Rubber drive wheel

Posted by Anonymous User

|

Anonymous User

Rubber drive wheel February 04, 2014 09:05PM |

I was thinking, maybe instead of a metal drive gear or hobbed bolt, a piece of rubber with a 5mm bore could be glued to the motor shaft and replace the drive gear. I think rubber would have enough grip to push the filament through the extruder, with the added bonus of not producing dust particles and deforming the filament. Has this been done before and if not, why?

|

Re: Rubber drive wheel February 04, 2014 09:17PM |

Registered: 13 years ago Posts: 1,780 |

|

Anonymous User

Re: Rubber drive wheel February 04, 2014 09:27PM |

|

Re: Rubber drive wheel February 04, 2014 09:38PM |

Registered: 10 years ago Posts: 564 |

I actually tried this and it didn't work very well. By the time I got enough compression force to drive the filament effectively, the rolling friction of the highly compressed rubber took a huge amount of torque. It takes a lot less torque to effectively cut teeth into the filament, which allow for a much higher driving force. It could be that playing around with different durometer rubber my make this work, but I'm a little skeptical.

One other idea is to press the filament into a v-groove in the drive roller - like is done with a V-belt. This will effectively increase the friction and maybe reduce deformation. Also, driving the idler roller as well as the main driving roller (ie, gearing the two together) will double the friction if you also put a V-groove in the idler.

One other idea is to press the filament into a v-groove in the drive roller - like is done with a V-belt. This will effectively increase the friction and maybe reduce deformation. Also, driving the idler roller as well as the main driving roller (ie, gearing the two together) will double the friction if you also put a V-groove in the idler.

|

Anonymous User

Re: Rubber drive wheel February 04, 2014 09:44PM |

|

Re: Rubber drive wheel February 04, 2014 10:11PM |

Admin Registered: 11 years ago Posts: 1,063 |

i tried it when i built my printrbot, simple heatshrink on an M8 bolt , it sort of worked on 1.75mm but ended up deforming and slipping, i also tried a neoprene wheel (what skateboard wheels are made of) and that worked up until the gripping surface got dirty ,

however so far i still haven't been able to find anything better in terms of grip than either the blddk hobbs or the reprap discount ones, and the reprap discounts ones have the teeth cut in a way that they are self cleaning and easier to tension,

if any tries the heatshrink it's best to use the stuff with the glue in it otherwise it'll deform quicker

however so far i still haven't been able to find anything better in terms of grip than either the blddk hobbs or the reprap discount ones, and the reprap discounts ones have the teeth cut in a way that they are self cleaning and easier to tension,

if any tries the heatshrink it's best to use the stuff with the glue in it otherwise it'll deform quicker

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: Rubber drive wheel February 05, 2014 02:48AM |

Registered: 13 years ago Posts: 177 |

I tried this too but my rubber was too soft and no good traction could be achieved.

Plastic does to seem to grip well to rubber.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Plastic does to seem to grip well to rubber.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: Rubber drive wheel February 05, 2014 03:35AM |

Registered: 10 years ago Posts: 474 |

|

Re: Rubber drive wheel February 05, 2014 03:46AM |

Registered: 11 years ago Posts: 313 |

|

Re: Rubber drive wheel February 05, 2014 10:29AM |

Registered: 10 years ago Posts: 38 |

Quote

LoboCNC

One other idea is to press the filament into a v-groove in the drive roller - like is done with a V-belt. This will effectively increase the friction and maybe reduce deformation.

Thats what I did. Works great.

Ohioplastics, you have a lathe, right? You can do this. Details here

Works great. I have not experienced any slippage at all, with any filament, since performing this mod months ago.

|

Anonymous User

Re: Rubber drive wheel February 05, 2014 11:40AM |

|

Re: Rubber drive wheel February 06, 2014 12:36AM |

Registered: 11 years ago Posts: 173 |

An alternative - wrap the filament around the drive gear for better grip

Drive gear with a 1mm groove cut with a dremel ( [deltaprinter.co.za] )

Drive gear with a 1mm groove cut with a dremel ( [deltaprinter.co.za] )

|

Re: Rubber drive wheel February 06, 2014 05:16AM |

Registered: 11 years ago Posts: 544 |

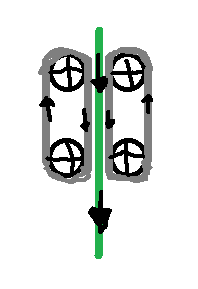

someone should try making a drive that uses two flat rubber belts. the belts would run like a tread mill and the filament would be in between the two sets of belts. sorry for the crude drawing. you could use four timing pulleys and two small continous timing belts.

