WOW New Materials!?

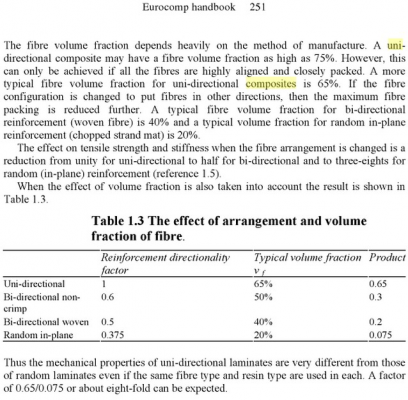

Posted by mrPrik

|

WOW New Materials!? February 26, 2014 03:14AM |

Registered: 10 years ago Posts: 39 |

I watch a lot of 3d print videos on youtube.

This just appeared [www.youtube.com]

Their pre-order site describes kevlar, fiberglass and carbon fiber filament becoming available.

[markforged.com]

Obviously I will not purchase their printer, I will wait for filament prices to dcrease then bust them thru my reprap, but this sounds potentially awesome.

This just appeared [www.youtube.com]

Their pre-order site describes kevlar, fiberglass and carbon fiber filament becoming available.

[markforged.com]

Obviously I will not purchase their printer, I will wait for filament prices to dcrease then bust them thru my reprap, but this sounds potentially awesome.

|

Re: WOW New Materials!? February 26, 2014 09:11AM |

Registered: 10 years ago Posts: 553 |

Not sure if you can send that filament through any printer, not many details on that printer yet but its been known for a while. I think its even been on Hackaday, but I have seen it on either 3ders or Fabbaloo. There is also this company - [www.proto-pasta.com] - that sells PLA infused with carbor fiber and other specialty filaments.

|

Re: WOW New Materials!? February 26, 2014 12:01PM |

Registered: 10 years ago Posts: 869 |

I still struggle trying to figure out how carbon fiber infused filament would make it stronger. In order to be extruded at some always variable length/width/height the fibers would need to be extremely short. And being so short, you lose all the advantages of the long carbon crystaline structure that gives carbon fibers it's strength. You might as well mix in some charcoal dust...it'd be cheaper.Quote

tjb1

that sells PLA infused with carbor fiber and other specialty filaments.

|

Re: WOW New Materials!? February 26, 2014 12:26PM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

cdru

I still struggle trying to figure out how carbon fiber infused filament would make it stronger. In order to be extruded at some always variable length/width/height the fibers would need to be extremely short. And being so short, you lose all the advantages of the long carbon crystaline structure that gives carbon fibers it's strength. You might as well mix in some charcoal dust...it'd be cheaper.

That is true for filaments like what Proto-Pasta is making. In fact, Proto-Pasta even provides data that shows that their carbon-infused PLA is not as strong as plain PLA. It is, however, significantly stiffer.

The MakerForged printer claims to be different though, using continuous carbon fiber with a cutting blade which should make for extremely strong parts, at least in the fiber direction.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: WOW New Materials!? February 26, 2014 12:44PM |

Registered: 10 years ago Posts: 553 |

Quote

cdru

I still struggle trying to figure out how carbon fiber infused filament would make it stronger. In order to be extruded at some always variable length/width/height the fibers would need to be extremely short. And being so short, you lose all the advantages of the long carbon crystaline structure that gives carbon fibers it's strength. You might as well mix in some charcoal dust...it'd be cheaper.Quote

tjb1

that sells PLA infused with carbor fiber and other specialty filaments.

I didn't say it was any good

|

Re: WOW New Materials!? February 26, 2014 12:46PM |

Registered: 10 years ago Posts: 553 |

Quote

NewPerfection

Quote

cdru

I still struggle trying to figure out how carbon fiber infused filament would make it stronger. In order to be extruded at some always variable length/width/height the fibers would need to be extremely short. And being so short, you lose all the advantages of the long carbon crystaline structure that gives carbon fibers it's strength. You might as well mix in some charcoal dust...it'd be cheaper.

