Why does it seem few care about print strength and how to compare it?

Posted by strantor

|

Why does it seem few care about print strength and how to compare it? January 27, 2014 12:47AM |

Registered: 10 years ago Posts: 38 |

Hello RepRap forum, this is my first post. I'm relatively new to 3D printing. I got a 3D printer for one reason: to build a prosthetic hand for my father. For this, I need strong (in all 3 axes), durable prints. You could say that getting super strong prints is all I care about, and I'm feeling almost all alone in that.

Since entering the world of 3D printing, I find an overwhelming amount of information on every topic regarding 3D printing, except for how to get the strongest, most durable prints possible. It seems 95% of information regarding selecting a material, only covers scant details about ABS Vs. PLA, when there are far more material choices out there (could be they just arrived on scene around the same time I did).

This forum, having 97 subforums, doesn't even have a subforum for materials (that I could see; maybe I'm looking for the wrong buzz-words). No dedicated place to talk about Nylon Vs. PET Vs. acetone-dipped ABS Vs. fill-in-the-blank, or post-processing steps to increase parts strength. I mention this, not to degrade this fine forum, but to illustrate my point: Nobody seems to care, even enough to account for a meager 1% of subforum content.

Why?

When I was printing out fingers for my prosthetic hand and breaking them, I was thinking to myself "surely there is a standardized parts strength test I can perform, and compare my numbers other people's numbers, to get an idea if I'm doing it right; see if this is the best I can get out of a 3D printer or if other people are getting significantly better results than I am."

I found no such test. I still cannot wrap my head around that. How could there be no test? So, I devised my own test. So far I have tested ABS with a cooling fan Vs. ABS with no cooling fan Vs. Nylon 645. I have some Taulman T-glase coming this week, and I will test it against that data already gathered, Plus ABS dipped in acetone, and ABS, Nylon, and T-glase printed inside an enclosed, heated printer.

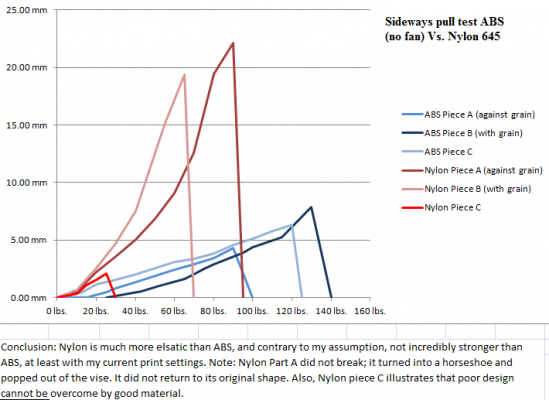

Here is a sample of what my test results look like; the numbers from my Nylon Vs. ABS test:

Doesn't this seem like valuable data to have? Wouldn't it be beneficial if everybody did this and found out how their numbers stack up against everybody else's? Who knows, maybe your prints really relatively suck in terms of strength and you never knew! Maybe comparing your numbers and talking to those with superior numbers could help you out, and give the whole community some steps in the right direction. Why am I the only one I'm aware of doing this?

Edited 1 time(s). Last edit at 01/27/2014 12:49AM by strantor.

Since entering the world of 3D printing, I find an overwhelming amount of information on every topic regarding 3D printing, except for how to get the strongest, most durable prints possible. It seems 95% of information regarding selecting a material, only covers scant details about ABS Vs. PLA, when there are far more material choices out there (could be they just arrived on scene around the same time I did).

This forum, having 97 subforums, doesn't even have a subforum for materials (that I could see; maybe I'm looking for the wrong buzz-words). No dedicated place to talk about Nylon Vs. PET Vs. acetone-dipped ABS Vs. fill-in-the-blank, or post-processing steps to increase parts strength. I mention this, not to degrade this fine forum, but to illustrate my point: Nobody seems to care, even enough to account for a meager 1% of subforum content.

Why?

When I was printing out fingers for my prosthetic hand and breaking them, I was thinking to myself "surely there is a standardized parts strength test I can perform, and compare my numbers other people's numbers, to get an idea if I'm doing it right; see if this is the best I can get out of a 3D printer or if other people are getting significantly better results than I am."

I found no such test. I still cannot wrap my head around that. How could there be no test? So, I devised my own test. So far I have tested ABS with a cooling fan Vs. ABS with no cooling fan Vs. Nylon 645. I have some Taulman T-glase coming this week, and I will test it against that data already gathered, Plus ABS dipped in acetone, and ABS, Nylon, and T-glase printed inside an enclosed, heated printer.

Here is a sample of what my test results look like; the numbers from my Nylon Vs. ABS test:

Doesn't this seem like valuable data to have? Wouldn't it be beneficial if everybody did this and found out how their numbers stack up against everybody else's? Who knows, maybe your prints really relatively suck in terms of strength and you never knew! Maybe comparing your numbers and talking to those with superior numbers could help you out, and give the whole community some steps in the right direction. Why am I the only one I'm aware of doing this?

