Importance of a fan shroud?

Posted by Ohmarinus

|

Importance of a fan shroud? March 09, 2014 06:01AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi, I've been trying to improve the cooling on the PEEK of my J-head.

Right now I was so desperate that I just cut off the 30mm fan with pliers, added a connector to the open wire so I could put on different fans with ease and now I am using a 50mm fan with 'ok' results.

The 1.75mm PLA kept on jamming all of a sudden while it would print really well before. After checking the usual things like thermistors being secured, ceramic heater being well-seated, etcetera I decided to just brute-force some cooling with a 50mm fan on the J-head.

Now, I am working next to the printer and I notice airflow going over my hands since adding the 50mm fan. I have designed a nice step-up fan connector from 30mm to 50mm but I am not using a fan shroud.

So, I moved my hand in the airflow that goes over my hand and I found out that there is some air coming from the sides of the 50mm fan. I think a good fan shroud might improve the air intake but I am not sure.

Does anyone have a good understanding or airflow dynamics and will a well-designed fan shroud help me get more cm/3 or air past my PEEK part?

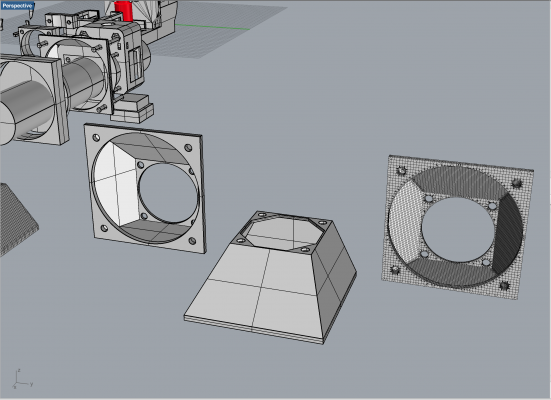

This is how my 30mm to 50mm fan converter looks like:

Edited 1 time(s). Last edit at 03/09/2014 06:32AM by Ohmarinus.

Right now I was so desperate that I just cut off the 30mm fan with pliers, added a connector to the open wire so I could put on different fans with ease and now I am using a 50mm fan with 'ok' results.

The 1.75mm PLA kept on jamming all of a sudden while it would print really well before. After checking the usual things like thermistors being secured, ceramic heater being well-seated, etcetera I decided to just brute-force some cooling with a 50mm fan on the J-head.

Now, I am working next to the printer and I notice airflow going over my hands since adding the 50mm fan. I have designed a nice step-up fan connector from 30mm to 50mm but I am not using a fan shroud.

So, I moved my hand in the airflow that goes over my hand and I found out that there is some air coming from the sides of the 50mm fan. I think a good fan shroud might improve the air intake but I am not sure.

Does anyone have a good understanding or airflow dynamics and will a well-designed fan shroud help me get more cm/3 or air past my PEEK part?

This is how my 30mm to 50mm fan converter looks like:

Edited 1 time(s). Last edit at 03/09/2014 06:32AM by Ohmarinus.

|

Re: Importance of a fan shroud? March 09, 2014 07:29AM |

Registered: 10 years ago Posts: 329 |

Hi Ohmarinus, I am using your Jhead cooling shield on my OrdBot. It works very well (I am dave3dprinter on thingiverse). I do just ABS now at 235 deg C.

[www.thingiverse.com]

I have a hotends.com Mk V jhead and your shield with a 30mm fan on full all the time. It is wired in parallel with the heater.

On mine I found the temperature would occillate a bit when cold air was blown into the shield. I reversed the fan so it sucked hot air out instead and it is now very stable. Cold air comes in from openings around the shield.

I think your jamming may be due to another cause. Have you checked the ptfe tube inside the peek body? I had one that eroded and formed a small cavity at the end where it enters the nozzle. I bought a new tube from Brian.

I don't think it needs a bigger fan imho.

[www.thingiverse.com]

I have a hotends.com Mk V jhead and your shield with a 30mm fan on full all the time. It is wired in parallel with the heater.

