|

Printing with the new t-glase from taulman3d January 27, 2014 10:50PM |

Registered: 11 years ago Posts: 160 |

You may look at the t-glase and say cool! But then if you are like me you look at the price and go "darn". On to how I decided to start using t-glase. I was trying to print quadcopter frames that I designed in taulman 618. 618 is some amazing stuff, but very difficult on certain prints to keep from warping, even after you lift it off the build plate. My frames are one of those prints that present that difficulty. So I contacted taulman and he offered to print my stl file and see if he could get it right. However, he was not set up for printing nylon at the moment and printed my frame in t-glase clear. he printed on 3 different machines with 3 different nozzles. He printed on glass at 76C 100% fill, .38mm, .5mm, .74mm nozzles. I then paid for the shipping and he sent me the pieces to check out. I was pretty impressed how straight the prints were.

My main focus of getting into 3D printing is to make functional parts that last. Not into the vase making or puppy dog stuff too much. So trying to manufacture these small precise parts becomes a pretty big challenge. Lucky for me there is so many new filaments making it to the market. So the first thing I did with one of his prints was to measure the accuracy of it, then put it in a vise and grab it with a pliers at twist. Not very scientific, but I have been in fabrication for 35+years. While I don't have exact strength numbers I can tell you that it is substantially stronger than ABS, and not as strong as 618. Seemed like this would work and solve the problem I was faced with for months. So I bought 4 rolls. I also bought 2 rolls of 645 nylon, and he sent me some 910 for testing. I will post my results with those. I know shipping is pricey with taulman, but you can put 6 rolls in one box for the same price. For what I plan on doing, the price is fine. I want to sell my work, already have. So I can recoup some of my investment and keep my hobby going.

On to the printing attempts. Now if you read the web-site, you may get confused and think you need a bigger nozzle, or you would have to play with nozzle settings and layer height. I am here to say if you already print with ABS, your settings will be almost the same.

First try. I printed at 225C on glass with hair spray at 60C. Using a makerfarm i3, .4mm E3D nozzle, .2mm layer height ,50mm print speed. I realized it was printing a little too fast and slowed it down 50% during the print. Print stuck fine, was a little sloppy. Testing it in the vise revealed that the layers were not bonding fully. If I see the print break apart evenly across a layer, my heat is too low. I am all about maximum adhesion between layers, as that makes the part stronger.