Edited 1 time(s). Last edit at 01/27/2014 12:49AM by strantor.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 12:58AM |

Admin Registered: 11 years ago Posts: 1,063 |

it is actually very valuable data, the problem with printed parts in particular is that they are viewed in a similar light to that of timber where things like tensile strength for example can vary from print to print machine to machine and even plastic types,

couple that with slicers and hotends getting better that changes all the variables again,

the best place to start would the the polymer working group

couple that with slicers and hotends getting better that changes all the variables again,

the best place to start would the the polymer working group

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 01:30AM |

Registered: 11 years ago Posts: 334 |

There are few people working on it but they are out there. You might want to look into protopasta products as well. FYI You can find standard parts strength test prints on thingiverse.

One of the problems is that there are so many factors involved. If you are going to continue doing testing on your own you will really need to make sure you track everything. Some of the main factors are design, print material type, print material brand, temp controlled environment (oven), acetone treatment, print temp and infill.

Could you add that information to the data you are sharing? If you could also post your methodology you might find a few other people on here willing to test what they have. Personally I have found that printing ABS at a high temp with a metal hotend can really increase strength. Depending on the ABS I would consider trying 260-280. Acetone treatment also improves strength greatly.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

One of the problems is that there are so many factors involved. If you are going to continue doing testing on your own you will really need to make sure you track everything. Some of the main factors are design, print material type, print material brand, temp controlled environment (oven), acetone treatment, print temp and infill.

Could you add that information to the data you are sharing? If you could also post your methodology you might find a few other people on here willing to test what they have. Personally I have found that printing ABS at a high temp with a metal hotend can really increase strength. Depending on the ABS I would consider trying 260-280. Acetone treatment also improves strength greatly.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 01:39AM |

Registered: 12 years ago Posts: 2,470 |

Thanks for the info, i were actually looking for something like this.

PET (like T-Glase) might really be interesting to you, it is lightweight and seriously strong while much easier to print than nylon and less warp prone than ABS.

Edited 1 time(s). Last edit at 01/27/2014 01:40AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

PET (like T-Glase) might really be interesting to you, it is lightweight and seriously strong while much easier to print than nylon and less warp prone than ABS.

Edited 1 time(s). Last edit at 01/27/2014 01:40AM by Srek.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 03:10AM |

Registered: 11 years ago Posts: 544 |

Ive found that getting proper adhesion is fairly consistent amongst different materials, for example all thermoplastics perform better when they are dried before printing, except for pla using a heated build chamber always helps with adhesion. Ive printed some large 12x12x12 pieces in abs and the warping forces actually made a split along the xy plane about half way through a 50 hour print, even with a 120c heated bed. After that waste of time i decided to setup a heated build chamber running at about 90c, the abs came out of the nozzle like hershey's chocolate syrup, and the print had no warp, infact it kind of drooped a bit in the infilled sections, to the point where it really needed a better pattern.

so from my discoveries there are three things that can make any print stronger in abs/nylon/polycarb: dry the filament out all the way, Use a heated bed and build chamber, if possible use a solvent to further increase the bond strength of the plastic with a vapor bath. also to doecrease warping without a heated chamber you need to increase the layer time.

DCM can be used for polycarbonate but look up the msds first. for nylon tetrafluoropropanol is the solvent to use.

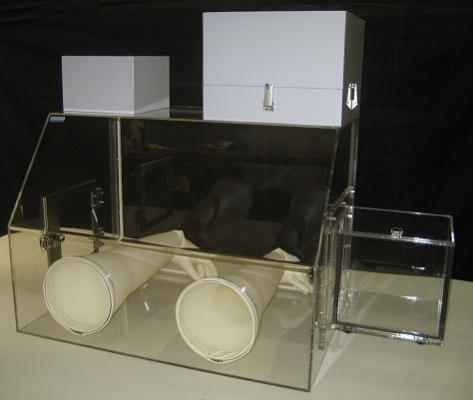

If you were going to be doing this a lot it might be worth making something like this so you arent working directly with the solvents. you might even be able to fit your printer in there, if you can't fit it you can even make into a fun project "reprap in a bottle".

[www.laboratory-supply.net]

Edited 1 time(s). Last edit at 01/27/2014 03:14AM by aduy.

so from my discoveries there are three things that can make any print stronger in abs/nylon/polycarb: dry the filament out all the way, Use a heated bed and build chamber, if possible use a solvent to further increase the bond strength of the plastic with a vapor bath. also to doecrease warping without a heated chamber you need to increase the layer time.

DCM can be used for polycarbonate but look up the msds first. for nylon tetrafluoropropanol is the solvent to use.

If you were going to be doing this a lot it might be worth making something like this so you arent working directly with the solvents. you might even be able to fit your printer in there, if you can't fit it you can even make into a fun project "reprap in a bottle".

[www.laboratory-supply.net]

Edited 1 time(s). Last edit at 01/27/2014 03:14AM by aduy.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 05:22AM |

Registered: 11 years ago Posts: 198 |

I did some testing last year, but I haven't had the time to move on with a more systematic test.

It was fun to build the rig, but very time consuming to actually do some tests.

[ralfsfablab.blogspot.dk]

I have mostly done tests with ABS, which just confirms that higher temp=higher strength, within reason of course.

