Bowden vs Direct Feed Extruder?

Posted by ayouden

|

Bowden vs Direct Feed Extruder? April 24, 2014 02:19PM |

Registered: 10 years ago Posts: 190 |

Hey,

I am thinking of building a 3D printer from the ground up.

I have outlined that It should be fast and have great print quality.

However, I have seem to run into an issue.

The Replicator 2 is known for its high quality, and the Ultimaker is known for its high print speed.

The reason (I can tell) is down to the types of extrusion and where the extruder is located.

On the Replicator it is on the X-carriage, while in the Ultimaker, it is off the carriage and located somewhere else.

So, Is the print quality going to drop if I use a Bowden extruder?

If there are anyt other factors, or Pros/Cons that I have missed, please let me know!

Thanks.

NFireLabs - The World First Modular 3D Printer - At An Affordable Price!

I am thinking of building a 3D printer from the ground up.

I have outlined that It should be fast and have great print quality.

However, I have seem to run into an issue.

The Replicator 2 is known for its high quality, and the Ultimaker is known for its high print speed.

The reason (I can tell) is down to the types of extrusion and where the extruder is located.

On the Replicator it is on the X-carriage, while in the Ultimaker, it is off the carriage and located somewhere else.

So, Is the print quality going to drop if I use a Bowden extruder?

If there are anyt other factors, or Pros/Cons that I have missed, please let me know!

Thanks.

NFireLabs - The World First Modular 3D Printer - At An Affordable Price!

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 02:33PM |

Registered: 13 years ago Posts: 2,947 |

Quote

ayouden

The Replicator 2 is known for its high quality, and the Ultimaker is known for its high print speed.

The Ultimaker produces prints thousands of times better than a Replicator.

IMHO the artifacts that are caused by a large moving mass (extruder attached to the carriage) are completely unacceptable. That leaves only Bowden, also be sure to use 3mm as it is far more capable of being pushed through a bowden tube and you will have a far better chance of ever getting the new softer filaments to work since there is almost no way they will work in a 1.7mm bowden machine.

This is a picture taken by Makerbot of their own design (automated dragon)

And this is a picture from an Ultimaker by Dave Durant

As you can see there is no comparison.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 02:42PM |

Registered: 10 years ago Posts: 790 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 02:49PM |

Registered: 13 years ago Posts: 2,947 |

Quote

MrDoctorDIV

This has me rethinking my entire thought of direct vs bowden..

So there is [again, in your humble opinion] no real reason to go direct?

If you plan on printing with the new soft materials coming out then direct would be a benefit. But you then need to be satisfied with the ghosting effect left from the heavy carriage oscillating.

Picture of extreme ripples by jbernardis

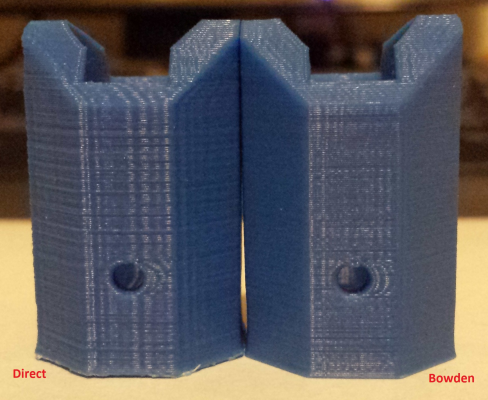

Comparison by Sublime

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 02:53PM |

Registered: 10 years ago Posts: 190 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:01PM |

Registered: 13 years ago Posts: 2,947 |

Quote

ayouden

ahhhh! I have wondered what these ripples were! it all makes sense now!

Thanks, And I think I will upgrade my current 3D printer to Bowden to see how good it is compared to that of my current direct set up.

Ayouden

Be sure to use a good hotend that is well known to work with a Bowden extruder (j-head from hotends.com work well for Tantillus). Be sure to use a Bowden tube that is large enough that is offers little to no friction (1/8" for 3mm as 1/8" is 3.15mm) and be sure to check your filament goes through the tube as tubing is not made to have the inside diameter perfect and could have tight spots even if rated at 3.15mm. You will need to re-learn a bit since Bowdens require faster travel speeds, longer retracts and the most important is faster retracts.