That is true for filaments like what Proto-Pasta is making. In fact, Proto-Pasta even provides data that shows that their carbon-infused PLA is not as strong as plain PLA. It is, however, significantly stiffer.

The MakerForged printer claims to be different though, using continuous carbon fiber with a cutting blade which should make for extremely strong parts, at least in the fiber direction.

That makes it unlikely that RepRaps will be able to just use the filament without serious modification and at that point I think you are just buying stranded carbon fiber, guess we have to wait for more details about the printer.

|

Re: WOW New Materials!? February 26, 2014 04:03PM |

Registered: 10 years ago Posts: 1,381 |

If you look at the hot end in the videos, it's not printing with carbon fiber, they have not shown a part made with it,

nor have they shown how the fiber is extruded, or if the fiber is sold with a coating, nothing has been disclosed.

I didn't find a patent with a quick search.

I'm curious as to what technique they have chosen to push rope, and what will be patented.

nor have they shown how the fiber is extruded, or if the fiber is sold with a coating, nothing has been disclosed.

I didn't find a patent with a quick search.

I'm curious as to what technique they have chosen to push rope, and what will be patented.

|

Re: WOW New Materials!? February 27, 2014 07:03PM |

Registered: 10 years ago Posts: 39 |

I'd be willing to mod my reprap if I could print kevlar and carbon fibre. could make bullet proof iron man suit

the hotend shown 3:08 in the vid is a weird shape.

(original vid) [www.youtube.com]

it clearly has fan cooling and some other familiar features but has extended heat block and some parts I cant see properly. There are two extruders within the hotend, one is carbon one is nylon.

another company presentation here:

[www.youtube.com]

the hotend shown 3:08 in the vid is a weird shape.

(original vid) [www.youtube.com]

it clearly has fan cooling and some other familiar features but has extended heat block and some parts I cant see properly. There are two extruders within the hotend, one is carbon one is nylon.

another company presentation here:

[www.youtube.com]

|

Re: WOW New Materials!? February 27, 2014 07:07PM |

Registered: 11 years ago Posts: 560 |

|

Re: WOW New Materials!? February 27, 2014 07:18PM |

Registered: 11 years ago Posts: 1,171 |

|

Re: WOW New Materials!? February 27, 2014 07:19PM |

Registered: 10 years ago Posts: 39 |

is it possible to form the fibre as it prints? how is it made usually?

answer:

The process for making carbon fibers is part chemical and part mechanical. The precursor is drawn into long strands or fibers and then heated to a very high temperature (1,000-3,000° C) with-out allowing it to come in contact with oxygen. Without oxygen, the fiber cannot burn. Instead, the high temperature causes the atoms in the fiber to vibrate violently until most of the non-carbon atoms are expelled. This process is called carbonization and leaves a fiber composed of long, tightly inter-locked chains of carbon atoms with only a few non-carbon atoms remaining.

About 90% of the carbon fibers produced are made from polyacrylonitrile (PAN). The remaining 10% are made from rayon or petroleum pitch.

so no, traditional carbon fibres cannot be created out of a reprap nozzle, they must already be present within the filament(?).

answer:

The process for making carbon fibers is part chemical and part mechanical. The precursor is drawn into long strands or fibers and then heated to a very high temperature (1,000-3,000° C) with-out allowing it to come in contact with oxygen. Without oxygen, the fiber cannot burn. Instead, the high temperature causes the atoms in the fiber to vibrate violently until most of the non-carbon atoms are expelled. This process is called carbonization and leaves a fiber composed of long, tightly inter-locked chains of carbon atoms with only a few non-carbon atoms remaining.