On mine I found the temperature would occillate a bit when cold air was blown into the shield. I reversed the fan so it sucked hot air out instead and it is now very stable. Cold air comes in from openings around the shield.

I think your jamming may be due to another cause. Have you checked the ptfe tube inside the peek body? I had one that eroded and formed a small cavity at the end where it enters the nozzle. I bought a new tube from Brian.

I don't think it needs a bigger fan imho.

|

Re: Importance of a fan shroud? March 09, 2014 08:33AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi Dave, thanks for your reply.

Well, there is a difference between PLA and ABS when it comes to cooling, for PLA the transition zone from filament to molten goo needs to be as short as possible because PLA gets soft really easy, also the 1.75mm filament is more prone to jamming because it has less material so the new cold material that is fed into the hotend is smaller and cools the cold zone less.

For now I have re-designed the whole cooling shield, and am using a completely new system It is nice to see people that use my cooling shield. I will try to improve the shield for you if you want, there are some flaws in the design.

It is nice to see people that use my cooling shield. I will try to improve the shield for you if you want, there are some flaws in the design.

Right now I'm trying out the new 50mm fan in combination with the fan shroud and it seems to hold up, but I have yet to see how it holds up when it is printing for an hour

Still printing after 43 minutes and it seems to hold up, I'm curious for how much longer!

Video:

[youtu.be]

Update:

Interesting fact, the extruder starts skipping at EXACTLY the same point as my last print that failed. After 1:09 hour at layer height around 31 and 37.50 it starts skipping and the PLA jams. I then have to push it in by hand to help and the problem disappears.

The extruder somehow gets into trouble. But the problem is focused around the hotend where the filament jams.

I am now turning up the print speed to 120% to see if it helps if new filament is going into the hotend to cool matters down. Pointing a big fan on the machine, somehow I suspect the gcode is doing something weird. The times when it skips always happen on the same places.

Edited 1 time(s). Last edit at 03/09/2014 09:08AM by Ohmarinus.

Well, there is a difference between PLA and ABS when it comes to cooling, for PLA the transition zone from filament to molten goo needs to be as short as possible because PLA gets soft really easy, also the 1.75mm filament is more prone to jamming because it has less material so the new cold material that is fed into the hotend is smaller and cools the cold zone less.

For now I have re-designed the whole cooling shield, and am using a completely new system

It is nice to see people that use my cooling shield. I will try to improve the shield for you if you want, there are some flaws in the design.

It is nice to see people that use my cooling shield. I will try to improve the shield for you if you want, there are some flaws in the design.Right now I'm trying out the new 50mm fan in combination with the fan shroud and it seems to hold up, but I have yet to see how it holds up when it is printing for an hour

Still printing after 43 minutes and it seems to hold up, I'm curious for how much longer!

Video:

[youtu.be]

Update:

Interesting fact, the extruder starts skipping at EXACTLY the same point as my last print that failed. After 1:09 hour at layer height around 31 and 37.50 it starts skipping and the PLA jams. I then have to push it in by hand to help and the problem disappears.

The extruder somehow gets into trouble. But the problem is focused around the hotend where the filament jams.

I am now turning up the print speed to 120% to see if it helps if new filament is going into the hotend to cool matters down. Pointing a big fan on the machine, somehow I suspect the gcode is doing something weird. The times when it skips always happen on the same places.

Edited 1 time(s). Last edit at 03/09/2014 09:08AM by Ohmarinus.

|

Re: Importance of a fan shroud? March 09, 2014 09:03AM |

Admin Registered: 17 years ago Posts: 7,879 |

All the heat at the top of a J-head is convected from the heater. If you insulate the heater it barely needs any cooling at all.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Importance of a fan shroud? March 09, 2014 09:10AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

nophead

All the heat at the top of a J-head is convected from the heater. If you insulate the heater it barely needs any cooling at all.