It was fun to build the rig, but very time consuming to actually do some tests.

[ralfsfablab.blogspot.dk]

I have mostly done tests with ABS, which just confirms that higher temp=higher strength, within reason of course.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 06:43AM |

Registered: 10 years ago Posts: 120 |

I guess there are too many variables for getting reliable and comparable results when exchanging the data. Every printer is a little different, other nozzle, other layer height and width, different speed, bowden-extruder or direct drive, ...

There are countless variables which all might change the strength of the part. Maybe, if there was a huge set of samples, we could get an estimate if ABS is stronger than PLA or something, but if you take those values and print other parts on your own printer, YMMV.

There are countless variables which all might change the strength of the part. Maybe, if there was a huge set of samples, we could get an estimate if ABS is stronger than PLA or something, but if you take those values and print other parts on your own printer, YMMV.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 09:48AM |

Registered: 10 years ago Posts: 38 |

Sure thing. I will create a new thread for this purpose (Once I get all my data from upcoming tests). I will upload my raw data in spreadsheets, with test & printing conditions.Quote

jzatopa

If you are going to continue doing testing on your own you will really need to make sure you track everything. Some of the main factors are design, print material type, print material brand, temp controlled environment (oven), acetone treatment, print temp and infill.

Could you add that information to the data you are sharing?

Quote

jzatopa

If you could also post your methodology you might find a few other people on here willing to test what they have.

I linked to my video in the OP, wherein I describe exactly how I perform my test and demonstrate my test fixture. When I create the above mentioned test data thread, I will include a written test procedure as well

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 09:54AM |

Registered: 11 years ago Posts: 198 |

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 09:55AM |

Registered: 13 years ago Posts: 1,797 |

I always used tensile strength to compare plastics performance. not that it is perfect, and it really does not tell me much.

this tells me that bonding strength is different for each plastic, and it is the weakness of the parts structure.

now I'm curious as to why, is it temp difference or something else.

I actually found this data very useful.

graphs are nice, but seeing video of some sort of Gage or measurement device is more convincing. I'll try to find a link to a video for an example and edit this post later

I would encourage anyone working on such things,

thanks for your contribution!

Edited 2 time(s). Last edit at 01/27/2014 09:58AM by jamesdanielv.

this tells me that bonding strength is different for each plastic, and it is the weakness of the parts structure.

now I'm curious as to why, is it temp difference or something else.

I actually found this data very useful.

graphs are nice, but seeing video of some sort of Gage or measurement device is more convincing. I'll try to find a link to a video for an example and edit this post later

I would encourage anyone working on such things,

thanks for your contribution!

Edited 2 time(s). Last edit at 01/27/2014 09:58AM by jamesdanielv.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 09:56AM |

Registered: 10 years ago Posts: 38 |

Quote

Srek

Thanks for the info, i were actually looking for something like this.

PET (like T-Glase) might really be interesting to you, it is lightweight and seriously strong while much easier to print than nylon and less warp prone than ABS.

Yes, I have T-glase in the mail headed my way as speak. It is what I am waiting for before posting my test results.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 09:57AM |

Registered: 10 years ago Posts: 38 |

Quote

jamesdanielv

I always used tensile strength to compare plastics performance. not that it is perfect, and it really does not tell me much.

this tells me that bonding strength is different for each plastic.

now I'm curious as to why, is it temp difference or something else.

I actually found this data very useful.

graphs are nice, but seeing video of some sort of Gage or measurement device is more convincing. I'll try to find a link to a video for an example and edit this post later

I would encourage anyone working on such things,

thanks for your contribution!

Did you see my video in the first post?

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 10:02AM |

Registered: 10 years ago Posts: 38 |

Quote

aduy

Ive found that getting proper adhesion is fairly consistent amongst different materials, for example all thermoplastics perform better when they are dried before printing, except for pla using a heated build chamber always helps with adhesion. Ive printed some large 12x12x12 pieces in abs and the warping forces actually made a split along the xy plane about half way through a 50 hour print, even with a 120c heated bed. After that waste of time i decided to setup a heated build chamber running at about 90c, the abs came out of the nozzle like hershey's chocolate syrup, and the print had no warp, infact it kind of drooped a bit in the infilled sections, to the point where it really needed a better pattern.

so from my discoveries there are three things that can make any print stronger in abs/nylon/polycarb: dry the filament out all the way, Use a heated bed and build chamber, if possible use a solvent to further increase the bond strength of the plastic with a vapor bath. also to doecrease warping without a heated chamber you need to increase the layer time.

DCM can be used for polycarbonate but look up the msds first. for nylon tetrafluoropropanol is the solvent to use.

If you were going to be doing this a lot it might be worth making something like this so you arent working directly with the solvents. you might even be able to fit your printer in there, if you can't fit it you can even make into a fun project "reprap in a bottle".