Last thing is if your machine has a moving bed then you will still get ripples unless you are able to make it a lot lighter.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:10PM |

Registered: 11 years ago Posts: 250 |

Great info here, thanks!

I am currently making a CoreXY and will be using a bowden setup, although I have still opted for 1.75mm filament.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I am currently making a CoreXY and will be using a bowden setup, although I have still opted for 1.75mm filament.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:11PM |

Registered: 10 years ago Posts: 790 |

I used to have that on my Solidoodle, then I started playing with settings and nearly elimated those while still maintaining the same print speed [acceleration control was the main difference maker at 1200].

Material variety is a must, so direct drive it stays. Maybe amongst my future upgrades I'll make a quick switchable direct/bowden. Or direct main + bowden support material [or is support material finicky with bowden as well?]

Material variety is a must, so direct drive it stays. Maybe amongst my future upgrades I'll make a quick switchable direct/bowden. Or direct main + bowden support material [or is support material finicky with bowden as well?]

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:16PM |

Registered: 11 years ago Posts: 177 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:22PM |

Registered: 13 years ago Posts: 2,947 |

Quote

Evil Monkey

If I might jump in here, Sublime I was wondering if you could explain the reason why 3 mm works better than 1.75 mm in a Bowden setup? Less springy perhaps?

I am not saying that is works better necessarily. But with the new soft filaments like Ninja flex coming to market people are having a hard time even using them in direct 1.75mm machines.

Here is what I wrote last time I was asked about 1.75 vs 3mm for Bowden.

Quote

Sublime

1.75mm compresses more, most 2mm bowden tubes are thin wall which stretches easier and the fact they use 2mm id tube with flimsy 1.75mm filament means the filament snakes back and forth instead of staying straight against the outer wall, all of which equals hysteresis. For 3mm, 1/8"id x 1/4"od tubing has almost zero stretch and you can not compress 3mm filament much which equates to faster response times and the ability to accelerate the extruder really fast (10,000mm/s^2) during unretracts without the extrusion lagging behind the other axis which can result in missing extrusions at the start of a path. And now with all these new soft materials I think we will find people start to move back to 3mm or even the standard plastic welder 4mm diameter filament.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:25PM |

Registered: 13 years ago Posts: 2,947 |

Quote

MrDoctorDIV

I used to have that on my Solidoodle, then I started playing with settings and nearly elimated those while still maintaining the same print speed [acceleration control was the main difference maker at 1200].

Material variety is a must, so direct drive it stays. Maybe amongst my future upgrades I'll make a quick switchable direct/bowden. Or direct main + bowden support material [or is support material finicky with bowden as well?]

It is true that lower acceleration rates do reduce the ghosts but at the cost of definition. This is a picture by WillWorkForPlastic in the Tantillus forum. He reduced the acceleration to see if it changed anything in his Z banding which it did but at the cost of losing his sharp corners. He has since gone back to faster acceleration and fixed the Z banding with a cable driven Z axis.

Left is slower and right is faster.

Edited 1 time(s). Last edit at 04/24/2014 03:27PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:34PM |

Registered: 13 years ago Posts: 2,947 |

Quote

MrDoctorDIV

is support material finicky with bowden as well?

I have never had issues with the Support in Kisslicer with a Bowden. I have never tried any other slicers support so I can not say if it works with them. Also Kisslicer has the best support hands down as well as the best Print quality with Cura in second place and Skeinforge and Sfact following. I have also been hearing great things about Simplify3d slicer but the cost is way too high.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 03:37PM |

Registered: 11 years ago Posts: 177 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 04:59PM |

Registered: 10 years ago Posts: 474 |

The real root of the problem is that the machines people build are not rigid enough if the machine is rigid enough you can mount the extruder on the carriage. And have the best of both worlds there is nothing saying that you can't run high acceleration rates if your machine is solid enough. One of the main problems with most machines is unsupported linear rods and belts that are to narrow the handle the mass starting and stopping plus motors not being strong enough to accelerate and decelerate a heavy mass

Edited 2 time(s). Last edit at 04/24/2014 05:01PM by cnc dick.

Edited 2 time(s). Last edit at 04/24/2014 05:01PM by cnc dick.

