“Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures]

[Many Pictures]

Posted by RP Iron Man

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 01, 2014 09:21PM |

Registered: 10 years ago Posts: 1,381 |

Depending on the grade of brass the amount of lead will vary.

The most popular brass in the world is C360 (UNS C36000).

The lead content of C360 is between (2.5 - 3.7%), and makes it unsuited for food or medical grade use.

C360 is used in medical devices, but it has a heavy nickel, and chrome plate.

California law:

“not more than a weighted average of 0.25 percent lead content in pipe and fittings.”

I haven't seen any internally chrome plated brass nozzles, but if you did it's probably OK for food use.

Pure electroless nickel plating is food grade approved.

The higher the temperature, and depending on the type of reactive chemicals in the plastic resin,

lead might leach out of uncoated brass faster and in a higher concentration.

C330 brass lead content is 0.2 - 0.8%, and is considered food grade.

If the manufacturer doesn't state the materials used, assume the worse case scenario, and don't use it for food or medical device production.

Prometheus uses 304 SS nozzle, so there is no issue with lead that I can see.

The most popular brass in the world is C360 (UNS C36000).

The lead content of C360 is between (2.5 - 3.7%), and makes it unsuited for food or medical grade use.

C360 is used in medical devices, but it has a heavy nickel, and chrome plate.

California law:

“not more than a weighted average of 0.25 percent lead content in pipe and fittings.”

I haven't seen any internally chrome plated brass nozzles, but if you did it's probably OK for food use.

Pure electroless nickel plating is food grade approved.

The higher the temperature, and depending on the type of reactive chemicals in the plastic resin,

lead might leach out of uncoated brass faster and in a higher concentration.

C330 brass lead content is 0.2 - 0.8%, and is considered food grade.

If the manufacturer doesn't state the materials used, assume the worse case scenario, and don't use it for food or medical device production.

Prometheus uses 304 SS nozzle, so there is no issue with lead that I can see.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 05, 2014 06:15PM |

Registered: 11 years ago Posts: 246 |

Yeah, I don't think there should be any issues with food safe usage of this hot end.

The internals of the SS 304 Nozzle are also polished and cleaned so there is no risk of machining residue and gunk being printed into your food safe part either. I really want to experiment with T-Glase once I get some 0.6mm nozzles. I actually tried it with 0.4mm nozzles and it worked intermittently but just put WAY to much stress on my extruder assembly. T-Glase definitely requires a larger nozzle orifice diameter for practical printing.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

The internals of the SS 304 Nozzle are also polished and cleaned so there is no risk of machining residue and gunk being printed into your food safe part either. I really want to experiment with T-Glase once I get some 0.6mm nozzles. I actually tried it with 0.4mm nozzles and it worked intermittently but just put WAY to much stress on my extruder assembly. T-Glase definitely requires a larger nozzle orifice diameter for practical printing.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 05, 2014 07:18PM |

Registered: 11 years ago Posts: 41 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 07, 2014 05:35PM |

Registered: 11 years ago Posts: 246 |

Of course, I'll keep you informed

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 17, 2014 06:50PM |

Registered: 10 years ago Posts: 25 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 17, 2014 07:22PM |

Registered: 11 years ago Posts: 246 |

Quote

turutk

Your heatsink design seems thin due to shape.

Can I combine 2 of your hotends and use them with a single 4cm fan?

That's actually what I had in mind with the thin heat sink

The thin heat sink design allow two Prometheus hot ends to be placed very close together for Dual extrusion set-ups. Using a single fan may be sufficient to cool both heat sinks, though I have not tested this. The only uncertainty here is that generally cooling is less efficient when fans are "pulling" air over the heat sink vs "pushing" air, so the heat sink that is have air "pulled" through it may be less effectively cooled. However, this difference in cooling should be minimal so I doubt it would be a problem.

Anyway, you could actually get the hot ends closer together for Dual extrusion if you just used two fans attached to the outside face of each heat sink.

If you want to use a single cooling fan it should still work well (and also look way cooler

)

)**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 17, 2014 08:29PM |

Registered: 10 years ago Posts: 1,381 |

It would be very advantageous to minimize the distance between two nozzles.

The Dia 16 mm grove mount is your limiting factor of how close you can bring together two hot ends.

How do you plan to combine two hot ends?

Another challenge is leveling the nozzles, how do you plan to accomplish leveling with two hot ends combined together?

Heater Block

[i.imgur.com]

Heat Sink

[www.flickr.com]

Congrats on meeting your funding goal. , and I'm looking forward to reading the reviews of your Prometheus Hot End.

, and I'm looking forward to reading the reviews of your Prometheus Hot End.

The Dia 16 mm grove mount is your limiting factor of how close you can bring together two hot ends.

How do you plan to combine two hot ends?

Another challenge is leveling the nozzles, how do you plan to accomplish leveling with two hot ends combined together?

Heater Block

[i.imgur.com]

Heat Sink

[www.flickr.com]

Congrats on meeting your funding goal.

, and I'm looking forward to reading the reviews of your Prometheus Hot End.

, and I'm looking forward to reading the reviews of your Prometheus Hot End.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 20, 2014 11:33AM |

Registered: 12 years ago Posts: 5 |

Can you post more pictures and possible video of prints using rapid retracts? The X carriage was your only good example.

We have found that jams basically every all metal hotends tested to date.

Here is 1 example [www.thingiverse.com]

We have found that jams basically every all metal hotends tested to date.

Here is 1 example [www.thingiverse.com]

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 20, 2014 03:37PM |

Registered: 10 years ago Posts: 25 |

I was actually planning to use a high cfw fan from one end because my delta hub has a fan mount on it.

