“Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures]

[Many Pictures]

Posted by RP Iron Man

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 08, 2014 02:06AM |

Registered: 11 years ago Posts: 791 |

Try using a cheap WebCam for taking the video. They are light, small and readily available. I bought a few for this purpose on ebay and they cost less than $10 each.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 08, 2014 02:29AM |

Registered: 11 years ago Posts: 791 |

Quote

The nut below the heat sink is a necessary part of the design that I don't really like. The nut is necessary to secure the SS nozzle to the heat sink but impedes the cooling of the "cold-side".

I am using a similar design, but not all metal. To adjust the zones I also use the adjustment of the threaded length, but to fix the thread and the heatsink (and also the aluminium heater block) I use set screws or grubs screws they are called here in Australia. Both the heater block and the heatsink are drilled and tapped with M3 to take the set screws and the set screws bite into the threaded length.

I lightly set them to start with, do my testings and when I am happy, I screw them in tight because I wont want to move them again. Down side is that they can be hard to adjust later if needed. Upside is that they are neat, easy to fit, cost effective, less weight, no heat transfer.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 08, 2014 04:49AM |

Registered: 10 years ago Posts: 1,381 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 08, 2014 02:06PM |

Registered: 11 years ago Posts: 246 |

Quote

regpye

Try using a cheap WebCam for taking the video. They are light, small and readily available. I bought a few for this purpose on ebay and they cost less than $10 each.

That seems like a good idea for filming prints as it could be mounted to the carriage. How is the video quality?

Quote

regpye

I am using a similar design, but not all metal. To adjust the zones I also use the adjustment of the threaded length, but to fix the thread and the heatsink (and also the aluminium heater block) I use set screws or grubs screws they are called here in Australia. Both the heater block and the heatsink are drilled and tapped with M3 to take the set screws and the set screws bite into the threaded length.

I lightly set them to start with, do my testings and when I am happy, I screw them in tight because I wont want to move them again. Down side is that they can be hard to adjust later if needed. Upside is that they are neat, easy to fit, cost effective, less weight, no heat transfer.

This is something that I considered earlier on as it provides a much neater solution. However, there are a few reasons why I dropped the set screw design in favor of my current hex nut design. The obvious advantages to using set screw are that:

- they look good

- they eliminate the hex nut at the base of the heat sink (the most significant benefit)

- easy to find.

However, there are also some drawbacks to this design:

- Difficult to adjust the SS nozzle once the set screws are tightened. Try moving the SS Heater Cartridge in the heat block of your E3D hot end once you have printed with it at 200C+ and you will see what I mean. It is very difficult if not nearly impossible. This is due to the thermal expansion of the metal, but this problem may not be as significant in the heat sink where the metals are much cooler.

- Risk of the user over-tightening the set screws and damaging the threads on the SS nozzle and risk of under-tightening and having the nozzle move during printing.

- Theoretically less contact between the threads. In addition, since the set screws push the threaded portion against one side of the heat sink there may be uneven cooling of the "cold-zone" of the SS nozzle.

- Added machining operations of drilling and tapping.

Some of these drawbacks may not be significant in your testing, but they negatively affect easy of use and make it easier for the user to damage the product. If I was designing this for myself I may consider going with the set screw approach, but I think using hex nuts simplifies assembly and zone adjustment for the user and makes the design more rugged.

There are definitely trade-offs involved in this choice, but I think I made the appropriate choice based on the application.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 09, 2014 11:41PM |

Registered: 12 years ago Posts: 27 |

Wow! Looks Good! Almost like mine! ;-)

I built my new hot end from bits two weeks ago - End of Feb. 2014 - Motivated from a slipped out thermistor having created a Hot, Bubbling, Smoking, PEEK Melt Down!!!! [Factoid: Per Wikipedia -- PEEK "...melts around 343 °C (662 °F)..."]

Looking forward to see the Prometheus Indiegogo!

Brian

Pittsburgh, PA

I built my new hot end from bits two weeks ago - End of Feb. 2014 - Motivated from a slipped out thermistor having created a Hot, Bubbling, Smoking, PEEK Melt Down!!!! [Factoid: Per Wikipedia -- PEEK "...melts around 343 °C (662 °F)..."]

Looking forward to see the Prometheus Indiegogo!

Brian

Pittsburgh, PA

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 10, 2014 12:21AM |

Registered: 10 years ago Posts: 1,381 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 10, 2014 01:44AM |

Registered: 11 years ago Posts: 246 |

Quote

bstott

Wow! Looks Good! Almost like mine! ;-)

I built my new hot end from bits two weeks ago - End of Feb. 2014 - Motivated from a slipped out thermistor having created a Hot, Bubbling, Smoking, PEEK Melt Down!!!! [Factoid: Per Wikipedia -- PEEK "...melts around 343 °C (662 °F)..."]

Looking forward to see the Prometheus Indiegogo!

Brian

Pittsburgh, PA

Thanks! I'd really like to see your hot end

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 10, 2014 02:59AM |

Registered: 11 years ago Posts: 791 |

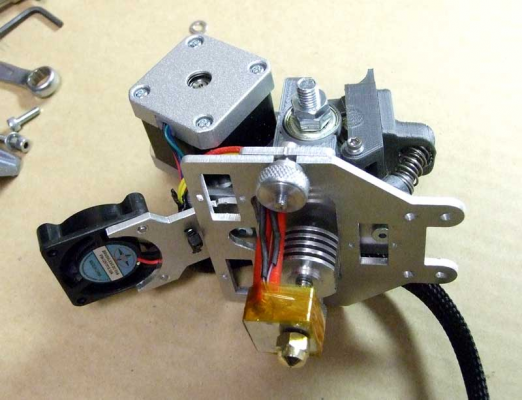

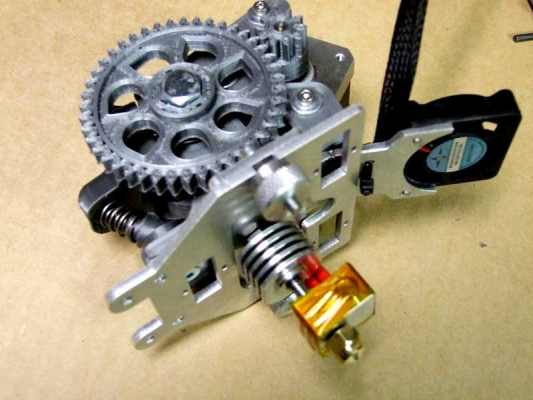

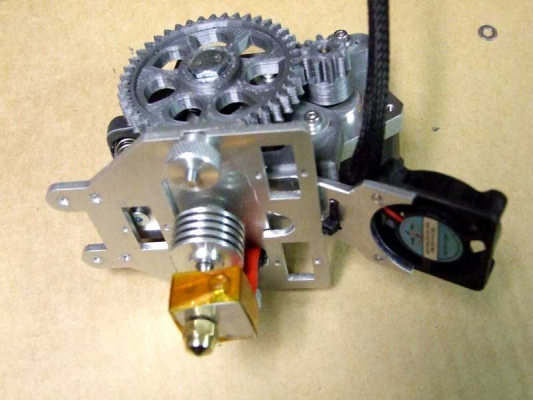

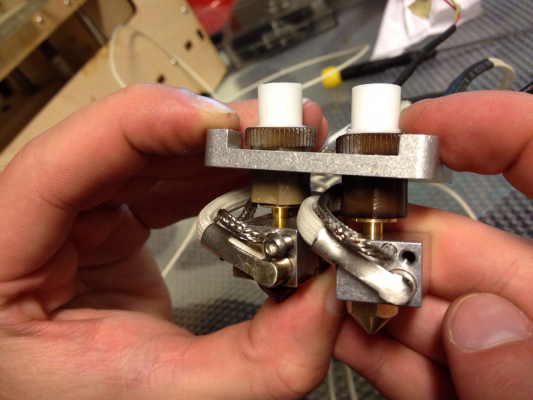

These are old photos and I have changed the hotend a little since then, however the same principles still apply.

