A call for help/ideas to develop the Heated Bed

Posted by casainho

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 23, 2010 06:02AM |

Registered: 16 years ago Posts: 204 |

nophead wrote:

> The idea of the vacuum table is to use a sheet of Kapton film rather

> that sticky tape.

Im thinking more about stainless steal bed, and the kapton tape attached with magnets.

[Edit: I added the "guys with beer" we've been using to announce working parties". -Sebastien]

Edited 1 time(s). Last edit at 01/25/2010 06:53PM by SebastienBailard.

Mendel build log: [blog.arcol.hu]

> The idea of the vacuum table is to use a sheet of Kapton film rather

> that sticky tape.

Im thinking more about stainless steal bed, and the kapton tape attached with magnets.

[Edit: I added the "guys with beer" we've been using to announce working parties". -Sebastien]

Edited 1 time(s). Last edit at 01/25/2010 06:53PM by SebastienBailard.

Mendel build log: [blog.arcol.hu]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 23, 2010 07:34AM |

Admin Registered: 17 years ago Posts: 7,879 |

Stainless steel is a very poor conductor of heat. The main reason for using aluminium is that it is a very good conductor, so the heat will be even across the whole bed with only a few heating elements. To use SS you would need a well distributed heat source.

Magnets do not stick to most stainless steels. Some alloys are attracted slightly to strong magnets, but not well enough to hold anything.

If you only hold the film around the edges there is nothing to stop the object lifting the middle as it tries to curl upwards. Even if you stretch it as tight as a drum it is still very easy to displace the middle vertically.

Edited 1 time(s). Last edit at 01/23/2010 08:06AM by nophead.

[www.hydraraptor.blogspot.com]

Magnets do not stick to most stainless steels. Some alloys are attracted slightly to strong magnets, but not well enough to hold anything.

If you only hold the film around the edges there is nothing to stop the object lifting the middle as it tries to curl upwards. Even if you stretch it as tight as a drum it is still very easy to displace the middle vertically.

Edited 1 time(s). Last edit at 01/23/2010 08:06AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 23, 2010 08:31AM |

Registered: 16 years ago Posts: 204 |

> Stainless steel is a very poor conductor of heat.

Yepp, but you use 6mm thick aluminium sheet, while 2mm steal sheet is more then enough, and not too heavy either. A 35x35cm piece of sheet is 2.3kg, while bitsfrombytes plastic bed is 1.3kg.

Steal is not really needed (or stainless steal), a regular cheap iron sheet is enough I think.

Using the magnets I have a slightly different idea. when the first layer is printed, I could place magnets around the object.

I need to experiment more, I will report my success or failure in some weeks;-)

Yepp, but you use 6mm thick aluminium sheet, while 2mm steal sheet is more then enough, and not too heavy either. A 35x35cm piece of sheet is 2.3kg, while bitsfrombytes plastic bed is 1.3kg.

Steal is not really needed (or stainless steal), a regular cheap iron sheet is enough I think.

Using the magnets I have a slightly different idea. when the first layer is printed, I could place magnets around the object.

I need to experiment more, I will report my success or failure in some weeks;-)

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 23, 2010 11:15AM |

Registered: 15 years ago Posts: 264 |

If you have a layer of aluminum below a layer of steel, the difference in conductivity will help to spread the heat out (it is easier for heat to move along the aluminum than straight out the steel). You need a better insulator below the aluminum otherwise you will lose all your heat that way. This is all rather complicated since it appears that a simple sheet of aluminum heated from the bottom does well enough.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 25, 2010 09:16AM |

Registered: 14 years ago Posts: 356 |

I added the schematic to wiki page and technical description.

I also got an answer from Bre Pettis of Makerbot, when I asked them:

"I am contacting Makerbot because I would like that Makerbot start selling heated build platforms. There are already good experiments and results (...)"

Answer: "Yup, we're on this! Thanks!".

