A call for help/ideas to develop the Heated Bed

Posted by casainho

|

A call for help/ideas to develop the Heated Bed January 19, 2010 08:58PM |

Registered: 14 years ago Posts: 356 |

Introdution

A heated build platform helps greatly to avoid the warp problems and permits the print without using raft!

RepRap wiki page: Heated bed.

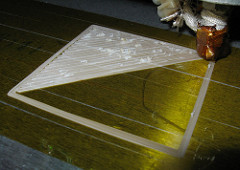

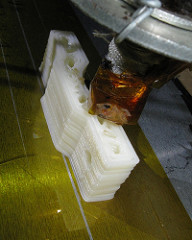

Some examples of my printings (heated build platform @ 110ºC, printing over kapton tape):

Some people already uses them but there is no documentation and they looks like experimental. I would like to start a discussion, so after we can use the best ideas to implement and document it, looking for a stable version.

What is needed to do

We need to keep the build platform at about 110ºC for ABS, while printing. 110ºC will make the ABS sticking to kapton tape and avoid it warping -- see here and here.

I know that if we low the temperature for 90ºC or 100ºC, the piece can start warping. To much temperature like 130ºC or more shrink the first layers... so a precise (~ +-3ºC) control of temperature is needed.

Also a slow decay temperature should be needed, at the end of the print. Like at least 15 minutes for platform cold, from the 110ºC to the room temperature (~25ºc). A very rapid cold will make the piece to warp.

How to implement the heated build platform

Mechanically, it's a really flat sheet of aluminium. The metal is hotted using nichrome wire or power resistors.

Power needed maybe about 100 watts. 100 watts for a quick start and after maybe 60W to maintain the the 110ºC. The power needed will vary depending on the size on the aluminium sheet.

One PC PSU can be used only for power this heated build platform.

The temperature sensor should be something calibrated, since temperature values interval is narrow. I would use LM35, the version that measures up to 150ºC. This IC is calibrated and outputs 10mV for ºC, like 0.2V at 20ºC and 1.1V at 110ºC.

For power controller I would use some mosfet that can handle 10 Amps and 12V.

For logic control of this system, I would make a stand alone module, independent of Extruder electronic board or Main electronic board. This way there is no mess on actual Mendel. Also not everyone may want the heated build platform. And also this system could be an add on.

I would use Arduino because it's easy for everyone to hack it. I also would put and 16X2 LCD to show the current temperature and some buttons, for let user to define the target temperature and also the slope characteristic for cold, like system taking 30 minutes from target temperature to room temperature.

This are my ideas, I would love to hear others :-)

My blog about RepRap: [casainho-emcrepstrap.blogspot.com]

Edited 6 time(s). Last edit at 02/04/2010 10:13PM by casainho.

A heated build platform helps greatly to avoid the warp problems and permits the print without using raft!

RepRap wiki page: Heated bed.

Some examples of my printings (heated build platform @ 110ºC, printing over kapton tape):

Some people already uses them but there is no documentation and they looks like experimental. I would like to start a discussion, so after we can use the best ideas to implement and document it, looking for a stable version.

What is needed to do

We need to keep the build platform at about 110ºC for ABS, while printing. 110ºC will make the ABS sticking to kapton tape and avoid it warping -- see here and here.

I know that if we low the temperature for 90ºC or 100ºC, the piece can start warping. To much temperature like 130ºC or more shrink the first layers... so a precise (~ +-3ºC) control of temperature is needed.

Also a slow decay temperature should be needed, at the end of the print. Like at least 15 minutes for platform cold, from the 110ºC to the room temperature (~25ºc). A very rapid cold will make the piece to warp.

How to implement the heated build platform

Mechanically, it's a really flat sheet of aluminium. The metal is hotted using nichrome wire or power resistors.

Power needed maybe about 100 watts. 100 watts for a quick start and after maybe 60W to maintain the the 110ºC. The power needed will vary depending on the size on the aluminium sheet.

One PC PSU can be used only for power this heated build platform.

The temperature sensor should be something calibrated, since temperature values interval is narrow. I would use LM35, the version that measures up to 150ºC. This IC is calibrated and outputs 10mV for ºC, like 0.2V at 20ºC and 1.1V at 110ºC.

For power controller I would use some mosfet that can handle 10 Amps and 12V.

For logic control of this system, I would make a stand alone module, independent of Extruder electronic board or Main electronic board. This way there is no mess on actual Mendel. Also not everyone may want the heated build platform. And also this system could be an add on.

I would use Arduino because it's easy for everyone to hack it. I also would put and 16X2 LCD to show the current temperature and some buttons, for let user to define the target temperature and also the slope characteristic for cold, like system taking 30 minutes from target temperature to room temperature.

This are my ideas, I would love to hear others :-)

My blog about RepRap: [casainho-emcrepstrap.blogspot.com]

Edited 6 time(s). Last edit at 02/04/2010 10:13PM by casainho.

|

Re: A call for help/ideas to develop the Heated Build Platform January 19, 2010 11:07PM |

Registered: 16 years ago Posts: 1,094 |

a big red or amber light when platform is hot may be a good safety feature.

I'd say your fet should be rated at 50A or more, since then it probably won't need a heatsink- the FDB 8880 (rated 54A) for example can carry 10A without a heatsink (10A^2 * (19mR@175C) * 62C/W + (50C ambient) = 167C die temperature)

I'd say your fet should be rated at 50A or more, since then it probably won't need a heatsink- the FDB 8880 (rated 54A) for example can carry 10A without a heatsink (10A^2 * (19mR@175C) * 62C/W + (50C ambient) = 167C die temperature)

|

Re: A call for help/ideas to develop the Heated Build Platform January 19, 2010 11:58PM |

Registered: 15 years ago Posts: 478 |

Would the primary target be for a Mendel heated bed?

The Mendel Build area is already specified as being 200mm X 200mm

As Nophead has a heated bed that is 6mm thick Aluminum that is 203.2 X 203.2

We already know from his sterling work on his heated bed exactly what power is required to heat the Bed. What we require is exactly as Nopheads heated Bed.