Here is my setup with E3D:

[drive.google.com]

There is no way I can fit 2 E3D hotends. I thought maybe two prometheuses can fit to the same hub.

I don't want to place the hotend under the hub.

By the way It would be great if this hotend had a bowden version where pfte tube goes inside the heatsink.

Edited 2 time(s). Last edit at 04/20/2014 04:25PM by turutk.

Here is my setup with E3D:

[drive.google.com]

There is no way I can fit 2 E3D hotends. I thought maybe two prometheuses can fit to the same hub.

I don't want to place the hotend under the hub.

By the way It would be great if this hotend had a bowden version where pfte tube goes inside the heatsink.

Edited 2 time(s). Last edit at 04/20/2014 04:25PM by turutk.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 20, 2014 04:02PM |

Registered: 10 years ago Posts: 1,381 |

Quote

RoyAvery

Can you post more pictures and possible video of prints using rapid retracts? The X carriage was your only good example.

We have found that jams basically every all metal hotends tested to date.

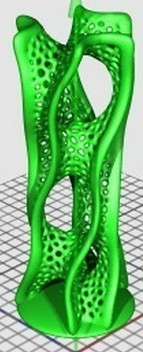

Jeremie Francois suggest printing Richrap's voronoi model to test retraction-cold end capabilities of the hot end.

Thoughts and hints around hot ends

[www.tridimake.com]

Quote

Jeremie Francois

it is easy to check that you did it right by printing an object that requires heavy retraction, such as those voronoi objects with fractal holes everywhere.

many retractions are a good test to check the filament flow reliability.

Probably the best kind of object to test retraction (design by richrap)

Still, my print is quite dirty, but at least I got no single plug,

Print competition Voronoi D Tower 1/4 res 1/2 size by @Dizingof

by RichRap, published Jun 2, 2012

[www.thingiverse.com]

Comments about retraction challenges can be found in this thread.

groove or grooveless hot end

[forums.reprap.org]

Edited 2 time(s). Last edit at 04/20/2014 04:12PM by A2.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 20, 2014 10:06PM |

Registered: 11 years ago Posts: 246 |

Quote

RoyAvery

Can you post more pictures and possible video of prints using rapid retracts? The X carriage was your only good example.

We have found that jams basically every all metal hotends tested to date.

Here is 1 example [www.thingiverse.com]

Hey Roy,

I have actually tested rapid retracts extensively. I printed a bunch of plastic "IGUS style printed bearings" (http://www.thingiverse.com/thing:24990) because I was planning on testing different plastic bushings on a printer. I printed the 0.5mm nozzle version with a 0.4mm nozzle with infill turned on so I had about 20 retracts per layer (it was about 2 retracts per second on infill). I printed these parts in crappy ESUN PLA, decent ABS, and Taulman Nylon without any jamming. The internal bore of the Prometheus 1-piece nozzle is polished so the friction with the "transition-zone" plug is less significant and with a 2mm to 3mm "transition-zone" the friction is not enough to pass the "point of friction failure" where the hot end jams and does not extrude no matter how much force you use.

I think I have some pictures of these IGUS style LM8UUs on my Flickr if you want to check them out, but I don't have time to dig them up right now. I am really busy with a lot of stuff ATM so I hope you can understand.

I'll try to print that funky looking vase that A2 posted as soon as I find the time to get one of my partially disassembled printers set up and printing. I have a lot of stuff on my plate and it is now hard to find time to sleep, LOL

Quote

turutk

I was actually planning to use a high cfw fan from one end because my delta hub has a fan mount on it.

Here is my setup with E3D:

[drive.google.com]

There is no way I can fit 2 E3D hotends. I thought maybe two prometheuses can fit to the same hub.

I don't want to place the hotend under the hub.

By the way It would be great if this hotend had a bowden version where pfte tube goes inside the heatsink.

Looks like you could fit two Prometheus Hot Ends easily.

As for the integrated bowden version, I am working on it. I have actually received a lot of requests for this. I am just redesigning the standard Prometheus heat sink to be used as either a direct drive version or a bowden version where the tube passes through the coupling and into the hot end

(Just like the E3D bowden version) The Early Bird perks will ship with the revised bowden compatible heat sink.

(Just like the E3D bowden version) The Early Bird perks will ship with the revised bowden compatible heat sink. I'll get the drawings up as soon as I have finalized them with my manufacturer!

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] April 23, 2014 06:55PM |

Registered: 10 years ago Posts: 12 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 12, 2014 06:26PM |

Registered: 10 years ago Posts: 24 |

My 1.75mm Prometheus bowden configuration is up and running! I've followed the stock assembly instructions at http://www.dta-labs.com/pages//instructions.

Fit and finish is very nice and assembly was quite easy. It heats very quickly, and with a PID tune I'm stable within about a 0.2C window. I did wrap the heater block with some silicone tape as extra insurance against a loose thermistor. I don't think it could happen, AND, I prefer to error to the safe side.

So far, I've tried hand feeding ABS without issue and then went straight to PLA. I've discovered that some PLA's will jam immediately upon stopping filament feed, while others do not have any issue. I also tried a wide range of print temperatures with the difficult PLA's without success.

Using the PLA that hand feeds fine, I ran a 4 1/2 hour print at 30mm/s with very heavy retraction without issues and good print results.

One suggest so far was to reduce the speed of the heat sink fan... which I've not yet tried and I'm not certain is the best route yet.