About 90% of the carbon fibers produced are made from polyacrylonitrile (PAN). The remaining 10% are made from rayon or petroleum pitch.

so no, traditional carbon fibres cannot be created out of a reprap nozzle, they must already be present within the filament(?).

|

Re: WOW New Materials!? February 27, 2014 07:26PM |

Registered: 10 years ago Posts: 39 |

|

Re: WOW New Materials!? February 27, 2014 08:17PM |

Registered: 11 years ago Posts: 560 |

They are talking some level of hype. While the parts may be stronger with a side directional load, the carbon fiber is being layed down in parallel lines and not being woven. I certainly wouldn't fly any airplane or drive any car with parts made like this. Layer wise, they would only be as strong as the melt-able material the carbon fiber is embedded in.

Edited 1 time(s). Last edit at 02/27/2014 09:41PM by Dirty Steve.

Edited 1 time(s). Last edit at 02/27/2014 09:41PM by Dirty Steve.

|

Anonymous User

Re: WOW New Materials!? February 28, 2014 12:18AM |

|

Re: WOW New Materials!? February 28, 2014 12:22AM |

Registered: 11 years ago Posts: 560 |

|

Re: WOW New Materials!? February 28, 2014 12:37AM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

Dirty Steve

sure, when it's layed up in a weave. This printing method is only as strong as it's fusable material.

A weave isn't the only way for carbon fiber to be useful. You just have to know its limitations. When you need high strength primarily in one direction, unidirectional carbon fiber is extremely useful.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Anonymous User

Re: WOW New Materials!? February 28, 2014 12:41AM |

|

Re: WOW New Materials!? February 28, 2014 01:57AM |

Registered: 10 years ago Posts: 1,381 |

Unidirectional (direct load path) is stronger in tensile, compression and bending than a bidirectional woven composite.

Half the strength can be lost with a bidirectional woven composite compared to a unidirectional composite.

[books.google.com]

Edited 1 time(s). Last edit at 02/28/2014 01:57AM by A2.

Half the strength can be lost with a bidirectional woven composite compared to a unidirectional composite.

[books.google.com]

Edited 1 time(s). Last edit at 02/28/2014 01:57AM by A2.

|

Re: WOW New Materials!? February 28, 2014 04:35AM |

Registered: 10 years ago Posts: 329 |

|

Re: WOW New Materials!? February 28, 2014 05:42AM |

Registered: 10 years ago Posts: 39 |

|

Re: WOW New Materials!? February 28, 2014 06:37AM |

Registered: 10 years ago Posts: 1,381 |

Carbon fiber tow $20 to $50 USD/lbs on ebay.

The Hexcel (HexTow) AS4 looks like it might be the easiest to physically handle, as it has the largest diameter.

Carbon fiber selector guide, (tow)

[www.hexcel.com]

Edited 1 time(s). Last edit at 02/28/2014 06:37AM by A2.

The Hexcel (HexTow) AS4 looks like it might be the easiest to physically handle, as it has the largest diameter.

Carbon fiber selector guide, (tow)

[www.hexcel.com]

Edited 1 time(s). Last edit at 02/28/2014 06:37AM by A2.

|

Re: WOW New Materials!? February 28, 2014 06:52AM |

Registered: 10 years ago Posts: 1,381 |

A small challenge is repeatedly cutting carbon fiber cleanly, i.e. shears dull quickly.

You can purchased a pair of hand shears (scissors) specially designed for cutting composites.

You probably would want to incorporate a burnishing tool into the hot end to help maintain a keen edge.

A relatively inexpensive workaround to shears sold specifically for composites is to purchase shears used to cut braided fishing line.

I have a small pair (Culprit, $12.00 on ebay) and they work well for composites.

[culprit.com]

Edited 3 time(s). Last edit at 02/28/2014 06:56AM by A2.

You can purchased a pair of hand shears (scissors) specially designed for cutting composites.

You probably would want to incorporate a burnishing tool into the hot end to help maintain a keen edge.

A relatively inexpensive workaround to shears sold specifically for composites is to purchase shears used to cut braided fishing line.

I have a small pair (Culprit, $12.00 on ebay) and they work well for composites.