The only area that would be most useful for us to examine in depth is how to make a lower profile heated bed. As any extra depth will be removed from our possible build height of 140mm on Mendel.

I personally would like to see a 4mm thick Aluminum plate for the bed as a start to making it low profile.

Now heating the bed that is a little thinner by will take less power we can re- use Nopheads calculations so we are not re-inventing the wheel any more.

We can then select the most suitable value for our heating resistors based on these calculations. That will also allow us to choose the most suitable size of FET to perform the required PID controlled switching task.

We need to solve these problems..

cutting 4mm sheet aluminum is quite hard/difficult to cut.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

The Mendel Build area is already specified as being 200mm X 200mm

As Nophead has a heated bed that is 6mm thick Aluminum that is 203.2 X 203.2

We already know from his sterling work on his heated bed exactly what power is required to heat the Bed. What we require is exactly as Nopheads heated Bed.

The only area that would be most useful for us to examine in depth is how to make a lower profile heated bed. As any extra depth will be removed from our possible build height of 140mm on Mendel.

I personally would like to see a 4mm thick Aluminum plate for the bed as a start to making it low profile.

Now heating the bed that is a little thinner by will take less power we can re- use Nopheads calculations so we are not re-inventing the wheel any more.

We can then select the most suitable value for our heating resistors based on these calculations. That will also allow us to choose the most suitable size of FET to perform the required PID controlled switching task.

We need to solve these problems..

cutting 4mm sheet aluminum is quite hard/difficult to cut.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 01:00AM |

Admin Registered: 17 years ago Posts: 1,791 |

I've created [Heated_Bed] for you guys to make notes on.

[objects.reprap.org]

It's a open wiki, so login and click "edit".

Probably the best thing to do is copy everything relevant from NopHead's blog into the wiki. I'd do it but I'm busy.

As a general RepRap style guide point, you are free to create and edit wiki pages. I actively encourage it. It's been hardcoded into policy by me and the other library gnomes, actually.

[objects.reprap.org]

[objects.reprap.org]

It's a open wiki, so login and click "edit".

Probably the best thing to do is copy everything relevant from NopHead's blog into the wiki. I'd do it but I'm busy.

As a general RepRap style guide point, you are free to create and edit wiki pages. I actively encourage it. It's been hardcoded into policy by me and the other library gnomes, actually.

[objects.reprap.org]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 05:41AM |

Admin Registered: 17 years ago Posts: 7,879 |

My friend with a CNC machine shop who made my bed for me is planning to make and sell these with Kapton sheet, etc. We are exploring a vacuum hold down system first before completing the final design.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 05:47AM |

Admin Registered: 17 years ago Posts: 7,879 |

BTW,

It looks like it works with PLA as well at about 55C. I have some more tests to do to confirm that with bigger objects. I will also try HDPE at 120-130C. I have no idea if that will work or not but I will know this evening hopefully.

[www.hydraraptor.blogspot.com]

It looks like it works with PLA as well at about 55C. I have some more tests to do to confirm that with bigger objects. I will also try HDPE at 120-130C. I have no idea if that will work or not but I will know this evening hopefully.

[www.hydraraptor.blogspot.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 06:23AM |

Registered: 14 years ago Posts: 356 |

BodgeIt Wrote:

-------------------------------------------------------

> I personally would like to see a 4mm thick

> Aluminum plate for the bed as a start to making it

> low profile.

>

> Now heating the bed that is a little thinner by

> will take less power we can re- use Nopheads

> calculations so we are not re-inventing the wheel

> any more.

Yes, a thinner plate is desirable however it will be easier to bend :-( -- and this plate really need to be flat! For example, using raft on this plate at 110ºC will not avoid warp! I already tested it... because raft will soft and other first layers will make force and warp, because raft is soft and temperature do not pass very well to upper layers (I can't explain better sorry).

> That will also allow us to choose the most

> suitable size of FET to perform the required PID

> controlled switching task.

Since I have a big aluminium sheet, I simple connected it directly to PSU and did control the current and voltage manually.

I also used before a small aluminium sheet of 3mm, but it bended and I coudln't print on it.

I believe there is no need for PID. If for cost sensitive product, maybe a simple op-amp is ok.

If Arduino, then we can do PID but I still think it will not be necessary.

nophead Wrote:

-------------------------------------------------------

> My friend with a CNC machine shop who made my bed

> for me is planning to make and sell these with

> Kapton sheet, etc. We are exploring a vacuum hold

> down system first before completing the final

> design.

Since I can't find a machined flat table local, I would buy that product from your friend.

I do not understand why the need for vacuum hold down system... I believe I don't need it. Can you explain?

It's very important that someone produces and sells for community! Please tell your friend that this is a good idea and that maybe he should contact Makerbot and others, so they could sell also his product! And I guess 200mmX200mm would be the correct size, thinking in Mendel. And your friend could work with Makerbot for make a specific table for the CupCake CNC :-)

> BTW,

> It looks like it works with PLA as well at about

> 55C. I have some more tests to do to confirm that

> with bigger objects. I will also try HDPE at

> 120-130C. I have no idea if that will work or not

> but I will know this evening hopefully.

I will be looking at your blog ;-)

NopHead, since you are testing this, do you think that we need PID? and is important to define the time for cool down? -- I would like to know if we need a system with Arduino or maybe if a simple op-amp or transistor would be ok for this task.

And also important, would you instead control this with main board so you could control in skeinforge? do you see the need for it?

Triffid_Hunter Wrote:

-------------------------------------------------------

> a big red or amber light when platform is hot may

> be a good safety feature.

>

> I'd say your fet should be rated at 50A or more,

> since then it probably won't need a heatsink- the

> FDB 8880 (rated 54A) for example can carry 10A

> without a heatsink (10A^2 * (19mR@175C) * 62C/W +

> (50C ambient) = 167C die temperature)

How much does it cost?

And nice your calculations (if they are correct), it's important to have some developers that knows about power dissipation needed.