|

Re: Rubber drive wheel February 06, 2014 09:01AM |

Registered: 10 years ago Posts: 553 |

Quote

Xabbax

An alternative - wrap the filament around the drive gear for better grip

Drive gear with a 1mm groove cut with a dremel ( [deltaprinter.co.za] )

[attachment 26340 drivegear.jpg]

That works fine for ABS but I have never had PLA that can handle a bend that tight. I had to toss an extruder I was designing because the PLA couldn't handle the bend and I was only wrapping about 15 degrees around.

|

Re: Rubber drive wheel February 06, 2014 09:19AM |

Registered: 11 years ago Posts: 265 |

Quote

aduy

someone should try making a drive that uses two flat rubber belts. the belts would run like a tread mill and the filament would be in between the two sets of belts. sorry for the crude drawing. you could use four timing pulleys and two small continous timing belts.

[attachment 26355 filamentdrive.png]

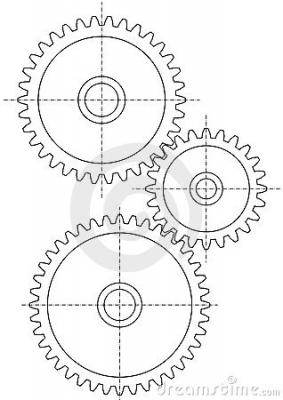

I was thinking of a three gear system to help

WORD OF CAUTION!!!!

Filament slippage is good. It saves your hotend from being blown out and destroyed if there truly is a jam.

Using more force or strength is not always the answer in mechanical design.

There will always be a main point of failure, and you want to be the one choosing where that is.

I'd always prefer my filament to strip than have the brass nozzle blown out of the PEEK on my J-Head.

|

Re: Rubber drive wheel February 06, 2014 10:16AM |

Registered: 10 years ago Posts: 553 |

Quote

aduy

someone should try making a drive that uses two flat rubber belts. the belts would run like a tread mill and the filament would be in between the two sets of belts. sorry for the crude drawing. you could use four timing pulleys and two small continous timing belts.

[attachment 26355 filamentdrive.png]

I was thinking of this last night when I saw this thread. Wouldnt the belts introduce some amount of backlash in to the extruding system? Or would they be so short that it would be negligible?

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Rubber drive wheel February 06, 2014 11:11AM |

Registered: 10 years ago Posts: 553 |

Quote

ShadowRam

Quote

aduy

someone should try making a drive that uses two flat rubber belts. the belts would run like a tread mill and the filament would be in between the two sets of belts. sorry for the crude drawing. you could use four timing pulleys and two small continous timing belts.

[attachment 26355 filamentdrive.png]

I was thinking of a three gear system to help

WORD OF CAUTION!!!!

Filament slippage is good. It saves your hotend from being blown out and destroyed if there truly is a jam.

Using more force or strength is not always the answer in mechanical design.

There will always be a main point of failure, and you want to be the one choosing where that is.

I'd always prefer my filament to strip than have the brass nozzle blown out of the PEEK on my J-Head.

If you blow out the threads on the nozzle with the extruder, share the design please because I would like it.

|

Re: Rubber drive wheel February 06, 2014 11:25AM |

Registered: 13 years ago Posts: 2,947 |

Quote

aduy

someone should try making a drive that uses two flat rubber belts. the belts would run like a tread mill and the filament would be in between the two sets of belts. sorry for the crude drawing. you could use four timing pulleys and two small continous timing belts.

[attachment 26355 filamentdrive.png]

Similar to this [www.thingiverse.com]

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Rubber drive wheel February 06, 2014 08:02PM |

Registered: 10 years ago Posts: 38 |

I've got a hunch that that's impossible. I don't know, I'll try increasing my purge in 100mm/s intervals until something happens.Quote

ShadowRam

Quote

aduy

someone should try making a drive that uses two flat rubber belts. the belts would run like a tread mill and the filament would be in between the two sets of belts. sorry for the crude drawing. you could use four timing pulleys and two small continous timing belts.

[attachment 26355 filamentdrive.png]

I was thinking of a three gear system to help

WORD OF CAUTION!!!!

Filament slippage is good. It saves your hotend from being blown out and destroyed if there truly is a jam.

Using more force or strength is not always the answer in mechanical design.

There will always be a main point of failure, and you want to be the one choosing where that is.