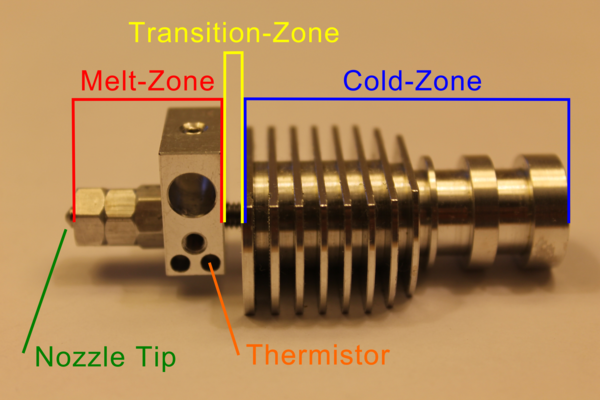

So... to dial in the hotend for the other PLAs, should I reduce the length of the transition zone based on the assembly hints? I'm at about 2.5mm right now.

Fit and finish is very nice and assembly was quite easy. It heats very quickly, and with a PID tune I'm stable within about a 0.2C window. I did wrap the heater block with some silicone tape as extra insurance against a loose thermistor. I don't think it could happen, AND, I prefer to error to the safe side.

So far, I've tried hand feeding ABS without issue and then went straight to PLA. I've discovered that some PLA's will jam immediately upon stopping filament feed, while others do not have any issue. I also tried a wide range of print temperatures with the difficult PLA's without success.

Using the PLA that hand feeds fine, I ran a 4 1/2 hour print at 30mm/s with very heavy retraction without issues and good print results.

One suggest so far was to reduce the speed of the heat sink fan... which I've not yet tried and I'm not certain is the best route yet.

So... to dial in the hotend for the other PLAs, should I reduce the length of the transition zone based on the assembly hints? I'm at about 2.5mm right now.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 12, 2014 06:59PM |

Registered: 11 years ago Posts: 246 |

@gen2eng

I am glad that you got your Prometheus Hot End all set up and running

I am curious why you have had success with some PLA but encountered difficulty with other PLA? This is not expected. You should not have trouble printing with PLA at all unless it is really low quality filament.

What is the difference between the PLA that works and the difficult PLA that doesn't? Are they different colors? Are they from different manufacturers? Is the diameter tolerance similar between the two?

Also, could you give me some info about your extruder? Is there any point in the filament feed where the plastic can buckle? Does this difficult PLA jam when you hand feed it through Prometheus? How about with other hot ends? This information will help us sort this out

I am happy that you are getting great results with the PLA you are currently using, but it is odd that you have issues with some select PLA filament.

I hope I can help you sort this out!

Cheers,

Eric

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

I am glad that you got your Prometheus Hot End all set up and running

I am curious why you have had success with some PLA but encountered difficulty with other PLA? This is not expected. You should not have trouble printing with PLA at all unless it is really low quality filament.

What is the difference between the PLA that works and the difficult PLA that doesn't? Are they different colors? Are they from different manufacturers? Is the diameter tolerance similar between the two?

Also, could you give me some info about your extruder? Is there any point in the filament feed where the plastic can buckle? Does this difficult PLA jam when you hand feed it through Prometheus? How about with other hot ends? This information will help us sort this out

I am happy that you are getting great results with the PLA you are currently using, but it is odd that you have issues with some select PLA filament.

I hope I can help you sort this out!

Cheers,

Eric

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 12, 2014 07:25PM |

Registered: 11 years ago Posts: 246 |

Also, I forgot to mention:

You should not have to further decrease the length of the "transition-zone". 2.5mm is already very short so this will not be the problem. As long as the fan is running at full speed then the "transition-zone" should be short enough.

As a test, try pushing this PLA filament into the nozzle and then removing it and checking the length of the "plug". The plug length should only be about 2mm to 3mm.

Eric

You should not have to further decrease the length of the "transition-zone". 2.5mm is already very short so this will not be the problem. As long as the fan is running at full speed then the "transition-zone" should be short enough.

As a test, try pushing this PLA filament into the nozzle and then removing it and checking the length of the "plug". The plug length should only be about 2mm to 3mm.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 12, 2014 08:33PM |

Registered: 10 years ago Posts: 24 |

Thanks Eric!

The PLAs that are working are manufactured by Prototype Supply (Green and Cool Grey). The PLAs not working are a blue Ultimachine which was very unexpected and a blue and grey PLA from MatterHackers. Diameters are 1.78 maximum to about 1.72 egg shape on the MatterHackers and the Ultimachine is a round 1.77 and the working Prototype Supply is a round 1.74.

The extruder is a direct drive from SeeMeCNC http://seemecnc.com/collections/parts-accesories/products/ezstruder-cold-end-kit. It does not have any room to allow buckling and simply grinds through the filament when it jams.

When I was hand feeding, the filament would easily feed on all filaments, but as soon as I stop, it jams... as in I can no longer push by hand without buckling. I discovered the issue when I was trying to determine an optimal print temperature by feel.

The plugs I was able to find are measuring a consistent 1.97 diameter and are 2.2 - 2.3mm long. There is a very sharp transition between the plug and un-melted plastic in that I can see extruder marks on the filament all the way until the plug forms. They would all easily pull from the nozzle.

I typically run the PLA's at 195 to 205. I did have to push the temp to 220 for the working Prototype Supply, AND, I've not yet calibrated against a lab verified thermocouple which will be done this weekend (loaner equipment from work).

Would increasing the transition zone length improve resistance against jams?

Ultimately, I am hoping to find an ideal configuration for PLA's with enough wiggle room to run some Nylons and ABS on occasion without reconfiguration. Don't know if it's possible or not, but I'm willing to give it a go. This is my first all metal hotend and I was close to ordering an E3d, but your campaign started just in time. I believe your design is the most robust currently available and I'm very willing to tweak and tune to get it right.