Would you use N or P mosfet? and why?

Edited 2 time(s). Last edit at 01/20/2010 06:35AM by casainho.

-------------------------------------------------------

> I personally would like to see a 4mm thick

> Aluminum plate for the bed as a start to making it

> low profile.

>

> Now heating the bed that is a little thinner by

> will take less power we can re- use Nopheads

> calculations so we are not re-inventing the wheel

> any more.

Yes, a thinner plate is desirable however it will be easier to bend :-( -- and this plate really need to be flat! For example, using raft on this plate at 110ºC will not avoid warp! I already tested it... because raft will soft and other first layers will make force and warp, because raft is soft and temperature do not pass very well to upper layers (I can't explain better sorry).

> That will also allow us to choose the most

> suitable size of FET to perform the required PID

> controlled switching task.

Since I have a big aluminium sheet, I simple connected it directly to PSU and did control the current and voltage manually.

I also used before a small aluminium sheet of 3mm, but it bended and I coudln't print on it.

I believe there is no need for PID. If for cost sensitive product, maybe a simple op-amp is ok.

If Arduino, then we can do PID but I still think it will not be necessary.

nophead Wrote:

-------------------------------------------------------

> My friend with a CNC machine shop who made my bed

> for me is planning to make and sell these with

> Kapton sheet, etc. We are exploring a vacuum hold

> down system first before completing the final

> design.

Since I can't find a machined flat table local, I would buy that product from your friend.

I do not understand why the need for vacuum hold down system... I believe I don't need it. Can you explain?

It's very important that someone produces and sells for community! Please tell your friend that this is a good idea and that maybe he should contact Makerbot and others, so they could sell also his product! And I guess 200mmX200mm would be the correct size, thinking in Mendel. And your friend could work with Makerbot for make a specific table for the CupCake CNC :-)

> BTW,

> It looks like it works with PLA as well at about

> 55C. I have some more tests to do to confirm that

> with bigger objects. I will also try HDPE at

> 120-130C. I have no idea if that will work or not

> but I will know this evening hopefully.

I will be looking at your blog ;-)

NopHead, since you are testing this, do you think that we need PID? and is important to define the time for cool down? -- I would like to know if we need a system with Arduino or maybe if a simple op-amp or transistor would be ok for this task.

And also important, would you instead control this with main board so you could control in skeinforge? do you see the need for it?

Triffid_Hunter Wrote:

-------------------------------------------------------

> a big red or amber light when platform is hot may

> be a good safety feature.

>

> I'd say your fet should be rated at 50A or more,

> since then it probably won't need a heatsink- the

> FDB 8880 (rated 54A) for example can carry 10A

> without a heatsink (10A^2 * (19mR@175C) * 62C/W +

> (50C ambient) = 167C die temperature)

How much does it cost?

And nice your calculations (if they are correct), it's important to have some developers that knows about power dissipation needed.

Would you use N or P mosfet? and why?

Edited 2 time(s). Last edit at 01/20/2010 06:35AM by casainho.

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 06:34AM |

Registered: 16 years ago Posts: 1,094 |

N-channel carry more current than p-channel. Vgs is important too- some fets will have a low enough Rds(on) at Vgs=4.5v, but you'll have to look for them - perhaps the IRF1405 in the link below?

If you want to know where the calculations came from, [www.mcmanis.com]

If you want to know where the calculations came from, [www.mcmanis.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 06:50AM |

Registered: 14 years ago Posts: 356 |

Triffid_Hunter Wrote:

-------------------------------------------------------

> N-channel carry more current than p-channel. Vgs

> is important too- some fets will have a low enough

> Rds(on) at Vgs=4.5v, but you'll have to look for

> them - perhaps the IRF1405 in the link below?

>

> If you want to know where the calculations came

> from,

> [www.mcmanis.com]

> 2/FET-power.html

I would go with that FDB 8880 that you said before. It's cheap, just costs 1,07€ and looks a powerful mosfet :-)

Are you able (or someone else) to make a schematic for the control of this mosfet? like I don't know if it needs a driver before it, since I remember it's good to have higher current on turn on/off slopes at gate, to minimize the power losses/heat problem on mosfet.

We could start doing the schematic, thinking that an Arduino pin or op-amp pin could control this power circuit.

Edited 1 time(s). Last edit at 01/20/2010 06:56AM by casainho.

-------------------------------------------------------

> N-channel carry more current than p-channel. Vgs

> is important too- some fets will have a low enough

> Rds(on) at Vgs=4.5v, but you'll have to look for

> them - perhaps the IRF1405 in the link below?

>

> If you want to know where the calculations came

> from,

> [www.mcmanis.com]

> 2/FET-power.html

I would go with that FDB 8880 that you said before. It's cheap, just costs 1,07€ and looks a powerful mosfet :-)

Are you able (or someone else) to make a schematic for the control of this mosfet? like I don't know if it needs a driver before it, since I remember it's good to have higher current on turn on/off slopes at gate, to minimize the power losses/heat problem on mosfet.

We could start doing the schematic, thinking that an Arduino pin or op-amp pin could control this power circuit.

Edited 1 time(s). Last edit at 01/20/2010 06:56AM by casainho.

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 08:33AM |

Admin Registered: 17 years ago Posts: 7,879 |

casainho,

The idea of the vacuum table is to use a sheet of Kapton film rather that sticky tape. When the part is built and cooled you can release the vacuum and simply peel the part off. The film can be a belt that moves over a roller to eject the part, or a moving arm could knock the part off. That would allow continuous unattended production. Also the bed only needs to be as big as the largest part reducing the power requirement and warm up time. It is maybe more complication than most people want though so it maybe just a delux option, assuming it works of course.

Even with 100W the warm up is going to be slow. I am using 200W which is not very practical to run @12V from a PC PSU, that is why I used 48V AC.

PID is not necessary when the thermocouple and heater are both in good contact with the aluminium. With band-bang the power flickers on and off and I get less than 1C swing.