Hi, yes I insulated it completely with ceramic insulation band, but still the heat travels up through the inside somehow.

I am pondering buying a new hotend, this thing has given me too many problems! It's a Jhead from reprapworld, my 3mm jhead functions perfectly, but this 1.75mm one just doesn't want to work.

Anyone got advice for a good hotend that prints 1.75mm without any known problems?

|

Re: Importance of a fan shroud? March 09, 2014 09:41AM |

Registered: 10 years ago Posts: 329 |

I have bought two 1.75mm/0.4mm nozzle Mk V Jheads plus a few spare parts from Hotends.com.

[www.hotends.com]

The machining is first class as is the service. They work very well on ABS. I don't have much experience with PLA.

I have just bought a micro lathe and a few lengths of peek and ptfe rod so I might have a go at making my own designs.

Edited 1 time(s). Last edit at 03/09/2014 09:47AM by dave3d.

[www.hotends.com]

The machining is first class as is the service. They work very well on ABS. I don't have much experience with PLA.

I have just bought a micro lathe and a few lengths of peek and ptfe rod so I might have a go at making my own designs.

Edited 1 time(s). Last edit at 03/09/2014 09:47AM by dave3d.

|

Re: Importance of a fan shroud? March 10, 2014 02:54PM |

Admin Registered: 15 years ago Posts: 1,470 |

Do you happen to know if the J-Head from reprapworld was made to Brian's specifications? And does the nozzle have the proper 2mm diameter melt zone, or is this a 3mm hot end with just the PTFE liner replaced with one with a smaller hole?Quote

Ohmarinus

It's a Jhead from reprapworld, my 3mm jhead functions perfectly, but this 1.75mm one just doesn't want to work.

If you have the space on your printer's extruder carriage, an E3D hot end is a popular, reliable choice. Or, get a 1.75mm J-Head from Brian himself at hotends.com. They are perpetually out-of-stock, but he posts new ones every Friday at about 12 noon EST, so if you are quick you can get a hold of one.Quote

Ohmarinus

Anyone got advice for a good hotend that prints 1.75mm without any known problems?

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Importance of a fan shroud? March 11, 2014 07:17AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

NewPerfection

Do you happen to know if the J-Head from reprapworld was made to Brian's specifications? And does the nozzle have the proper 2mm diameter melt zone, or is this a 3mm hot end with just the PTFE liner replaced with one with a smaller hole?Quote

Ohmarinus

It's a Jhead from reprapworld, my 3mm jhead functions perfectly, but this 1.75mm one just doesn't want to work.

If you have the space on your printer's extruder carriage, an E3D hot end is a popular, reliable choice. Or, get a 1.75mm J-Head from Brian himself at hotends.com. They are perpetually out-of-stock, but he posts new ones every Friday at about 12 noon EST, so if you are quick you can get a hold of one.Quote

Ohmarinus

Anyone got advice for a good hotend that prints 1.75mm without any known problems?

Yes, the reprapworld J-head is a high-quality hotend with all specifications up to par (so yes, 2mm wide melt-chamber and the PTFE-insert really only sits in the PEEK part). I measured every part and it's correctly produced. The only thing I wasn't able to measure was the nozzle diameter itself (no 0.5mm equivalent in my toolbox).

I'm thinking of making an open cooling-system instead of using a funnel that forces all the cool air passed the PEEK. It will probably not work, but you never know until you try.

After that I will de-construct the entire hotend again (yes again, what a party).

Also, maybe I will try to fiddle with the printing temperatures a little bit. I am currently printing at 200º, my thermistor is correctly configured and I didn't have any trouble with the 3mm printing. I might go even lower, 195º or something.