The PLAs that are working are manufactured by Prototype Supply (Green and Cool Grey). The PLAs not working are a blue Ultimachine which was very unexpected and a blue and grey PLA from MatterHackers. Diameters are 1.78 maximum to about 1.72 egg shape on the MatterHackers and the Ultimachine is a round 1.77 and the working Prototype Supply is a round 1.74.

The extruder is a direct drive from SeeMeCNC http://seemecnc.com/collections/parts-accesories/products/ezstruder-cold-end-kit. It does not have any room to allow buckling and simply grinds through the filament when it jams.

When I was hand feeding, the filament would easily feed on all filaments, but as soon as I stop, it jams... as in I can no longer push by hand without buckling. I discovered the issue when I was trying to determine an optimal print temperature by feel.

The plugs I was able to find are measuring a consistent 1.97 diameter and are 2.2 - 2.3mm long. There is a very sharp transition between the plug and un-melted plastic in that I can see extruder marks on the filament all the way until the plug forms. They would all easily pull from the nozzle.

I typically run the PLA's at 195 to 205. I did have to push the temp to 220 for the working Prototype Supply, AND, I've not yet calibrated against a lab verified thermocouple which will be done this weekend (loaner equipment from work).

Would increasing the transition zone length improve resistance against jams?

Ultimately, I am hoping to find an ideal configuration for PLA's with enough wiggle room to run some Nylons and ABS on occasion without reconfiguration. Don't know if it's possible or not, but I'm willing to give it a go. This is my first all metal hotend and I was close to ordering an E3d, but your campaign started just in time. I believe your design is the most robust currently available and I'm very willing to tweak and tune to get it right.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 13, 2014 12:36PM |

Registered: 12 years ago Posts: 177 |

Just wanted to wade in here and apologise about not getting back about the 500C thermistors. Basically my conclusion is that they aren't worth it, getting the ADC of an arduino to do the full curve over the (non-linear) range of the thermistor is hard, and leads to dodgy resolution/quantisation, the cost is very high too.

By the time you've purchased the very expensive thermistor etc, you may as well have just upgraded to a thermocouple and be done with it. You can get awesome results with a TC, with good known hardware and accurate measurements. 500C thermistors are neat and all, but they are pretty bleeding edge compared to a proven TC setup that outperforms them for a similar price.

P.S - I hear you guys on the dual nozzle hotend thing. We've got something cool to come soon.

By the time you've purchased the very expensive thermistor etc, you may as well have just upgraded to a thermocouple and be done with it. You can get awesome results with a TC, with good known hardware and accurate measurements. 500C thermistors are neat and all, but they are pretty bleeding edge compared to a proven TC setup that outperforms them for a similar price.

P.S - I hear you guys on the dual nozzle hotend thing. We've got something cool to come soon.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 13, 2014 08:02PM |

Registered: 11 years ago Posts: 246 |

@gen2eng

Wow, thanks for the detailed analysis. You really saved me a lot of time!

You should not lengthen the transition-zone length as doing so will increase the length of the PLA plug and increase the extrusion force required. If anything, further reducing the transition-zone may help, but 2.5mm should be enough.

Ahh, I see. It definitely looks like your extruder is the problem. Using a direct drive Nema 17 motor is pushing the limits for all-metal hot ends, especially for a bowden configuration. Many people have had issues printing PLA using all metal hot ends with direct Nema 17 extruders like the SeeMeCNC EZ Struder and the Bulldog Lite. These direct drive extruder usually work flawlessly with PTFE Lined hot ends because the extremely low friction of PTFE greatly decreases the required extrusion force. All metal hot ends do not have this low friction PTFE liner so the friction between the PLA plug and the walls of the SS Nozzle is more significant. The way we minimize the friction in all metal hot ends is by polishing the internal filament path where the plug forms.

On the Prometheus 1-Piece Nozzles, the entire length of the Nozzle is Electropolished. Electropolishing is one of the most advanced polishing methods available for Stainless Steel parts. This results in a very smooth path that will greatly reduce the friction in the hot end and minimize the possibility of PLA jams. However, even with the Electropolished Nozzle the friction is still greater than that of a PTFE Lined hot end and therefore the extrusion force will be higher.

This is why you found that the the extruder would start eating the filament when you tried to extrude. I have two suggestions for you that can fix this problem:

1) Tweak your extruder: This is tricky and is not really the optimal solution, but may be a quick fix.

First of all, if you are going to print PLA reliably with a direct drive Nema 17 extruder then you will need all of the torque that you can get.

- Turn the potentionmeter on your extruder Stepper Driver as high as possible until just before you hear the motors "buzz".

- Since you said your drive gear starts to eat filament you should increase the spring tension on your extruder until just before the extruder motor starts skipping steps.

- You may also need to check your extrusion acceleration settings and turn it down so that you will not require as much torque when you begin to extrude. This is where you are encountering problems and it is when you need the most torque from your extruder.

2) Upgrade to a geared extruder: I highly recommend upgrading to a geared extruder for many reasons.

- A direct Nema 17 extruder is really cutting it close while a geared extruder will give you more than enough torque for the job. I have people who are using geared extruders with my Prometheus Hot End and printing flawlessly with PLA at about 190C temperatures.

- The extra torque will allow you to increase your extrusion acceleration settings instead of decreasing this value. Increasing your extrusion acceleration is VERY beneficial for bowden setup as it mitigates the negative effects of hysteresis due to the bowden tube. Higher acceleration increases the effectiveness of retraction and you will not need such long retractions. It also increases the response time of your extrusion so that you will get more accurate prints at higher speeds.