I sent them the link for this forum message, I am sure they are following all our ideas and tests :-)

Let's see if they will come with a cheap and simple solution... I am curious.

Edited 2 time(s). Last edit at 01/25/2010 06:14PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

I also got an answer from Bre Pettis of Makerbot, when I asked them:

"I am contacting Makerbot because I would like that Makerbot start selling heated build platforms. There are already good experiments and results (...)"

Answer: "Yup, we're on this! Thanks!".

I sent them the link for this forum message, I am sure they are following all our ideas and tests :-)

Let's see if they will come with a cheap and simple solution... I am curious.

Edited 2 time(s). Last edit at 01/25/2010 06:14PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 25, 2010 06:08PM |

Admin Registered: 17 years ago Posts: 1,791 |

Thanks for working on this and thanks for starting this thread, by the way.

Want to attach the current working symbol for "working party" to the top?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

Want to attach the current working symbol for "working party" to the top?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 25, 2010 06:12PM |

Registered: 14 years ago Posts: 356 |

SebastienBailard Wrote:

-------------------------------------------------------

> Want to attach the current working symbol for

> "working party" to the top?

I don't understand what you mean.

Isn't there a way to use external images on wiki? And is possible to use an image at a different size, doing resize? defining with and height?

Edited 1 time(s). Last edit at 01/25/2010 06:20PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Want to attach the current working symbol for

> "working party" to the top?

I don't understand what you mean.

Isn't there a way to use external images on wiki? And is possible to use an image at a different size, doing resize? defining with and height?

Edited 1 time(s). Last edit at 01/25/2010 06:20PM by casainho.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 25, 2010 06:59PM |

Admin Registered: 17 years ago Posts: 1,791 |

> Want to attach the current working symbol for

> "working party" to the top? smileys with beer

I don't understand what you mean.

Sorry, that was obscure. I just added "smileys with beer" to the thread title, since this seems to be a working party.

Isn't there a way to use external images on wiki? And is possible to use an image at a different size, doing resize? defining with and height?

Yes, use the example here:

[objects.reprap.org]

We need to do that automatically for new pages by default, until we change or nuke the mediawiki. Right now I have to hand paste it in when I create new pages for folk. I'm hoping as we bootstrap a RepRap forum population that can hack mediawiki , we'll have more tools, and we'll evolve thingiverse-like functionality with the mediawiki software or go to a new software that does.

> "working party" to the top? smileys with beer

I don't understand what you mean.

Sorry, that was obscure. I just added "smileys with beer" to the thread title, since this seems to be a working party.

Isn't there a way to use external images on wiki? And is possible to use an image at a different size, doing resize? defining with and height?

Yes, use the example here:

[objects.reprap.org]

We need to do that automatically for new pages by default, until we change or nuke the mediawiki. Right now I have to hand paste it in when I create new pages for folk. I'm hoping as we bootstrap a RepRap forum population that can hack mediawiki , we'll have more tools, and we'll evolve thingiverse-like functionality with the mediawiki software or go to a new software that does.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 26, 2010 06:48AM |

Registered: 15 years ago Posts: 478 |

LoL party on dude..

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 26, 2010 12:16PM |

Registered: 14 years ago Posts: 356 |

I got PLA for the first time and did a print using heated bed at 55ºC, and it worked perfectly :-) -- so, the values reported by NopHead are correct for PLA and ABS.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 26, 2010 01:34PM |

Registered: 14 years ago Posts: 387 |

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 04:04AM |

Registered: 14 years ago Posts: 134 |

Just a though but you can get 9"x9"x1/4" ceramic sheet from mcmaster for $46, part number 8479K116

Lay a zig zag of nichrome wire and a suitable resistor on the bottom and RTV or epoxy in place you are done. Certainly you could do the same with aluminum but I think hot spots would be an issue.

12x12x1/8" aluminum sheet part number 89015K18 $26

Also might be worth looking at 12"x12" kapton sheets:

2271K1 $9

or with adhesive back

2271K71 $12

Edited 1 time(s). Last edit at 01/27/2010 04:08AM by goinreverse.

