Flexidrive is Flex3Drive Early Birds

Posted by Mutley3D

|

Anonymous User

Re: Flexidrive is Flex3Drive Early Birds June 01, 2014 08:49AM |

hey everybody,

sorry for the delay.

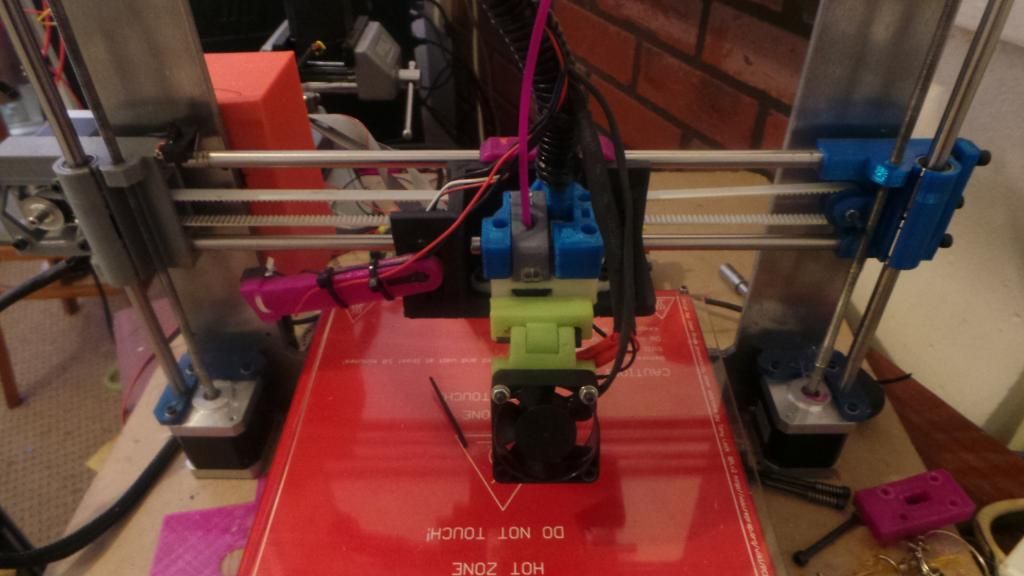

i made some photos of my flexi and compared weight to my old direct. Still stunning about the different.

my old extruder is more than 4x heavier than the flexi

both extruder were compared with connector, hotend, fan and all screws.

@ mutley

thx for the connector design for my printer. fits very good

and finally some pictures:

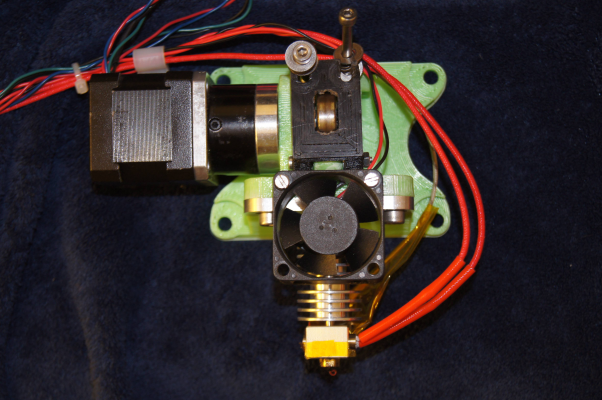

old directdrive extruder (770g)