No fan was required for cooling the hotend. I can put my fingers on the cooling fins while the hotend nozzle is up to temp of 220C and can hardly feel any heat at all.

The fan attached is for cooling PLA as it is being printed and is controlled by the D9 on RAMPS.

A little hard to see, however the adjustment is by the thread and set screws lock it in place once a satisfactory position has been found. Once found I set all other hotends the same from there on because they just work so well at that. Can print all day and night and very rarely get a jam, in fact the only time I have had a jam has been when there has been a thick section in the spool of PLA which happens sometimes, and the jam actually happens at the extruder, not the hotend.

Hope you get some ideas from these photos. The whole assembly connects to the aluminium carriage by two knurled nuts, so it is pretty quick to take the assembly off the machine if ever needed.

I made the nozzle removable so that I could change the size as required. I have 0.3mm, 0.4mm and 0.5mm nozzles.

The nozzles have been made with a seat inside that has a 118 degree land and the stainless shaft that goes through the heater block also has a 118 degree end to match. This stops any leaking I have found. It is important that the nozzle does not come in contact with the heater block, it must be away from it so that a good seal can be made against the lands.

You can see a small hole in the heater block that has a 3mm set screw inside. That is what locks the heater block in place. There is another similar in the aluminium heat sink (not visible) and this allows the heat sink to be moved up or down and the locked in place.

I mainly use this hotend for PLA as that is the main material that I print with.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

No fan was required for cooling the hotend. I can put my fingers on the cooling fins while the hotend nozzle is up to temp of 220C and can hardly feel any heat at all.

The fan attached is for cooling PLA as it is being printed and is controlled by the D9 on RAMPS.

A little hard to see, however the adjustment is by the thread and set screws lock it in place once a satisfactory position has been found. Once found I set all other hotends the same from there on because they just work so well at that. Can print all day and night and very rarely get a jam, in fact the only time I have had a jam has been when there has been a thick section in the spool of PLA which happens sometimes, and the jam actually happens at the extruder, not the hotend.

Hope you get some ideas from these photos. The whole assembly connects to the aluminium carriage by two knurled nuts, so it is pretty quick to take the assembly off the machine if ever needed.

I made the nozzle removable so that I could change the size as required. I have 0.3mm, 0.4mm and 0.5mm nozzles.

The nozzles have been made with a seat inside that has a 118 degree land and the stainless shaft that goes through the heater block also has a 118 degree end to match. This stops any leaking I have found. It is important that the nozzle does not come in contact with the heater block, it must be away from it so that a good seal can be made against the lands.

You can see a small hole in the heater block that has a 3mm set screw inside. That is what locks the heater block in place. There is another similar in the aluminium heat sink (not visible) and this allows the heat sink to be moved up or down and the locked in place.

I mainly use this hotend for PLA as that is the main material that I print with.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 10, 2014 03:14PM |

Registered: 12 years ago Posts: 27 |

@ RP Iron Man & regpye - Those look like art. Nice.

My SS hot end transmitts heat quite fast without a fan. But, with a fan - it is very manageable.

I posted regarding the event to making mine - http://forums.reprap.org/read.php?1,322466

My SS hot end transmitts heat quite fast without a fan. But, with a fan - it is very manageable.

I posted regarding the event to making mine - http://forums.reprap.org/read.php?1,322466

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 10, 2014 09:45PM |

Registered: 11 years ago Posts: 374 |

RP Iron Man,

this is Argento Hotend:

The Argento hotend is 2 years old and the current version is 4 and as you can see the design is quite similar. I've been through many battles against filament types, transition zone, temperatures, and much more. If you need some feedback on the design or even machining, let me know.

Regards from Argentina

Javier

(EDIT Note: image upload error)

Edited 3 time(s). Last edit at 03/10/2014 09:57PM by jameghino.

this is Argento Hotend:

The Argento hotend is 2 years old and the current version is 4 and as you can see the design is quite similar. I've been through many battles against filament types, transition zone, temperatures, and much more. If you need some feedback on the design or even machining, let me know.

Regards from Argentina

Javier

(EDIT Note: image upload error)

Edited 3 time(s). Last edit at 03/10/2014 09:57PM by jameghino.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 08:05AM |

Registered: 12 years ago Posts: 27 |

Regarding Prometheus -

On another thread -- A2 and I have had a short discussion about heat. It has come up that horizontal fins are not necessarily correct for the design of a passive hot end. I've reflected on this and have had experience with air cooled devices. A2 had already been discussing vertical heat flow so this brought to mind - fins radiating out from an item are generally intended to channel air flow from motion. Either motion of the device as in a motorcycle, auto or airplane engine head through the air or laminar air flow from an active fan. But, our hot ends are static. This means we ultimately will require a cooling fan to be truly effective. I remembered what happens to my previous use examples - the motors/engines, if not in motion - get hot. In the case of the auto and airplane, they overheat more slowly when static because they do have active fan systems in place. The auto's fan was connected to the flywheel in the case of an old Volks Wagen engine and a propellor in the case of an airplane.

What am I getting at? Well - our printers are not cruising through our environments - yet. They are sitting and the horizontal fin structure for cooling is demaning airflow to actually be efficient. They really do require a fan --- OR --- as A2 has suggested, in the other thread, we change the design to take more advantage of convective heat flow by using vertical fins. Then, if under heavy use, include the fans. Currently, the situation where horizontal/radial fins are working on a hot end wtihout a fan simply means that the delicate balance of the dissipative material's heat volume, external surface area and contact area to the heat source is sufficient to keep the hot ends functioning. (A Lucky guess has been realized.) Without the use of a fan, the present fins machined orthogonal to the riser are contributing very, very little to the actual cooling of the devices. That is ---- Again, we are currently being lucky ---- Not well engineered.

My little hot end - which is common to the designs we are discussing - requires a fan or it quickly heats and jams. It works. My best quesses, time and luck will show how well. It is sure, my printer will not print beyond the capability of its hot end or other limiting guessed at components.

Suggestion: We go vertical fins if we want to stay sans fan. But note that as we print faster we need more heat and with more heat and longer prints we have accumulation of heat in the components and we will require more active style cooling systems. It would not be hard to adapt computer water coolers but, do you print at that rate yet? OR - Maybe you wish to design such a component to be ready for the next wave of evolution in the printers?

As for this thread's hot end? There is deifnitely some more demand and interest to drain out of the new 3D printing market so, there is room for more crowd sourced same type items. Remember how many cereal varieties on the shelf we have at the stores. Many are the same type of flakes in different boxes from different sources yet, not really different. They compete with noise not difference. Here too there is not be any real difference or innovation- yet.

Oh, don't get me wrong ---- Our 3D market does not have enough easily known or accessed parts from reliable sources as this hot end. The market is Brand New and there are many discovering the industry. There are many wanting to enter to build printers and crowd source is a good venue to find parts and help each other. Many manufacturers are emerging and vying for space. So - this item is well timed. It just really isn't engineered or quite - WOW! - and not the next neat item but, its time is NOW! It is attractive. If you time your production to accurate delivery you will be a gem to your supporters. MHO FWIW

On another thread -- A2 and I have had a short discussion about heat. It has come up that horizontal fins are not necessarily correct for the design of a passive hot end. I've reflected on this and have had experience with air cooled devices. A2 had already been discussing vertical heat flow so this brought to mind - fins radiating out from an item are generally intended to channel air flow from motion. Either motion of the device as in a motorcycle, auto or airplane engine head through the air or laminar air flow from an active fan. But, our hot ends are static. This means we ultimately will require a cooling fan to be truly effective. I remembered what happens to my previous use examples - the motors/engines, if not in motion - get hot. In the case of the auto and airplane, they overheat more slowly when static because they do have active fan systems in place. The auto's fan was connected to the flywheel in the case of an old Volks Wagen engine and a propellor in the case of an airplane.