[www.laboratory-supply.net]

I did experiment with acetone DURING ABS printing. I had acetone evaporating in (sealed, but not pressure-sealed) crock pot, with a tube plumbed to my print head. The idea was to get acetone infused between layers to improve layer adhesion. Results were poor. The acetone condensed in the tube and dribbled out. I considered enclosing my printer and having ABS vapor inside, but that would eat my printer and create a very unsafe pressure chamber full of explosive atmosphere with a low flash point.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 10:05AM |

Registered: 13 years ago Posts: 1,797 |

strantor :

I just viewed it,

here is a video with an analog Gage.

[www.youtube.com]

those analog gages tell a lot to people.

Edited 1 time(s). Last edit at 01/27/2014 10:06AM by jamesdanielv.

I just viewed it,

here is a video with an analog Gage.

[www.youtube.com]

those analog gages tell a lot to people.

Edited 1 time(s). Last edit at 01/27/2014 10:06AM by jamesdanielv.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 10:24AM |

Registered: 10 years ago Posts: 38 |

Quote

jamesdanielv

strantor :

I just viewed it,

here is a video with an analog Gage.

[www.youtube.com]

those analog gages tell a lot to people.

Yes, as I mentioned in the video I also tried with an analog scale, and the recoil stripped the gears in the scale once the part broke. I considered purchasing this big game scale, but decided against it, as on top of the fact that it might also break, the scale works by a loaded spring, which makes testing elongation concurrently with force problematic. Imagine what would happen if you have the caliper around the test piece and it breaks, while there is 3" of spring distance payed out of the scale? Your caliper will be destroyed. If you can think of a way to prevent this, it would be helpful to anyone wishing to duplicate the test. I could not think of a solution, which is why I went with the load cell.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 11:07AM |

Registered: 10 years ago Posts: 106 |

The guys from Proto-Pasta have a set of tests they use.

See the Data Sheets for

1. Heat Deflection Temperature (HDT) Test.

2. Impact Resistance

3. Flexural Stiffness and Flexural Strength

I don't know how well their filament is... your thread just reminded me of seeing their kickstarter

See the Data Sheets for

1. Heat Deflection Temperature (HDT) Test.

2. Impact Resistance

3. Flexural Stiffness and Flexural Strength

I don't know how well their filament is... your thread just reminded me of seeing their kickstarter

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 12:11PM |

Registered: 11 years ago Posts: 544 |

Quote

strantor

Quote

aduy

Ive found that getting proper adhesion is fairly consistent amongst different materials, for example all thermoplastics perform better when they are dried before printing, except for pla using a heated build chamber always helps with adhesion. Ive printed some large 12x12x12 pieces in abs and the warping forces actually made a split along the xy plane about half way through a 50 hour print, even with a 120c heated bed. After that waste of time i decided to setup a heated build chamber running at about 90c, the abs came out of the nozzle like hershey's chocolate syrup, and the print had no warp, infact it kind of drooped a bit in the infilled sections, to the point where it really needed a better pattern.

so from my discoveries there are three things that can make any print stronger in abs/nylon/polycarb: dry the filament out all the way, Use a heated bed and build chamber, if possible use a solvent to further increase the bond strength of the plastic with a vapor bath. also to doecrease warping without a heated chamber you need to increase the layer time.

DCM can be used for polycarbonate but look up the msds first. for nylon tetrafluoropropanol is the solvent to use.

If you were going to be doing this a lot it might be worth making something like this so you arent working directly with the solvents. you might even be able to fit your printer in there, if you can't fit it you can even make into a fun project "reprap in a bottle".

[www.laboratory-supply.net]

I did experiment with acetone DURING ABS printing. I had acetone evaporating in (sealed, but not pressure-sealed) crock pot, with a tube plumbed to my print head. The idea was to get acetone infused between layers to improve layer adhesion. Results were poor. The acetone condensed in the tube and dribbled out. I considered enclosing my printer and having ABS vapor inside, but that would eat my printer and create a very unsafe pressure chamber full of explosive atmosphere with a low flash point.

strange, my experiments went well, i was able to smooth out a layer height of up to 1mm, and totally bond some other pieces that I left over night in a low concentration vapor bath without heating.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 05:43PM |

Registered: 10 years ago Posts: 38 |

To be clear, I was not talking about post processing in a vapor bath. I was talking about piping in vaporized acetone WHILE printing, so that it gets between the layers and nit just on the outside. Is that what you're talking about too?Quote

aduy

Quote

strantor

Quote

aduy

Ive found that getting proper adhesion is fairly consistent amongst different materials, for example all thermoplastics perform better when they are dried before printing, except for pla using a heated build chamber always helps with adhesion. Ive printed some large 12x12x12 pieces in abs and the warping forces actually made a split along the xy plane about half way through a 50 hour print, even with a 120c heated bed. After that waste of time i decided to setup a heated build chamber running at about 90c, the abs came out of the nozzle like hershey's chocolate syrup, and the print had no warp, infact it kind of drooped a bit in the infilled sections, to the point where it really needed a better pattern.

so from my discoveries there are three things that can make any print stronger in abs/nylon/polycarb: dry the filament out all the way, Use a heated bed and build chamber, if possible use a solvent to further increase the bond strength of the plastic with a vapor bath. also to doecrease warping without a heated chamber you need to increase the layer time.