For cool down I blow with a fan until it gets to 40C so is cool enough for me to handle comfortably.

I don't use Skeinforge to control my machine so I can add things like this by adding a few lines of code to my machine control script and don't have to slice the models again. I have a first layer temperature for each material and the machine waits for that to be reached. I then do the extruder warm up but they could be overlapped with a bit of logic that predicted how long it will take the bed to reach the target and scheduled the extruder warmup to overlap. After the first layer I have another material dependent bed temperature.

I would love to provide a complete solution with electronics and firmware patch but my view of how things should be done is so completely at odds with how RepRap does it that unfortunately none of my stuff like this or extruder designs are easy to drop in, which is one of the reasons I don't put them in the wiki.

[www.hydraraptor.blogspot.com]

The idea of the vacuum table is to use a sheet of Kapton film rather that sticky tape. When the part is built and cooled you can release the vacuum and simply peel the part off. The film can be a belt that moves over a roller to eject the part, or a moving arm could knock the part off. That would allow continuous unattended production. Also the bed only needs to be as big as the largest part reducing the power requirement and warm up time. It is maybe more complication than most people want though so it maybe just a delux option, assuming it works of course.

Even with 100W the warm up is going to be slow. I am using 200W which is not very practical to run @12V from a PC PSU, that is why I used 48V AC.

PID is not necessary when the thermocouple and heater are both in good contact with the aluminium. With band-bang the power flickers on and off and I get less than 1C swing.

For cool down I blow with a fan until it gets to 40C so is cool enough for me to handle comfortably.

I don't use Skeinforge to control my machine so I can add things like this by adding a few lines of code to my machine control script and don't have to slice the models again. I have a first layer temperature for each material and the machine waits for that to be reached. I then do the extruder warm up but they could be overlapped with a bit of logic that predicted how long it will take the bed to reach the target and scheduled the extruder warmup to overlap. After the first layer I have another material dependent bed temperature.

I would love to provide a complete solution with electronics and firmware patch but my view of how things should be done is so completely at odds with how RepRap does it that unfortunately none of my stuff like this or extruder designs are easy to drop in, which is one of the reasons I don't put them in the wiki.

[www.hydraraptor.blogspot.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 09:05AM |

Registered: 14 years ago Posts: 356 |

nophead Wrote:

-------------------------------------------------------

> casainho,

> The idea of the vacuum table is to use a sheet of

> Kapton film rather that sticky tape. When the part

> is built and cooled you can release the vacuum and

> simply peel the part off. The film can be a belt

> that moves over a roller to eject the part, or a

> moving arm could knock the part off. That would

> allow continuous unattended production. Also the

> bed only needs to be as big as the largest part

> reducing the power requirement and warm up time.

> It is maybe more complication than most people

> want though so it maybe just a delux option,

> assuming it works of course.

I guess then that vacuum table is not needed on RepRap Mendel, as it would complicate the system, make it more complex, fragile and expensive. And since I think that no ones need that automation on his desktop 3D printer.

Professional people should do or buy such complex systems.

Since my experience, kapton tape works perfectly and it's relative easy to remove the final piece. I have no problems with it, it's the best I found until now after using paper, acrylic and plastic tape.

Maybe your friend can still sell the aluminium bed without vacuum?

> Even with 100W the warm up is going to be slow. I

> am using 200W which is not very practical to run

> @12V from a PC PSU, that is why I used 48V AC.

I got about 30 minutes on my 150mm thick. For a no professional user, I guess 30 minutes is ok.

My PSU gives 10A @ 12V as maximum, so, 120W. I guess it can goes to 100W with safe. Even there maybe some other more powerful PSU on market.

> PID is not necessary when the thermocouple and

> heater are both in good contact with the

> aluminium. With band-bang the power flickers on

> and off and I get less than 1C swing.

Great, no need for PID.

> For cool down I blow with a fan until it gets to

> 40C so is cool enough for me to handle

> comfortably.

So you mean that you even accelerate the cool down process. I thought it needed to be larger in time that natural cool down, like need to going decreasing power over time.

For my experience natural cool down take a lot of time, I never waited for it to end :-)

So we can simple ignore this cool down functionality and let people using a fan or simple wait for natural way.

> I don't use Skeinforge to control my machine so I

> can add things like this by adding a few lines of

> code to my machine control script and don't have

> to slice the models again. I have a first layer

> temperature for each material and the machine

> waits for that to be reached. I then do the

> extruder warm up but they could be overlapped with

> a bit of logic that predicted how long it will

> take the bed to reach the target and scheduled the

> extruder warmup to overlap. After the first layer

> I have another material dependent bed

> temperature.

Ok.

> I would love to provide a complete solution with

> electronics and firmware patch but my view of how

> things should be done is so completely at odds

> with how RepRap does it that unfortunately none of

> my stuff like this or extruder designs are easy to

> drop in, which is one of the reasons I don't put

> them in the wiki.

Yes! We need to find some shop that sells the things for us. Like I would love to have your extruder, but I simple can't build it myself because I can't buy all the pieces or it simple is very expensive and difficult. The best would be someone selling it already assembled and tested.

As for heated bed, maybe we can make some prototypes and verify if it works correctly, after go to a shop like Makerbot and ask for help, for they invest, produce and sell to community. We can develop and test, no need to wait for them - remember that we have the source with us :-)

Edited 1 time(s). Last edit at 01/20/2010 09:10AM by casainho.

-------------------------------------------------------

> casainho,

> The idea of the vacuum table is to use a sheet of

> Kapton film rather that sticky tape. When the part

> is built and cooled you can release the vacuum and

> simply peel the part off. The film can be a belt

> that moves over a roller to eject the part, or a

> moving arm could knock the part off. That would

> allow continuous unattended production. Also the

> bed only needs to be as big as the largest part

> reducing the power requirement and warm up time.

> It is maybe more complication than most people

> want though so it maybe just a delux option,

> assuming it works of course.

I guess then that vacuum table is not needed on RepRap Mendel, as it would complicate the system, make it more complex, fragile and expensive. And since I think that no ones need that automation on his desktop 3D printer.