What am I getting at? Well - our printers are not cruising through our environments - yet. They are sitting and the horizontal fin structure for cooling is demaning airflow to actually be efficient. They really do require a fan --- OR --- as A2 has suggested, in the other thread, we change the design to take more advantage of convective heat flow by using vertical fins. Then, if under heavy use, include the fans. Currently, the situation where horizontal/radial fins are working on a hot end wtihout a fan simply means that the delicate balance of the dissipative material's heat volume, external surface area and contact area to the heat source is sufficient to keep the hot ends functioning. (A Lucky guess has been realized.) Without the use of a fan, the present fins machined orthogonal to the riser are contributing very, very little to the actual cooling of the devices. That is ---- Again, we are currently being lucky ---- Not well engineered.

My little hot end - which is common to the designs we are discussing - requires a fan or it quickly heats and jams. It works. My best quesses, time and luck will show how well. It is sure, my printer will not print beyond the capability of its hot end or other limiting guessed at components.

Suggestion: We go vertical fins if we want to stay sans fan. But note that as we print faster we need more heat and with more heat and longer prints we have accumulation of heat in the components and we will require more active style cooling systems. It would not be hard to adapt computer water coolers but, do you print at that rate yet? OR - Maybe you wish to design such a component to be ready for the next wave of evolution in the printers?

As for this thread's hot end? There is deifnitely some more demand and interest to drain out of the new 3D printing market so, there is room for more crowd sourced same type items. Remember how many cereal varieties on the shelf we have at the stores. Many are the same type of flakes in different boxes from different sources yet, not really different. They compete with noise not difference. Here too there is not be any real difference or innovation- yet.

Oh, don't get me wrong ---- Our 3D market does not have enough easily known or accessed parts from reliable sources as this hot end. The market is Brand New and there are many discovering the industry. There are many wanting to enter to build printers and crowd source is a good venue to find parts and help each other. Many manufacturers are emerging and vying for space. So - this item is well timed. It just really isn't engineered or quite - WOW! - and not the next neat item but, its time is NOW! It is attractive. If you time your production to accurate delivery you will be a gem to your supporters. MHO FWIW

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 03:19PM |

Registered: 11 years ago Posts: 246 |

Quote

jameghino

The Argento hotend is 2 years old and the current version is 4 and as you can see the design is quite similar. I've been through many battles against filament types, transition zone, temperatures, and much more. If you need some feedback on the design or even machining, let me know.

Regards from Argentina

Javier

Thanks for sharing this Javier

Do you have any problems printing PLA with your hot end? Is it actively cooled with a fan? Have you done any sort of internal polishing on the SS barrel?

Quote

bstott

Regarding Prometheus -

On another thread -- A2 and I have had a short discussion about heat. It has come up that horizontal fins are not necessarily correct for the design of a passive hot end. I've reflected on this and have had experience with air cooled devices. A2 had already been discussing vertical heat flow so this brought to mind - fins radiating out from an item are generally intended to channel air flow from motion. Either motion of the device as in a motorcycle, auto or airplane engine head through the air or laminar air flow from an active fan. But, our hot ends are static. This means we ultimately will require a cooling fan to be truly effective. I remembered what happens to my previous use examples - the motors/engines, if not in motion - get hot. In the case of the auto and airplane, they overheat more slowly when static because they do have active fan systems in place. The auto's fan was connected to the flywheel in the case of an old Volks Wagen engine and a propellor in the case of an airplane.

What am I getting at? Well - our printers are not cruising through our environments - yet. They are sitting and the horizontal fin structure for cooling is demaning airflow to actually be efficient. They really do require a fan --- OR --- as A2 has suggested, in the other thread, we change the design to take more advantage of convective heat flow by using vertical fins. Then, if under heavy use, include the fans. Currently, the situation where horizontal/radial fins are working on a hot end wtihout a fan simply means that the delicate balance of the dissipative material's heat volume, external surface area and contact area to the heat source is sufficient to keep the hot ends functioning. (A Lucky guess has been realized.) Without the use of a fan, the present fins machined orthogonal to the riser are contributing very, very little to the actual cooling of the devices. That is ---- Again, we are currently being lucky ---- Not well engineered.

My little hot end - which is common to the designs we are discussing - requires a fan or it quickly heats and jams. It works. My best quesses, time and luck will show how well. It is sure, my printer will not print beyond the capability of its hot end or other limiting guessed at components. winking smiley

Suggestion: We go vertical fins if we want to stay sans fan. But note that as we print faster we need more heat and with more heat and longer prints we have accumulation of heat in the components and we will require more active style cooling systems. It would not be hard to adapt computer water coolers but, do you print at that rate yet? OR - Maybe you wish to design such a component to be ready for the next wave of evolution in the printers?

As for this thread's hot end? There is deifnitely some more demand and interest to drain out of the new 3D printing market so, there is room for more crowd sourced same type items. Remember how many cereal varieties on the shelf we have at the stores. Many are the same type of flakes in different boxes from different sources yet, not really different. They compete with noise not difference. Here too there is not be any real difference or innovation- yet.

Oh, don't get me wrong ---- Our 3D market does not have enough easily known or accessed parts from reliable sources as this hot end. The market is Brand New and there are many discovering the industry. There are many wanting to enter to build printers and crowd source is a good venue to find parts and help each other. Many manufacturers are emerging and vying for space. So - this item is well timed. It just really isn't engineered or quite - WOW! - and not the next neat item but, its time is NOW! It is attractive. If you time your production to accurate delivery you will be a gem to your supporters. MHO FWIW

grinning smiley

I don't think you intended this but I feel pretty insulted by your incomplete assessment of my design. Your assessment ignores many engineering constraints that I had to deal with and seems to oversimplify the problems involved with hot end design.

Quote

bstott

there is room for more crowd sourced same type items...Here too there is not be any real difference or innovation- yet. ...

First of all, my design is NOT a "same type item". In fact if you look at all other all metal hot end designs, mine is by far the most unique as enables users to modify the "melt-zone", "transition-zone", and thermistor position in the "melt-zone" so each user can have a hot end fully customized to their needs! In fact, the reason I chose to develop this design is because I thought the hot end market was becoming too stagnant with iterations of all metal hot ends that did not achieve anything more than "high temperature printing". This is a SIGNIFICANT difference in innovation because it serves as an all-in-one solution that is fully user customizable so this design can be optimized for a variety of printer configurations. No other all metal hot ends on the market are capable of this. Being able to modify these parameters is actually a huge leap forward as these parameters are key features of a hot end that govern extrusion behaviour.

Quote

bstott

It just really isn't engineered or quite - WOW! - and not the next neat item but, its time is NOW!

I don't understand why you would say this. This statement is simply just wrong. EVERY single aspect of this design is fully engineered and optimized for the performance of customizability of the hot end. If you have any doubts about anything just ask and I will clarify my design decisions. Since you were initially discussing the heat sink/cooling design, I will assume that you were referring to that aspect of my hot end so I will try to respond to that.

You and A2 were discussing how using a passively cooled heat sink with vertical fins would be superior (and more innovative?) than the standard actively cooled heat sink with horizontal fins that you find on conventional designs. I can tell you that this is not the case for a variety of reasons. First of all, always remember that if something is being done a certain way for a long time (horizontal heat sinks in this case) there is probably a good reason. In this case, there are many good reasons. Lets start by outlining the advantages and disadvantages of each design:

Passively cooled heat sink with vertical fins:

----Advantages-----

- No cooling fan (I am not sure why this is so important as the benefits of a cooling fan completely outweigh the drawbacks)

- Heat rises so this design takes advantage of the natural convection of the hot air radiating from the heat sink.