DCM can be used for polycarbonate but look up the msds first. for nylon tetrafluoropropanol is the solvent to use.

If you were going to be doing this a lot it might be worth making something like this so you arent working directly with the solvents. you might even be able to fit your printer in there, if you can't fit it you can even make into a fun project "reprap in a bottle".

[www.laboratory-supply.net]

I did experiment with acetone DURING ABS printing. I had acetone evaporating in (sealed, but not pressure-sealed) crock pot, with a tube plumbed to my print head. The idea was to get acetone infused between layers to improve layer adhesion. Results were poor. The acetone condensed in the tube and dribbled out. I considered enclosing my printer and having ABS vapor inside, but that would eat my printer and create a very unsafe pressure chamber full of explosive atmosphere with a low flash point.

strange, my experiments went well, i was able to smooth out a layer height of up to 1mm, and totally bond some other pieces that I left over night in a low concentration vapor bath without heating.

|

Re: Why does it seem few care about print strength and how to compare it? January 27, 2014 05:54PM |

Registered: 10 years ago Posts: 38 |

Quote

Ralf

I did some testing last year, but I haven't had the time to move on with a more systematic test.

It was fun to build the rig, but very time consuming to actually do some tests.

[ralfsfablab.blogspot.dk]

I have mostly done tests with ABS, which just confirms that higher temp=higher strength, within reason of course.

Nice setup. Nice to see someone like-minded. Hiw much did your setup cost?

|

Re: Why does it seem few care about print strength and how to compare it? January 28, 2014 04:20AM |

Registered: 11 years ago Posts: 198 |

I had the steel laying around from another project, so it was only the load cell and an instrumentation amplifier (INA125P) that I had to buy, so that was ~40€ in total.

Of course it is completely undocumented but if there is any interest, that wouldn't be too dificult.

It is lacking deflection measuring, but a potientiometer, a string and some more code, should be able to do that.

Of course it is completely undocumented but if there is any interest, that wouldn't be too dificult.

It is lacking deflection measuring, but a potientiometer, a string and some more code, should be able to do that.

|

Re: Why does it seem few care about print strength and how to compare it? January 28, 2014 07:27AM |

Registered: 10 years ago Posts: 38 |

Quote

Ralf

I had the steel laying around from another project, so it was only the load cell and an instrumentation amplifier (INA125P) that I had to buy, so that was ~40€ in total.

Of course it is completely undocumented but if there is any interest, that wouldn't be too dificult.

It is lacking deflection measuring, but a potientiometer, a string and some more code, should be able to do that.

All of the digital calipers I've seen, even the cheapies have a port. It's used for calibration but it could be used to transmit data to a PC, via some interface.

It would sure be nice if the data went straight to the PC instead of having to stop every 10LBS and make a recording. That's tedious.

[www.robotroom.com]

|

Re: Why does it seem few care about print strength and how to compare it? January 28, 2014 07:45AM |

Registered: 14 years ago Posts: 3,742 |

Electronic digital caliper to computer interface

Caliper2PC - Digital Caliper Types Supported

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Caliper2PC - Digital Caliper Types Supported

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Why does it seem few care about print strength and how to compare it? January 28, 2014 11:02PM |

Registered: 10 years ago Posts: 26 |

I can really appreciate the effort put into this testing and I see that you will get good comparable data for materials. By pulling at the holes you are measuring the tear-out strength of the piece which has as much to do with the geometry as it does the material strength. In fact, tear-out stress is calculated as 1/2(F/lt) where F is the load applied, l is the distance from the edge of the hole to the end of the piece and t is the thickness of the sample. If you are able to use this data to calculate and verify when a certain geometry will fail, I would continue using this as a method of testing. If you are more concerned with overall tensile strength, I would recommend looking into printing dogbone shaped materials so that your failure is in pure tension.

Here is a link I found which shows a good example (most likely extremely costly):

Way Expensive Tensile Test Example

To change your setup to be pure tension on the sample, try increasing the "l" in the tear-out equation so that you can increase the force required to failure. You want this to be higher than the tensile failure (as mentioned already in this thread) so that your sample doesn't break at the attachment point. A good reference point is to make the distance from the edge of the part to the hole greater than the diameter of the hole.

Either way, I think you are doing important work and when I saw your thread, I thought to myself, "He's right!" There isn't a large emphasis placed on actual material strength.

Here is a link I found which shows a good example (most likely extremely costly):

Way Expensive Tensile Test Example

To change your setup to be pure tension on the sample, try increasing the "l" in the tear-out equation so that you can increase the force required to failure. You want this to be higher than the tensile failure (as mentioned already in this thread) so that your sample doesn't break at the attachment point. A good reference point is to make the distance from the edge of the part to the hole greater than the diameter of the hole.