I'd always prefer my filament to strip than have the brass nozzle blown out of the PEEK on my J-Head.

|

Re: Rubber drive wheel February 07, 2014 07:01AM |

Registered: 10 years ago Posts: 87 |

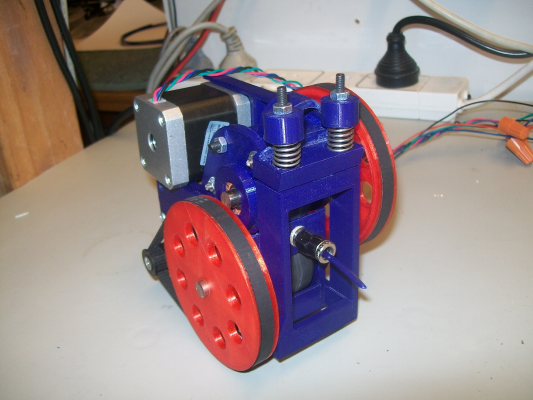

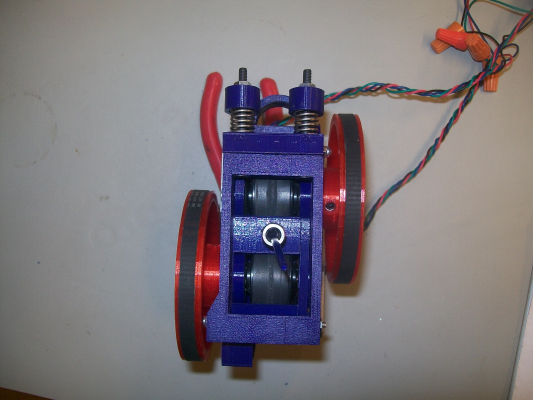

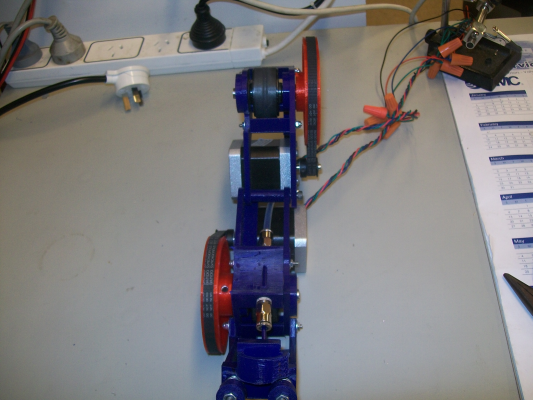

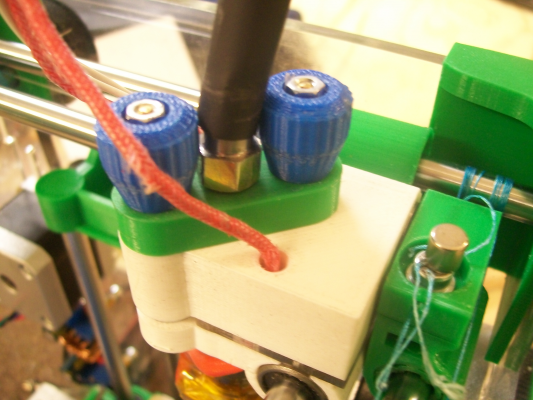

For documentations sake I thought I would post up my failed rubber drive extruder. It was a dual motor/dual rubber wheel drive. The wheels were 40mm to increase contact area and reduce wear/indentation. It was supposed to revolutionise bowden tube printing as we know it!

It did work but suffered from slippage. Stantor says that filament slippage is good. After a lot of experimenetation I would say its bad. If you want something to slip let it be the stepper motor. e.g. turn the current down so it will slip when things are broken.

There are plenty more images here

The other problem with rubber and trust me I used good rubber. The rubber flakes onto the filament which can cause head blockages.

You can see the rubber wear here and if you try hard urethane, it's too slippery!.

One thing I noted using two steppers is that running them in parellel or series is plain silly. The back emf gets out of phase which can cause one motor to stall, especially at speed. I changed the firmware so that motor 0 was driven from E0 and motor 1 was driven from E1. I still had linearity problems using 0.9 degreee Wantai motors as they were mechanically trying to stay in sync being driven together. It only takes a few percent of non linearity to make them fight.

One thing I learnt is, if I had a Prusa I would surely run the second Z motor on E1 and tweak the firmware. I am running a Tantillus.

The whole reason I tried this was the hobbed bolt I am using really damages the filament which means I can't drive the filament through a precision bowden tube. I wanted a precision bowden tube so I could take out the hysteresis.backlash out of my retracts. I will have another crack at this but rubber rollers are out.

I hope this info is useful or you at least think my extruder looks pretty. It did clip together which was cool.

It did work but suffered from slippage. Stantor says that filament slippage is good. After a lot of experimenetation I would say its bad. If you want something to slip let it be the stepper motor. e.g. turn the current down so it will slip when things are broken.

There are plenty more images here

The other problem with rubber and trust me I used good rubber. The rubber flakes onto the filament which can cause head blockages.

You can see the rubber wear here and if you try hard urethane, it's too slippery!.