Professional people should do or buy such complex systems.

Since my experience, kapton tape works perfectly and it's relative easy to remove the final piece. I have no problems with it, it's the best I found until now after using paper, acrylic and plastic tape.

Maybe your friend can still sell the aluminium bed without vacuum?

> Even with 100W the warm up is going to be slow. I

> am using 200W which is not very practical to run

> @12V from a PC PSU, that is why I used 48V AC.

I got about 30 minutes on my 150mm thick. For a no professional user, I guess 30 minutes is ok.

My PSU gives 10A @ 12V as maximum, so, 120W. I guess it can goes to 100W with safe. Even there maybe some other more powerful PSU on market.

> PID is not necessary when the thermocouple and

> heater are both in good contact with the

> aluminium. With band-bang the power flickers on

> and off and I get less than 1C swing.

Great, no need for PID.

> For cool down I blow with a fan until it gets to

> 40C so is cool enough for me to handle

> comfortably.

So you mean that you even accelerate the cool down process. I thought it needed to be larger in time that natural cool down, like need to going decreasing power over time.

For my experience natural cool down take a lot of time, I never waited for it to end :-)

So we can simple ignore this cool down functionality and let people using a fan or simple wait for natural way.

> I don't use Skeinforge to control my machine so I

> can add things like this by adding a few lines of

> code to my machine control script and don't have

> to slice the models again. I have a first layer

> temperature for each material and the machine

> waits for that to be reached. I then do the

> extruder warm up but they could be overlapped with

> a bit of logic that predicted how long it will

> take the bed to reach the target and scheduled the

> extruder warmup to overlap. After the first layer

> I have another material dependent bed

> temperature.

Ok.

> I would love to provide a complete solution with

> electronics and firmware patch but my view of how

> things should be done is so completely at odds

> with how RepRap does it that unfortunately none of

> my stuff like this or extruder designs are easy to

> drop in, which is one of the reasons I don't put

> them in the wiki.

Yes! We need to find some shop that sells the things for us. Like I would love to have your extruder, but I simple can't build it myself because I can't buy all the pieces or it simple is very expensive and difficult. The best would be someone selling it already assembled and tested.

As for heated bed, maybe we can make some prototypes and verify if it works correctly, after go to a shop like Makerbot and ask for help, for they invest, produce and sell to community. We can develop and test, no need to wait for them - remember that we have the source with us :-)

Edited 1 time(s). Last edit at 01/20/2010 09:10AM by casainho.

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 09:25AM |

Registered: 15 years ago Posts: 478 |

Nophead

Is right as soon as you start adding vitamins like this.

RepRap ceases to be RepRap

This is also the answer to Sebastien's questions

Sorry Sebastien this not an absolute quote

Why is everyone producing separate blogs instead of posting here

~ it was because we respected the purity of the RepRap project

~ also in the beginning it was frowned upon if you were deviating from RepRapable parts.

Since RapMan and Makerbot that are impure derivatives of RepRap.

Have appeared on the scene the forum has changed and relaxed a little.

I still believe that the RepRap project can retain its purity,

It has already worked it has proven itself in so many ways already it begat

RapMan and Makerbot into viable businesses.

So as long as we maintain a pure RepRap as the low cost self replicating starting block.

Thus we will maintain the principal and purity of "Wealth without Money"

Curently being one of those without money at the moment I fully embrace this part!!

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Is right as soon as you start adding vitamins like this.

RepRap ceases to be RepRap

This is also the answer to Sebastien's questions

Sorry Sebastien this not an absolute quote

Why is everyone producing separate blogs instead of posting here

~ it was because we respected the purity of the RepRap project

~ also in the beginning it was frowned upon if you were deviating from RepRapable parts.

Since RapMan and Makerbot that are impure derivatives of RepRap.

Have appeared on the scene the forum has changed and relaxed a little.

I still believe that the RepRap project can retain its purity,

It has already worked it has proven itself in so many ways already it begat

RapMan and Makerbot into viable businesses.

So as long as we maintain a pure RepRap as the low cost self replicating starting block.

Thus we will maintain the principal and purity of "Wealth without Money"

Curently being one of those without money at the moment I fully embrace this part!!

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 09:46AM |

Registered: 15 years ago Posts: 264 |

I built a heated bed some time ago and I never blogged about it because I didn't consider it much of a success.

I had no idea how much heat would be required to heat my 150x75 mm aluminum plate. I initially started with two 10 Ohm lengths of nichrome wire in parallel held in place on the bottom of the plate and powered by 12 volts. This results in about 30 W, which clearly wasn't enough. Next I went to three 8 Ohm lengths in parallel giving me about 50 W. This got to 100 C after a very long warm up.

To reduce the warmup time I abandoned the control circuitry and just wired directly to my power supply's 12 V. It never got higher than 110 C.

I printed a number of ABS parts on this. The first few things printed without warping, as long as I left the parts on the plate to cool down with it after I was done. Eventually I found some larger or long-shaped parts that warped regardless. I eventually ran out of ABS, switched to PLA and removed the heated base plate.

The aluminum plate was bolted to my MDF build platform with a couple washers providing a gap so I didn't crush my thermistor. I did not think the nichrome wire, which was in contact with the aluminum plate would get hot enough to burn the MDF, but there are some burn marks that follow the path of the wire. I am considering buying some aluminum tape to cover the un-cooled side of the nichrome wire so it doesn't get so hot. I'll be using this on heater barrels as well.

I've seen a few blogs of people building heated base plates, but no one has posted good results specifying power used and working temperature. I take this to mean that most of the experiments ended like mine did with less than perfect results. If anyone has successful results please post them. The numbers I am most interested in is the dimensions of the aluminum plate, the max power used by the heater and the working temperature.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

I had no idea how much heat would be required to heat my 150x75 mm aluminum plate. I initially started with two 10 Ohm lengths of nichrome wire in parallel held in place on the bottom of the plate and powered by 12 volts. This results in about 30 W, which clearly wasn't enough. Next I went to three 8 Ohm lengths in parallel giving me about 50 W. This got to 100 C after a very long warm up.