Either way, I think you are doing important work and when I saw your thread, I thought to myself, "He's right!" There isn't a large emphasis placed on actual material strength.

|

Re: Why does it seem few care about print strength and how to compare it? January 28, 2014 11:28PM |

Registered: 11 years ago Posts: 1,171 |

Not as detailed but I started a thread about strength awhile back here [forums.reprap.org]

|

Re: Why does it seem few care about print strength and how to compare it? January 29, 2014 12:04AM |

Admin Registered: 13 years ago Posts: 730 |

There was another thread about this some time ago here: Questions about durability of repraped models. Nophead posted a link to this work (by Zaggo of whistle fame?) [pleasantsoftware.com]

In the same thread, Have Blue pointed out that there are a lot of academic papers written on this sort of thing. Unfortunately a lot of these papers are behind paywalls, but there are occasional pdf's to be found. For example, try searching for "Anisotropic material properties of fused deposition modeling ABS" by SH Ahn et. al.

In the same thread, Have Blue pointed out that there are a lot of academic papers written on this sort of thing. Unfortunately a lot of these papers are behind paywalls, but there are occasional pdf's to be found. For example, try searching for "Anisotropic material properties of fused deposition modeling ABS" by SH Ahn et. al.

|

Re: Why does it seem few care about print strength and how to compare it? January 29, 2014 12:51AM |

Registered: 10 years ago Posts: 1,381 |

@strantor:

I've designed, and conducted tensile test on professional equipment, a few ideas for you to consider.

The faceted sides of the Allen wrench create stress risers, best to use a round steel rod for consistent readings.

I'm not able to see how you are mounting the Allen wrench to evenly distribute the tensile load.

But side loading will generate poor test results.

The rate that the force is applied should be mechanically controlled. Use a lead screw with a motor.

Test: the spring force gauge can be dampened with a gas shock (from an automobile).

In addition to tensile testing with the lay, and against the lay,

print a scarf joint lay pattern (i.e. print at an angle), it should increase the strength.

Bending test should support the object with round profiles separated with a known distance.

Again I'm not able to see how you were supporting the test samples.

Consistency:

Filament should be dried before use.

Test samples should be printed in an enclosed temperature controlled environment.

The test samples should also be dried before testing, and/or pretreated in a humid environment.

All machine and environmental factors should be recorded.

Test speciemens dimensions should be measured, and the weight recorded before testing.

Dog-bone test samples would make for an improved test specimen,

as it would allow you to clamp the ends with more force away from the region that is going to fail, and is a standardized form.

You can print geometric forms in the center of the dog-bone, but this is not a 1:1 comparison to the holes on the end with a metal rod.

Dog-bone test samples thickness can be increased, possibly this would allow you

to see if there is a nonlinear response, or inconsistency in your method of fabrication,

and to clue you in on to what thickness would work best for your application.

I wouldn't abandon your test specimen design (i.e. holes at the ends) as it allows you to test for tear-out strength,

which is important to know for hardware mounting.

Flexural/bending, creep, wear/abrasive, impact, drop test, U.V. ozone, conductivity, and

solvent, acid/alkaline, lipid, blood contact, and other types of tests will

also help you to better understand the device design, and the material choice.

Ultimately you are concerned with product performance in the real world.

Dog-bone specimens is just a starting point to help you understand the material and manufacturing process.

Eventually you should be testing the final product under real world conditions.

Edited 1 time(s). Last edit at 01/29/2014 12:55AM by A2.

I've designed, and conducted tensile test on professional equipment, a few ideas for you to consider.

The faceted sides of the Allen wrench create stress risers, best to use a round steel rod for consistent readings.

I'm not able to see how you are mounting the Allen wrench to evenly distribute the tensile load.

But side loading will generate poor test results.

The rate that the force is applied should be mechanically controlled. Use a lead screw with a motor.

Test: the spring force gauge can be dampened with a gas shock (from an automobile).

In addition to tensile testing with the lay, and against the lay,

print a scarf joint lay pattern (i.e. print at an angle), it should increase the strength.

Bending test should support the object with round profiles separated with a known distance.

Again I'm not able to see how you were supporting the test samples.

Consistency:

Filament should be dried before use.

Test samples should be printed in an enclosed temperature controlled environment.

The test samples should also be dried before testing, and/or pretreated in a humid environment.

All machine and environmental factors should be recorded.

Test speciemens dimensions should be measured, and the weight recorded before testing.

Dog-bone test samples would make for an improved test specimen,

as it would allow you to clamp the ends with more force away from the region that is going to fail, and is a standardized form.

You can print geometric forms in the center of the dog-bone, but this is not a 1:1 comparison to the holes on the end with a metal rod.

Dog-bone test samples thickness can be increased, possibly this would allow you

to see if there is a nonlinear response, or inconsistency in your method of fabrication,

and to clue you in on to what thickness would work best for your application.

I wouldn't abandon your test specimen design (i.e. holes at the ends) as it allows you to test for tear-out strength,

which is important to know for hardware mounting.

Flexural/bending, creep, wear/abrasive, impact, drop test, U.V. ozone, conductivity, and

solvent, acid/alkaline, lipid, blood contact, and other types of tests will

also help you to better understand the device design, and the material choice.

Ultimately you are concerned with product performance in the real world.

Dog-bone specimens is just a starting point to help you understand the material and manufacturing process.

Eventually you should be testing the final product under real world conditions.