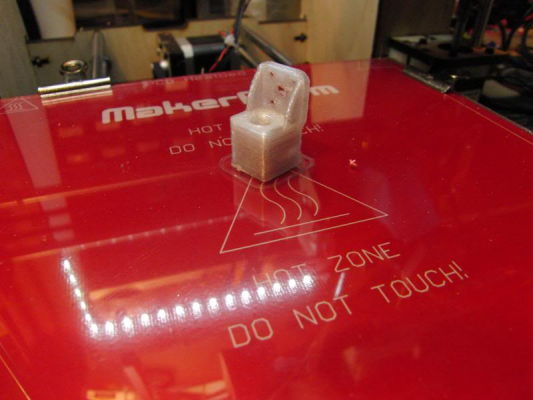

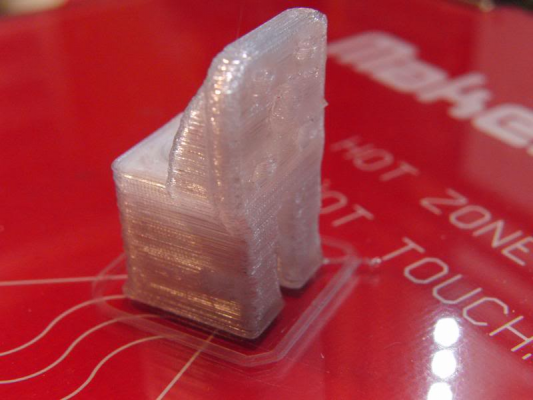

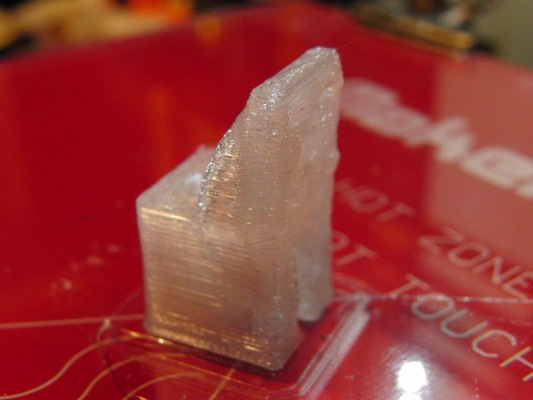

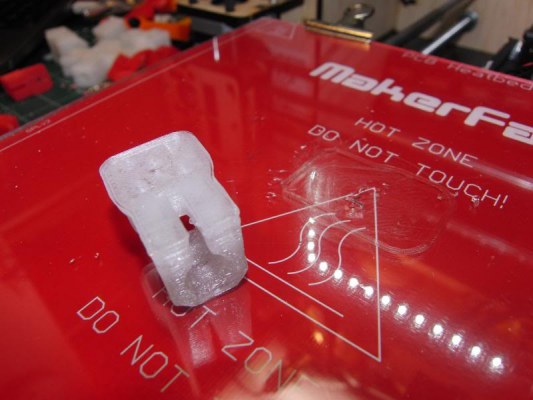

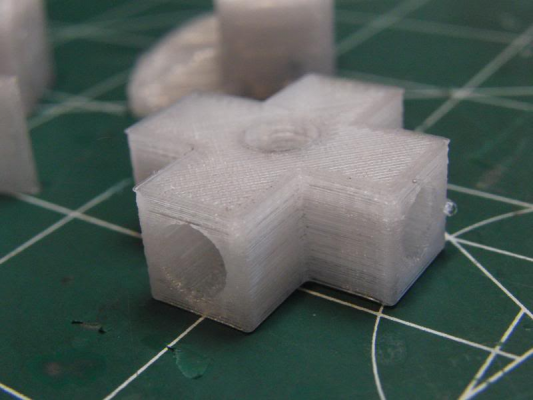

After that attempt I wandered over to the taulman web-site to look for advice on printing. I got sucked into the bigger nozzle idea, and raised my layer height to .3mm. Slowed my print speed down. Raised HE to 235C Print got sloppier but bonded a little better. Holes did not come out round as you can see by the smiley face.....lol

Put in a vise to simulate the strain that will be placed on the motor pod. It clamps onto arrow shafts. No cracking really, but seemed like it could go hotter.

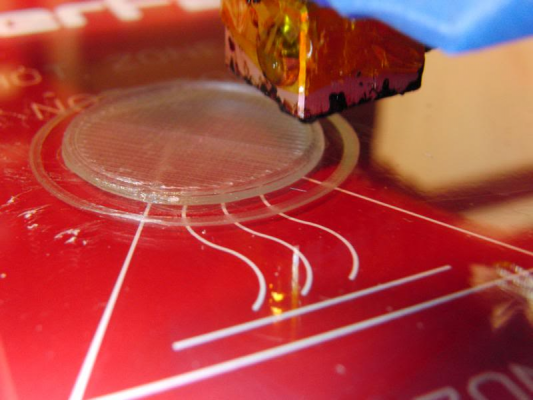

For some reason I diverted and tried to print out a goblet. I got all hung up on the clear look and that it is FDA approved food safe. However the over hang on the bottom of the goblet didn't work out so well for me. But I included a picture of the base so you can see just how clear t-glase can be.

So then I upped the heat again to 240C. Print speed 30mm and reduced the flow to 94%. Prints started getting better. The t-glase however grabbed a small chip in the glass and made it much bigger when cooling.