I am sure that you could find a printed geared bowden extruder to use with your Nema 17 motor. I think RichRap (Richard Horne) has designed a great bowden extruder so you can try printing that out. (I'll try to find a link to it later)

If you want to keep your EZ Struder set-up you can look at the off-the-shelf geared extruders. A 5:1 geared Nema 11, Nema 14, or Nema 17 would be more than adequate. I get my geared steppers from OMC Stepper Online. They are really well built geared steppers. Since you have a bowden extruder you may as well get the beefy 5:1 geared Nema 17 since it will not contribute to the moving mass. However, keep in mind that you will need to figure out a way to mount one of these to your EZ Struder. These geared steppers also have 6mm shafts (instead of 5mm on the standard Nema17 motors) so you would have to drill out your drive gear with a 6mm bit.

-----------------

You can try out tweaking your extruder now, as this should help you print your other PLA filaments. However, I would suggest upgrading to a geared extruder for flawless printing and the added performance benefits of having a very high extrusion acceleration. The added torque is a real benefit, and since you are using a bowden configuration there are no drawbacks to having a slightly heavier extruder.

I am completely confident that you will not have any issues with any PLA using a geared extruder!

I hope this helps!

Thanks,

Eric

Edited 1 time(s). Last edit at 08/13/2014 08:03PM by RP Iron Man.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Wow, thanks for the detailed analysis. You really saved me a lot of time!

You should not lengthen the transition-zone length as doing so will increase the length of the PLA plug and increase the extrusion force required. If anything, further reducing the transition-zone may help, but 2.5mm should be enough.

Ahh, I see. It definitely looks like your extruder is the problem. Using a direct drive Nema 17 motor is pushing the limits for all-metal hot ends, especially for a bowden configuration. Many people have had issues printing PLA using all metal hot ends with direct Nema 17 extruders like the SeeMeCNC EZ Struder and the Bulldog Lite. These direct drive extruder usually work flawlessly with PTFE Lined hot ends because the extremely low friction of PTFE greatly decreases the required extrusion force. All metal hot ends do not have this low friction PTFE liner so the friction between the PLA plug and the walls of the SS Nozzle is more significant. The way we minimize the friction in all metal hot ends is by polishing the internal filament path where the plug forms.

On the Prometheus 1-Piece Nozzles, the entire length of the Nozzle is Electropolished. Electropolishing is one of the most advanced polishing methods available for Stainless Steel parts. This results in a very smooth path that will greatly reduce the friction in the hot end and minimize the possibility of PLA jams. However, even with the Electropolished Nozzle the friction is still greater than that of a PTFE Lined hot end and therefore the extrusion force will be higher.

This is why you found that the the extruder would start eating the filament when you tried to extrude. I have two suggestions for you that can fix this problem:

1) Tweak your extruder: This is tricky and is not really the optimal solution, but may be a quick fix.

First of all, if you are going to print PLA reliably with a direct drive Nema 17 extruder then you will need all of the torque that you can get.

- Turn the potentionmeter on your extruder Stepper Driver as high as possible until just before you hear the motors "buzz".

- Since you said your drive gear starts to eat filament you should increase the spring tension on your extruder until just before the extruder motor starts skipping steps.

- You may also need to check your extrusion acceleration settings and turn it down so that you will not require as much torque when you begin to extrude. This is where you are encountering problems and it is when you need the most torque from your extruder.

2) Upgrade to a geared extruder: I highly recommend upgrading to a geared extruder for many reasons.

- A direct Nema 17 extruder is really cutting it close while a geared extruder will give you more than enough torque for the job. I have people who are using geared extruders with my Prometheus Hot End and printing flawlessly with PLA at about 190C temperatures.

- The extra torque will allow you to increase your extrusion acceleration settings instead of decreasing this value. Increasing your extrusion acceleration is VERY beneficial for bowden setup as it mitigates the negative effects of hysteresis due to the bowden tube. Higher acceleration increases the effectiveness of retraction and you will not need such long retractions. It also increases the response time of your extrusion so that you will get more accurate prints at higher speeds.

I am sure that you could find a printed geared bowden extruder to use with your Nema 17 motor. I think RichRap (Richard Horne) has designed a great bowden extruder so you can try printing that out. (I'll try to find a link to it later)

If you want to keep your EZ Struder set-up you can look at the off-the-shelf geared extruders. A 5:1 geared Nema 11, Nema 14, or Nema 17 would be more than adequate. I get my geared steppers from OMC Stepper Online. They are really well built geared steppers. Since you have a bowden extruder you may as well get the beefy 5:1 geared Nema 17 since it will not contribute to the moving mass. However, keep in mind that you will need to figure out a way to mount one of these to your EZ Struder. These geared steppers also have 6mm shafts (instead of 5mm on the standard Nema17 motors) so you would have to drill out your drive gear with a 6mm bit.

-----------------

You can try out tweaking your extruder now, as this should help you print your other PLA filaments. However, I would suggest upgrading to a geared extruder for flawless printing and the added performance benefits of having a very high extrusion acceleration. The added torque is a real benefit, and since you are using a bowden configuration there are no drawbacks to having a slightly heavier extruder.

I am completely confident that you will not have any issues with any PLA using a geared extruder!

I hope this helps!

Thanks,

Eric

Edited 1 time(s). Last edit at 08/13/2014 08:03PM by RP Iron Man.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 15, 2014 06:06AM |

Registered: 10 years ago Posts: 24 |

After having run a few smaller prints with the PLA that has worked, I have tried the troublesome PLA's again with much improved results.

1. I've been able to reduce temperatures down to about 200C.

2. Complete jams are gone.

3. I do get occasional motors skips (after reaching full extrusion speed). I can't increase current much more without overheating the stepper. A geared extruder build as mentioned should help this.