Edited 1 time(s). Last edit at 01/29/2014 12:55AM by A2.

|

Re: Why does it seem few care about print strength and how to compare it? January 29, 2014 12:07PM |

Registered: 10 years ago Posts: 38 |

Good point. I will use a round bar henceforth.Quote

A2

The faceted sides of the Allen wrench create stress risers, best to use a round steel rod for consistent readings.

Understood, this the purpose of the "wire halo" on top to evenly distribute weight on both side of the allen wrench. On the bottom, the allen wrench is blocked under the machined vise jaws, which are (should be) perfectly perpendicular to the drill quill. So, in (my) theory, there should be no appreciable loading more on one side than the other.Quote

A2

I'm not able to see how you are mounting the Allen wrench to evenly distribute the tensile load.

But side loading will generate poor test results.

You're right, in a perfect world it should be a more controlled linear pull than what I am doing by hand. But the way I see it, if it's going to break @ 120 lbs, it should break @ 120 lbs whether that number is arrived at in a perfectly linear increase, or in a stepped increase with possible occasional minor tension releases. But I'm not a thermoplastics engineer and I could be wrong. Am I wrong?Quote

A2

The rate that the force is applied should be mechanically controlled. Use a lead screw with a motor.

I'm having trouble visualizing this. If a gas shock behaved like a non-newtonian fluid; if it had no inherent force of it's own, was free to move (very little resistance) at low speed and only resisted quick changes acted upon it, then yes, I can see that working. However the traditional shock absorber like in an automobile suspension or trunk hatch movement dampener, does have it's own inherent force. It's like a gas-powered spring. I've replaced the shocks in my car, both suspension and trunk, and can attest to the fact that these things are quite hard to compress. I think they would greatly skew the measurement. ...unless you're talking about a different type of shock that I'm unaware of. Can you elaborate?Quote

A2

Test: the spring force gauge can be dampened with a gas shock (from an automobile).

That's a good point I suppose, but at some point more data is not not more helpful data. I feel like the test already involves a cumbersome amount of data. I have to split the results up into several graphs in order for it to make immediate sense; otherwise it's just colorful collage. I'm not sure if one more graph would be of any help. I will wait until I get feedback from the test results that I plan to post this weekend, and see if that's something that people want to see, or if it's "good enough."Quote

A2

In addition to tensile testing with the lay, and against the lay,

print a scarf joint lay pattern (i.e. print at an angle), it should increase the strength.

I think I know where you're going with this, and that is the reason why I made the test pieces a full 10cm long. I figure people will complain about the print time, but with a test piece that long, it should be adaptable to a wide array of test fixures without the fixures needing a micron-level spec on the distances involved. The longer test piece is more forgiving on the dimensions of the fixture. I simply place "whatever is left" of the test peice, after one or both of the eyelets have been ripped out, under the jaws of my vise, and adjust the vise to the point where it's almost clamping the piece, but not clamping it. This gives a reasonably repeatable distance; I've never measured the distance, but it's always about the same. As far as round profiles, probably not gonna happen. I don't see the point for machining anything special for this test. I don't think it would have enough effect to make it worthwhile, but again, you sound like you know more about it than I do, so if you have a convincing reason why, I'd be glad to listen.Quote

A2

Bending test should support the object with round profiles separated with a known distance.

Again I'm not able to see how you were supporting the test samples.

I don't completely agree. I whole-heartedly agree that all these things should be recorded, but not that they should be controlled. We are not testing only the polymers, we are testing the process as well. Maybe your process involves dried filament, temp controlled printing environment, et. al., and maybe mine doesn't; maybe my test pieces with water-logged filament, printed on my back porch in a blizzard outperform yours (of course, not going to happen, just a hyperbolic example). If I had matched all your controls, there would be no indication of what process variables had beneficial impact on my success or failure.Quote

A2

Consistency:

Filament should be dried before use.

Test samples should be printed in an enclosed temperature controlled environment.

The test samples should also be dried before testing, and/or pretreated in a humid environment.

All machine and environmental factors should be recorded.

Test speciemens dimensions should be measured, and the weight recorded before testing.

I think it should be "to each his own (process, filament, print settings, etc.)" and whoever leads the pack, we look at their condition data and replicate it. If they didn't dry their filament, then we try not drying our filament, etc.

Thanks for the tip, but I don't think I'll be using dog bone samples unless further testing convinces me that I need to (I will be thinking about it). I designed the process to test things that we (or maybe just me) care about (real life). How often do you actually care about the tensile strength of a piece? That's an honest question, not a rhetorical one. For me, I didn't care about tensile strength until I bent the fingers of my 3D printed hand backwards, and the hinged joints ripped out (tear-out strength). This is actually more a function of layer adhesion than tensile strength. So I designed the test to give me an indication that I cared about, and I think it's pretty good at that. The actual value of the test result is not as important as it's relative (to other people's #s) value.Quote

A2

Dog-bone test samples would make for an improved test specimen,

as it would allow you to clamp the ends with more force away from the region that is going to fail, and is a standardized form.

You can print geometric forms in the center of the dog-bone, but this is not a 1:1 comparison to the holes on the end with a metal rod.

