Why is an acme rod good?

Posted by jpan

|

Why is an acme rod good? February 03, 2014 09:11AM |

Registered: 10 years ago Posts: 125 |

|

Re: Why is acme rod good? February 03, 2014 09:21AM |

Registered: 11 years ago Posts: 349 |

|

Re: Why is acme rod good? February 03, 2014 09:40AM |

Registered: 11 years ago Posts: 198 |

What he said..

And also, the thread on ACME rod is 29 degrees vs. 60 degrees on normal threaded rod, so in case of a slightly bend rod, the linearity isn't affected as much as it would have had on a normal threaded rod.

For me switching to Trapezoid/ACME rod really did the trick, but if you don't have any wobble in the z-rods, it won't really make any huge difference.

And also, the thread on ACME rod is 29 degrees vs. 60 degrees on normal threaded rod, so in case of a slightly bend rod, the linearity isn't affected as much as it would have had on a normal threaded rod.

For me switching to Trapezoid/ACME rod really did the trick, but if you don't have any wobble in the z-rods, it won't really make any huge difference.

|

Re: Why is acme rod good? February 03, 2014 11:06AM |

Registered: 10 years ago Posts: 67 |

ACME rods are built to tolerance specifications. Regular threaded rod is not. ACME was designed for linear motion. Threaded rod was designed for tightening things together. Threaded rod has alot of variance because it does not hinder its intended use by having the variance. Also since threaded rod has so much variance, the accompanying nuts for the threaded rod have alot of play. ACME nuts have much better tolerance and are repeatable. They too also have play, but it is repeatable and easy to apply anti-backlash methods without causing drag or galling to the threads.

|

Re: Why is acme rod good? February 03, 2014 11:18AM |

Registered: 10 years ago Posts: 564 |

Acme rod does tend to be straighter, but I've certainly seen some crooked ACME rod, too. The main advantage of an ACME thread over a standard thread for power transmission applications is that the more square thread (29 deg. v. 60 deg. as Ralf points out) reduces the friction in the axial direction (the direction you are pushing). The down side of that is if there is any side loading of the nut on the rod, it can actually create a lot more friction. ACME threads do get used in screws and other clamping applications (like C-clamps), but almost always where you are regularly needing to reverse the screw and don't want that extra friction holding it stuck in place.

|

Re: Why is acme rod good? February 03, 2014 12:56PM |

Registered: 10 years ago Posts: 474 |

Everybody thinks the wobbly Z screws cause the problem which in essence is true. But the root of the problem is that the linear guides and possibly what it is mounted to are not rigid enough there is no way that the action of the drive screw should be shoving the z-axis the guide should be much stronger than the screw. Should use supported rail and strong frame and then it really wouldn't matter what the screw is doing as far as wobble goes. Accuracy that's another thing and the the power to drive a warped screw while holding the Z'axis solid in essence bending the screw straight as it turns

Edited 1 time(s). Last edit at 02/03/2014 12:57PM by cnc dick.

Edited 1 time(s). Last edit at 02/03/2014 12:57PM by cnc dick.

|

Re: Why is acme rod good? February 03, 2014 02:10PM |

Registered: 11 years ago Posts: 198 |

I don't believe that the primary reason for banding in prints because of bend leadscrews, is the Y carrige being pushed around by the leadscrews.

No matter how stable your z-axis is suspended, if you have wobbly z leadscrews the motion along z isn't linear, because the contact point between the threaded rod and the nut is moving around inside the nut, thus changing the angle of contact between rod and nut, resulting in shifting layer heights. This leads to compression of some layers and expanding other layers, which is seen as waves along the z-axis.

If you then suspend the z leadscrews in both ends, and they are not straight, they might also push the y carrige around.

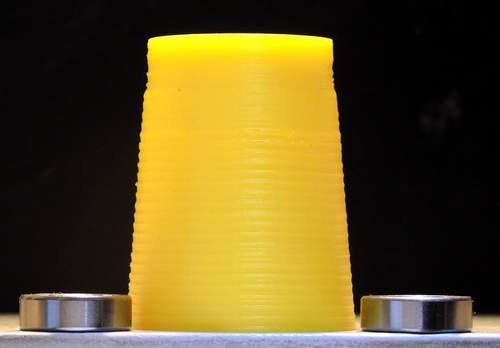

This picture is a prime example of layer compression/expansion, the layers is not shifted sideways, but you still see a lot of banding:

No matter how stable your z-axis is suspended, if you have wobbly z leadscrews the motion along z isn't linear, because the contact point between the threaded rod and the nut is moving around inside the nut, thus changing the angle of contact between rod and nut, resulting in shifting layer heights. This leads to compression of some layers and expanding other layers, which is seen as waves along the z-axis.

