stepper motors, look for something in the 3V/1.6A range with at least 45 oz-in of torque. You want to run your steppers at multiples of their rated voltage, not at their rated voltage. For a heavy Y you may want to step up to a larger driver like the DRV8825, and perhaps even a NEMA23 stepper.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

As far as stepper motors, look for something in the 3V/1.6A range with at least 45 oz-in of torque. You want to run your steppers at multiples of their rated voltage, not at their rated voltage. For a heavy Y you may want to step up to a larger driver like the DRV8825, and perhaps even a NEMA23 stepper.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Bed modification question January 09, 2014 04:14PM |

Registered: 10 years ago Posts: 64 |

Just want to say that with 600W you will NOT need an external unit. You could run a 4x4 grid of beds and still be okay.

Also, my NEMA 17 motors are all 76 oz/in which is a LOT. They're longer than most, but that's okay because they kick so much ass. I recommend something like this for your Y axis. I currently run them at a medium speed and they don't even get warm, neither do the steppers. They have much much much more room to be pushed, and they'd for sure handle your large bed.

Point is, no need for NEMA 23.

OH I FORGOT. They sell a huge extra long heated bed on eBay! I've bought from them before and their products are top-notch, made in USA. It might not be a full 400mm (I don't remember, sizes in inches anyway) but it might just be the key for your project.

Good luck!

EDIT: Just looked and they have a footlong heated bed that's the standard width. It looks ridiculous. They also mention that they do custom sizes, and he put his freaking phone number at the end of the eBay auction. A single custom size might be the ticket, and that guy seems reliable.

Edited 1 time(s). Last edit at 01/09/2014 04:17PM by SamS.

Also, my NEMA 17 motors are all 76 oz/in which is a LOT. They're longer than most, but that's okay because they kick so much ass. I recommend something like this for your Y axis. I currently run them at a medium speed and they don't even get warm, neither do the steppers. They have much much much more room to be pushed, and they'd for sure handle your large bed.

Point is, no need for NEMA 23.

OH I FORGOT. They sell a huge extra long heated bed on eBay! I've bought from them before and their products are top-notch, made in USA. It might not be a full 400mm (I don't remember, sizes in inches anyway) but it might just be the key for your project.

Good luck!

EDIT: Just looked and they have a footlong heated bed that's the standard width. It looks ridiculous. They also mention that they do custom sizes, and he put his freaking phone number at the end of the eBay auction. A single custom size might be the ticket, and that guy seems reliable.

Edited 1 time(s). Last edit at 01/09/2014 04:17PM by SamS.

|

Re: Bed modification question January 12, 2014 02:52PM |

Registered: 10 years ago Posts: 36 |

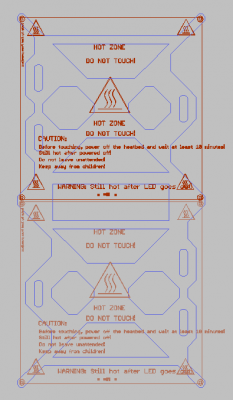

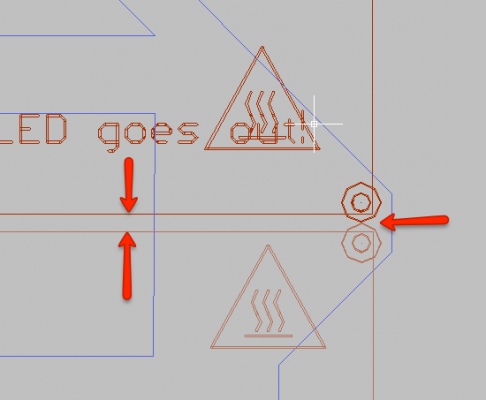

Thanks to all for the replies and suggestions. I have attached a mockup drawing of a longer bed.

I don't know if the small gap between the two heat beds will be an issue with the machine. I also am not sure if you can overlap the two heating elements to use the same hole on the bed, perhaps making a hot spot.

Any advise?

I don't know if the small gap between the two heat beds will be an issue with the machine. I also am not sure if you can overlap the two heating elements to use the same hole on the bed, perhaps making a hot spot.

Any advise?

|

Re: Bed modification question January 12, 2014 04:00PM |

Registered: 10 years ago Posts: 553 |

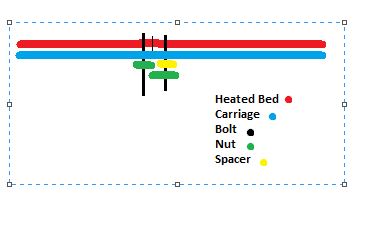

Try stacking the nuts under the bed in a staggered pattern. Kinda like this:

Edited 2 time(s). Last edit at 01/12/2014 04:06PM by gmh39.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Edited 2 time(s). Last edit at 01/12/2014 04:06PM by gmh39.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Bed modification question January 12, 2014 05:15PM |

Registered: 10 years ago Posts: 36 |

|

Re: Bed modification question January 13, 2014 08:48AM |

Registered: 10 years ago Posts: 553 |

I wouldn't be so much worried about hotter ares, but rather the ridge it would cause when they are stacked.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Bed modification question January 13, 2014 02:50PM |

Registered: 13 years ago Posts: 1,797 |

also you could place aluminum tape across the tops of the pcb board heaters. there is some variance in between the spaces of the copper wire traces as well. either way i would want to also insulate the bottom of the bed to prevent a lot of heat loss.

use a relay to push the current thru both pcb heaters. be sure to wire the heaters up separately all the way to the power source as the wire length and gauge limit your current.

also in the connection of the aluminum place to the bed, the bolt holes should be over-sized, and clamped into place with springs below. you want the bolt to be holding the bed in place, but the aluminum place beneath will expand. if there is no give in the design for this the aluminum bed frame will warp.

Edited 2 time(s). Last edit at 01/13/2014 02:58PM by jamesdanielv.

use a relay to push the current thru both pcb heaters. be sure to wire the heaters up separately all the way to the power source as the wire length and gauge limit your current.

also in the connection of the aluminum place to the bed, the bolt holes should be over-sized, and clamped into place with springs below. you want the bolt to be holding the bed in place, but the aluminum place beneath will expand. if there is no give in the design for this the aluminum bed frame will warp.

Edited 2 time(s). Last edit at 01/13/2014 02:58PM by jamesdanielv.

|

Re: Bed modification question January 16, 2014 01:28PM |

Registered: 10 years ago Posts: 36 |

|

Re: Bed modification question January 17, 2014 07:55AM |

Registered: 10 years ago Posts: 172 |

Quote

Just want to say that with 600W you will NOT need an external unit. You could run a 4x4 grid of beds and still be okay.

That's not very clear. If he's using a 600W computer PSU then the 12V rail won't be able to supply adequate current to the nozzle and both beds. Additionally, the Ramps board will probably (not for sure, though) go up in smoke if you power two beds and a nozzle from it. Having said that, Ramps is designed to support two hot ends and a single bed so why couldn't it support two beds and one nozzle? for what it's worth, Q1, Q2 and Q3, which are the three mosfets that control the current to D8 D9 and D10 terminals are all rated to 55A which is WAAAAY in excess of what the traces on the boards are rated for. The traces would be your weak point. Having said all that, I'd lay money on the fact that the Ramps will support two beds and one nozzle.

|

Re: Bed modification question January 17, 2014 08:24AM |

Registered: 11 years ago Posts: 349 |

Sorry, only registered users may post in this forum.