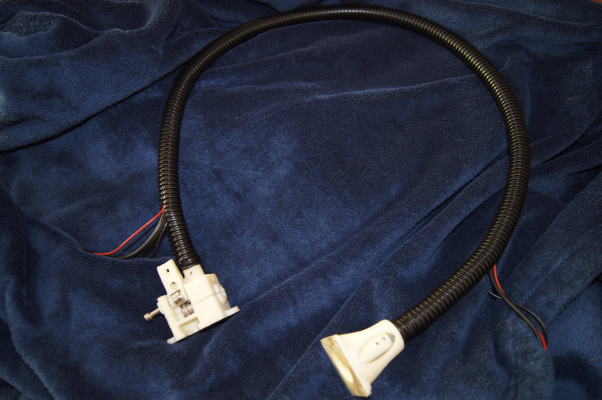

flexi as it arrives

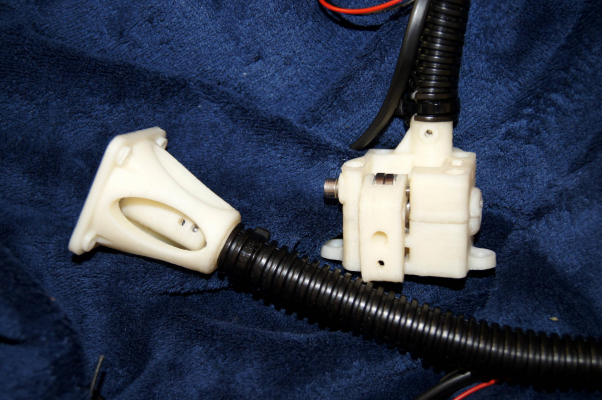

closeup

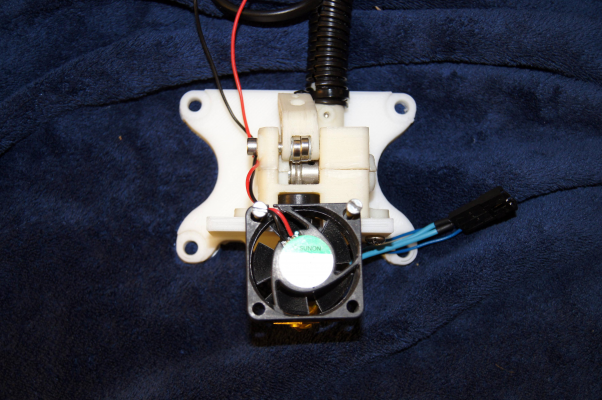

flexi assembled (175g)

i guess end of next week i'll be able to tell more about the flexi. it will be stress-tested and i post printpics and maybe some videos.

best

Edited 5 time(s). Last edit at 06/01/2014 08:55AM by Repper.

sorry for the delay.

i made some photos of my flexi and compared weight to my old direct. Still stunning about the different.

my old extruder is more than 4x heavier than the flexi

both extruder were compared with connector, hotend, fan and all screws.

@ mutley

thx for the connector design for my printer. fits very good

and finally some pictures:

old directdrive extruder (770g)

flexi as it arrives

closeup

flexi assembled (175g)

i guess end of next week i'll be able to tell more about the flexi. it will be stress-tested and i post printpics and maybe some videos.

best

Edited 5 time(s). Last edit at 06/01/2014 08:55AM by Repper.

|

Re: Flexidrive is Flex3Drive Early Birds June 02, 2014 10:40PM |

Registered: 9 years ago Posts: 425 |

Quote

karabas

What is your retract settings?

If f.e. Torsional Deflection = 6(12) degrees per ft per lb and effective diameter of hobbed bolt = 8 mm and stepper max torque = 4.4kg/cm

for 900mm shaft and 40:1 reductor

we get about max 0.125 - 0.3 mm e-feed error.

I wonder if it is acceptable. It seems it's better than bowden.

Hi Karabas,

Id suggest using 6-12 degrees assesses a worst case scenrio and in this instance if you were to halve them, say 3-6 degrees this would still be generous but closer to actual values, so yes, a feed error approaching 0.0625mm is more realistic, and its pretty impressive when looked at like this.

My retract varies between 0.7 to 1.1 depending on speed of travel, with a high travel speed your effectively just relieving the back pressure whilst giving the smallest amount of actual filament retraction prior to that high speed travel move.

Mutley

Edited 2 time(s). Last edit at 06/03/2014 04:57AM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds June 03, 2014 05:07AM |

Registered: 9 years ago Posts: 425 |

@ Repper

Thanks for the post and pictures and good to hear your happy with it. Greatly looking forward to seeing others printing with Flex3Drive as this was the ultimate goal. It has been a lot of hard work and effort. If you need any features added or modifications (no matter how small or trivial) to the X car i drew up for you just let me know and i can do that too and then sign it off as a released finalised part for that particular printer model. Thanks for the feedback and keep it coming.