Oh, also just to make sure, my digital caliper is laying next to my machine and the tolerance of the PLA filament is always 1.75/1.76

Edited 2 time(s). Last edit at 03/11/2014 07:18AM by Ohmarinus.

|

Re: Importance of a fan shroud? March 11, 2014 11:39AM |

Admin Registered: 15 years ago Posts: 1,470 |

In that case I would ask them for a replacement. With proper cooling that hot end should have no problem extruding PLA. Shouldn't need a cooling duct or anything, just some air flow over the PEEK.Quote

Ohmarinus

Yes, the reprapworld J-head is a high-quality hotend with all specifications up to par (so yes, 2mm wide melt-chamber and the PTFE-insert really only sits in the PEEK part). I measured every part and it's correctly produced. The only thing I wasn't able to measure was the nozzle diameter itself (no 0.5mm equivalent in my toolbox).

Edit: only other thing I can think of is the possibility of poor quality PLA with contaminants or fillers. Where is your PLA from? Have you tried natural PLA, or other brands?

Edited 1 time(s). Last edit at 03/11/2014 11:42AM by NewPerfection.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Importance of a fan shroud? March 11, 2014 12:11PM |

Registered: 10 years ago Posts: 172 |

|

Re: Importance of a fan shroud? April 10, 2014 06:23PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

umdpru

The fact that the problem occured at exactly the same point in time and location in the print should point the finger at the G-code, in my opinion. that is, unless you have printed other objects with different G-code with success or failure at some other point.

Just to come back at this topic, I have never had any clogging or other problems with printing except for this specific one... Crazy. Big chance it was the Gcode, however, Cura and Repetier+Slic3r both produced the same error.

Meanwhile I've finally received my radial fans today and I must say the airflow is phenomenal! It is incomparable with a normal axial fan. Axial fans are not nearly putting out as much cm3 of air.

Also ordered a new hotend, the Merlin. And when that one gets here I will start designing a new hotend system for my MendelMax. Together with the new radial fan, silicon tape, firegum and PTFE tubes to insulate the thermistor leads...

This is gonna rock!

Edited 1 time(s). Last edit at 04/10/2014 06:23PM by Ohmarinus.

|

Re: Importance of a fan shroud? April 11, 2014 07:05AM |

Registered: 11 years ago Posts: 791 |

Quote

Ohmarinus

Quote

nophead

All the heat at the top of a J-head is convected from the heater. If you insulate the heater it barely needs any cooling at all.

Hi, yes I insulated it completely with ceramic insulation band, but still the heat travels up through the inside somehow.

I am pondering buying a new hotend, this thing has given me too many problems! It's a Jhead from reprapworld, my 3mm jhead functions perfectly, but this 1.75mm one just doesn't want to work.

Anyone got advice for a good hotend that prints 1.75mm without any known problems?

If you have the means, make your own.

I have been using a self designed hotend for a few years now, never had a jam with PLA ever.

The design has a couple of extra parts, but these parts are very important.

A standard heater block as used on most hotends is used, just aluminium with a M6 threaded hole for the nozzle shaft and a 6mm hole at 90 degrees for the heater cartridge.

Both are held in place with a small grub screw each. One of the grib screw holes is also used to place the thermistor in.

The M6 threaded rod made of brass has a 2mm hole through it. The nozzle end is machined to 118 degrees (same as a drill end)

The nozzles have a matching 118 degree land so that the nozzle and shaft will mate together without any leakage problems.

The brass M6 shaft is just long enough to allow a short piece of PEEK to be screwed onto it (also has an M6 threaded hole)

At the other end of the PEEK a second piece of brass M6 thread is screwed to which a heatsink is attached (will also work without the heatsink)

The secret is that the two pieces of brass thread do not meet, there is a small gap between them that forms a very good heat barrier.

The white piece in the middle I no longer use, it was a small piece of PTFE and I found that it caused more problems than it was worth. A small air gap is all that is needed (less than 0.5mm)

The original nozzles I first made from brass dome nuts and re-machined them. I now have them made by CNC machine from stock brass hex.

Also a finned heat sink I have added to the top section, although the hotends worked fine without it.

The later hotends can be seen in these photos. An exploded view would be better however I don't have one available at this time to share.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Sorry, only registered users may post in this forum.