Lay a zig zag of nichrome wire and a suitable resistor on the bottom and RTV or epoxy in place you are done. Certainly you could do the same with aluminum but I think hot spots would be an issue.

12x12x1/8" aluminum sheet part number 89015K18 $26

Also might be worth looking at 12"x12" kapton sheets:

2271K1 $9

or with adhesive back

2271K71 $12

Edited 1 time(s). Last edit at 01/27/2010 04:08AM by goinreverse.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 07:39AM |

I ordered some peltier units from here,[www.virtualvillage.co.uk][/url] , they heat up very quickly and can cool by reversing the polarity, not as cheap as nichrome etc but neat units at the price, this site also do PID controllers at a very reasonable price.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 09:03AM |

Registered: 14 years ago Posts: 356 |

johnrpm Wrote:

-------------------------------------------------------

> I ordered some peltier units from

> here,[www.virtualvillage.co.uk]

> XJxJ8CFV1d4wod2VuThg , they heat up very quickly

> and can cool by reversing the polarity, not as

> cheap as nichrome etc but neat units at the price,

> this site also do PID controllers at a very

> reasonable price.

That's important to have an idea and going discover about it ;-)

I also have at home a peltier bought on Ebay, porbably equals to yours. I quick tested it and looks like it's quick, however I had read that they have a maximum delta temperature between the 2 faces, or it will "burn", go to trash, I mean.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> I ordered some peltier units from

> here,[www.virtualvillage.co.uk]

> XJxJ8CFV1d4wod2VuThg , they heat up very quickly

> and can cool by reversing the polarity, not as

> cheap as nichrome etc but neat units at the price,

> this site also do PID controllers at a very

> reasonable price.

That's important to have an idea and going discover about it ;-)

I also have at home a peltier bought on Ebay, porbably equals to yours. I quick tested it and looks like it's quick, however I had read that they have a maximum delta temperature between the 2 faces, or it will "burn", go to trash, I mean.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 09:28AM |

Registered: 14 years ago Posts: 356 |

goinreverse Wrote:

-------------------------------------------------------

> Just a though but you can get 9"x9"x1/4" ceramic

> sheet from mcmaster for $46, part number 8479K116

Very expensive but good for under side of the bed, for temperature insulating.

> Lay a zig zag of nichrome wire and a suitable

> resistor on the bottom and RTV or epoxy in place

> you are done. Certainly you could do the same with

> aluminum but I think hot spots would be an issue.

I am using aluminium and nichrome wire. Local I can find various sizes of nichrome wire and cheap :-)

I never worked with epoxy, but if it would help me to fixe the wire to aluminum, then it could be the best option... I am using katpon tape and after a PCB to try press the wire agains aluminium.

Aluminiun is a good temperature conductor, so is good for this appication where we may have just a few heated spots but we need all upper face hot at same value.

> 12x12x1/8" aluminum sheet part number 89015K18

> $26

Would be nice maybe to have one that matches Mendel size, or at least maxium mendel pieces size :-)

And someone would need to buy this sheets and test. They have also machine sheets: "Consistently flat, square, and parallel on all six sides, you can simply place these blanks in your CNC machine and start machining. Each comes with a traceable lot number and physical test report. Tolerance on all dimensions is ±0.002". Very expensive... maybe we don't need such flatness. Part Number: 9057K13.

> Also might be worth looking at 12"x12" kapton

> sheets:

>

> 2271K1 $9

>

> or with adhesive back

>

> 2271K71 $12

Adhesive back is a must, but $12 for one sheet is very expensive, IMO. I am using a 24mm large katpon tape. 33 meters of it just costs $4.20 including shipping!

However, we could add this items to wiki page, having a few options so people can choose his best ones.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> Just a though but you can get 9"x9"x1/4" ceramic

> sheet from mcmaster for $46, part number 8479K116

Very expensive but good for under side of the bed, for temperature insulating.