If you then suspend the z leadscrews in both ends, and they are not straight, they might also push the y carrige around.

This picture is a prime example of layer compression/expansion, the layers is not shifted sideways, but you still see a lot of banding:

|

Re: Why is acme rod good? February 03, 2014 02:21PM |

Registered: 10 years ago Posts: 474 |

I've been building industrial machines all my life and believe me that is what's happening you would never design anything that would be this flimsy. If you put it dial indicator on it and raise the screw you will see the actual movement it doesn't take much on these to shove it side to side with unsupported shafts were talking .01. And also of course while printing the momentum is also shoving the shafts back and forth. I do agree that standard 60° screws should not be used me personally I use professional ballscrews

Edited 1 time(s). Last edit at 02/03/2014 02:26PM by cnc dick.

Edited 1 time(s). Last edit at 02/03/2014 02:26PM by cnc dick.

|

Re: Why is acme rod good? February 03, 2014 04:03PM |

Registered: 11 years ago Posts: 198 |

Still if you look closely at the print, you will see that the layers is not shifted sideways.

The above print was one of the first I printed on my all steel repstrap, with 16mm hardened smooth rods. The z leadscrews is only suspended in one end, so there is no way that they would be able to push the y carrige arount to cause that ammount banding.

At the time I struggled with the problem, the compresion effect was confirmed using a dial indicator, raising the z height 0.1mm at the time. This revealed travel between 0.08mm and 0.12mm, however every full revolution of the z leadscrews it measured spot on. Also there was no dectable lateral movement of the y carrige, when changing the z height.

The above print was one of the first I printed on my all steel repstrap, with 16mm hardened smooth rods. The z leadscrews is only suspended in one end, so there is no way that they would be able to push the y carrige arount to cause that ammount banding.

At the time I struggled with the problem, the compresion effect was confirmed using a dial indicator, raising the z height 0.1mm at the time. This revealed travel between 0.08mm and 0.12mm, however every full revolution of the z leadscrews it measured spot on. Also there was no dectable lateral movement of the y carrige, when changing the z height.

|

Re: Why is acme rod good? February 03, 2014 04:45PM |

Registered: 11 years ago Posts: 661 |

I think Dick and Ralf are talking about two different artifacts. The way I understand it is Dick is talking about shifted Z layers due to wobble and Ralf is talking about the variances between layer heights due to the tolerances of threaded rod. There is a slight slop in the threaded rod/ nut config, for example on my i3s. The leadscrew design of my Mendelmax 2s do not exhibit that slop. What Ralf was experiencing is one of the reasons Prusa developed the layer calculator. Based on the pitch of the threads, it calculates the optimum layer height for that rod but can't take into account any variance in the lower cost material. The differences in cost are pretty significant between threaded rod and leadscrews. (as I'm sure Dick, Ralf and many others have found) For most first time DIY builders with limited tools and skills the vanilla Prusa (or other entry level printer) is just fine. The cost of the M5 threaded rods are a couple of bucks and the lead screws and nuts can range from US$20 to US$100 a set for a quality part. I've just received a sample of a helical lead screw from a high end name brand manufacturer that looks great. Unfortunately it's radically expensive.

For the new builders once you master your linear bearing/ drill rod machines moving to precision rod and other motion components can give better print quality. But in order for that to happen the builder has to know the machine, have the motion parameters and temperature parameters well dialed and have enough experience with the machine to be able to determine what is happening when there is an irregularity. With the higher end parts the builds and calibration aren't as forgiving as they are with threaded rod and drill rod. The closer tolerances demand a more exacting build and calibration and the so called (in the US, anyway) "fudge factor"that one is allowed by using parts with less precision is largely eliminated.