4. The most troublesome PLA works without jamming, but I have to run a tight 201 to 202C window to prevent skips. The other PLA's are not as heat sensitive. AND, of all the PLA's this is probably the lowest quality based on roughness of the filament and size variation.

I also experimented a bit with the extruder fan speeds and have determined that faster is better in that it takes more force to extrude at lower fan speeds.

When I received the hotend, I noticed a heavy detergent odor. I'm wondering if a bit of cleaning residue was left in the nozzle after the electrolyte removal process and it took a bit of printing to work it's way out? I deal with electropolished stainless castings on daily basis and cleanliness issues from electrolyte removal crop up from time to time in small crevices, holes, etc. It may warrant soaking the nozzle in acetone before assembly.

I will continue printing and will look into printing a gear extruder solution.

Edited 1 time(s). Last edit at 08/15/2014 06:07AM by gen2eng.

1. I've been able to reduce temperatures down to about 200C.

2. Complete jams are gone.

3. I do get occasional motors skips (after reaching full extrusion speed). I can't increase current much more without overheating the stepper. A geared extruder build as mentioned should help this.

4. The most troublesome PLA works without jamming, but I have to run a tight 201 to 202C window to prevent skips. The other PLA's are not as heat sensitive. AND, of all the PLA's this is probably the lowest quality based on roughness of the filament and size variation.

I also experimented a bit with the extruder fan speeds and have determined that faster is better in that it takes more force to extrude at lower fan speeds.

When I received the hotend, I noticed a heavy detergent odor. I'm wondering if a bit of cleaning residue was left in the nozzle after the electrolyte removal process and it took a bit of printing to work it's way out? I deal with electropolished stainless castings on daily basis and cleanliness issues from electrolyte removal crop up from time to time in small crevices, holes, etc. It may warrant soaking the nozzle in acetone before assembly.

I will continue printing and will look into printing a gear extruder solution.

Edited 1 time(s). Last edit at 08/15/2014 06:07AM by gen2eng.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 15, 2014 08:33AM |

Registered: 11 years ago Posts: 246 |

@gen2eng

I am happy to hear about your success

I am curious about that detergent odour. As far as I know the nozzles are completely scentless However, the package could have been shipped next to another smelly package and picked up the odour.

However, the package could have been shipped next to another smelly package and picked up the odour.

Also, you will notice that the PTFE Tubing I sent has a very strong "factory smell" odour so maybe that's what you are smelling. This is very noticeable when you cut the PTFE tubing and I actually cut the PTFE tubing right before I packed it with the machined parts, so this is likely the cause of the unpleasant smell.

It's great to hear about the results you are getting with your direct drive, and I am sure that PLA printing will be completely flawless once you upgrade to a geared extruder!

Eric

EDIT: I forgot to mention this. If you have not already done this you should have a good cooling fan blowing over the stepper motor and another blowing over the stepper drivers on your controller board. This will allow you to increase the maximum current applied to the stepper motors without having them skip steps.

Edited 1 time(s). Last edit at 08/15/2014 08:46AM by RP Iron Man.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

I am happy to hear about your success

I am curious about that detergent odour. As far as I know the nozzles are completely scentless

However, the package could have been shipped next to another smelly package and picked up the odour.

However, the package could have been shipped next to another smelly package and picked up the odour. Also, you will notice that the PTFE Tubing I sent has a very strong "factory smell" odour so maybe that's what you are smelling. This is very noticeable when you cut the PTFE tubing and I actually cut the PTFE tubing right before I packed it with the machined parts, so this is likely the cause of the unpleasant smell.

It's great to hear about the results you are getting with your direct drive, and I am sure that PLA printing will be completely flawless once you upgrade to a geared extruder!

Eric

EDIT: I forgot to mention this. If you have not already done this you should have a good cooling fan blowing over the stepper motor and another blowing over the stepper drivers on your controller board. This will allow you to increase the maximum current applied to the stepper motors without having them skip steps.

Edited 1 time(s). Last edit at 08/15/2014 08:46AM by RP Iron Man.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] September 02, 2014 08:13PM |

Registered: 10 years ago Posts: 24 |

I was able to narrow the jamming down to the surface roughness of the PLA. You were spot on it was more friction related than anything. The PLAs with polished surface would print without issues, and anything with a satin or rough finish would jam.

I have completed design, print, and assembly of an Accessible Wade's style extruder and have been able to lower my temperatures back to 195 and easily print without jams.

I'm running a 2.84 gear ratio on the extruder to keep speeds up and hope to push the printer to higher speeds.

Thanks again for a solid hot end design. I believe you've one-up'd the E3D and similar clones with the one piece nozzle and the strength it provides.

I have completed design, print, and assembly of an Accessible Wade's style extruder and have been able to lower my temperatures back to 195 and easily print without jams.

I'm running a 2.84 gear ratio on the extruder to keep speeds up and hope to push the printer to higher speeds.

Thanks again for a solid hot end design. I believe you've one-up'd the E3D and similar clones with the one piece nozzle and the strength it provides.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] September 05, 2014 11:28PM |

Registered: 11 years ago Posts: 246 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] November 02, 2014 11:15PM |

Registered: 11 years ago Posts: 246 |

Hey Everyone,

Michael "ZennmasterM" Zenner just posted a review of the Prometheus Hot End!

You can check it out here if you are interested:

[www.youtube.com]

It has been several months since I first started this thread about my Prometheus Hot End and I have come a long way since then. I would not have been able to accomplish anything without the RepRap community so I'd like to thank you guys for all of the incredible support.

Keep on printing!

Eric

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Michael "ZennmasterM" Zenner just posted a review of the Prometheus Hot End!