Mutley

Thanks for the post and pictures and good to hear your happy with it. Greatly looking forward to seeing others printing with Flex3Drive as this was the ultimate goal. It has been a lot of hard work and effort. If you need any features added or modifications (no matter how small or trivial) to the X car i drew up for you just let me know and i can do that too and then sign it off as a released finalised part for that particular printer model. Thanks for the feedback and keep it coming.

Mutley

|

Re: Flexidrive is Flex3Drive Early Birds June 05, 2014 08:38AM |

Registered: 9 years ago Posts: 425 |

Hello, Just a brief update on a couple of items id like to share with you that im quite excited about...

1. The website mutley3d.com is now live with a place to make purchase, there is a bit of a discount offered to first few buys through the site to celebrate the website and a place of purchase

2. Lots of all the background stuff you dont need to know about mostly sorted and back focused to assembly dispatch and delivery, as you can see first ones have shipped

3. What im really excited about aswell is the item in the photo below that the nice postman delivered today, for the next stage of fun development, relating to the hot end for dual filament.

This is a twin flute uncoated endmill for milling brass and soft metals but gently does it....its 0.5mm diameter with a custom ground clearance length of 13.7mm to reach down to where i need it to go using the CNC. Waited a couple of weeks for these to come through as they were specially made. (notice the nice flex ripple free fast print behind it too - yes im shameless aswell

Anyway thats all for now....mutley3d.com check it out now (includes stl downloads for full mendelflex printer including the Flex3Drive printed parts released) Open Source Rulez!

Edited 1 time(s). Last edit at 06/05/2014 08:40AM by Mutley3D.

1. The website mutley3d.com is now live with a place to make purchase, there is a bit of a discount offered to first few buys through the site to celebrate the website and a place of purchase

2. Lots of all the background stuff you dont need to know about mostly sorted and back focused to assembly dispatch and delivery, as you can see first ones have shipped

3. What im really excited about aswell is the item in the photo below that the nice postman delivered today, for the next stage of fun development, relating to the hot end for dual filament.

This is a twin flute uncoated endmill for milling brass and soft metals but gently does it....its 0.5mm diameter with a custom ground clearance length of 13.7mm to reach down to where i need it to go using the CNC. Waited a couple of weeks for these to come through as they were specially made. (notice the nice flex ripple free fast print behind it too - yes im shameless aswell

Anyway thats all for now....mutley3d.com check it out now (includes stl downloads for full mendelflex printer including the Flex3Drive printed parts released) Open Source Rulez!

Edited 1 time(s). Last edit at 06/05/2014 08:40AM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds June 05, 2014 10:49AM |

Registered: 10 years ago Posts: 172 |

|

Re: Flexidrive is Flex3Drive Early Birds June 05, 2014 11:39AM |

Registered: 10 years ago Posts: 790 |

I would love to know as soon as you have a dual extrusion version, the only reason I don't have dual on my Solidoodle is weight and size.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds June 05, 2014 01:39PM |

Registered: 9 years ago Posts: 425 |

Quote

MrDoctorDIV

I would love to know as soon as you have a dual extrusion version, the only reason I don't have dual on my Solidoodle is weight and size.

MrDoctorDiv

I think when it boils down to it that is the same for everyone else, both pure users, and those that consider designing such items. At the end of the day for me, the sooner i get a steady ship by way of sales of the Uno, those people that have purchased will have in turn supported the delivery of the Duo. I myself have funded the whole delivery of the main body of concept in the single drive version. You will need everything that is in the single drive version to upgrade. The upgrade will of course also be cheaper.

Mybe i should mention there is a bit of a discount if you buy through the website at this time and you know your worth it so treat yourself, and promote the speedy delivery of the duo.

Mutley3D

|

Re: Flexidrive is Flex3Drive Early Birds June 05, 2014 01:44PM |

Registered: 9 years ago Posts: 425 |

Quote

umdpru

what kind of cable is used to drive the mechanism? Is it a small flexible shaft like a dremel rotary shaft or a larger diameter hollow shaft? Does the filament go to the hot end through the shaft or separately?