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 05:02PM |

Registered: 10 years ago Posts: 790 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 05:09PM |

Registered: 10 years ago Posts: 474 |

Nema 23's are a lot better than Nema 17 is far as torque goes for the same amperage. But again it all depends on how big your machine is might not be enough. As far as 12 mm rods I would say no anything around even a foot with a round rod is terrible in the middle it will spring back and forth the linear motion has to be supported all the way with a frame member that strong enough to take the mass accelerating and decelerating. And you should run belts that are wider to take the load or possibly high lead ballscrews 20 to 30 mm per turn

Edited 1 time(s). Last edit at 04/24/2014 05:16PM by cnc dick.

Edited 1 time(s). Last edit at 04/24/2014 05:16PM by cnc dick.

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 05:21PM |

Registered: 10 years ago Posts: 790 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 05:29PM |

Registered: 10 years ago Posts: 474 |

It's the mass of the moving parts when you try to start and stop real quickly it pushes on the frame every action has an equal and opposite reaction. A unsupported round rod is terrible as far as rigidity. And believe it or not it's easiest to make the frame strong with the bed moving down low in other words like the regular Mendel's if you have a lot of mass the higher you go on your frame the worse it will be it will be a lever

Edited 1 time(s). Last edit at 04/24/2014 05:36PM by cnc dick.

Edited 1 time(s). Last edit at 04/24/2014 05:36PM by cnc dick.

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 05:39PM |

Registered: 10 years ago Posts: 790 |

|

Re: Bowden vs Direct Feed Extruder? April 24, 2014 05:46PM |

Registered: 10 years ago Posts: 474 |

We are kind of taking this guy's thread over you should start your own on the strength of components maybe. You had mentioned you did take a look at supported round rods with open-ended bearings these aren't that bad at all for a low-budget small reprap. Better stuff gets expensive even on eBay used but the THK or many other different brands linear rail is rectangular and has ball grooves ground into the sides and tops and have a series of screws running down the middle of the rail. And again what you mount it to has to be rigid enough

|

Re: Bowden vs Direct Feed Extruder? April 25, 2014 02:39AM |

Registered: 12 years ago Posts: 2,470 |

If you were to use NEMA 23 to mount the extruder on the carriage and still maintain sufficient acceleration this would mean that you need a higher amperage than the usual reprap electronics (pololu etc.) can support. I was in the same dilemma and decided to go for Bowden.

Increasing rod diameter, going for NEMA 23, higher specced bearings, this all leads to a bulkier machine and a higher price. Personally i'm currently going in the opposite direction, keeping things lightweight and only as big as needed. Small mass means small problems

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Increasing rod diameter, going for NEMA 23, higher specced bearings, this all leads to a bulkier machine and a higher price. Personally i'm currently going in the opposite direction, keeping things lightweight and only as big as needed. Small mass means small problems

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Bowden vs Direct Feed Extruder? April 25, 2014 09:16AM |

Registered: 10 years ago Posts: 474 |

bowden is not my favorite but again that's peoples opinions on cars none of them necessarily right a wrong just personal preference. If you buy 23's that are rated somewhere around 4 to 5 volt and 1 1/2 amp you'll have quite an increase in torque anywhere from 125 to 166 ounce inch. This is because of the diameter of the motor gives a greater mechanical advantage lever to the center

|

Re: Bowden vs Direct Feed Extruder? April 25, 2014 09:36AM |

Registered: 10 years ago Posts: 790 |

|

Re: Bowden vs Direct Feed Extruder? April 25, 2014 09:59AM |

Admin Registered: 11 years ago Posts: 3,096 |

To be honest, I chose for bowden just for the experience of having it.

It works great, and it's fun to learn new things. However, I don't think it really made my printing faster, but maybe at the current speed, if I would've had a direct extruder, my prints might have been much more sloppy.

I feel like the speed is being limited by the ability of the plastic to adhere to the print. This might be due to vibration. Since I have the new Merlin hotend, I had to slow the print speed down to about 3/5th of the original print speed I managed with the J-head, but the J-head would clog sometimes (even with a 50mm fan on it).

Probably still have to calibrate more, for example set the vibration settings in Slic3r, which I couldn't find in Cura. Cura is printing fine with the Bowden, but with Slic3r I have more control over the print variables, but it sometimes solves things in an illogical way.