For the new builders once you master your linear bearing/ drill rod machines moving to precision rod and other motion components can give better print quality. But in order for that to happen the builder has to know the machine, have the motion parameters and temperature parameters well dialed and have enough experience with the machine to be able to determine what is happening when there is an irregularity. With the higher end parts the builds and calibration aren't as forgiving as they are with threaded rod and drill rod. The closer tolerances demand a more exacting build and calibration and the so called (in the US, anyway) "fudge factor"that one is allowed by using parts with less precision is largely eliminated.

|

Re: Why is acme rod good? February 03, 2014 05:46PM |

Registered: 12 years ago Posts: 1,236 |

I think what people call "Z wobble" is better called Z banding. Z banding is a combination of Z wobble (movement in the X-Y plane) + Z non-linearity (non linear motion in the Z axis). There may be a further effect due to layer height not being an integral multiple of the full step size, I am not sure on that one.

Eliminating one effect does not necessarily eliminate the other. I think confusion creeps in because people try something to eliminate "Z banding", and it only partially solves the problem so they conclude it wasn't the root cause.

With threaded rod, you can reduce the wobble quite a lot, but the Z non-linearity remains, I found exactly that with my printer. Replacing threaded rod with precision lead screw or a belt drive is I think the best way to solve that, but you could also calibrate it and compensate in software, as some people have done.

I'm not convinced that spending money on expensive ballscrews is a cost-effective method. For the sort of thing I print it's not a problem, people at work using my printer cubicle hooks are not commenting on the artifact. If you are expecting 0.001" for machine parts, you are probably not going to be printing them in plastic in the first place.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Eliminating one effect does not necessarily eliminate the other. I think confusion creeps in because people try something to eliminate "Z banding", and it only partially solves the problem so they conclude it wasn't the root cause.

With threaded rod, you can reduce the wobble quite a lot, but the Z non-linearity remains, I found exactly that with my printer. Replacing threaded rod with precision lead screw or a belt drive is I think the best way to solve that, but you could also calibrate it and compensate in software, as some people have done.

I'm not convinced that spending money on expensive ballscrews is a cost-effective method. For the sort of thing I print it's not a problem, people at work using my printer cubicle hooks are not commenting on the artifact. If you are expecting 0.001" for machine parts, you are probably not going to be printing them in plastic in the first place.

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

|

Re: Why is acme rod good? February 03, 2014 10:14PM |

Registered: 10 years ago Posts: 474 |

|

Anonymous User

Re: Why is acme rod good? February 03, 2014 10:24PM |

|

Re: Why is acme rod good? February 03, 2014 11:06PM |

Registered: 10 years ago Posts: 67 |

|

Anonymous User

Re: Why is acme rod good? February 03, 2014 11:19PM |

|

Re: Why is acme rod good? February 03, 2014 11:40PM |

Registered: 12 years ago Posts: 809 |

Trapezoidal thread

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Why is acme rod good? February 03, 2014 11:43PM |

Registered: 10 years ago Posts: 564 |

|

Re: Why is acme rod good? February 04, 2014 12:19AM |

Registered: 11 years ago Posts: 730 |

|

Re: Why is acme rod good? February 04, 2014 12:34AM |

Registered: 12 years ago Posts: 809 |

ACME rod is not good. If you want problems use ACME. M6 or 1mm pitch M8 is all you need. If you really want to use a high quality screw on z get a 10mm trapezoidal screw with a 2mm pitch and use a decoupler to isolate the screw from the x-end. You do not want the screw to touch the x-end, ever. You want to decouple the x and z axes so that any unwanted motion in z isnt transmitted to the x-axis.

And dont calibrate the z-axis. Just use the calculated step value. If you want z-artifacts calibrate your z-axis.

Roton has trapezoidal screws.

Some more advice. Use full-step layer heights. Use 1mm pitch leadscrews. Never use imperial leadscrews, ever.

Just for fun:

Assume: 1mm pitch screw, 200 step motors and full-step mode driver.

Thats 0.005mm per step which is more than enough resolution on z.

Now consider a 16-turn ACME rod with the same stepper and driver.

Thats 0.0079375 mm per step. And you shold also know that the modern slicers are only capable of using 3 significant digits, so the rest becomes error. Error that shows up in the walls of prints.

And use nopheads z-couplings with silicone tubing. Outperforms every other coupling I've ever used on z.

Edited 1 time(s). Last edit at 02/04/2014 12:37AM by akhlut.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

And dont calibrate the z-axis. Just use the calculated step value. If you want z-artifacts calibrate your z-axis.

Roton has trapezoidal screws.

Some more advice. Use full-step layer heights. Use 1mm pitch leadscrews. Never use imperial leadscrews, ever.

