what are we really trying to acomplish with the cooling fan

Posted by Bill Clark

|

what are we really trying to acomplish with the cooling fan April 12, 2014 06:57PM |

Registered: 10 years ago Posts: 239 |

|

Re: what are we really trying to acomplish with the cooling fan April 12, 2014 08:34PM |

Registered: 10 years ago Posts: 474 |

|

Re: what are we really trying to acomplish with the cooling fan April 13, 2014 03:49AM |

Registered: 10 years ago Posts: 239 |

|

Re: what are we really trying to acomplish with the cooling fan April 13, 2014 04:57AM |

Registered: 12 years ago Posts: 1,450 |

I have tried using nozzles as well as a ring jet very close to the nozzle. My intention was to cool the extruded plastic to a point where it was solitd enough to resist creeping, while hot enough to minimise distortion.

Also seen in [www.youtube.com]

You will notice that I also use the exhaust from the heatsink fan directed against the (insulated) square block of the heater - this creates burble - turbulence which gives a better distribution of air. That does work well.

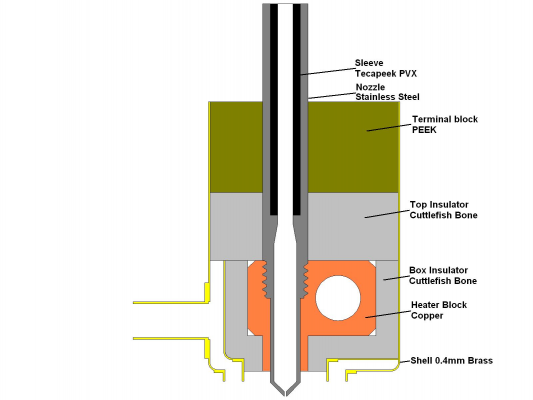

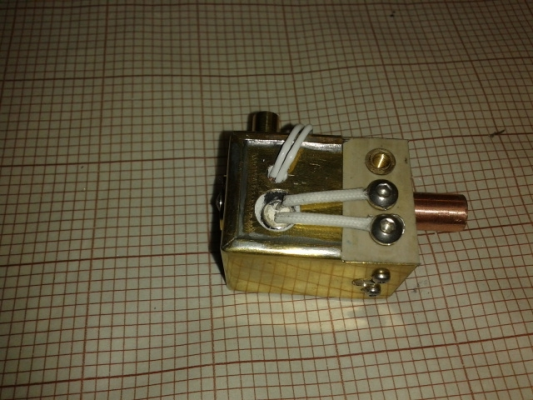

The air ring looked like this

Although I use the air ring, my conclusion is that is isn't snake oil (doesn't cure all ills). For both the nozzle and air ring setup the optimum flow seems to be about 4 liters per minute.

Mike

edit: in the sectioned picture I show Tecapeek used for the tube to the hot end. This was a failure DO NOT DO IT.

Edited 1 time(s). Last edit at 04/13/2014 05:01AM by leadinglights.

Also seen in [www.youtube.com]

You will notice that I also use the exhaust from the heatsink fan directed against the (insulated) square block of the heater - this creates burble - turbulence which gives a better distribution of air. That does work well.

The air ring looked like this

Although I use the air ring, my conclusion is that is isn't snake oil (doesn't cure all ills). For both the nozzle and air ring setup the optimum flow seems to be about 4 liters per minute.

Mike

edit: in the sectioned picture I show Tecapeek used for the tube to the hot end. This was a failure DO NOT DO IT.

Edited 1 time(s). Last edit at 04/13/2014 05:01AM by leadinglights.

|

Re: what are we really trying to acomplish with the cooling fan April 13, 2014 12:58PM |

Registered: 10 years ago Posts: 239 |

|

Re: what are we really trying to acomplish with the cooling fan April 17, 2014 09:09AM |

Registered: 11 years ago Posts: 253 |

Last year, I used an iwata airbrush pump to put air where I needed it. on the cold end section right above the hotend. it was noisy, and didn't help eliminate jamming.

I'll try to dig up a picture shortly, of the CAD image at least. I was thinking this would be a good way to bring cold air into a heated build chamber. not sure it's necessary to do this.

I also tried a lumbar air pump from a Ford truck (low flow) and some ebay air pumps, plus a Keurig pump from a dead coffee maker. This cold directed air idea just stopped for me.

I like a simple fan flowing over the extruder motor, because on long prints, the motor heats up and the since it's a direct drive setup, the PLA softens at the pinch wheels.

I turn off the extruder motor when not used, so that helps reduce heat if idle.

Also, very well known, the fan flow is useful to cool the printed part to prevent sag, when the heat builds up in the print.

Finally, the cold end heatsink always benefits from flow.

I'll try to dig up a picture shortly, of the CAD image at least. I was thinking this would be a good way to bring cold air into a heated build chamber. not sure it's necessary to do this.

I also tried a lumbar air pump from a Ford truck (low flow) and some ebay air pumps, plus a Keurig pump from a dead coffee maker. This cold directed air idea just stopped for me.

I like a simple fan flowing over the extruder motor, because on long prints, the motor heats up and the since it's a direct drive setup, the PLA softens at the pinch wheels.

I turn off the extruder motor when not used, so that helps reduce heat if idle.

Also, very well known, the fan flow is useful to cool the printed part to prevent sag, when the heat builds up in the print.

Finally, the cold end heatsink always benefits from flow.

Sorry, only registered users may post in this forum.