I also sometimes see people use bowden and then making a huge hotend-holder for their printer, I think that is a bit too much, if you go Bowden, then also try to design a light carriage. Just because the extruder is not mounted on the X-carriage anymore doesn't mean you can just strap other heavy things to it

Also keep in mind the kind of movement system you want to use in your printer, the CoreXY platform seems very good for bowden, and the traditional Reprap setup feels more limiting in speed if you have a heavy print bed. I made my print bed out of aluminum, but am pondering a redesign thats even lighter (2mm alu instead of the current 3mm).

If you do the ultimaker-kind of approach, you don't have the printbed weight, so you can get even more out of your bowden setup, also the way the axis' are moving is quite efficient. Don't think you can compare it to CoreXY/H-bot though.

It works great, and it's fun to learn new things. However, I don't think it really made my printing faster, but maybe at the current speed, if I would've had a direct extruder, my prints might have been much more sloppy.

I feel like the speed is being limited by the ability of the plastic to adhere to the print. This might be due to vibration. Since I have the new Merlin hotend, I had to slow the print speed down to about 3/5th of the original print speed I managed with the J-head, but the J-head would clog sometimes (even with a 50mm fan on it).

Probably still have to calibrate more, for example set the vibration settings in Slic3r, which I couldn't find in Cura. Cura is printing fine with the Bowden, but with Slic3r I have more control over the print variables, but it sometimes solves things in an illogical way.

I also sometimes see people use bowden and then making a huge hotend-holder for their printer, I think that is a bit too much, if you go Bowden, then also try to design a light carriage. Just because the extruder is not mounted on the X-carriage anymore doesn't mean you can just strap other heavy things to it

Also keep in mind the kind of movement system you want to use in your printer, the CoreXY platform seems very good for bowden, and the traditional Reprap setup feels more limiting in speed if you have a heavy print bed. I made my print bed out of aluminum, but am pondering a redesign thats even lighter (2mm alu instead of the current 3mm).

If you do the ultimaker-kind of approach, you don't have the printbed weight, so you can get even more out of your bowden setup, also the way the axis' are moving is quite efficient. Don't think you can compare it to CoreXY/H-bot though.

|

Re: Bowden vs Direct Feed Extruder? April 25, 2014 10:01AM |

Registered: 11 years ago Posts: 251 |

On stationary/vertical moving bed machines (ultimaker, delta bot etc) then Bowden makes most sense - they have minimal carriage mass, which you want to keep as low as possible.

For moving bed machines, the bed mass is the likely limiting factor in speed/acceleration, therefore a Bowden doesn't really seem worth the effort.

For moving bed machines, the bed mass is the likely limiting factor in speed/acceleration, therefore a Bowden doesn't really seem worth the effort.

|

Re: Bowden vs Direct Feed Extruder? April 25, 2014 10:21AM |

Registered: 10 years ago Posts: 474 |

I would agree with thatQuote

konwiddak

On stationary/vertical moving bed machines (ultimaker, delta bot etc) then Bowden makes most sense - they have minimal carriage mass, which you want to keep as low as possible.

For moving bed machines, the bed mass is the likely limiting factor in speed/acceleration, therefore a Bowden doesn't really seem worth the effort.

|

Re: Bowden vs Direct Feed Extruder? November 16, 2014 12:33AM |

Registered: 9 years ago Posts: 37 |

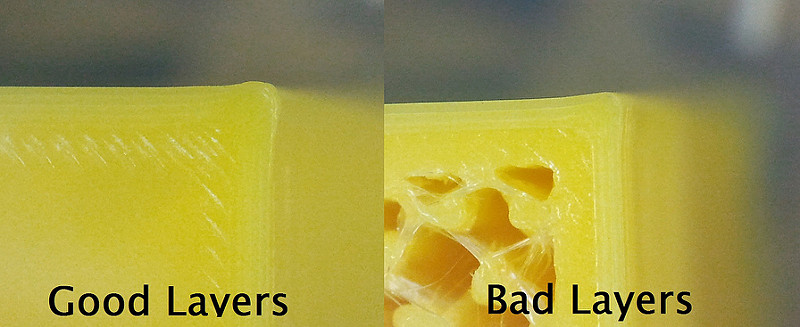

I can honestly say the Bowden feed extruder setup does produce better looking perimeters/layers over the direct feed setup.