-----Disadvantages------

- LARGE (VERY large) heat sink required because you are not using active cooling. This will add A LOT of weight and bulk to the hot end. Alternatively, to minimise the heat transfer to the heat sink, you would have to lengthen the "transition-zone" and this would decrease reliability. This would not work with my customizable design and would not allow you to have a very short "transition-zone". Added weight and decreased reliability are not ideal for a consumer hot end.

- MOST OF THE HEAT GETS TRAPPED UNDER THE CARRIAGE so the vertical fins are actually not a good idea. If you look at the standard x carriage, you will see that there will be nowhere for the air to go if you have vertically oriented fins. Vertical fins are not rocket science and I (and I am sure many other hot end developers) have though about this before. It will just rise and get trapped and heat up the plastic carriage. While the carriage does not move super fast on most printers, the convection generated by the moving carriage will provide better cooling for horizontally oriented fins which is why it may even be better to have a horizontal heat sink for passively cooled hot ends.

- Added machining costs. It is MUCH cheaper to turn in the fins of a horizontal heat sink than to mill vertical fins. I have received quotes for earlier designs that illustrate this vast increase in cost.

- Very little room for error as the "cold-zone" boundaries are not as strictly controlled. This leads to inconsistent performance across different temperatures.

Actively cooled heat sink with horizontal fins:

----Advantages-----

- Heat sink can be designed so that the cooling fan blows air directly over the fins to maximize cooling. As in my heat sink design where cooling is optimized.

- Heat does not get trapped under the carriage.

- Lightweight and compact as you do not require a large heat sink.

- Consistent performance in a range of printing scenarios due to the controlled "cold-zone" boundaries that are possible with active cooling.

- Large margins for error. Important for ALL consumer products as different people have different printer set ups.

- Having a more control over the "cold-zone" boundaries allows you to shorten the "transition-zone" and is necessary for my customizable design as it ensures that the hot end will be able to perform in all "melt-zone" and "transition-zone" configurations.

- Much lower machining costs.

- OVERALL: In all scenarios the added reliability and performance of an active cooled hot end is very important for a consumer product.

-----Disadvantages------

Requires a cooling fan. (Though this should not be seen as a disadvantage as it more than makes up for the extra hassle of wiring it up to you electronics)

-----------------

I am not sure why you think my design is a "same type item" or "isn't engineered" and I am not sure why you would claim that a passively cooled vertically oriented heat sink would be more innovative? (as it would not add any performance enhancement to the hot end) Engineering decisions are a lot more complex than just "fan or no fan" and there are a large number of good reasons why my hot end is designed the way it is. In fact, in this case the benefits of having a fan easily outweigh the disadvantages. If you are unsure about something then just ask. I am happy to clarify my design decisions

TL;DR

Just please don't make a post like that which states your narrow conjectures as absolutes. I am sure there are people who may not know about the merits of active cooled designs and they may not be able to make a critical assessment of your claims. Your statements will encourage people to think that my design is just another plain old hot end that was not clearly thought out while it has actually been very thoroughly engineered for its application.

Eric

Edited 1 time(s). Last edit at 03/11/2014 06:02PM by RP Iron Man.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 06:00PM |

Registered: 11 years ago Posts: 246 |

Hey guys,

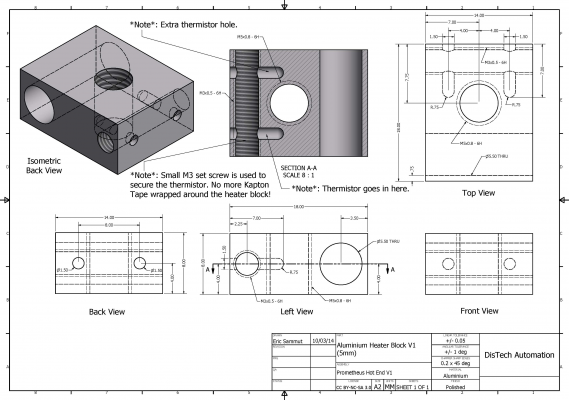

Over the last few days I have been making some last minute improvements to the design.

I have recently made some slight adjustments to the heater block in order to improve a few details of the design. I think the most important improvement is that the thermistor will no longer be secured to the heater block by Kapton Tape! Wrapping Kapton Tape around the heater block is a messy, unreliable, and unattractive way to secure the thermistor so I really wanted to do away with this approach.

Wrapping Kapton Tape around the heater block is a messy, unreliable, and unattractive way to secure the thermistor so I really wanted to do away with this approach.

Check out a revised technical drawing of the heater block design below:

I recently came up with a simple solution that allows the user to secure the thermistor without the use of Kapton Tape. As illustrated in the technical drawing above, a set screw secures the thermistor in the heater block and eliminates the possibility of the thermistor falling out. This is an improvement to both the reliability of the thermistor and the aesthetic appeal of the hot end. As you guys probably noticed in my videos, having Kapton Tape wrapped around the heater block didn't look pretty so this design improvement should help the Prometheus Hot End look as good as it performs

This improvement adds to the manufacturing costs but I will absorb this cost as I think the benefit of not having a Kapton Tape secured thermistor is worth it. To balance out the increased manufacturing costs a little I eliminated the support for the EPCOS thermistor since it is a discontinued item anyway. Now the extra thermistor hole also sized to fit the standard Semitec 100K glass bead thermistor. This still allows for a second “redundant” thermistor for added reliability but it must be a Semitec thermistor.

All my revised drawings are now up on my Flickr Photostream here.

What do you guys think of this?

Eric

Over the last few days I have been making some last minute improvements to the design.

I have recently made some slight adjustments to the heater block in order to improve a few details of the design. I think the most important improvement is that the thermistor will no longer be secured to the heater block by Kapton Tape!

Wrapping Kapton Tape around the heater block is a messy, unreliable, and unattractive way to secure the thermistor so I really wanted to do away with this approach.

Wrapping Kapton Tape around the heater block is a messy, unreliable, and unattractive way to secure the thermistor so I really wanted to do away with this approach. Check out a revised technical drawing of the heater block design below:

I recently came up with a simple solution that allows the user to secure the thermistor without the use of Kapton Tape. As illustrated in the technical drawing above, a set screw secures the thermistor in the heater block and eliminates the possibility of the thermistor falling out. This is an improvement to both the reliability of the thermistor and the aesthetic appeal of the hot end. As you guys probably noticed in my videos, having Kapton Tape wrapped around the heater block didn't look pretty so this design improvement should help the Prometheus Hot End look as good as it performs

This improvement adds to the manufacturing costs but I will absorb this cost as I think the benefit of not having a Kapton Tape secured thermistor is worth it. To balance out the increased manufacturing costs a little I eliminated the support for the EPCOS thermistor since it is a discontinued item anyway. Now the extra thermistor hole also sized to fit the standard Semitec 100K glass bead thermistor. This still allows for a second “redundant” thermistor for added reliability but it must be a Semitec thermistor.

All my revised drawings are now up on my Flickr Photostream here.

What do you guys think of this?

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 06:07PM |

Admin Registered: 15 years ago Posts: 1,470 |

I'm having trouble visualizing how this would work without the set screw shearing the thermistor leads or damaging the thermistor itself. Have you tried this solution in practice? Maybe I'm thinking about it wrong and it works just fine.Quote

RP Iron Man

a set screw secures the thermistor in the heater block and eliminates the possibility of the thermistor falling out.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 06:35PM |

Registered: 11 years ago Posts: 246 |

Quote

NewPerfection

I'm having trouble visualizing how this would work without the set screw shearing the thermistor leads or damaging the thermistor itself. Have you tried this solution in practice? Maybe I'm thinking about it wrong and it works just fine.Quote

RP Iron Man

a set screw secures the thermistor in the heater block and eliminates the possibility of the thermistor falling out.