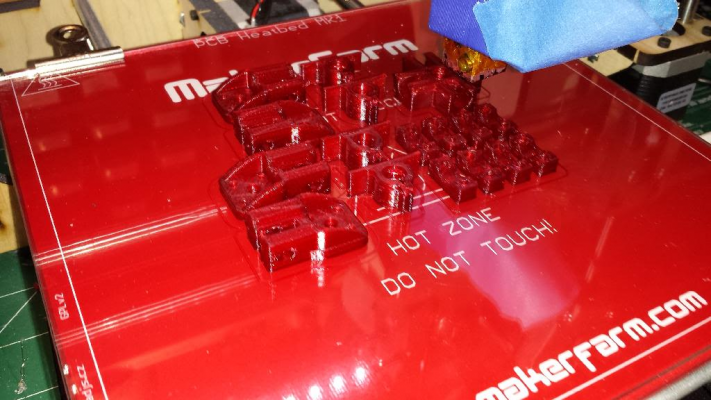

Finally good enough to sell. I am sure I can refine it a little more, and I will post if I do. I just swapped out to the t-glase red and printing out another build plate of quad frame. Will post the pictures next. I am extremely pleased so far with this filament, and if it holds up well during my application, I would say it is well worth the money. Stuff prints great! Very good filament to work with.

My main focus of getting into 3D printing is to make functional parts that last. Not into the vase making or puppy dog stuff too much. So trying to manufacture these small precise parts becomes a pretty big challenge. Lucky for me there is so many new filaments making it to the market. So the first thing I did with one of his prints was to measure the accuracy of it, then put it in a vise and grab it with a pliers at twist. Not very scientific, but I have been in fabrication for 35+years. While I don't have exact strength numbers I can tell you that it is substantially stronger than ABS, and not as strong as 618. Seemed like this would work and solve the problem I was faced with for months. So I bought 4 rolls. I also bought 2 rolls of 645 nylon, and he sent me some 910 for testing. I will post my results with those. I know shipping is pricey with taulman, but you can put 6 rolls in one box for the same price. For what I plan on doing, the price is fine. I want to sell my work, already have. So I can recoup some of my investment and keep my hobby going.

On to the printing attempts. Now if you read the web-site, you may get confused and think you need a bigger nozzle, or you would have to play with nozzle settings and layer height. I am here to say if you already print with ABS, your settings will be almost the same.

First try. I printed at 225C on glass with hair spray at 60C. Using a makerfarm i3, .4mm E3D nozzle, .2mm layer height ,50mm print speed. I realized it was printing a little too fast and slowed it down 50% during the print. Print stuck fine, was a little sloppy. Testing it in the vise revealed that the layers were not bonding fully. If I see the print break apart evenly across a layer, my heat is too low. I am all about maximum adhesion between layers, as that makes the part stronger.

After that attempt I wandered over to the taulman web-site to look for advice on printing. I got sucked into the bigger nozzle idea, and raised my layer height to .3mm. Slowed my print speed down. Raised HE to 235C Print got sloppier but bonded a little better. Holes did not come out round as you can see by the smiley face.....lol

Put in a vise to simulate the strain that will be placed on the motor pod. It clamps onto arrow shafts. No cracking really, but seemed like it could go hotter.

For some reason I diverted and tried to print out a goblet. I got all hung up on the clear look and that it is FDA approved food safe. However the over hang on the bottom of the goblet didn't work out so well for me. But I included a picture of the base so you can see just how clear t-glase can be.

So then I upped the heat again to 240C. Print speed 30mm and reduced the flow to 94%. Prints started getting better. The t-glase however grabbed a small chip in the glass and made it much bigger when cooling.