Hi Umdpru

It is a 3mm diameter 900mm long flexible driveshaft, it is supported within a PTFE tube and conduit assembly, Filament is fed into the top of the extruder body and does not run through the conduit, it simpy feeds as if into a normal direct drive extruder, which the Flex3Drive is too.

I hope this helps to clarify, there are also some exploded diagrams on the website www.mutley3d.com which help describe the construction pictorally, and all the files are there for download, both instruction docs and stl's, along with the direct buy limited time discount to celebrate the release of the source and launch of the site. Why not take advantage

Hope this helps, feel free to ask any more questions you may have.

Edited 1 time(s). Last edit at 06/05/2014 01:50PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds June 13, 2014 08:04PM |

Registered: 10 years ago Posts: 16 |

I am working with a Kraken quad extruder on a Rostock Max, and was wondering if you had considered working with Sanjay over at E3D to adapt your design to match with the Kraken. One of the big disadvantage of the Kraken is the need for four bowden setups, but your product might be a way to overcome that.

|

Re: Flexidrive is Flex3Drive Early Birds June 19, 2014 04:46PM |

Registered: 9 years ago Posts: 1 |

|

Re: Flexidrive is Flex3Drive Early Birds June 21, 2014 01:38PM |

Registered: 9 years ago Posts: 425 |

Hi Pyrophreek

I am currently working in developing a number of solutions that go alongside and support deployment of Flex3Drive to various machines and i have been aware of the Kraken which looks like a great piece of kit.

A quad drive Flex3Drive for Kracken would be a great development and yet another serious groundbreaker. I would be most happy to discuss and explore technical matters with Sanjay. Would he? I am intending to fit an E3Dv6 to one of my machines to confirm its compatibility with the Flex3Drive.

Id also be happy to enter into discussions with any other interested parties that wish to inject support to the expedition of various Flex3Drive based solutions for their machines, such support would allow for a laser focus on this work thus removing some of the obstacles that dont alllow for progress as fast as could be possible without said obstacles and distraction.

I am currently working in developing a number of solutions that go alongside and support deployment of Flex3Drive to various machines and i have been aware of the Kraken which looks like a great piece of kit.

A quad drive Flex3Drive for Kracken would be a great development and yet another serious groundbreaker. I would be most happy to discuss and explore technical matters with Sanjay. Would he? I am intending to fit an E3Dv6 to one of my machines to confirm its compatibility with the Flex3Drive.

Id also be happy to enter into discussions with any other interested parties that wish to inject support to the expedition of various Flex3Drive based solutions for their machines, such support would allow for a laser focus on this work thus removing some of the obstacles that dont alllow for progress as fast as could be possible without said obstacles and distraction.

Quote

pyrophreek

I am working with a Kraken quad extruder on a Rostock Max, and was wondering if you had considered working with Sanjay over at E3D to adapt your design to match with the Kraken. One of the big disadvantage of the Kraken is the need for four bowden setups, but your product might be a way to overcome that.

|

Re: Flexidrive is Flex3Drive Early Birds June 21, 2014 03:50PM |

Registered: 10 years ago Posts: 903 |

Quote

Mutley3D

A quad drive Flex3Drive for Kracken would be a great development and yet another serious groundbreaker. I would be most happy to discuss and explore technical matters with Sanjay. Would he? I am intending to fit an E3Dv6 to one of my machines to confirm its compatibility with the Flex3Drive.

Someone has already cut the motor count in half:

http://coherent-reprap.blogspot.co.uk/2014/02/introducing-coherent-extruder-4-color-2.html

While I'm sure that you can easily make this work with two Flex3Drive cables,I'm going to challenge you to make it work with one cable and a solenoid for switching cams.....

|

Re: Flexidrive is Flex3Drive Early Birds June 21, 2014 10:31PM |

Registered: 11 years ago Posts: 374 |

|

Re: Flexidrive is Flex3Drive Early Birds June 23, 2014 09:13AM |

Registered: 9 years ago Posts: 210 |

Quote

vreihen

http://coherent-reprap.blogspot.co.uk/2014/02/introducing-coherent-extruder-4-color-2.html

While I'm sure that you can easily make this work with two Flex3Drive cables,I'm going to challenge you to make it work with one cable and a solenoid for switching cams.....