Ok, I definitely did not explain that very clearly.

The basic idea is that you push the thermistor all the way into the hole past the threaded portion until it touches the end, and then you screw in the set screw until it covers about half of the thermistor hole. This way the thermistor cannot be pulled back out of the hole unless the set screw is unscrewed. This way the set screw prevents the thermistor from being pulled out without exerting force on the actual thermistor (the set screw is not tightened against the thermistor bead). I just came up with this yesterday so I haven't physically tested this but there does not seem to be any problem with this solution.

The set screw would end up shearing the thermistor leads if you just kept on threading the set screw past the thermistor hole, but that is easy to avoid with some clear instructions. I am going to use M3 x 3mm set screws and the distance between the center of the thermistor hole and the side of the heater block is exactly 3mm so you would just have to thread it flush with the side of the heater block. There is even room for a little over-tightening/under-tightening so that should not be an issue. Of course, I will include all of this in the instructions.

If anyone notices a major problem with this design please let me know.

Eric

Edited 1 time(s). Last edit at 03/11/2014 06:36PM by RP Iron Man.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 06:59PM |

Admin Registered: 15 years ago Posts: 1,470 |

The issue I see is that the set-screw cannot be tightened to stay in place, so would require a thread locking compound to keep it from working loose. Also, I could see many people not reading directions properly and screwing in the set-screw too far and shearing the thermistor leads.Quote

RP Iron Man

If anyone notices a major problem with this design please let me know.

A possible solution to consider is using a regular screw (with maybe a low-profile head to look nice) that was the proper length (any M3x3mm screw should work), so that it could be inserted and tightened down without worrying about it loosening or damaging the thermistor.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 07:11PM |

Registered: 11 years ago Posts: 246 |

Quote

NewPerfection

The issue I see is that the set-screw cannot be tightened to stay in place, so would require a thread locking compound to keep it from working loose. Also, I could see many people not reading directions properly and screwing in the set-screw too far and shearing the thermistor leads.Quote

RP Iron Man

If anyone notices a major problem with this design please let me know.

A possible solution to consider is using a regular screw (with maybe a low-profile head to look nice) that was the proper length (any M3x3mm screw should work), so that it could be inserted and tightened down without worrying about it loosening or damaging the thermistor.

Yeah, I wasn't sure about that either. I didn't consider regular M3 screws for aesthetic reasons. However, it may be better to do as you suggest and use a low profile screw so that I won't have to worry about the screw loosening or damaging the leads. Easy of assembly is definitely more important than looks.

Unfortunately, my hardware supplier does not carry M3x3 button head screws. These are actually pretty hard to find so I will probably have to get these from overseas

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 08:30PM |

Admin Registered: 15 years ago Posts: 1,470 |

Are you located in the US? If so: [www.mcmaster.com] or [www.ebay.com] ($0.04 each or $0.03 each)Quote

RP Iron Man

Unfortunately, my hardware supplier does not carry M3x3 button head screws. These are actually pretty hard to find so I will probably have to get these from overseas

If you are concerned about looks, another option is to countersink the M3 hole and use a flat head screw: [www.mcmaster.com] or [www.mrmetric.com] ($0.06 each or $0.01 each, plus the cost associated with an extra machining step)

Edited 1 time(s). Last edit at 03/11/2014 08:36PM by NewPerfection.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 08:48PM |

Registered: 11 years ago Posts: 246 |

Quote

NewPerfection

Are you located in the US? If so: [www.mcmaster.com] or [www.ebay.com] ($0.04 each or $0.03 each)Quote

RP Iron Man

Unfortunately, my hardware supplier does not carry M3x3 button head screws. These are actually pretty hard to find so I will probably have to get these from overseas

If you are concerned about looks, another option is to countersink the M3 hole and use a flat head screw: [www.mcmaster.com] or [www.mrmetric.com] ($0.06 each or $0.01 each, plus the cost associated with an extra machining step)

Thanks for the info. I live in Canada so I am not sure if McMaster Carr ships here.

I don't want to add any more machining steps so I'll probably just stick with the cap screws. The ones you linked to would work fine. I already found a good Chinese supplier of M3x3 button head cap screws and I am already using M3 button head cap screws to secure the cooling fan to the heat sink so I would rather remain consistent. These fasteners weigh a fraction of a gram so shipping should not be too expensive. If I have problems with ordering these I can just use the Philips head fasteners you mentioned as backup, so in either case I should be fine.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 09:08PM |

Registered: 12 years ago Posts: 27 |

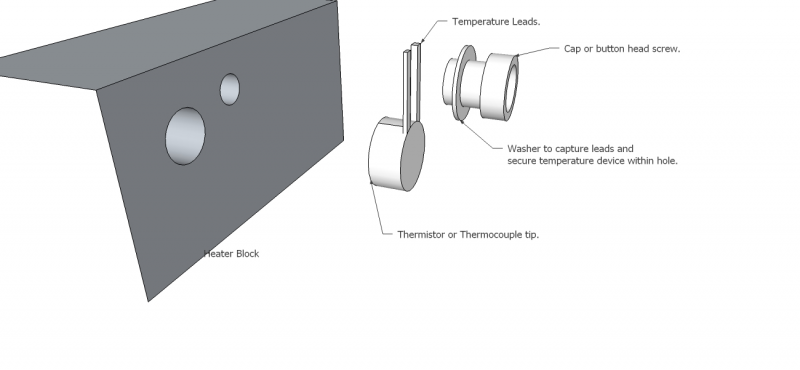

Screw Thermistor?

Just a quickie --- I've seen screw mount thermistors. Here's a picture. Would you be able to drill a set screw center and pass through the thermistor leads? Then silicone seal the device into the head? Hand tight?

Oh, Eric --- I'm kinda beat today --- I'll respond to your hurt feelings. I know you are putting in effort - we all do. And I like the look. It is a jewel. Later, Brian.

P.S. button head screws ---- boltdepot.com

edit: I forgot. Use the button head of the screw with a washer to capture the thermistor leads against the block and hold the thermistor in the hole. A dab of RTV silicone seal to cover up the Thermistor - Good to over 300°C.

Edited 2 time(s). Last edit at 03/11/2014 09:15PM by bstott.

Just a quickie --- I've seen screw mount thermistors. Here's a picture. Would you be able to drill a set screw center and pass through the thermistor leads? Then silicone seal the device into the head? Hand tight?

Oh, Eric --- I'm kinda beat today --- I'll respond to your hurt feelings. I know you are putting in effort - we all do. And I like the look. It is a jewel. Later, Brian.

P.S. button head screws ---- boltdepot.com

edit: I forgot. Use the button head of the screw with a washer to capture the thermistor leads against the block and hold the thermistor in the hole. A dab of RTV silicone seal to cover up the Thermistor - Good to over 300°C.

Edited 2 time(s). Last edit at 03/11/2014 09:15PM by bstott.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 11, 2014 10:44PM |

Registered: 11 years ago Posts: 246 |

Quote

bstott

Screw Thermistor?

Just a quickie --- I've seen screw mount thermistors. Here's a picture. Would you be able to drill a set screw center and pass through the thermistor leads? Then silicone seal the device into the head? Hand tight?

Oh, Eric --- I'm kinda beat today --- I'll respond to your hurt feelings. I know you are putting in effort - we all do. And I like the look. It is a jewel. Later, Brian.