Finally good enough to sell. I am sure I can refine it a little more, and I will post if I do. I just swapped out to the t-glase red and printing out another build plate of quad frame. Will post the pictures next. I am extremely pleased so far with this filament, and if it holds up well during my application, I would say it is well worth the money. Stuff prints great! Very good filament to work with.

|

Re: Printing with the new t-glase from taulman3d January 27, 2014 10:59PM |

Registered: 10 years ago Posts: 38 |

|

Re: Printing with the new t-glase from taulman3d January 27, 2014 11:44PM |

Registered: 11 years ago Posts: 160 |

Oh! one very important tip, because if you are half witted like me, you might miss it. The spools come with some netting on them....DO NOT TAKE OFF THE netting. It will quickly unravel, and you will have a mess. The filament is meant to feed out from under the netting. Same thing with the nylon spools. Make sure your spring tension for your idler is good and tight, and that your extruder motor is tuned!

|

Re: Printing with the new t-glase from taulman3d January 28, 2014 12:46AM |

Registered: 11 years ago Posts: 160 |

Lookin pretty! Oh and the netting is tricky also. It can sometimes get hung up, so I am open to ideas. BEfore I knew what the netting was when using the nylon, I actually respooled some of it on a bigger spool. The nylon isn't as bad, but once you heat it to dry it, it starts unraveling.

|

Re: Printing with the new t-glase from taulman3d January 28, 2014 01:00AM |

Registered: 10 years ago Posts: 120 |

|

Re: Printing with the new t-glase from taulman3d January 28, 2014 09:01AM |

Registered: 11 years ago Posts: 490 |

From your images, the t-glase looks quite pretty and the more complex objects are rather intriguing due to the translucency.

I have a spool of PET from plastic2print which also prints very nicely - it is very transparent like glass and getting it to stick to the heated bed is very easy. However, the PET is very brittle and will shatter (or more like explode) into a million pieces when hit with a hammer - like glass or a big chunk of sugar. It also gets soft at about >=60°C...

As it seems, the taulman product is far less brittle (the vice test you did would have already completely devastated the other PET). So the higher cost might be justified for mechanical applications...

Do you know at which point the t-glase gets soft? I am currently in the process of choosing a filament with which one could print the frame of a small printer like the tantillus and would like to have a heated or IR chamber (which is insulated, so the plastic frame isn't directly in contact with the hot air or IR radiation).

Edited 1 time(s). Last edit at 01/28/2014 09:03AM by uGen.

I have a spool of PET from plastic2print which also prints very nicely - it is very transparent like glass and getting it to stick to the heated bed is very easy. However, the PET is very brittle and will shatter (or more like explode) into a million pieces when hit with a hammer - like glass or a big chunk of sugar. It also gets soft at about >=60°C...

As it seems, the taulman product is far less brittle (the vice test you did would have already completely devastated the other PET). So the higher cost might be justified for mechanical applications...

Do you know at which point the t-glase gets soft? I am currently in the process of choosing a filament with which one could print the frame of a small printer like the tantillus and would like to have a heated or IR chamber (which is insulated, so the plastic frame isn't directly in contact with the hot air or IR radiation).

Edited 1 time(s). Last edit at 01/28/2014 09:03AM by uGen.

|

Re: Printing with the new t-glase from taulman3d January 28, 2014 09:14AM |

Registered: 10 years ago Posts: 38 |

Quote

Antslake

Oh! one very important tip, because if you are half witted like me, you might miss it. The spools come with some netting on them....DO NOT TAKE OFF THE netting. It will quickly unravel, and you will have a mess. The filament is meant to feed out from under the netting. Same thing with the nylon spools. Make sure your spring tension for your idler is good and tight, and that your extruder motor is tuned!

With my taulman nylon, I left it in the bag it was shipped in, with dessicant inside. I snipped a tiny hole for the filament to come out, and through that same hole I poked the scissors and snipped off that net, one strand at a time. I poked my spool bar through the bag so it made its own holes. So total of 3 tiny holes in the bag, and the nylon is free to spool out until it runs out. It's ready on the fly, and dry (or at least it was last time I used it).

|

Re: Printing with the new t-glase from taulman3d January 28, 2014 08:44PM |

Registered: 11 years ago Posts: 160 |

Quote

uGen

From your images, the t-glase looks quite pretty and the more complex objects are rather intriguing due to the translucency.