> Lay a zig zag of nichrome wire and a suitable

> resistor on the bottom and RTV or epoxy in place

> you are done. Certainly you could do the same with

> aluminum but I think hot spots would be an issue.

I am using aluminium and nichrome wire. Local I can find various sizes of nichrome wire and cheap :-)

I never worked with epoxy, but if it would help me to fixe the wire to aluminum, then it could be the best option... I am using katpon tape and after a PCB to try press the wire agains aluminium.

Aluminiun is a good temperature conductor, so is good for this appication where we may have just a few heated spots but we need all upper face hot at same value.

Quote

My chat with NopHEad

> Yes, but there is the need to put the power

> resistors on it, electronic box with control

> circuit and temperature insulators for under the

> bed. I wish I could buy all that already assembled

> and working perfectly.

I think it will become available eventually. There are a few things to optimise for commercial production though. Tapping blind M2 threads is tricky and time consuming. I don't know if can be automated. Switching to the T0220 resistors mean less holes and bigger is easier to tap. Perhaps 4 will work just as well as 9. Maybe even one big one in the middle is sufficient. Or a stick on silicone sheet heater could be used for much less labour, but a lot more parts cost.

> 12x12x1/8" aluminum sheet part number 89015K18

> $26

Would be nice maybe to have one that matches Mendel size, or at least maxium mendel pieces size :-)

And someone would need to buy this sheets and test. They have also machine sheets: "Consistently flat, square, and parallel on all six sides, you can simply place these blanks in your CNC machine and start machining. Each comes with a traceable lot number and physical test report. Tolerance on all dimensions is ±0.002". Very expensive... maybe we don't need such flatness. Part Number: 9057K13.

> Also might be worth looking at 12"x12" kapton

> sheets:

>

> 2271K1 $9

>

> or with adhesive back

>

> 2271K71 $12

Adhesive back is a must, but $12 for one sheet is very expensive, IMO. I am using a 24mm large katpon tape. 33 meters of it just costs $4.20 including shipping!

However, we could add this items to wiki page, having a few options so people can choose his best ones.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 10:47AM |

Peltier units have a hot side and a cold side, (thermocouples) and they have to have a heatsink and fan, but this could be the bedplate perhaps, they can also generate electricity if heated, which makes them interesting. I am using mine at the moment to cool a block of alluminium, 50x50x20 and it gets down to -5C in a few minutes, they are used in those tiny fridges that hold one milk bottle.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 11:36AM |

Registered: 14 years ago Posts: 356 |

So, how do you think it could be used? maybe placed under the aluminium and glued?

And since we need 120ºC for ABS and 55ºC for PLA, do you think it could handle it?

Can you make tests for that temperatures?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

And since we need 120ºC for ABS and 55ºC for PLA, do you think it could handle it?

Can you make tests for that temperatures?

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 02:58PM |

Registered: 16 years ago Posts: 1,094 |

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 03:04PM |

Registered: 14 years ago Posts: 356 |

Triffid_Hunter Wrote:

-------------------------------------------------------

> last time I checked, peltiers have a max delta t

> of about 65 celsius so you'd need to stack two or

> three of them

I didn't know that was possible. Will it work? I hope someone can test this.

But I suspect that nichrome wire will be much more cheaper than that solution.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

-------------------------------------------------------

> last time I checked, peltiers have a max delta t

> of about 65 celsius so you'd need to stack two or

> three of them

I didn't know that was possible. Will it work? I hope someone can test this.

But I suspect that nichrome wire will be much more cheaper than that solution.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 05:27PM |

Registered: 14 years ago Posts: 134 |

I guess expense is all relative. $40 for a pre-cut to size of sheet metal to someone without a bandsaw/etc seems like a pretty good deal...