P.S. button head screws ---- boltdepot.com

edit: I forgot. Use the button head of the screw with a washer to capture the thermistor leads against the block and hold the thermistor in the hole. A dab of RTV silicone seal to cover up the Thermistor - Good to over 300°C.

Yeah, I have seen these screw thermistors before but I never found out where you can buy them! They would solve all of these problems. I could try to "make my own type of screw thermistor" but I will need something simpler and out of the box for production. That's why I think my new heater block design is the simplest solution for the thermistor problem.

As for your earlier post, don't worry about it

My feelings aren't hurt as long as you read my response and understand the engineering trade-offs that were involved in developing my hot end.

My feelings aren't hurt as long as you read my response and understand the engineering trade-offs that were involved in developing my hot end. Nothing is as simple as it looks and everything is the way it is for a reason.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 10:01AM |

Registered: 11 years ago Posts: 490 |

One thing I am rather confused about is that about every all-metal hot end comes with a thermistor as default. This doesn't make much sense to me since the purpose of these hot ends is the higher temperature capability and while E3D also has thermocouples on stock, these are PTFE-coated, again limiting the maximum working temperature to 260°C.

So, what I would absolutely love to see is an option to choose between the default thermistor and a thermocouple. Eric, do you think this might be possible to include in your design?

K-Type Thermocouple on ebay

This one here came to my mind after seeing the screw-in thermistor. Guess that would improve reliability a bit and make everything look rather neat, similar to the one Ultimaker is using:

So, what I would absolutely love to see is an option to choose between the default thermistor and a thermocouple. Eric, do you think this might be possible to include in your design?

K-Type Thermocouple on ebay

This one here came to my mind after seeing the screw-in thermistor. Guess that would improve reliability a bit and make everything look rather neat, similar to the one Ultimaker is using:

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 01:59PM |

Registered: 11 years ago Posts: 246 |

Quote

uGen

One thing I am rather confused about is that about every all-metal hot end comes with a thermistor as default. This doesn't make much sense to me since the purpose of these hot ends is the higher temperature capability and while E3D also has thermocouples on stock, these are PTFE-coated, again limiting the maximum working temperature to 260°C.

So, what I would absolutely love to see is an option to choose between the default thermistor and a thermocouple. Eric, do you think this might be possible to include in your design?

K-Type Thermocouple on ebay

This one here came to my mind after seeing the screw-in thermistor. Guess that would improve reliability a bit and make everything look rather neat, similar to the one Ultimaker is using:

Thermocouple capability is definitely something I would like to include in my design.

There are a few reasons why I am currently using a thermistor. They are cheap, they are compatible with all electronics boards, and they can measure up to 300C which is sufficient for most high temperature plastics. Printing Ultimachine Polycarbonate at 300C produces indestructible parts and you could easily drop the temperature to 280C without having to worry about delamination. However, I did notice that a little while ago you had started a thread about your experiences printing Chinese PC and you mentioned that you were having adhesion problems even at 300C. In this case, I am sure you would have experienced much better adhesion if you were printing at say 350C. In these scenarios it is annoying how "high temperature hot ends" cannot print at the higher temperatures that you need!

I don't like the idea of the thermistor being the limiting factor in my design so I will definitely look into thermocouple support. While a thermocouple would provide more accurate high temperature readings and eliminate the 300C limit, there are some problems that are introduced by using thermocouples. Namely they are more expensive and they require an external board which adds even more to the cost. If I were to offer thermocouple support it would have to be as an add-on at an additional cost. I am sure many people would still be interested in this so I will start looking into it.. I realistically won't be able to add thermocouple support before I launch the Indiegogo campaign, but I will try to sort this out ASAP and introduce it as an add-on later. I will already have an M3 thread in the heater block so if I could just find a cheap high temperature thermocouple with M3 threaded tip that would solve all of my problems!

EDIT: It looks like the Ultimaker thermocouple also uses an M3 thread. I just need to find out where they source their thermocouples...

Eric

Edited 1 time(s). Last edit at 03/12/2014 02:07PM by RP Iron Man.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 03:19PM |

Registered: 12 years ago Posts: 27 |

Hi Eric,

You really need to read what I wrote and try to understand what it says. I do have experience and the history around the forums. But, I do not want to detract from your project.

I stood back and took another look at your item and I did see the thought into the fan and fins. I conceed that it is good. I never said it was not. I said it was SAME TYPE --- AND IT IS!

I don't see a great deal of engineering but, adjustability. Adjustability is not engineering but a feature. Pretty CAD is not engineering but, it does add to the organization, illustration and ability to build. The materials selected are not new or uncommon to the hacked hot ends made over five plus years. Many are using fins - E3D as an example

As to passive? I was not advocating. If you read and pay attention the hacked end I made is active and I said nothing that it was to be otherwise. A2 did lean to passive from his questions.

Oh, Vertical heatsink - large. NO IT WOULD NOT HAVE TO BE LARGE! If you had read the forums over the years and seen the popular designs - MakerBot MK5/MK6 for example, it is stainless with a very small heatsink with vertical fins. It works well - I've two.

javascript:editor_tools_handle_b()

BY YOUR taking my entire diatribe (wall-O-words) and bashing at your targeted individual sentences alone --- HURTS or Bullies me. YOU did not want to read the entirety as such and understand to learn but, to take points you could construe for attacks then illustrate them into a fight which is not true.

I back out --- I see clearly that typing will be tedious. If you choose to talk PM me. I know we'd be able to have a good and fun discussion. We are loosing too much with the typing. But, I'll not give future industry insight on your project.

Thermistor/Thermocouple

Use a screwed in thermistor OR Drill a bigger hole for a thermocouple - Have a button head screw and washer to capture the items leads so the measurement ends stay in their holes. That is how mine are configured - 3 years! Use RTV silicone if you worry about conductivity and stability of the items. The hole will not be need to be adjustable if you find the thermistor and thermocouple which are similar and you supply. Other customers can weild a drill to make a hole to fit. To install: You bend the temperture device at a 90° angle and capture the leads against the block.

You really need to read what I wrote and try to understand what it says. I do have experience and the history around the forums. But, I do not want to detract from your project.

I stood back and took another look at your item and I did see the thought into the fan and fins. I conceed that it is good. I never said it was not. I said it was SAME TYPE --- AND IT IS!

I don't see a great deal of engineering but, adjustability. Adjustability is not engineering but a feature. Pretty CAD is not engineering but, it does add to the organization, illustration and ability to build. The materials selected are not new or uncommon to the hacked hot ends made over five plus years. Many are using fins - E3D as an example

As to passive? I was not advocating. If you read and pay attention the hacked end I made is active and I said nothing that it was to be otherwise. A2 did lean to passive from his questions.

Oh, Vertical heatsink - large. NO IT WOULD NOT HAVE TO BE LARGE! If you had read the forums over the years and seen the popular designs - MakerBot MK5/MK6 for example, it is stainless with a very small heatsink with vertical fins. It works well - I've two.

javascript:editor_tools_handle_b()

BY YOUR taking my entire diatribe (wall-O-words) and bashing at your targeted individual sentences alone --- HURTS or Bullies me. YOU did not want to read the entirety as such and understand to learn but, to take points you could construe for attacks then illustrate them into a fight which is not true.

I back out --- I see clearly that typing will be tedious. If you choose to talk PM me. I know we'd be able to have a good and fun discussion. We are loosing too much with the typing. But, I'll not give future industry insight on your project.

Thermistor/Thermocouple

Use a screwed in thermistor OR Drill a bigger hole for a thermocouple - Have a button head screw and washer to capture the items leads so the measurement ends stay in their holes. That is how mine are configured - 3 years! Use RTV silicone if you worry about conductivity and stability of the items. The hole will not be need to be adjustable if you find the thermistor and thermocouple which are similar and you supply. Other customers can weild a drill to make a hole to fit. To install: You bend the temperture device at a 90° angle and capture the leads against the block.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 04:24PM |

Registered: 11 years ago Posts: 246 |

Ok, Brian. I think you misunderstood my response.