To reduce the warmup time I abandoned the control circuitry and just wired directly to my power supply's 12 V. It never got higher than 110 C.

I printed a number of ABS parts on this. The first few things printed without warping, as long as I left the parts on the plate to cool down with it after I was done. Eventually I found some larger or long-shaped parts that warped regardless. I eventually ran out of ABS, switched to PLA and removed the heated base plate.

The aluminum plate was bolted to my MDF build platform with a couple washers providing a gap so I didn't crush my thermistor. I did not think the nichrome wire, which was in contact with the aluminum plate would get hot enough to burn the MDF, but there are some burn marks that follow the path of the wire. I am considering buying some aluminum tape to cover the un-cooled side of the nichrome wire so it doesn't get so hot. I'll be using this on heater barrels as well.

I've seen a few blogs of people building heated base plates, but no one has posted good results specifying power used and working temperature. I take this to mean that most of the experiments ended like mine did with less than perfect results. If anyone has successful results please post them. The numbers I am most interested in is the dimensions of the aluminum plate, the max power used by the heater and the working temperature.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 10:32AM |

Admin Registered: 17 years ago Posts: 7,879 |

@casainho,

Yes the non-vacuum version might be the simplest but it is difficult to remove big flat parts like the x-carriage without prizing with a knife. That risks damaging the part or the bed slightly. Some people may not care. Or you can just tap it with a hammer!

I use a fan to cool it down because it cools about 3 times slower than it heats otherwise and I don't want to wait that long.

Even if people could buy my extruder it would not work with the RepRap electronics or firmware. It needs a micro stepping controller that will do 1.5A. I have designed one with RS485 so in theory it would work with the RepRap hardware except I don't have extra wires for doing 5D control as I think it is barmy.

@mccoyn,

Yes I get great results and have blogged the power required, etc, See all my posts since the start of the year.

Edited 1 time(s). Last edit at 01/20/2010 10:56AM by nophead.

[www.hydraraptor.blogspot.com]

Yes the non-vacuum version might be the simplest but it is difficult to remove big flat parts like the x-carriage without prizing with a knife. That risks damaging the part or the bed slightly. Some people may not care. Or you can just tap it with a hammer!

I use a fan to cool it down because it cools about 3 times slower than it heats otherwise and I don't want to wait that long.

Even if people could buy my extruder it would not work with the RepRap electronics or firmware. It needs a micro stepping controller that will do 1.5A. I have designed one with RS485 so in theory it would work with the RepRap hardware except I don't have extra wires for doing 5D control as I think it is barmy.

@mccoyn,

Yes I get great results and have blogged the power required, etc, See all my posts since the start of the year.

Edited 1 time(s). Last edit at 01/20/2010 10:56AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 10:58AM |

Registered: 14 years ago Posts: 356 |

nophead Wrote:

-------------------------------------------------------

> @casainho,

>

> Yes the non-vacuum version might be the simplest

> but it is difficult to remove big flat parts like

> the x-carriage without prizing with a knife. That

> risks damaging the part or the bed slightly. Some

> people may not care. Or you can just tap it with a

> hammer!

Ok, then still good to go without vacuum.

> I use a fan to cool it down because it cools about

> 3 times slower than it heats otherwise and I don't

> want to wait that long.

If with fan it do not warp, than natural cool down will also not warp. I guess people can wait or then can go like you.

> Even if people could buy my extruder it would not

> work with the RepRap electronics for firmware. It

> needs a micro stepping controller that will do

> 1.5A. I have designed one with RS485 so in theory

> it would work with the RepRap hardware except I

> don't have extra wires for doing 5D control as I

> think it is barmy.

Well, I really like your printed results and you say your extruder is important for that. Let's leave this discussion for some other message in the forum. Let's continue the focus here on heated bed.

(by the way, I am even not using any RepRap hardware or firmware, things get really complicated)

> @mccoyn,

> Yes I get great results and have blogged the

> power required, etc, See all my posts since the

> start of the year.

I even did resume them on initial message and linked to your original message...

I am thinking in starting the design for the simple schematic, using Kicad. Ardunio + temperature sensor + mosfet + LCD + knob :-)

Edited 3 time(s). Last edit at 01/20/2010 11:02AM by casainho.

-------------------------------------------------------

> @casainho,

>

> Yes the non-vacuum version might be the simplest

> but it is difficult to remove big flat parts like

> the x-carriage without prizing with a knife. That

> risks damaging the part or the bed slightly. Some

> people may not care. Or you can just tap it with a

> hammer!

Ok, then still good to go without vacuum.

> I use a fan to cool it down because it cools about

> 3 times slower than it heats otherwise and I don't

> want to wait that long.

If with fan it do not warp, than natural cool down will also not warp. I guess people can wait or then can go like you.

> Even if people could buy my extruder it would not

> work with the RepRap electronics for firmware. It

> needs a micro stepping controller that will do

> 1.5A. I have designed one with RS485 so in theory

> it would work with the RepRap hardware except I

> don't have extra wires for doing 5D control as I

> think it is barmy.

Well, I really like your printed results and you say your extruder is important for that. Let's leave this discussion for some other message in the forum. Let's continue the focus here on heated bed.

(by the way, I am even not using any RepRap hardware or firmware, things get really complicated)

> @mccoyn,

> Yes I get great results and have blogged the

> power required, etc, See all my posts since the

> start of the year.

I even did resume them on initial message and linked to your original message...

I am thinking in starting the design for the simple schematic, using Kicad. Ardunio + temperature sensor + mosfet + LCD + knob :-)

Edited 3 time(s). Last edit at 01/20/2010 11:02AM by casainho.

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 11:12AM |

Registered: 15 years ago Posts: 264 |

> Yes I get great results and have blogged the power required, etc, See all my posts since the start of the year.