You can check it out here if you are interested:

[www.youtube.com]

It has been several months since I first started this thread about my Prometheus Hot End and I have come a long way since then. I would not have been able to accomplish anything without the RepRap community so I'd like to thank you guys for all of the incredible support.

Keep on printing!

Eric

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] December 10, 2014 06:27PM |

Registered: 9 years ago Posts: 7 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] January 11, 2015 12:50PM |

Registered: 10 years ago Posts: 66 |

Please excuse me if this has been answered here before.

Does the Prometheus hot end mount in the same 'slot' as J-head or ALUhotends?

I had excellent results with the V5 ALUhotend on my repstrap, but the V6 I have on my Wilson seems to be having flow problems with the same PLA filament that worked well on the older hotend.

I have not yet tried swapping hot ends between the machines (it would be a mechanical nightmare at this point as the repstrap's x carriage is quite Rube Goldberg!)

When I have the funds available I would very much like to try replacing the ALUhotend in the Wilson with the Prometheus if it will be a drop in place without having to re-engineer the extruder (Marty's direct drive design fits J-Head style groove mount hotends, The ALUhot end fits well and he claims the E6D will mount also).

Does the Prometheus hot end mount in the same 'slot' as J-head or ALUhotends?

I had excellent results with the V5 ALUhotend on my repstrap, but the V6 I have on my Wilson seems to be having flow problems with the same PLA filament that worked well on the older hotend.

I have not yet tried swapping hot ends between the machines (it would be a mechanical nightmare at this point as the repstrap's x carriage is quite Rube Goldberg!)

When I have the funds available I would very much like to try replacing the ALUhotend in the Wilson with the Prometheus if it will be a drop in place without having to re-engineer the extruder (Marty's direct drive design fits J-Head style groove mount hotends, The ALUhot end fits well and he claims the E6D will mount also).

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] January 11, 2015 01:08PM |

Registered: 11 years ago Posts: 246 |

There should be no problems using the Prometheus in your set-up

My hot end uses exactly the same mounting dimensions as the J Head so it should be an easy drop in replacement.

Let me know if you have any more questions!

Thanks.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

My hot end uses exactly the same mounting dimensions as the J Head so it should be an easy drop in replacement.

Let me know if you have any more questions!

Thanks.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 07, 2015 05:47PM |

Registered: 11 years ago Posts: 246 |

Hey Everyone!

It has been a long time since I posted in these forums. It’s good to be back

With the success of the Prometheus hot end and hundreds of happy users around the world, we have received a lot of feedback about our product. In an effort to perfect the Prometheus Hot End we have developed Prometheus V2, an optimized, simpler, and more professional version of the original Prometheus V1. The goal with Prometheus V2 is to eliminate all of the quirks of V1 while further improving performance and user experience.

A few of the improvements over V1 include a quieter cooling fan, a professional heater cartridge and high temperature sleeving on the thermistor, simplified assembly with no soldering or Kapton tape required, embedded bowden collet for both 1.75mm and 3mm versions, and many more.

We are now selling Prometheus V2 (Beta) hot ends on our webstore

The objective of the beta release is to obtain feedback about our improvements and suggestions about anything else that can be further improved before the official V2 release.

There is a limited time offer of 10% off all store purchases for early adopters so do not hesitate to grab your V2 hot end today!

We also now offer 0.3mm, 0.4mm, and 0.6mm nozzles with V2 (which are also backward compatible with Prometheus V1).

They say a picture is worth a thousand words so I’ll just show you some pictures of Prometheus V2 instead of just blabbering on about it:

Below is a comprehensive outline of the design features of Prometheus V2:

V2 Design Features

- Durable, actively cooled, compact, all-metal construction for high-temperature extrusion up to 300C.

- Professional internal polishing along the full length of the nozzle creates a near mirror finish which reduces friction in the hot end. This eliminates jamming when printing PLA, even with long retractions in a Bowden system.

- The nozzle is machined from a single piece of stainless steel. The 1-piece design eliminates all internal “melt-zone” junctions making hot end leaks a thing of the past.

- Variable length “melt-zone” allows for the hot end to be customized according to your needs. From high precision to high speed printing, Prometheus V2 does it all.

- Heat Sink efficiently dissipates heat from the nozzle maintaining a sharp 2mm thermal transition at temperatures up to 300C. Optimized heat dissipation allows for a quieter cooling fan and minimizes vibrations.

- Internal geometry allows for the Bowden collet to be inserted directly into the heat sink enabling easy compact Bowden integration for both 1.75mm and 3mm versions. All heat sinks are Bowden compatible and switching between Bowden and Direct configuration takes just a few seconds.

- In both the Bowden and Direct configurations, a PTFE tube passes into the heat sink and facilitates a smooth filament path directly from your extruder into the 1-piece nozzle. This improves performance when printing flexible filaments like NinjaFlex. [Note: PTFE tubing is not subjected to high temperatures within the hot end.]

- Compact design conserves z-height and allows two hot ends to be placed as close as 16mm from each other, conserving print space in a dual extrusion set-up.

- Professional heater cartridge and high temp sleeving on the thermistor means that no messy Kapton tape is required! The thermistor is held in place with an M3 bolt and washer.

- Standard J-Head groovemount dimensions means that Prometheus V2 should fit most extruders and is a drop-in replacement for your old hot end.

-----------------------------------------------------------------

I’d be happy to hear any comments about Prometheus V2! Let me know what you think and just ask if you have any more questions

Happy Printing!