[culprit.com]

Edited 3 time(s). Last edit at 02/28/2014 06:56AM by A2.

|

Re: WOW New Materials!? February 28, 2014 07:21AM |

Registered: 10 years ago Posts: 256 |

Quote

Dirty Steve

carbon fiber in PLA wouldn't do much of anything for strength, carbon fiber strength is in the weave, not parallel threads of material.

Actually the reverse. weaving carbon fibre weakens the fibres and the crimping reduces stiffness since the filament is no longer straight. For highest performance unidirectional carbon is used. The direction of the strands is varied dependent on the required properties (See also triaxial carbon fabric) woven material is more convenient only. Unidirectional fabric must be handled carefully.

Anyway that printer is Cool! I want one!

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: WOW New Materials!? February 28, 2014 09:08AM |

Registered: 10 years ago Posts: 869 |

|

Re: WOW New Materials!? February 28, 2014 10:38AM |

Registered: 10 years ago Posts: 256 |

Quote

cdru

Any discussion about higest strength, performance, etc is pointless unless what context it would be used and evaulated with is defined.Quote

kwikius

For highest performance unidirectional carbon is used.

Not sure that its pointless ? Surely the required Mechanical Properties of materials are well defined? For a particular material for a particular context, that is where you would start?

"High performance" uses of carbon include car bodies engines, disc brakes, racing yacht hulls, masts and sails, racing bikes, fishing rods, etc. etc. I dont think that is just fashion.. though adding carbon fibre to your product description can be good marketing

In each case the requirements are similar. Light weight, stiffness,compressive and tensile strength. Or am I missing something?

In each case the requirements are similar. Light weight, stiffness,compressive and tensile strength. Or am I missing something?Of course these properties arent much use if you want to make soup I agree

regards

Andy

Ormerod #318

www.zoomworks.org - Free and Open Source Stuff

|

Re: WOW New Materials!? February 28, 2014 02:39PM |

Registered: 10 years ago Posts: 39 |

|

Re: WOW New Materials!? February 28, 2014 04:33PM |

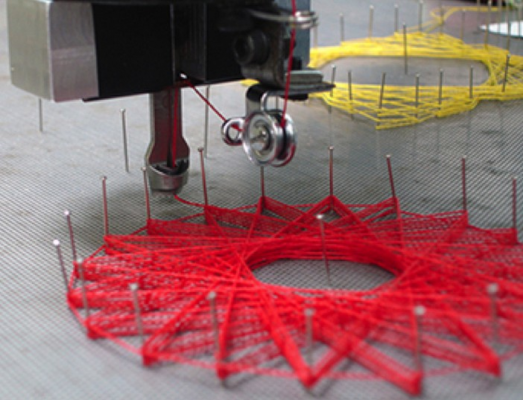

Registered: 10 years ago Posts: 1,381 |

Quote

mrPrik

so the resin coated fibre filament must be a 1:1 extrusion from the print head, with a cut made for each path drawn.

Composites with the least amount of epoxy resin produce the strongest structural components,

i.e. less resin, and more carbon fiber for a given area equates to a stronger part.

Code to decide when to cut would need to be based on several factors such as,

the desired stress/strain profile, ease of manufacture, and manual intervention.

Nothing has been disclosed about the carbon fiber layup process.

There could be a non epoxy coating on the fibers that is heat activated during the extrusion process.

Looking at the hot end, and extruder in the videos, it's possible that they have not implemented automatic cutting,

and re-threading of the carbon fiber, and instead are relying on operator intervention.

The extrusion process might be only capable of simple layup patterns,

(e.g. oval, circular, square, figure 8) of the carbon fiber tow around 3d printed structures.

Simulating 3d printing by robotic placement for textile reinforced composite structures.

It might be required that the operator infuses the carbon fiber with epoxy,

and that the printed Nylon plastic is simply a form, and mold to help hold,

and position the fibers in a predetermined pattern.

There are other fibers that you can experiment with such as, E-glass, S-glass, Kevlar, Basalt, and cotton thread.

If you plan to experiment with carbon fiber aircraft Spruce suggest starting with the 6K tow, but your millage may vary.

It appears that the 6K tow will prove most practical for homebuilding applications.