Oh sorry about that. I haven't been keeping up with the blogs in the last few weeks. It should be worth the read.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

Oh sorry about that. I haven't been keeping up with the blogs in the last few weeks. It should be worth the read.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 06:01PM |

Registered: 14 years ago Posts: 458 |

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 08:16PM |

Registered: 14 years ago Posts: 356 |

Grogyan Wrote:

-------------------------------------------------------

> Has anyone tried, say a 3mm thick sheet atop of

> the normal platform, usually mdf?

I did and I bought that 3mm sheet on a local shop. It came already bended and even when I fixed it using screws it got even bended on other directions.

Since 3mm is thin, it's very is to bend, even while they store it on shop it bends... a larger sheet is much more difficult to bend, that's why I asked for it on shop and my is almost perfect flat.

-------------------------------------------------------

> Has anyone tried, say a 3mm thick sheet atop of

> the normal platform, usually mdf?

I did and I bought that 3mm sheet on a local shop. It came already bended and even when I fixed it using screws it got even bended on other directions.

Since 3mm is thin, it's very is to bend, even while they store it on shop it bends... a larger sheet is much more difficult to bend, that's why I asked for it on shop and my is almost perfect flat.

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 09:10PM |

Registered: 14 years ago Posts: 458 |

casainho Wrote:

-------------------------------------------------------

> Grogyan Wrote:

> --------------------------------------------------

> -----

> > Has anyone tried, say a 3mm thick sheet atop of

> > the normal platform, usually mdf?

>

> I did and I bought that 3mm sheet on a local shop.

> It came already bended and even when I fixed it

> using screws it got even bended on other

> directions.

>

> Since 3mm is thin, it's very is to bend, even

> while they store it on shop it bends... a larger

> sheet is much more difficult to bend, that's why I

> asked for it on shop and my is almost perfect

> flat.

It was just a thought, to use one of the FET outputs on the motherboard to drive the heated bed without having to buy a second power supply.

And with it being thinner, it will have less thermal mass to heat up, so the bed should get got sooner.

There must be a way, or I could be an idiot.

-------------------------------------------------------

> Grogyan Wrote:

> --------------------------------------------------

> -----

> > Has anyone tried, say a 3mm thick sheet atop of

> > the normal platform, usually mdf?

>

> I did and I bought that 3mm sheet on a local shop.

> It came already bended and even when I fixed it

> using screws it got even bended on other

> directions.

>

> Since 3mm is thin, it's very is to bend, even

> while they store it on shop it bends... a larger

> sheet is much more difficult to bend, that's why I

> asked for it on shop and my is almost perfect

> flat.

It was just a thought, to use one of the FET outputs on the motherboard to drive the heated bed without having to buy a second power supply.

And with it being thinner, it will have less thermal mass to heat up, so the bed should get got sooner.

There must be a way, or I could be an idiot.

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 09:18PM |

Admin Registered: 17 years ago Posts: 1,791 |

Stupid question: would a simple sheet of tempered glass bedded in silicone laid down over framing work? Or is it too tricky to heat up? Because I know that we can get tempered glass cut to spec everywhere.

(via this fascinating derail: [www.metafilter.com])

(via this fascinating derail: [www.metafilter.com])

|

Re: A call for help/ideas to develop the Heated Build Platform January 20, 2010 10:24PM |

Registered: 14 years ago Posts: 117 |

Aluminum plate made to fit a Mendel with one of these on the underside

[www.mcmaster.com]

Put a very simple potentiometer setup on the heater and you have a heated platform. These flat blanket heaters even come with adhesive on one side. I used these back in the day to pre-heat and heat up injection tools and they get quite hot! You get the flat profile and ease of use just dial in your temp and walk away no code to mess with. Simple easy and elegant.

Edited 1 time(s). Last edit at 01/20/2010 10:29PM by Curlrup.

[www.mcmaster.com]

Put a very simple potentiometer setup on the heater and you have a heated platform. These flat blanket heaters even come with adhesive on one side. I used these back in the day to pre-heat and heat up injection tools and they get quite hot! You get the flat profile and ease of use just dial in your temp and walk away no code to mess with. Simple easy and elegant.

Edited 1 time(s). Last edit at 01/20/2010 10:29PM by Curlrup.

|

Re: A call for help/ideas to develop the Heated Build Platform January 21, 2010 07:35AM |

Registered: 14 years ago Posts: 356 |

I just made the schematic. Please everyone verify (SEE THE ATTACHMENT) if there are some problems on it, or any changes that should be done. There is an .png file and the sources files for Kicad.

Soon I may buy the temperature sensor and mosfet from Farnell.com. I have all other material with me. If someone can test this circuit, please report later :-)

SebastienBailard Wrote:

-------------------------------------------------------

> Stupid question: would a simple sheet of tempered

> glass bedded in silicone laid down over framing

> work? Or is it too tricky to heat up? Because I

> know that we can get tempered glass cut to spec

> everywhere.

I think glass is bad at conduct the temperature, with aluminium we can get under a few hot spots and in top side the temperature may get almost equal in all area.

Curlrup Wrote:

-------------------------------------------------------

> Aluminum plate made to fit a Mendel with one of

> these on the underside

>

> [www.mcmaster.com]

>

> Put a very simple potentiometer setup on the

> heater and you have a heated platform. These flat

> blanket heaters even come with adhesive on one

> side. I used these back in the day to pre-heat

> and heat up injection tools and they get quite

> hot! You get the flat profile and ease of use

> just dial in your temp and walk away no code to

> mess with. Simple easy and elegant.

Would be important if someone post images and tests with that solution.

Edited 4 time(s). Last edit at 01/21/2010 09:55AM by casainho.

Soon I may buy the temperature sensor and mosfet from Farnell.com. I have all other material with me. If someone can test this circuit, please report later :-)

SebastienBailard Wrote:

-------------------------------------------------------

> Stupid question: would a simple sheet of tempered

> glass bedded in silicone laid down over framing

> work? Or is it too tricky to heat up? Because I

> know that we can get tempered glass cut to spec

> everywhere.