I just made the switch from direct to Bowden and yeah, major improvement. What I discovered is the Bowden provides a more consistent flow rate over the direct method, as the hobbed bolt is having to contend with a changing filament tension as it moves to and from the filament reel. Here's a video explaining it YouTube

Photos:

I just made the switch from direct to Bowden and yeah, major improvement. What I discovered is the Bowden provides a more consistent flow rate over the direct method, as the hobbed bolt is having to contend with a changing filament tension as it moves to and from the filament reel. Here's a video explaining it YouTube

Photos:

|

Re: Bowden vs Direct Feed Extruder? November 16, 2014 02:52PM |

Registered: 9 years ago Posts: 425 |

OK ill throw in my tuppence worth for the discussion. There is an alternative to bowden and direct drive extruders. Flex3Drive.A direct drive extruder, but driven with a flexible driveshaft whereby the motor is mounted off carriage. Flex3Drive gives the benefits of low moving mass, improved speeds without comprimising quality, whilst retaining a direct drive extrusion method. I know this sounds like a pitch, its not meant to be, just bringing attention to it in a relevant topic.

It is also my very firm view based on my experiences that ripple/ringing is NOT as a result of printer vibrations. This is not to say artifacts dont occur as a result of vibrations, but the ringing artifacts seen with acceleration away from corners is in my view absolutely categorically not from vibrations. Our machines dont vibrate like church bells! I realise some may find contention with this view. There is a particular direction i would go in my attempts to research and resolve this phenomena based on what i have seen during the obligatory endless hours of machine tuning. I have however not documented this information as yet for various reasons (time money and other focus).

Swinging back round to the original question comparison of Replicator and Ultimaker machines. I would without hesitation or question go with the Ultimaker/UM2 based on its performance (I have one of each here) and the up front customer service, as opposed to the Replicator Cust service which is known to be very poor. I also make note that the IMakr stores have withdrawm Replicator machines due to all the customer complaints they were getting about the machine and the follow up service they were (not) getting.

Edited 1 time(s). Last edit at 11/16/2014 03:16PM by Mutley3D.

It is also my very firm view based on my experiences that ripple/ringing is NOT as a result of printer vibrations. This is not to say artifacts dont occur as a result of vibrations, but the ringing artifacts seen with acceleration away from corners is in my view absolutely categorically not from vibrations. Our machines dont vibrate like church bells! I realise some may find contention with this view. There is a particular direction i would go in my attempts to research and resolve this phenomena based on what i have seen during the obligatory endless hours of machine tuning. I have however not documented this information as yet for various reasons (time money and other focus).

Swinging back round to the original question comparison of Replicator and Ultimaker machines. I would without hesitation or question go with the Ultimaker/UM2 based on its performance (I have one of each here) and the up front customer service, as opposed to the Replicator Cust service which is known to be very poor. I also make note that the IMakr stores have withdrawm Replicator machines due to all the customer complaints they were getting about the machine and the follow up service they were (not) getting.

Edited 1 time(s). Last edit at 11/16/2014 03:16PM by Mutley3D.

|

Re: Bowden vs Direct Feed Extruder? November 16, 2014 03:16PM |

Registered: 9 years ago Posts: 45 |

|

Re: Bowden vs Direct Feed Extruder? November 16, 2014 10:46PM |

Registered: 11 years ago Posts: 364 |

i have a direct drive on my mendelmax and a bowden on my 3dr... The direct drive does have shadowing and rippling in it. The bowden has a problem that when you suddenly change speeds ... for example go from 70 mm/s infill layer to a 40mm/s solid layer you will see a little extra flow of filament causing bands to appear in the prints... The direct drive doesnot have this issue... I have the exact same hot end on both the printers and have printed with the same filament...

I dont know if this is observed by other people or if i am making a mistake somewhere .. The only solution is to not use too much of speed changes ... Also if you use print the outermost perimeters with a slower speed than the other periemeters you start seeing a strange banding effect....

I use slic3r for all the prints ..

I dont know if this is observed by other people or if i am making a mistake somewhere .. The only solution is to not use too much of speed changes ... Also if you use print the outermost perimeters with a slower speed than the other periemeters you start seeing a strange banding effect....

I use slic3r for all the prints ..

Sorry, only registered users may post in this forum.