Just for fun:

Assume: 1mm pitch screw, 200 step motors and full-step mode driver.

Thats 0.005mm per step which is more than enough resolution on z.

Now consider a 16-turn ACME rod with the same stepper and driver.

Thats 0.0079375 mm per step. And you shold also know that the modern slicers are only capable of using 3 significant digits, so the rest becomes error. Error that shows up in the walls of prints.

And use nopheads z-couplings with silicone tubing. Outperforms every other coupling I've ever used on z.

Edited 1 time(s). Last edit at 02/04/2014 12:37AM by akhlut.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Why is acme rod good? February 04, 2014 02:40AM |

Registered: 11 years ago Posts: 661 |

TR is available from a variety of sources in a variety of materials and finishes. If you are getting raw sticks you'll need to figure something out for the couplers. Either making something or turning down the end that will couple to the motor. If you go with someone that provides finished parts they'll have stepped ends available in a variety of configurations. I've used TR10 x2 recently on a stock MM2 build and they've worked well. To get a better variety of metric sizes McMaster or Grainger aren't good bets. Better to go with a motion specialist like Thomson, Misumi, Igus or Pacific. I've seen lead screws as small as TR6 x1 in the US though many places I've seen start at 10 or 12. There is also a bunch of it available in Shanghai/Ningbo though by the time you get it shipped over it's not that much less expensive and not all of it is good quality. If you go with someone like NEFF or Igus you'll pay a bit more but for me it's worth piece of mind.

|

Re: Why is acme rod good? February 04, 2014 04:49AM |

Registered: 11 years ago Posts: 198 |

Quote

cnc dick

Jpan asked specifically about Acme threaded rods helping z wobble and he was the one that started the post. Ralf posted a picture which is definitely Z banding and not z wobble

But the banding was caused by bend z leadscrews, leading non linear motion of the Z axis. And banding is quite often confused with wobble.

I think we can agree, that bend leadscrews is bad, as they cause Z artefacts. And if you buy ACME leadscrews, they are more likely to be straight, so less problems with wobble, and other artefacts.

|

Re: Why is acme rod good? February 04, 2014 04:53AM |

Registered: 12 years ago Posts: 1,236 |

Heh, I do feel sorry for the OP in these situations. He asks a quite reasonable question, but he gets a range of replies with conflicting information, some of it nonsense and some nuggets of useful information. The strength of feeling an opinion is made with does not correlate with the quality of information, unfortunately.

Good luck sorting that lot out!

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

Good luck sorting that lot out!

What is Open Source?

What is Open Source Hardware?

Open Source in a nutshell: the Four Freedoms

CC BY-NC is not an Open Source license

|

Re: Why is acme rod good? February 04, 2014 08:20AM |

Registered: 12 years ago Posts: 809 |

Like OP, I too had this issue. I thought it was a bent leadscrew as well, so I replaced them. When that didn't work I added x-z decouplers. This helped eliminate z-wobble. Beefing up my Z-axis to 10mm rods helped as well. But I was still getting banding. Then, like OP I figured 'better screws'. So I went and ordered 1/4"-16 ACME screws from McMaster. Installed them and still the banding. Went insane and ordered 10mm trapezoidal screws from Roton (gorgeous and absolutely straight). They didn't fix the problem either. So then it was back to the drawing board. I quit thinking 'better' because it didn't solve my problem. I read up on what others were using for screws. Prusa had switched the i3 to M6, so I figured it can't hurt. So I ordered some and installed it. Still got banding but not as noticeable. So it was at this point that I realized it was not which screw I was using, but something else. There was error in the amount of plastic being extruded. Even miniscule errors accumulate over time, and this is what I was seeing in my prints. It's incredible actually that such a small thing can have huge effects. So I followed some advice (not believing it at the time) that I should not calibrate my Z-axis. I did so reluctantly and POOF my prints were nearly perfect. It was like a magic trick. Why did this work? As best I can figure out, calibrating the Z- axis means you'll create oddball ideal layer heights. By that I mean your full-step layer heights will have more than 3 significant digits. This introduces the error.

Example:

You have an M6 rod that has a 1mm pitch, 200 step motors and they're driven @ full step. That's a Z-axis value of 200 in firmware, and the ideal layer height will be a multiple of 0.005mm - this is perfect. So let's calibrate the axis, and say that it takes 199 steps to go 1mm. That means your ideal layer height is a multiple of 0.00502512562814070351758793969849. This is a problem, as slic3r cannot use it as a layer height.