Wow that would be awesome! Of course! A quad extruder with the weight of a bowden setup and only one stepper and a board to switch between thermistors and heaters would be really great.

|

Re: Flexidrive is Flex3Drive Early Birds June 23, 2014 09:21AM |

Registered: 10 years ago Posts: 790 |

Quote

Dejay

... and a board to switch between thermistors and heaters would be really great.

That would make for some extremely long prints having to reheat each time a change occurs. Firmwares as I know will also seize automatically when a thermistor goes below/above a certain point and will not even dry run, I can't imagine what disonnecting the signal all together would do, but for programmers I'm sure that's a small issue. The reheating each time is what is getting me.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds June 23, 2014 01:33PM |

Registered: 9 years ago Posts: 425 |

Quote

crispy1

Hey Mutley, could we get a quick update on where you are with shipping the original beta kits out?

Hi Crispy1,

I am pleased to be able to confirm that shipping is well underway and your tracking detail has been sent to you. I am very grateful for your patience, as my anxiety levels have been through the roof but i am now making up ground real fast. Yours is en route

|

Re: Flexidrive is Flex3Drive Early Birds June 23, 2014 03:41PM |

Registered: 9 years ago Posts: 425 |

Quote

vreihen

Quote

Mutley3D

A quad drive Flex3Drive for Kracken would be a great development and yet another serious groundbreaker. I would be most happy to discuss and explore technical matters with Sanjay. Would he? I am intending to fit an E3Dv6 to one of my machines to confirm its compatibility with the Flex3Drive.

Someone has already cut the motor count in half:

http://coherent-reprap.blogspot.co.uk/2014/02/introducing-coherent-extruder-4-color-2.html

While I'm sure that you can easily make this work with two Flex3Drive cables,I'm going to challenge you to make it work with one cable and a solenoid for switching cams.....

Hi vreihen

I would be most happy to execute upon and complete your challenge with great effect. In return I shall counter challenge you to fund your challenge upon me whilst it is underway? << No joking....otherwise i shall have to remain focused on what actually keeps the roof over my heaq <<< that too is no joke but said with a smile

In realities though, all the above ideas can be executed by me with not too much difficulty, just some time and thought to get the correct implementation and part designs. There are many possibilities that the flex brings and I would most dearly enjoy and much prefer to be workin on developing various flex based solutions rather than focus on sales to turn a pound of rent so if someone wants to back me on this, then there are possibilities to create massive change and improvement upon our printers.

Mutley

|

Re: Flexidrive is Flex3Drive Early Birds July 06, 2014 03:56PM |

Registered: 11 years ago Posts: 973 |

|

Re: Flexidrive is Flex3Drive Early Birds July 07, 2014 06:52PM |

Registered: 9 years ago Posts: 3 |

|

Re: Flexidrive is Flex3Drive Early Birds July 09, 2014 07:43AM |

Registered: 9 years ago Posts: 425 |

OK A Quick Update....Product is now shipping. Horahhh....Or at least its sitting ready to ship. booooo.

[imgur.com]

There are a couple of extra units made in this batch assembled ready to sell to help get all these bought an paid for items shipped fast. So to get things moving again im going to put up an offer.

The Next FIVE Flex3Drives to sell through mutley3d.com will each come with a FREE Genuine JHEAD - 0.5 or .35. This is both a give back offer an a do what needs to be done basis (in order to get everything shipped asap). These five Flex3Drives will ship early next week if they sell by the weekend. State "FreeJHead" When ordering.

All non printed parts are guaranteed (since you can print spares of course ).

).

There is going more to be more detailed information put into the website now that the assembly phase is done for this batch. If you wish to kickstart the next batch then please do help me get it going asap.