I think glass is bad at conduct the temperature, with aluminium we can get under a few hot spots and in top side the temperature may get almost equal in all area.

Curlrup Wrote:

-------------------------------------------------------

> Aluminum plate made to fit a Mendel with one of

> these on the underside

>

> [www.mcmaster.com]

>

> Put a very simple potentiometer setup on the

> heater and you have a heated platform. These flat

> blanket heaters even come with adhesive on one

> side. I used these back in the day to pre-heat

> and heat up injection tools and they get quite

> hot! You get the flat profile and ease of use

> just dial in your temp and walk away no code to

> mess with. Simple easy and elegant.

Would be important if someone post images and tests with that solution.

Edited 4 time(s). Last edit at 01/21/2010 09:55AM by casainho.

|

Re: A call for help/ideas to develop the Heated Build Platform January 22, 2010 01:11AM |

Registered: 14 years ago Posts: 134 |

this seemed like a stupidly simple solution:

[prusadjs.cz]

Makerbot sells nichrome wire

Also you might consider buying a reptile heating pad at a petstore and using a different power source to supply more current, a good temp seems to be 140-160 if plastic bed The reptile warmers are just nichrome wire laid out between two plastic sheets.

[prusadjs.cz]

Makerbot sells nichrome wire

Also you might consider buying a reptile heating pad at a petstore and using a different power source to supply more current, a good temp seems to be 140-160 if plastic bed The reptile warmers are just nichrome wire laid out between two plastic sheets.

|

Re: A call for help/ideas to develop the Heated Build Platform January 22, 2010 05:18AM |

Registered: 15 years ago Posts: 478 |

What a neat simple solution with a choice of colour and finish.

The depths being 6mm ~ 9mm Tiles can be cut to any size or shape easily.

With shiny Marble composite being available in 6mm I believe.

They also make tile heater element for under tile heating that it might be possible to utilize if it has a low enough resistance for our low voltage requirement.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

The depths being 6mm ~ 9mm Tiles can be cut to any size or shape easily.

With shiny Marble composite being available in 6mm I believe.

They also make tile heater element for under tile heating that it might be possible to utilize if it has a low enough resistance for our low voltage requirement.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: A call for help/ideas to develop the Heated Build Platform January 22, 2010 06:46AM |

Registered: 14 years ago Posts: 356 |

goinreverse Wrote:

-------------------------------------------------------

> this seemed like a stupidly simple solution:

>

> [prusadjs.cz]

You are using acrylic which is problematic on this application, as both NopHead and me reported.

> Also you might consider buying a reptile heating

> pad at a petstore and using a different power

> source to supply more current, a good temp seems

> to be 140-160 if plastic bed The reptile warmers

> are just nichrome wire laid out between two

> plastic sheets.

Looks a good idea but until someone buy such thing and test and report, it's just an idea :-)

I already contacted Makerbot asking if they can help us, by building and selling such system.

I saw that there is a wiki page on Makerbot about this same subject... and since Makerbot have much more users (and will continue to grow because it's a service that puts 3D printers on peoples hands) eventually we will see the first system for it, since Makerbot community is bigger - the numbers on Makerbot CupCake CNC out there are for sure higher than RepRap Mendel.

-------------------------------------------------------

> this seemed like a stupidly simple solution:

>

> [prusadjs.cz]

You are using acrylic which is problematic on this application, as both NopHead and me reported.

> Also you might consider buying a reptile heating

> pad at a petstore and using a different power

> source to supply more current, a good temp seems

> to be 140-160 if plastic bed The reptile warmers

> are just nichrome wire laid out between two

> plastic sheets.

Looks a good idea but until someone buy such thing and test and report, it's just an idea :-)

I already contacted Makerbot asking if they can help us, by building and selling such system.

I saw that there is a wiki page on Makerbot about this same subject... and since Makerbot have much more users (and will continue to grow because it's a service that puts 3D printers on peoples hands) eventually we will see the first system for it, since Makerbot community is bigger - the numbers on Makerbot CupCake CNC out there are for sure higher than RepRap Mendel.

|

Re: A call for help/ideas to develop the Heated Build Platform January 22, 2010 04:23PM |

Admin Registered: 17 years ago Posts: 1,791 |

I already contacted Makerbot asking if they can help us, by building and selling such system.

They're very keen at building and selling stuff, and I'm sure we'll see some documentation from them up on [[Heated_Bed]] soon enough.

Edited 1 time(s). Last edit at 01/22/2010 04:23PM by SebastienBailard.

They're very keen at building and selling stuff, and I'm sure we'll see some documentation from them up on [[Heated_Bed]] soon enough.

Edited 1 time(s). Last edit at 01/22/2010 04:23PM by SebastienBailard.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 22, 2010 05:22PM |

Registered: 14 years ago Posts: 10 |

If you are using a metal plate as your base, why not use an infrared lamp set up below the plate to heat it? It would be simple to control the heating effect using diac/triac chopped mains control and feed back sensor such as a thermister. Basically, you could use the heater control circuit from the extruder and control an electronic relay rated for mains voltage. You would need some sort of electrical isolation though. This way you could have decent thermal inertia on a relatively thin base plate, controllable cool down cycle and a high, stable, top temp. And it is relatively simple.

Just an idea.

Just an idea.

|

Re: A call for help/ideas to develop the Heated Build Platform January 22, 2010 06:01PM |

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 22, 2010 06:48PM |

Registered: 14 years ago Posts: 387 |

|

Re: A call for help/ideas to develop the Heated Build Platform January 22, 2010 09:36PM |

Admin Registered: 17 years ago Posts: 1,791 |

I wonder if an induction heater would work for something like this. If we need the bed to heat up and cool down quickly, induction might be the ticket (though I think we'd have to use something other than aluminum for the bed).

Nope. Resistive heating is easier. Fun idea though, but much better to melt a coffe-mug of bronze or something.

Nope. Resistive heating is easier. Fun idea though, but much better to melt a coffe-mug of bronze or something.

Sorry, only registered users may post in this forum.