I have a spool of PET from plastic2print which also prints very nicely - it is very transparent like glass and getting it to stick to the heated bed is very easy. However, the PET is very brittle and will shatter (or more like explode) into a million pieces when hit with a hammer - like glass or a big chunk of sugar. It also gets soft at about >=60°C...

As it seems, the taulman product is far less brittle (the vice test you did would have already completely devastated the other PET). So the higher cost might be justified for mechanical applications...

Do you know at which point the t-glase gets soft? I am currently in the process of choosing a filament with which one could print the frame of a small printer like the tantillus and would like to have a heated or IR chamber (which is insulated, so the plastic frame isn't directly in contact with the hot air or IR radiation).

good info!

From the web-site, the measured TG of t-glase is 78C.

|

Re: Printing with the new t-glase from taulman3d January 29, 2014 05:54AM |

Registered: 11 years ago Posts: 490 |

Thanks for the info!

The glass transition temperature affects softening of amorphous plastics mostly if I remember correctly. The more the plastic becomes crystalline, the more the thermal breakdown of the crystal structures affect softening. Given that t-glase is highly transparent, I doubt that the percentage of crystalline structures is high (else, refraction between amorphous and crystalline domains in the material would make the plastic gradually more opaque which can be impressively witnessed here)... Then again, I am just someone with eclectic interests who read that up some time ago, so I might be completely wrong.

Also, TG does not necessarily indicate when a plastic part becomes structurally weak. PE for example has a TG of -125°C, but is still usable to +50 or 60°C

But the TG value you quoted is pretty much in the ballpark of the properties of my PET (TG: 60°C), so I guess TG and softening point of PET are closely linked (at least in 3D printing filaments)...

The glass transition temperature affects softening of amorphous plastics mostly if I remember correctly. The more the plastic becomes crystalline, the more the thermal breakdown of the crystal structures affect softening. Given that t-glase is highly transparent, I doubt that the percentage of crystalline structures is high (else, refraction between amorphous and crystalline domains in the material would make the plastic gradually more opaque which can be impressively witnessed here)... Then again, I am just someone with eclectic interests who read that up some time ago, so I might be completely wrong.

Also, TG does not necessarily indicate when a plastic part becomes structurally weak. PE for example has a TG of -125°C, but is still usable to +50 or 60°C

But the TG value you quoted is pretty much in the ballpark of the properties of my PET (TG: 60°C), so I guess TG and softening point of PET are closely linked (at least in 3D printing filaments)...

|

Re: Printing with the new t-glase from taulman3d February 02, 2014 04:14PM |

Registered: 10 years ago Posts: 38 |

So I got the t-glase in and started printing with the last slicer config I used. 100mm/s. It was coming out white, not sticking, fail. So I took your advice and slowed down to 25mm/s. It seemed like no plastic was coming out. You know, how when ABS is jammed and you can tell that it's just doodling in the hairspray and not actually printing? Well, that's what it looked like. I cancelled my print, purged my extruder, cleaned the bed, and started over 4 times. Then I said "screw it" and just let it go, to see if it would clear its jam at some point and start printing. Well, much to my surprise, it WAS printing! It's friggin CLEAR (just as clear as the filament on the roll) at that speed, and you can't see it in a puddle of hair spray until it gets about 10 layers high. This stuff is pretty cool. I hope it's as strong as I believe it might be.

The thing I'm worried about though, I guess is what you guys were talking about (glass transition temperature). It seems to be like floppy fruit-roll-up material when I remove it from the bed at 110C. I am hoping to use this as material for a prosthetic hand. If you were to make a hand out of this, and you let the hand rest on the hot dash board of your car for too long, would it be like rubber chicken full pull-cords?