Also looking at making hardware and gear kits available for developers and self source DIY Builds which would require you to print your own parts, source conduit and cables and self assembly. Comment below if this would interest you...It would include the Hobbed wheel, Worm and wheel gears and the required bearings.

[imgur.com]

There are a couple of extra units made in this batch assembled ready to sell to help get all these bought an paid for items shipped fast. So to get things moving again im going to put up an offer.

The Next FIVE Flex3Drives to sell through mutley3d.com will each come with a FREE Genuine JHEAD - 0.5 or .35. This is both a give back offer an a do what needs to be done basis (in order to get everything shipped asap). These five Flex3Drives will ship early next week if they sell by the weekend. State "FreeJHead" When ordering.

All non printed parts are guaranteed (since you can print spares of course

).

). There is going more to be more detailed information put into the website now that the assembly phase is done for this batch. If you wish to kickstart the next batch then please do help me get it going asap.

Also looking at making hardware and gear kits available for developers and self source DIY Builds which would require you to print your own parts, source conduit and cables and self assembly. Comment below if this would interest you...It would include the Hobbed wheel, Worm and wheel gears and the required bearings.

|

Re: Flexidrive is Flex3Drive Early Birds July 09, 2014 09:17AM |

Registered: 9 years ago Posts: 3 |

|

Re: Flexidrive is Flex3Drive Early Birds July 09, 2014 04:38PM |

Registered: 9 years ago Posts: 425 |

Quote

Rob_l

@Mutley3D

So to clarify, all the units you have sold to date should be shipped out before the middle of next week?..

Are you sending emails to inform people that their units are on the way?..

cheers

Rob_I Welcome to the Forums I note you have just joined, have you bought one? Is there one that I may have missed?

I hope to have everything shipped by next week yes correct, i have all the required stock and material to do this now that all the other work is complete, however they need to be shipped and as a result of the extended time prior to shipping Landlords still need paying so im raising funds to cover this. Want to pitch in>?

|

Re: Flexidrive is Flex3Drive Early Birds July 20, 2014 07:24AM |

Registered: 9 years ago Posts: 425 |

OK so heres an update and its not good news im afraid, but i cant hold this back any longer.

Following a couple of decisions full of bad luck on my part, i was left in a position where i was pretty much stuck. I purchased a CNC machine with an issue that i was not told about because "I didnt ask" according to the seller. I spent weeks trying to fix it, so that it could produce another product i was selling, and the funds from these sales would have funded further development of the flex for dual and triple versions, along with shipping existing units etc.

As it has turned out i have fixed the machine and it is now making good parts, however i cant afford to run it any longer. The machine issues caused customer issues, disputes, 2 refunds, lots of money spent on broken machining bits and wasted material, but most of all the biggest cost was in lost time. etc. I was not to know the supplied parts were faulty until they were fitted. These were automotive parts.

The person that provided the machine had claimed or insinuated they were making perfect partsand had sold lots of them without issue. As it turns out after all the grief, and some firm questioning, i was shocked to learn i was not given the whole truth. This person then claimed they didnt tell me certainn things because "i did not ask".

I am sure if one asks "Is there anything else i need to know" this really does mean, is there anything else i need to know. So i am not blamining anyone, just stating the facts, i worked extremely hard to put the situation right but was walking a tightrope. Now with a couple more little knocks that would normally be water of a ducks back, in the position i was left, they were critical knocks. So....I cant hide from the severe difficulties i am now facing.

As a result of the difficulties everything kept backing up, bills, rent and so forth.

This weekend it has imploded and fallen apart badly.

Given the situation i am walking away from the other opportunity to concentrate on the Flex as this was the original goal, to support this development that will benefit othrs far more than the other product that was just meant to be a fund raiser.

I realise some might think "why not just do a kickstarter" or similar. Well maybe i could, but something stops me, maybe its my lack of organisation, lack of time, or simply not seeing wood for trees due to trying to contain all the difficulties. (i suspect its the latter).

Therefore i write this post to inform you of this, and to see if something good can be turned around from this situation to provoke and push the flex back to where it should be.

It wont take much, but it needs something real, and pretty quick too.