So it's not just a z-axis issue. It's a calibration issue, a slicing issue, a layer-height choice issue and possible a z-wobble issue, all rolled up into one problem. D:

I'm sharing this because it's a dragon that I chased for a long time and at considerable expense. If I can spare someone else from going through the same thing that I did then it was worth it.

And don't get me started on the quest for the perfect coupler, only to wind up where I started - with nophead's couplers.

Aaaand I'm late for work.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Example:

You have an M6 rod that has a 1mm pitch, 200 step motors and they're driven @ full step. That's a Z-axis value of 200 in firmware, and the ideal layer height will be a multiple of 0.005mm - this is perfect. So let's calibrate the axis, and say that it takes 199 steps to go 1mm. That means your ideal layer height is a multiple of 0.00502512562814070351758793969849. This is a problem, as slic3r cannot use it as a layer height.

So it's not just a z-axis issue. It's a calibration issue, a slicing issue, a layer-height choice issue and possible a z-wobble issue, all rolled up into one problem. D:

I'm sharing this because it's a dragon that I chased for a long time and at considerable expense. If I can spare someone else from going through the same thing that I did then it was worth it.

And don't get me started on the quest for the perfect coupler, only to wind up where I started - with nophead's couplers.

Aaaand I'm late for work.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Why is acme rod good? February 04, 2014 05:30PM |

Registered: 10 years ago Posts: 125 |

Thanks for every reply anyways.. I posted some picture of my prints, hope someone could help me.

post containing pictures

Edited 1 time(s). Last edit at 02/04/2014 05:30PM by jpan.

post containing pictures

Edited 1 time(s). Last edit at 02/04/2014 05:30PM by jpan.

|

Re: Why is acme rod good? February 04, 2014 08:31PM |

Registered: 13 years ago Posts: 1,780 |

Quote

akhlut

... As best I can figure out, calibrating the Z- axis means you'll create oddball ideal layer heights. By that I mean your full-step layer heights will have more than 3 significant digits. This introduces the error.

Example:

You have an M6 rod that has a 1mm pitch, 200 step motors and they're driven @ full step. That's a Z-axis value of 200 in firmware, and the ideal layer height will be a multiple of 0.005mm - this is perfect. So let's calibrate the axis, and say that it takes 199 steps to go 1mm. That means your ideal layer height is a multiple of 0.00502512562814070351758793969849. This is a problem, as slic3r cannot use it as a layer height.

So it's not just a z-axis issue. It's a calibration issue, a slicing issue, a layer-height choice issue and possible a z-wobble issue, all rolled up into one problem. D:

...

Is anyone still running their z motors at full steps? This was an issue before microstepping controllers. Is this still an issue when you now have 3200 or 6400 steps per revolution? I don't worry about setting my layer height in this way and I don't have z wobble in a Prusa2 and Ordbot Hadron once I make sure that the z nut is free to move laterally to account for bent threaded rods.

Also, calibrating the z axis is just a matter of using the thread pitch in a simple equation. There's no real need to measure.

Edited 2 time(s). Last edit at 02/04/2014 08:34PM by brnrd.

|

Re: Why is acme rod good? February 04, 2014 08:48PM |

Registered: 12 years ago Posts: 809 |

Yeah. I dont bother with microstepping on z because there is no point. As far as calibrating z that is exactly what im advocating - dont measure, just plug the ouput drom the equation pitch/(stepper resolution×microstep rate).

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Why is acme rod good? February 04, 2014 08:57PM |

Registered: 13 years ago Posts: 1,780 |

Quote

akhlut

Yeah. I dont bother with microstepping on z because there is no point. As far as calibrating z that is exactly what im advocating - dont measure, just plug the ouput drom the equation pitch/(stepper resolution×microstep rate).

If you're worried about round off errors, then you should use microstepping in z. It also makes for a quite printer.

|

Re: Why is an acme rod good? February 05, 2014 11:04PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Why is an acme rod good? February 05, 2014 11:48PM |

Registered: 12 years ago Posts: 809 |

|

Re: Why is an acme rod good? February 08, 2014 03:56PM |

Registered: 10 years ago Posts: 239 |

Sorry, only registered users may post in this forum.