FYI I assure you that I have read through your entire post and I do understand everything that you said. My response was NOT meant to "bully" you at all. Maybe I used too much ALL CAPS and bold type but this was just to bring your attention to certain point, NOT to attack you. I was not raging at you while I wrote that post I can be honest and assure you of that. I was just trying to bring your attention to the way you assessed my design. As I stated at the bottom of my response, you concluded absolutes based on narrow conjectures that did not consider all of the facets of my design. I just wanted you to understand why I made the decisions that I did. That's all. I have no hard feelings AT ALL toward you and I like your little hot end in the other thread. I really try to be as objective as possible in my posts on these forums but it is easy for words to sound more aggressive then they are intended to be. Please understand that I did not mean to offend you.

I can be honest and assure you of that. I was just trying to bring your attention to the way you assessed my design. As I stated at the bottom of my response, you concluded absolutes based on narrow conjectures that did not consider all of the facets of my design. I just wanted you to understand why I made the decisions that I did. That's all. I have no hard feelings AT ALL toward you and I like your little hot end in the other thread. I really try to be as objective as possible in my posts on these forums but it is easy for words to sound more aggressive then they are intended to be. Please understand that I did not mean to offend you.

Believe me, I have thought though the information in your post and I understand what you were saying about the heat sink design. Yes, it is possible to design a heat sink with vertical fins that is NOT HUGE (as in the example you gave) but for my adjustable design the passively cooled vertical heat sink is not ideal (for the many reasons I gave in my response). If I were to use a passive vertical heat sink in my design it would have to be HUGE to allow for the user to customize a very short "transition-zone" in various scenarios (I mentioned more details in my previous response). This is why the E3D hot end has an actively cooled horizontal heat sink and not a passive vertical heat sink.

And of course the materials, basic horizontal fin design, cooling fan etc used in my design is the same as many other hot ends that have been developed over the past several years. I did not invent some new earth-shattering technology, this design simply builds on the knowledge of previous designs. I just tried to make some small improvements (more compact, lighter, adjustable, 1 piece nozzle, no fan duct etc) that would increase the performance and enable users to experiment with changing the zones. That's all. If that is not considered engineering then we can say that I did not "engineer" my hot end design but rather "improved" on well known hot end features. I don't consider myself an engineer at this point in my life anyway. I guess I am more of a tinkerer

I am aware that your hot end is actively cooled. I have been reading your other thread (although not posting in it) and I have read your discussion with A2 already. And you did not directly advocate vertical passively cooled heat sink but your previous post seemed to imply that a hot end that could utilize the passive vertical design would be the next engineering step (correct me if I am wrong). As I mentioned above, I just wanted you to understand that there are many good reasons why my hot end (and the E3D and many other all metal hot ends) are designed the way they are with horizontal actively cooled heat sinks, and they will probably remain that way. If you think otherwise then please tell us I would really like to hear a detailed analysis of the possible improvements to current heat sink designs.

I would really like to hear a detailed analysis of the possible improvements to current heat sink designs.

Regarding your thermistor design: It would be great if you could post a picture to help us visualize that. I basically need a way to secure the thermistor purely "mechanically" WITHOUT any silicone or messy Kapton Tape. I think my heater block design is more than adequate but I would be interested to see if your solution is more appropriate for my design. Please share it with us

In conclusion, I am truly sorry that you felt bullied. This was not my intention. I am thankful that you have taken the time to contemplate my design and offer critiques, I just felt that your previous post painted my efforts in an unfavorable light by not addressing all of the details. I hope you understand that I was trying to clear up any ambiguity that your post created and I was not attacking you. I see no reason why we should we on bad terms with each other.

Eric

Edited 1 time(s). Last edit at 03/12/2014 04:55PM by RP Iron Man.

FYI I assure you that I have read through your entire post and I do understand everything that you said. My response was NOT meant to "bully" you at all. Maybe I used too much ALL CAPS and bold type but this was just to bring your attention to certain point, NOT to attack you. I was not raging at you while I wrote that post

I can be honest and assure you of that. I was just trying to bring your attention to the way you assessed my design. As I stated at the bottom of my response, you concluded absolutes based on narrow conjectures that did not consider all of the facets of my design. I just wanted you to understand why I made the decisions that I did. That's all. I have no hard feelings AT ALL toward you and I like your little hot end in the other thread. I really try to be as objective as possible in my posts on these forums but it is easy for words to sound more aggressive then they are intended to be. Please understand that I did not mean to offend you.

I can be honest and assure you of that. I was just trying to bring your attention to the way you assessed my design. As I stated at the bottom of my response, you concluded absolutes based on narrow conjectures that did not consider all of the facets of my design. I just wanted you to understand why I made the decisions that I did. That's all. I have no hard feelings AT ALL toward you and I like your little hot end in the other thread. I really try to be as objective as possible in my posts on these forums but it is easy for words to sound more aggressive then they are intended to be. Please understand that I did not mean to offend you.Believe me, I have thought though the information in your post and I understand what you were saying about the heat sink design. Yes, it is possible to design a heat sink with vertical fins that is NOT HUGE (as in the example you gave) but for my adjustable design the passively cooled vertical heat sink is not ideal (for the many reasons I gave in my response). If I were to use a passive vertical heat sink in my design it would have to be HUGE to allow for the user to customize a very short "transition-zone" in various scenarios (I mentioned more details in my previous response). This is why the E3D hot end has an actively cooled horizontal heat sink and not a passive vertical heat sink.

And of course the materials, basic horizontal fin design, cooling fan etc used in my design is the same as many other hot ends that have been developed over the past several years. I did not invent some new earth-shattering technology, this design simply builds on the knowledge of previous designs. I just tried to make some small improvements (more compact, lighter, adjustable, 1 piece nozzle, no fan duct etc) that would increase the performance and enable users to experiment with changing the zones. That's all. If that is not considered engineering then we can say that I did not "engineer" my hot end design but rather "improved" on well known hot end features. I don't consider myself an engineer at this point in my life anyway. I guess I am more of a tinkerer

I am aware that your hot end is actively cooled. I have been reading your other thread (although not posting in it) and I have read your discussion with A2 already. And you did not directly advocate vertical passively cooled heat sink but your previous post seemed to imply that a hot end that could utilize the passive vertical design would be the next engineering step (correct me if I am wrong). As I mentioned above, I just wanted you to understand that there are many good reasons why my hot end (and the E3D and many other all metal hot ends) are designed the way they are with horizontal actively cooled heat sinks, and they will probably remain that way. If you think otherwise then please tell us

I would really like to hear a detailed analysis of the possible improvements to current heat sink designs.

I would really like to hear a detailed analysis of the possible improvements to current heat sink designs.Regarding your thermistor design: It would be great if you could post a picture to help us visualize that. I basically need a way to secure the thermistor purely "mechanically" WITHOUT any silicone or messy Kapton Tape. I think my heater block design is more than adequate but I would be interested to see if your solution is more appropriate for my design. Please share it with us

In conclusion, I am truly sorry that you felt bullied. This was not my intention. I am thankful that you have taken the time to contemplate my design and offer critiques, I just felt that your previous post painted my efforts in an unfavorable light by not addressing all of the details. I hope you understand that I was trying to clear up any ambiguity that your post created and I was not attacking you. I see no reason why we should we on bad terms with each other.