So the purpose of this statement is two fold.

1. If your a potential backer, a company involved in 3D or an open source proponent and would be interested in a rescue and backing arrangment please get in touch. It wont take much to turn this around, in fact peanuts compared to the possibilities, but when you have nothing left in the tank, even a gravy bone seems like a meal.

2. If you have ordered, i have your product sitting here, I have a couple of UK orders to ship and i will ship them as soon as i have the pennies, if you are an international order and are prepared to arrange your own shipping to collect the parcel, ill have it ready for collection, and will offer a free dual version if i get that far, which i hope i will. Alternatively if you are happy to wait until i possibly get through this place im in, then it will be sent at some point but right now, i dont know when.

I tried. I failed. Sorry to let all of you down

Edit - Before anyone else does it, please dont do any paypal claims as you will get the flex's very shortly, im just being honest above, any claim will seriously damage my ability to recover the situation for everyone.

O

Edited 3 time(s). Last edit at 07/20/2014 01:54PM by Mutley3D.

Following a couple of decisions full of bad luck on my part, i was left in a position where i was pretty much stuck. I purchased a CNC machine with an issue that i was not told about because "I didnt ask" according to the seller. I spent weeks trying to fix it, so that it could produce another product i was selling, and the funds from these sales would have funded further development of the flex for dual and triple versions, along with shipping existing units etc.

As it has turned out i have fixed the machine and it is now making good parts, however i cant afford to run it any longer. The machine issues caused customer issues, disputes, 2 refunds, lots of money spent on broken machining bits and wasted material, but most of all the biggest cost was in lost time. etc. I was not to know the supplied parts were faulty until they were fitted. These were automotive parts.

The person that provided the machine had claimed or insinuated they were making perfect partsand had sold lots of them without issue. As it turns out after all the grief, and some firm questioning, i was shocked to learn i was not given the whole truth. This person then claimed they didnt tell me certainn things because "i did not ask".

I am sure if one asks "Is there anything else i need to know" this really does mean, is there anything else i need to know. So i am not blamining anyone, just stating the facts, i worked extremely hard to put the situation right but was walking a tightrope. Now with a couple more little knocks that would normally be water of a ducks back, in the position i was left, they were critical knocks. So....I cant hide from the severe difficulties i am now facing.

As a result of the difficulties everything kept backing up, bills, rent and so forth.

This weekend it has imploded and fallen apart badly.

Given the situation i am walking away from the other opportunity to concentrate on the Flex as this was the original goal, to support this development that will benefit othrs far more than the other product that was just meant to be a fund raiser.

I realise some might think "why not just do a kickstarter" or similar. Well maybe i could, but something stops me, maybe its my lack of organisation, lack of time, or simply not seeing wood for trees due to trying to contain all the difficulties. (i suspect its the latter).

Therefore i write this post to inform you of this, and to see if something good can be turned around from this situation to provoke and push the flex back to where it should be.

It wont take much, but it needs something real, and pretty quick too.

So the purpose of this statement is two fold.

1. If your a potential backer, a company involved in 3D or an open source proponent and would be interested in a rescue and backing arrangment please get in touch. It wont take much to turn this around, in fact peanuts compared to the possibilities, but when you have nothing left in the tank, even a gravy bone seems like a meal.

2. If you have ordered, i have your product sitting here, I have a couple of UK orders to ship and i will ship them as soon as i have the pennies, if you are an international order and are prepared to arrange your own shipping to collect the parcel, ill have it ready for collection, and will offer a free dual version if i get that far, which i hope i will. Alternatively if you are happy to wait until i possibly get through this place im in, then it will be sent at some point but right now, i dont know when.

I tried. I failed. Sorry to let all of you down

Edit - Before anyone else does it, please dont do any paypal claims as you will get the flex's very shortly, im just being honest above, any claim will seriously damage my ability to recover the situation for everyone.