The thing I'm worried about though, I guess is what you guys were talking about (glass transition temperature). It seems to be like floppy fruit-roll-up material when I remove it from the bed at 110C. I am hoping to use this as material for a prosthetic hand. If you were to make a hand out of this, and you let the hand rest on the hot dash board of your car for too long, would it be like rubber chicken full pull-cords?

|

Re: Printing with the new t-glase from taulman3d February 03, 2014 04:54PM |

Registered: 11 years ago Posts: 490 |

PET should have a slightly lower softening point and TG than ABS, I guess you should be ok with that. The link I posted in my last comment shows a polyester filament (most likely something very similar - if not - PET) after treatment in a dish washer @ 70°C, which still looks fine - if not better than before.

If you want to have a really heat resistant material that is generally available, I have found taulman's 645 material to be able to withstand the heated bed set to 110°C easily. It gets a little bit more flexible, but retains its shape. In theory, other nylon materials (618 and the Nylon6 available from RepRapWorld and 3ntr) available at the time of writing should behave similarly.

If you want to have a really heat resistant material that is generally available, I have found taulman's 645 material to be able to withstand the heated bed set to 110°C easily. It gets a little bit more flexible, but retains its shape. In theory, other nylon materials (618 and the Nylon6 available from RepRapWorld and 3ntr) available at the time of writing should behave similarly.

|

Re: Printing with the new t-glase from taulman3d February 03, 2014 05:45PM |

Registered: 10 years ago Posts: 86 |

I think 110C is too high a bed temperature to print on, I have found that 70C gives brilliant adhesion onto Kapton cleaned with acetone, and easy to remove if you print with a brim. Here my nozzle temp of 208C could be a bit higher, or my print speed slowed down. these were done at 40mm/sec. It's still nice and clear but it could be better.

This stuff is amazingly easy to print with... highly recommended! No warping whatsoever.

This stuff is amazingly easy to print with... highly recommended! No warping whatsoever.

|

Re: Printing with the new t-glase from taulman3d February 03, 2014 09:51PM |

Registered: 10 years ago Posts: 38 |

|

Re: Printing with the new t-glase from taulman3d February 03, 2014 09:56PM |

Registered: 11 years ago Posts: 160 |

|

Re: Printing with the new t-glase from taulman3d February 04, 2014 03:13AM |

Registered: 10 years ago Posts: 86 |

|

Re: Printing with the new t-glase from taulman3d February 06, 2014 08:50AM |

Registered: 10 years ago Posts: 98 |

|

Re: Printing with the new t-glase from taulman3d February 13, 2014 02:27PM |

Registered: 11 years ago Posts: 160 |

Quote

MiguelKendrick

Taulman T-Glass is one of my favourite, I'm personally using this: --Link Removed--. It has a brilliant luster and great complimentary industrial material. To stay away from any hassle, always follow the standard heated platform when printing Taulamn (temperature of 110C and a Nozzle temperature of 212C).

I definately would not recommend those temps. At 70C bed temp t-glase is so soft you can't take it off without bending it. Taulman recommends 60-70c bed temp for t-glase. And up to 240 for nozzle temp, which is where I print at for maximum adhesion.

Edited 1 time(s). Last edit at 02/13/2014 07:28PM by NewPerfection.

|

Re: Printing with the new t-glase from taulman3d February 13, 2014 06:34PM |

Registered: 10 years ago Posts: 98 |

|

Re: Printing with the new t-glase from taulman3d February 13, 2014 08:54PM |

Registered: 14 years ago Posts: 800 |

i want to try that filament, but there shipping to canada just is not worth it.

[mike-mack.blogspot.com]

[mike-mack.blogspot.com]

|

Re: Printing with the new t-glase from taulman3d February 14, 2014 02:10PM |

Registered: 10 years ago Posts: 98 |

|

Re: Printing with the new t-glase from taulman3d March 30, 2014 04:07PM |

Registered: 10 years ago Posts: 15 |

|

Re: Printing with the new t-glase from taulman3d June 29, 2014 06:35PM |

Registered: 10 years ago Posts: 5 |

Sorry, only registered users may post in this forum.

I thought i'd make him a clock! this was a scaled down prototype just to fiddle with temperatures etc

I thought i'd make him a clock! this was a scaled down prototype just to fiddle with temperatures etc