Eric

Edited 1 time(s). Last edit at 03/07/2015 06:53PM by RP Iron Man.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

It has been a long time since I posted in these forums. It’s good to be back

With the success of the Prometheus hot end and hundreds of happy users around the world, we have received a lot of feedback about our product. In an effort to perfect the Prometheus Hot End we have developed Prometheus V2, an optimized, simpler, and more professional version of the original Prometheus V1. The goal with Prometheus V2 is to eliminate all of the quirks of V1 while further improving performance and user experience.

A few of the improvements over V1 include a quieter cooling fan, a professional heater cartridge and high temperature sleeving on the thermistor, simplified assembly with no soldering or Kapton tape required, embedded bowden collet for both 1.75mm and 3mm versions, and many more.

We are now selling Prometheus V2 (Beta) hot ends on our webstore

The objective of the beta release is to obtain feedback about our improvements and suggestions about anything else that can be further improved before the official V2 release.

There is a limited time offer of 10% off all store purchases for early adopters so do not hesitate to grab your V2 hot end today!

We also now offer 0.3mm, 0.4mm, and 0.6mm nozzles with V2 (which are also backward compatible with Prometheus V1).

They say a picture is worth a thousand words so I’ll just show you some pictures of Prometheus V2 instead of just blabbering on about it:

Below is a comprehensive outline of the design features of Prometheus V2:

V2 Design Features

- Durable, actively cooled, compact, all-metal construction for high-temperature extrusion up to 300C.

- Professional internal polishing along the full length of the nozzle creates a near mirror finish which reduces friction in the hot end. This eliminates jamming when printing PLA, even with long retractions in a Bowden system.

- The nozzle is machined from a single piece of stainless steel. The 1-piece design eliminates all internal “melt-zone” junctions making hot end leaks a thing of the past.

- Variable length “melt-zone” allows for the hot end to be customized according to your needs. From high precision to high speed printing, Prometheus V2 does it all.

- Heat Sink efficiently dissipates heat from the nozzle maintaining a sharp 2mm thermal transition at temperatures up to 300C. Optimized heat dissipation allows for a quieter cooling fan and minimizes vibrations.

- Internal geometry allows for the Bowden collet to be inserted directly into the heat sink enabling easy compact Bowden integration for both 1.75mm and 3mm versions. All heat sinks are Bowden compatible and switching between Bowden and Direct configuration takes just a few seconds.

- In both the Bowden and Direct configurations, a PTFE tube passes into the heat sink and facilitates a smooth filament path directly from your extruder into the 1-piece nozzle. This improves performance when printing flexible filaments like NinjaFlex. [Note: PTFE tubing is not subjected to high temperatures within the hot end.]

- Compact design conserves z-height and allows two hot ends to be placed as close as 16mm from each other, conserving print space in a dual extrusion set-up.

- Professional heater cartridge and high temp sleeving on the thermistor means that no messy Kapton tape is required! The thermistor is held in place with an M3 bolt and washer.

- Standard J-Head groovemount dimensions means that Prometheus V2 should fit most extruders and is a drop-in replacement for your old hot end.

-----------------------------------------------------------------

I’d be happy to hear any comments about Prometheus V2! Let me know what you think and just ask if you have any more questions

Happy Printing!

Eric

Edited 1 time(s). Last edit at 03/07/2015 06:53PM by RP Iron Man.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 07, 2015 05:55PM |

Registered: 10 years ago Posts: 66 |

I've read the assembly instructions on line and something seems to have been left out. In the pictures there appear to be two "grub" or "locking" screws that would clamp the heatsink on the nozzle once the transition zone length has been set. The instructions do not mention the need to tighten these, I assume that this would be required to prevent the nozzle from moving in the heat sink.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 07, 2015 06:01PM |

Registered: 11 years ago Posts: 246 |

Thanks for proofreading! I'll add that in right away

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] August 06, 2015 07:16PM |

Registered: 11 years ago Posts: 246 |

Hey Everyone,

It has been a while since I last posted here. I have recently put together a comprehensive user guide for the Prometheus V2! This guide outlines the trade-offs involved in configuring the Melt-Zone and Transition-Zone of the Prometheus and will help you get the most out of your hot end. Check it out:

User Guide

We are also now offering new Prometheus V2 nozzles in 0.3mm, 0.4mm, 0.6mm, and 1mm nozzle sizes! These extra nozzles are available here:

V2 Nozzles

The nozzle length scales with orifice size so the larger orifice nozzles can be assembled with longer Melt-Zones to allow for higher flow rates. It also makes nozzle identification much easier

24V electronics are now available as an option for those of you who run 24V printers ([www.dta-labs.com]).

The old V1.1 nozzles are now heavily discounted for quick sale at just $15.50 each ([www.dta-labs.com]).

Our 10% off sale ends on August 14 so be sure to grab your Prometheus V2 before it's over!

Happy Printing

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

It has been a while since I last posted here. I have recently put together a comprehensive user guide for the Prometheus V2! This guide outlines the trade-offs involved in configuring the Melt-Zone and Transition-Zone of the Prometheus and will help you get the most out of your hot end. Check it out:

User Guide

We are also now offering new Prometheus V2 nozzles in 0.3mm, 0.4mm, 0.6mm, and 1mm nozzle sizes! These extra nozzles are available here:

V2 Nozzles

The nozzle length scales with orifice size so the larger orifice nozzles can be assembled with longer Melt-Zones to allow for higher flow rates. It also makes nozzle identification much easier

24V electronics are now available as an option for those of you who run 24V printers ([www.dta-labs.com]).

The old V1.1 nozzles are now heavily discounted for quick sale at just $15.50 each ([www.dta-labs.com]).

Our 10% off sale ends on August 14 so be sure to grab your Prometheus V2 before it's over!

Happy Printing

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

Sorry, only registered users may post in this forum.