One thing I noted using two steppers is that running them in parellel or series is plain silly. The back emf gets out of phase which can cause one motor to stall, especially at speed. I changed the firmware so that motor 0 was driven from E0 and motor 1 was driven from E1. I still had linearity problems using 0.9 degreee Wantai motors as they were mechanically trying to stay in sync being driven together. It only takes a few percent of non linearity to make them fight.

One thing I learnt is, if I had a Prusa I would surely run the second Z motor on E1 and tweak the firmware. I am running a Tantillus.

The whole reason I tried this was the hobbed bolt I am using really damages the filament which means I can't drive the filament through a precision bowden tube. I wanted a precision bowden tube so I could take out the hysteresis.backlash out of my retracts. I will have another crack at this but rubber rollers are out.

I hope this info is useful or you at least think my extruder looks pretty. It did clip together which was cool.

|

Re: Rubber drive wheel February 07, 2014 07:35AM |

Registered: 10 years ago Posts: 1,381 |

@Robonz:

What was the advertised use of the PU wheel?

What was the durometer of the PU?

Who was the mfg/supplier, got a link?

Roller skate wheels 50-60 D Scale .

Shopping cart wheels 90-95 A Scale.

[www.gallaghercorp.com]

[www.smooth-on.com]

What was the advertised use of the PU wheel?

What was the durometer of the PU?

Who was the mfg/supplier, got a link?

Roller skate wheels 50-60 D Scale .

Shopping cart wheels 90-95 A Scale.

[www.gallaghercorp.com]

[www.smooth-on.com]

|

Re: Rubber drive wheel February 07, 2014 07:47AM |

Registered: 10 years ago Posts: 87 |

The rubber wheel was from a 5000 dollar comercial laser printer that I had the fun of scrapping, really nice wheels already mounted on 8mm shaft. I mainly wanted the laser mirror for my laser lights. Knowing my skate wheels it feels like about 85A durometer, so it did grip really nicely without a lot of tension. I have some other wheels here I looked at using e.g. a chain tensioner at 95A but its just too slippery. I also have skate wheels going from 78A up to 85A and they would wear to easily with such a small contact point. It did successfuly print a part but I got debris in the bowden and occasional slippage.

|

Re: Rubber drive wheel February 07, 2014 08:17AM |

Registered: 13 years ago Posts: 177 |

I'm thinking of making an on printer pellet extruder.

Would solve so many issues.

Found someone who mad a filament extruder with a wood auger so I think its possible if it can be small enough.

The biggest thing I cant find out is how big the pellets are as they have to fit easily in to the spirals of the auger bit so it determines the smallest you can have.

May end up heavy so would be better perhaps if the extruder was stationery and everything else moved but it doesn't put me off.

Make your Mendel twice as accurate.

[www.thingiverse.com]

Would solve so many issues.

Found someone who mad a filament extruder with a wood auger so I think its possible if it can be small enough.

The biggest thing I cant find out is how big the pellets are as they have to fit easily in to the spirals of the auger bit so it determines the smallest you can have.

May end up heavy so would be better perhaps if the extruder was stationery and everything else moved but it doesn't put me off.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: Rubber drive wheel February 07, 2014 08:21AM |

Registered: 10 years ago Posts: 38 |

Quote

Robonz

It did work but suffered from slippage. Stantor says that filament slippage is good. After a lot of experimenetation I would say its bad.

You've got your peoples mixed up. I'm the guy who modified my hobbed bolt to include T-Rex teeth for zero slippage. ShadowRam is the one who came after, saying "slippage is good." That theory sounds silly to me also.

|

Re: Rubber drive wheel February 07, 2014 08:26AM |

Registered: 10 years ago Posts: 87 |

|

Re: Rubber drive wheel February 07, 2014 11:01AM |

Registered: 13 years ago Posts: 1,780 |

I found that it's better for the stepper to skip than for the filament drive gear to slip. When the steppers skip, it only causes a defect in the spot where the extruder didn't put enough plastic, When the gear slips, plastic gets stuck between the teeth which results in more slippage that eventually lead to the gear eating into the plastic. At that point, the whole print job is ruined. I suppose, if the rubber drive drive wheel doesn't dig into the plastic, slippage won't be so bad. But, either the plastic or the rubber is bound to wear down if there's slippage which would build up more crud and would probably lead to more slippage. So, in the end, I think slippage is always bad.

|

Re: Rubber drive wheel February 08, 2014 04:01AM |

Registered: 11 years ago Posts: 544 |

|

Re: Rubber drive wheel February 08, 2014 04:38AM |

Registered: 10 years ago Posts: 87 |

If you did a real pro job you would use an encoder to montior the filament. This would detect blockages etc and yes, shut down the print. I have found cleaning nozzle regularly with the fishing method avoids failures. I made some thumb nuts so it only takes a few seconds to open the top of the nozzle.

Sorry, only registered users may post in this forum.