Eric

Edited 1 time(s). Last edit at 03/12/2014 04:55PM by RP Iron Man.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 04:40PM |

Registered: 10 years ago Posts: 553 |

If you do offer the ability to switch between a thermocouple and thermistor, I think you should include both parts with the hotend. Yes, it increases cost, but if your goal is adjustability I think it is necessary.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 04:49PM |

Registered: 11 years ago Posts: 246 |

Quote

gmh39

If you do offer the ability to switch between a thermocouple and thermistor, I think you should include both parts with the hotend. Yes, it increases cost, but if your goal is adjustability I think it is necessary.

That's what I would like to do, but the thing is that some people would rather not have not pay for the thermocouple if they are not going to go over 300C.

The thermocouple would add a significant cost to the hot end so I think it would be more appropriate to have it as an optional add-on for people who are willing to pay extra for the 300C+ temperature capability. If you look at the E3D website the combined cost of the thermocouple extension board and the thermocouple itself together add A LOT to the cost (about 36.5USD together)

It wouldn't be so expensive if electronics boards would start implementing built-in thermocouple support... but I have not seen any boards that offer this

Eric

Edited 3 time(s). Last edit at 03/12/2014 04:52PM by RP Iron Man.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 05:07PM |

Registered: 12 years ago Posts: 27 |

Thermistor installation suggestion

----

My little hack was always intended to be active - there was not a passive to it.

Almost all is good.

Almost all is good.

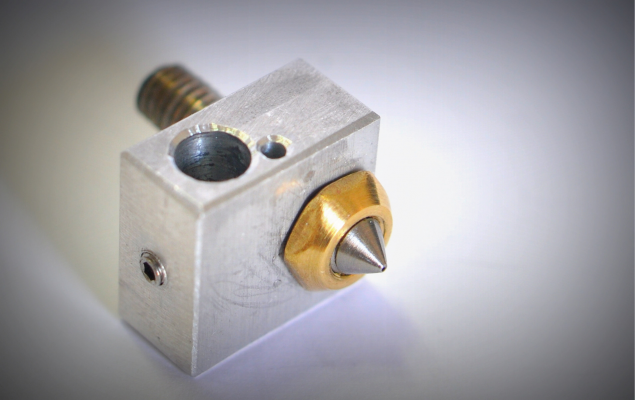

Hey, you seen anything like this? My hot end nozzle split. Know why? Ha, Ha... The same reason my riser broke.

Some claimed better design ---- The interior diameter was too large with the exterior threads being too deep. This

left the material thickness to hold the part together too thin --- So the parts fell apart. What you are seeing here is

a hot end nozzle which has burst in use. It caused the hot end to leak/ooze and not print properly. This is after I had

a riser failure from the same poor design. That was between the thermistor slipping out, on the same design

AND my PEEK burning UP! LOL....

----

My little hack was always intended to be active - there was not a passive to it.

Almost all is good.

Almost all is good.Hey, you seen anything like this? My hot end nozzle split. Know why? Ha, Ha... The same reason my riser broke.

Some claimed better design ---- The interior diameter was too large with the exterior threads being too deep. This

left the material thickness to hold the part together too thin --- So the parts fell apart. What you are seeing here is

a hot end nozzle which has burst in use. It caused the hot end to leak/ooze and not print properly. This is after I had

a riser failure from the same poor design. That was between the thermistor slipping out, on the same design

AND my PEEK burning UP! LOL....

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 05:19PM |

Registered: 12 years ago Posts: 27 |

For cost and use --- better to have option --- One or the other and not supply both.

When you actively build or print you tend to standardize and not goof around with many things. You really have a lot of varying variables and do not just keep swapping stuff. Each thermistor or thermocouple require different electronics and firmware then also settings. So, not practical at the supplier stage either. Just my experience. I have machines with thermocouples and they are good but, I'm not going through the headache to set them up with a thermisor and the electronics. As too with the present machine I've recently built - It has a thermistor and the required electronics. Here, I am not going to build or buy the electronics to convert to a thermocouple and find the firmware adjustments to convert this. Not worth the efforts. As for Thermistors - as noted somewhere in this thread -- they are rated upto+ of 300°C far and above the materials we build the machines with and the materials we print with. If you are going for wire --- You should have a good time with your build. I understand that a few years ago that thermistors may not have been readily available and cheap enough at the temperatures to print so some began to move to a thermocouple. But, as most items, thermistors are now more readily available, the control easier, the electronics less and their functional operating temperatures rising as their costs plummet. So, we use more thermistors now. ???

When you actively build or print you tend to standardize and not goof around with many things. You really have a lot of varying variables and do not just keep swapping stuff. Each thermistor or thermocouple require different electronics and firmware then also settings. So, not practical at the supplier stage either. Just my experience. I have machines with thermocouples and they are good but, I'm not going through the headache to set them up with a thermisor and the electronics. As too with the present machine I've recently built - It has a thermistor and the required electronics. Here, I am not going to build or buy the electronics to convert to a thermocouple and find the firmware adjustments to convert this. Not worth the efforts. As for Thermistors - as noted somewhere in this thread -- they are rated upto+ of 300°C far and above the materials we build the machines with and the materials we print with. If you are going for wire --- You should have a good time with your build. I understand that a few years ago that thermistors may not have been readily available and cheap enough at the temperatures to print so some began to move to a thermocouple. But, as most items, thermistors are now more readily available, the control easier, the electronics less and their functional operating temperatures rising as their costs plummet. So, we use more thermistors now. ???

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 12, 2014 06:01PM |

Registered: 11 years ago Posts: 246 |

Quote

bstott

Thermistor installation suggestion

[attachment 28496 thermisto.capturer.jpg]

I like your thermistor installation, Brian. It is nice and simple

I'll consider it.

I'll consider it. Quote

bstott

----

My little hack was always intended to be active - there was not a passive to it.

Almost all is good.

Hey, you seen anything like this? My hot end nozzle split. Know why? Ha, Ha... The same reason my riser broke.

Some claimed better design ---- The interior diameter was too large with the exterior threads being too deep. This

left the material thickness to hold the part together too thin --- So the parts fell apart. What you are seeing here is

a hot end nozzle which has burst in use. It caused the hot end to leak/ooze and not print properly. This is after I had

a riser failure from the same poor design. That was between the thermistor slipping out, on the same design

AND my PEEK burning UP! LOL....

[attachment 28497 burst-printer-nozzle.2.jpg]

LOL, I have never heard of nozzles bursting before! I know that some acorn cap nuts used as nozzles sometimes have small holes where the cap meets the nut which can cause leaking, but this is something else entirely. This shows how much force is actually involved in extrusion, sometimes thin metal in not even strong enough

Quote

bstott

For cost and use --- better to have option --- One or the other and not supply both.

When you actively build or print you tend to standardize and not goof around with many things. You really have a lot of varying variables and do not just keep swapping stuff. Each thermistor or thermocouple require different electronics and firmware then also settings. So, not practical at the supplier stage either. Just my experience. I have machines with thermocouples and they are good but, I'm not going through the headache to set them up with a thermisor and the electronics. As too with the present machine I've recently built - It has a thermistor and the required electronics. Here, I am not going to build or buy the electronics to convert to a thermocouple and find the firmware adjustments to convert this. Not worth the efforts. As for Thermistors - as noted somewhere in this thread -- they are rated upto+ of 300°C far and above the materials we build the machines with and the materials we print with. If you are going for wire --- You should have a good time with your build. I understand that a few years ago that thermistors may not have been readily available and cheap enough at the temperatures to print so some began to move to a thermocouple. But, as most items, thermistors are now more readily available, the control easier, the electronics less and their functional operating temperatures rising as their costs plummet. So, we use more thermistors now. ???

Yeah, I agree. I would definitely have this as an optional add on. However, it would be nice if electronics board developers could start working on implementing built in thermocouple support to keep up with the new wave of all metal hot ends that are popping up. Its a shame to have to limit the temperature to 300C on an all metal design.

Eric

Sorry, only registered users may post in this forum.