This size will be available in the small units shown. The 3K and 12K sizes are offered in full spools only.

The 3K tow is used primarily by weavers. The 12K is difficult to wet out but can be done by diligent brushing.

[www.aircraftspruce.com]

MICROSTRUCTURE AND MECHANICAL PROPERTIES OF HEAT

RESISTANT COMPOSITES REINFORCED WITH BASALT FIBRES

[www.ceramics-silikaty.cz]

Edited 1 time(s). Last edit at 02/28/2014 04:34PM by A2.

|

Re: WOW New Materials!? February 28, 2014 04:42PM |

Registered: 11 years ago Posts: 1,171 |

I wonder if it would be possible to print with UHMWPE This is a polyethylene material used in bullet proof vests, high end kites and super light super strong fishing line. I use to fish a lot and our old 2lb line for trout fishing was very thin lightweight. Now the same size and weight line can hold closer to 12lbs. If it could be printed, I would think it would blow past what this carbon fiber printer is doing strength wise. Not that it's stronger than properly made carbon fiber items but I just don't think this particular method is taking advantage of it's strength except in one direction, that's very limiting.

|

Re: WOW New Materials!? February 28, 2014 05:16PM |

Registered: 10 years ago Posts: 1,381 |

@tmorris9:

You are comparing two very different materials.

There are many material properties to consider for an application, and each application is different,

some material characteristics are toughness, hardness, ultimate tensile strength,

flexural, tensile modulus, density, max/min temperature, thermal conductivity, surface energy, etc, etc.

There is a coating on Spectra fishing line that would prevent it from adhering to epoxy.

You can purchase uncoated Spectra tow, but it will still be difficult to get it to adhere to epoxy due to it's low surface energy.

Low surface energy

The tendency of a surface to repel, rather than attract, an adhesive.

Low surface energy prevents an adhesive from sufficiently wetting a surface.

[www.toolingu.com]

Joining polyethylene

Adhesives and solvents are rarely used because polyethylene is nonpolar and has a high resistance to solvents.

Pressure-sensitive adhesives (PSA) are feasible if the surface is flame treated or corona treated.

[en.wikipedia.org]

Using an Instron tensile testing machine I've tested a lot of different brands, and materials of fishing lines, and knots.

The values posted on the box can be under, and over rated, moisture, and oil exposure further reduces the tensile modulus.

My expectation is for the fishing line to break at the value advertised, that is not always the case.

Edited 2 time(s). Last edit at 02/28/2014 05:18PM by A2.

You are comparing two very different materials.

There are many material properties to consider for an application, and each application is different,

some material characteristics are toughness, hardness, ultimate tensile strength,

flexural, tensile modulus, density, max/min temperature, thermal conductivity, surface energy, etc, etc.

Quote

tmorris9

I wonder if it would be possible to print with UHMWPE

There is a coating on Spectra fishing line that would prevent it from adhering to epoxy.

You can purchase uncoated Spectra tow, but it will still be difficult to get it to adhere to epoxy due to it's low surface energy.

Low surface energy

The tendency of a surface to repel, rather than attract, an adhesive.

Low surface energy prevents an adhesive from sufficiently wetting a surface.

[www.toolingu.com]

Joining polyethylene

Adhesives and solvents are rarely used because polyethylene is nonpolar and has a high resistance to solvents.

Pressure-sensitive adhesives (PSA) are feasible if the surface is flame treated or corona treated.

[en.wikipedia.org]

Using an Instron tensile testing machine I've tested a lot of different brands, and materials of fishing lines, and knots.

The values posted on the box can be under, and over rated, moisture, and oil exposure further reduces the tensile modulus.

My expectation is for the fishing line to break at the value advertised, that is not always the case.

Edited 2 time(s). Last edit at 02/28/2014 05:18PM by A2.

|

Re: WOW New Materials!? February 28, 2014 06:04PM |

Registered: 10 years ago Posts: 39 |

Sorry, only registered users may post in this forum.