O

Edited 3 time(s). Last edit at 07/20/2014 01:54PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds July 20, 2014 01:48PM |

Registered: 9 years ago Posts: 210 |

Really sorry to hear about your troubles. It really sucks that you got ripped off :/

I know from personal experience running a business (and crashing and burning it lol) it is very hard if you don't have the right disposition. Especially if you are an idealistic engineer that wants mainly to create not earn. Businessmen know how to deal with engineers, but it's not always the other way around. You shouldn't blame yourself, IMHO trying something new and failing is still a noble endeavor. Shit happens.

I know from personal experience running a business (and crashing and burning it lol) it is very hard if you don't have the right disposition. Especially if you are an idealistic engineer that wants mainly to create not earn. Businessmen know how to deal with engineers, but it's not always the other way around. You shouldn't blame yourself, IMHO trying something new and failing is still a noble endeavor. Shit happens.

|

Re: Flexidrive is Flex3Drive Early Birds July 20, 2014 02:45PM |

Registered: 11 years ago Posts: 173 |

First step to successQuote

Mutley3D

I tried. I failed. Sorry to let all of you down

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Flexidrive is Flex3Drive Early Birds July 20, 2014 06:50PM |

Registered: 10 years ago Posts: 790 |

Highly inaccurate statement. I'd be trouble to find anyone here who feels you let them down. You've done good work, you're still doing good work, and I'm pretty sure you're going to continue to do so. Good work doesn't mean no problems, it is rare that a plan goes without shortfall or change in how a goal is achieved. It's not your fault, and I, for one of many, do not blame you or feel let down. I think it's quite noble and respectable that you did not give up the endeavor. You were honest. You're still trying. That speaks volumes of your character, especially that you are a person who is here for the good of people, not to make a quick buck. Press on.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds July 21, 2014 03:09AM |

Registered: 10 years ago Posts: 12 |

|

Re: Flexidrive is Flex3Drive Early Birds July 22, 2014 11:59AM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds August 08, 2014 01:47AM |

Registered: 9 years ago Posts: 425 |

Just a very brief update to say www.mutley3d.com has had a bit (well quite a bit) of an update. The emphasis of the web update has been on making the info and data current and available.

1. Full STL file release of all printed parts for the "MendelFlex 3D Printer" in a single .rar file - These can be applied to any mendelmax1.5 with or without a Flex3Drive. X Y and Z axis have some improvements, these can be done individualy or as a whole, or selected as required. Images of each part also shown on the download page.

2. Flex3Drive stl's have been updated, no major changes to speak of, just a couple of tiny imperfections that were showing up in netfabb have been cleaned up / recitified.

3. All current modified X Axis Carriages have been presented and made available for download. It is also confirmed the flex fits onto Kossel Mini Deta end effector with no modification, straight bolt on

4. Assembly and build manuals added. (Still some work to do on the printer asembly doc, but its there for anyone that needs the info)

5. Links to videos on the mutley3d youtube channel with infovids on setting up and running the Flex3Drive....and more to come aswell

6. A "Shop" link has also been added to make it easier to find and purchase

Peace

M

1. Full STL file release of all printed parts for the "MendelFlex 3D Printer" in a single .rar file - These can be applied to any mendelmax1.5 with or without a Flex3Drive. X Y and Z axis have some improvements, these can be done individualy or as a whole, or selected as required. Images of each part also shown on the download page.

2. Flex3Drive stl's have been updated, no major changes to speak of, just a couple of tiny imperfections that were showing up in netfabb have been cleaned up / recitified.

3. All current modified X Axis Carriages have been presented and made available for download. It is also confirmed the flex fits onto Kossel Mini Deta end effector with no modification, straight bolt on

4. Assembly and build manuals added. (Still some work to do on the printer asembly doc, but its there for anyone that needs the info)

5. Links to videos on the mutley3d youtube channel with infovids on setting up and running the Flex3Drive....and more to come aswell

6. A "Shop" link has also been added to make it easier to find and purchase

Peace

M

|

Re: Flexidrive is Flex3Drive Early Birds August 16, 2014 08:33AM |

Registered: 10 years ago Posts: 3 |

Adapted to an (already modified) Ulitmaker original. This is the very first print:

[www.youtube.com]

[www.youtube.com]

Sorry, only registered users may post in this forum.