$12 for a sheet of kapton also seems like no-brainer to me if it improves the quality of the prints and takes less time than cutting and pasting 30 strips of kapton tape. Then again I am generally looking to print molds and prototypes that get turned in to $5,000 to $20,000 toolings for injection molding and vacuum forming, YMMV.

My experience with peltiers is that they may not have a very good durability profile for the temperature ranges relevant here. There is a good reason when we don't have peltiers as stove tops or in ovens. Given that nichrome is so dirt cheap I don't get the reasoning.

$12 for a sheet of kapton also seems like no-brainer to me if it improves the quality of the prints and takes less time than cutting and pasting 30 strips of kapton tape. Then again I am generally looking to print molds and prototypes that get turned in to $5,000 to $20,000 toolings for injection molding and vacuum forming, YMMV.

My experience with peltiers is that they may not have a very good durability profile for the temperature ranges relevant here. There is a good reason when we don't have peltiers as stove tops or in ovens. Given that nichrome is so dirt cheap I don't get the reasoning.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 27, 2010 06:48PM |

Admin Registered: 17 years ago Posts: 1,791 |

Hey folk. I added this forum thread to:

[objects.reprap.org]

as a possible entry if you guys are interested on working towards this. If you guys think this is inappropriate, confer amongst yourselves, and then have one of you tweak the wiki appropriately, following up with a post in this thread so that we know what's going on.

In part, I wanted to "seed", or start. the page with some entries, and you guys looked good. It was impulsive, but I hope that wasn't innapropriate.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

[objects.reprap.org]

as a possible entry if you guys are interested on working towards this. If you guys think this is inappropriate, confer amongst yourselves, and then have one of you tweak the wiki appropriately, following up with a post in this thread so that we know what's going on.

In part, I wanted to "seed", or start. the page with some entries, and you guys looked good. It was impulsive, but I hope that wasn't innapropriate.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 28, 2010 03:40AM |

I am not saying peltier units are the best way to go, I am simply pointing out alternatives, some years ago I built a small sls system, it needed the powder bed heated, simple problem you would think, but the parts had different characteristics in different areas of the bed, when a thermal camera was used it showed a distinct heat map across the platform, this may not be a critical issue with the reprap but it taught me a lesson on the complexities of dealing with heat.

my current project is all about cooling, but I would like to use them for energy recovery at some point,

> Can you make tests for that temperatures?

Yes but time is always an issue, what tests would you like me to do

my current project is all about cooling, but I would like to use them for energy recovery at some point,

> Can you make tests for that temperatures?

Yes but time is always an issue, what tests would you like me to do

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 28, 2010 08:02PM |

Registered: 14 years ago Posts: 356 |

> > Can you make tests for that temperatures?

>

> Yes but time is always an issue, what tests would

> you like me to do

I mean testing your idea, using peltier module to head a aluminium bed.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

>

> Yes but time is always an issue, what tests would

> you like me to do

I mean testing your idea, using peltier module to head a aluminium bed.

---

New cutting edge RepRap electronics, ARM 32 bits @ 100MHz runs RepRap @ 725mm/s:

[www.3dprinting-r2c2.com]

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 28, 2010 09:42PM |

Registered: 14 years ago Posts: 278 |

johnrpm Wrote:

-------------------------------------------------------

> my current project is all about cooling, but I

> would like to use them for energy recovery at some

> point,

Just to be sure, Peltier devices are very inefficient (5-10% theoretical limits), both in terms of cooling, and in terms of energy production. I did read some research project a few years back that attempted to get much higher efficiencies at the nano-scale, but at this point, I am not aware as to whether any device came out of it. For heat differential generation and energy production, a sterling system or reverse Rankine systems have much greater efficiencies, typically 30-40%.

However, as heating devices, Peltier units have much greater efficiency than, say, nichrome wire, assuming you good heat supply to draw from; they both generate heat internally, and move heat from your supply into your 'hot' zone.