Dog-bone test samples thickness can be increased, possibly this would allow you

to see if there is a nonlinear response, or inconsistency in your method of fabrication,

and to clue you in on to what thickness would work best for your application.

I wouldn't abandon your test specimen design (i.e. holes at the ends) as it allows you to test for tear-out strength,

which is important to know for hardware mounting.

That stuff is mostly above my head, and I don't care enough about it right now to invest the time to educate myself about it. Going down that rabbit hole would be a huge distraction from my ultimate goal, to make a prosthetic hand. But, I share this test with the world, in the spirit of open-source development. I encourage others to perform the test. To standardize on a test, any test (this test, if nothing better shows its face). I hope, that those who share in the interest and in the spirit of open-source development will pick up the ball an run with it. You, or anybody else who wants to test these things, is more than welcome to do so. I would love to hear the results, even if I don't fully understand them. I only ask one thing; If you're going to use my STL file, don't modify it. it is a constant.Quote

A2

Flexural/bending, creep, wear/abrasive, impact, drop test, U.V. ozone, conductivity, and

solvent, acid/alkaline, lipid, blood contact, and other types of tests will

also help you to better understand the device design, and the material choice.

I definitely will. I have already built the hand a couple of times and destroyed it a couple of times. That's what prompted me to design the test. It's just too time consuming to build a whole hand just to destroy it. Once I settle on the best material and best process I can find, I will build the hand again and destroy it again, just to see what it takes, and then build it again.Quote

A2

Ultimately you are concerned with product performance in the real world.

Dog-bone specimens is just a starting point to help you understand the material and manufacturing process.

Eventually you should be testing the final product under real world conditions.

Thank you for taking the time to provide all these tips & hints. I apologize for not agreeing with everything you said; I hope I did not sound standoffish. I hope I did come across as pissing on golden nuggets of information provided by a world-renown industry professional. I don't know you from Adam; the only thing I know is what seems intuitive to me, and what I have time to research. I hope this discussion proves beneficial for the community.

|

Re: Why does it seem few care about print strength and how to compare it? February 03, 2014 09:44PM |

Registered: 10 years ago Posts: 38 |

I have created another thread to post my test results, as promised. I did not get around to testing all the things I talked about, but I will, in time.

|

Re: Why does it seem few care about print strength and how to compare it? February 10, 2014 09:27PM |

Registered: 10 years ago Posts: 38 |

So, 6 days ago I sent two emails; one to Taulman and one to Proto pasta. I informed them about what I'm trying to do with the strength testing.

My email to Taulman contained:

(excerpt)

My email to Proto-Pasta contained:

(excerpt)

I offered free advertising and asked nothing in return, no "samples," no "previews," nothing on the house. As of yet, they have both opted not to reply.

Apparently this data is so worthless that even the manufacturers see no incentive whatsoever to me posting it, or even replying to my email. It's not even worth 2 hours and postage. There is zero advertising value in a third party proving to the world the extent of how strong parts printed with your polymer can be? How is that possible?

Or am I just way off base here? Is my test that much of a joke? If it is, let me know. Or come up with a better one. The world doesn't have to standardize on my test. But there should be a standardized test to compare print strength in all 3 axes. If someone else can come up with a better test, that everybody likes, I will gladly abandon my own to follow that one.

Edited 1 time(s). Last edit at 02/10/2014 09:30PM by strantor.

My email to Taulman contained:

(excerpt)

Quote

[...]And that's why I'm contacting you. If anybody knows how to print the strongest 3D prints with Taulamn polymers, it's Taulman. So, I'm asking you to print my .STL file [on a RepRap-style printer with your best possible known settings and polymer] and send me the prints so that I can test them and publish the results in open forum. This will give us a "baseline." As you can see, I've already posted some test data on your products, and I don't know if I'm doing them justice. I'm giving you the chance to up the ante, and I'm offering free advertising.

My email to Proto-Pasta contained:

(excerpt)

Quote

[...]And that's why I'm contacting you. If anybody knows how to print the strongest 3D prints with ProtoPasta polymers, it's ProtoPasta. So, I'm asking you to print my .STL file [on a RepRap-style printer with you best possible known settings and polymer] and send me the prints so that I can test them and publish the results in open forum. This will give us a "baseline." As you can see, I've already posted some test data on Taulman's products. I don't know if I'm doing their products justice. I'm giving you the chance to up the ante, and I'm offering free advertising.

I offered free advertising and asked nothing in return, no "samples," no "previews," nothing on the house. As of yet, they have both opted not to reply.

Apparently this data is so worthless that even the manufacturers see no incentive whatsoever to me posting it, or even replying to my email. It's not even worth 2 hours and postage. There is zero advertising value in a third party proving to the world the extent of how strong parts printed with your polymer can be? How is that possible?

Or am I just way off base here? Is my test that much of a joke? If it is, let me know. Or come up with a better one. The world doesn't have to standardize on my test. But there should be a standardized test to compare print strength in all 3 axes. If someone else can come up with a better test, that everybody likes, I will gladly abandon my own to follow that one.

Edited 1 time(s). Last edit at 02/10/2014 09:30PM by strantor.

Sorry, only registered users may post in this forum.