-------------------------------------------------------

> my current project is all about cooling, but I

> would like to use them for energy recovery at some

> point,

Just to be sure, Peltier devices are very inefficient (5-10% theoretical limits), both in terms of cooling, and in terms of energy production. I did read some research project a few years back that attempted to get much higher efficiencies at the nano-scale, but at this point, I am not aware as to whether any device came out of it. For heat differential generation and energy production, a sterling system or reverse Rankine systems have much greater efficiencies, typically 30-40%.

However, as heating devices, Peltier units have much greater efficiency than, say, nichrome wire, assuming you good heat supply to draw from; they both generate heat internally, and move heat from your supply into your 'hot' zone.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 28, 2010 10:07PM |

Registered: 16 years ago Posts: 1,094 |

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 28, 2010 10:38PM |

Registered: 14 years ago Posts: 278 |

Triffid_Hunter Wrote:

-------------------------------------------------------

> last I checked, they were reasonably efficient for

> no moving parts- a 50w peltier would give you 50w

> of cooling and 100w of heat to dissipate on the

> hot side. not sure how that translates into

> percentage since I don't know the theoretical

> limits of moving thermal energy

The theoretical limit for pumping heat from a 10 Celcius to 35 Celcius is 12x the energy input. You need the temperature variation to determine the exact efficiency for the numbers you've expressed; I'm guessing the numbers you were giving were moving heat from a hot zone to a cool zone (E.G, the cooling effect?) Assuming it was at an average of 8% heat pump efficiency, that means a conventional pressure based heat pump would move 3 times as much heat or so (50W would give you 150W of cooling or 200W of heat, assuming you could figure out a way to extract the heat generated by the working machine, or 150W minimum, anyway..)

I'm not trying to discourage the concept though; actually, the opposite; using a Peltier for heating could improve the heated platform efficiency to the point that long term, its worth the extra cost.

-------------------------------------------------------

> last I checked, they were reasonably efficient for

> no moving parts- a 50w peltier would give you 50w

> of cooling and 100w of heat to dissipate on the

> hot side. not sure how that translates into

> percentage since I don't know the theoretical

> limits of moving thermal energy

The theoretical limit for pumping heat from a 10 Celcius to 35 Celcius is 12x the energy input. You need the temperature variation to determine the exact efficiency for the numbers you've expressed; I'm guessing the numbers you were giving were moving heat from a hot zone to a cool zone (E.G, the cooling effect?) Assuming it was at an average of 8% heat pump efficiency, that means a conventional pressure based heat pump would move 3 times as much heat or so (50W would give you 150W of cooling or 200W of heat, assuming you could figure out a way to extract the heat generated by the working machine, or 150W minimum, anyway..)

I'm not trying to discourage the concept though; actually, the opposite; using a Peltier for heating could improve the heated platform efficiency to the point that long term, its worth the extra cost.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 29, 2010 02:48AM |

Registered: 14 years ago Posts: 134 |

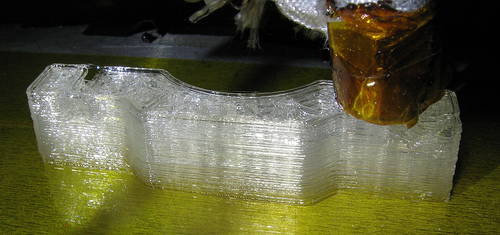

"official makerbot solution" based on the hive76 guys:

[wiki.makerbot.com]

Nichrome wire embedded in clear silicone, electrically safe and fairly fire resistant, relatively cheap. Seems like a strong solution.

[wiki.makerbot.com]

Nichrome wire embedded in clear silicone, electrically safe and fairly fire resistant, relatively cheap. Seems like a strong solution.

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 29, 2010 04:39AM |

Registered: 14 years ago Posts: 134 |

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 30, 2010 11:26AM |

|

Re: A call for help/ideas to develop the [[Heated Bed]] Build Platform January 30, 2010 12:26PM |

Registered: 16 years ago Posts: 184 |

Sorry, only registered users may post in this forum.