Flexidrive is Flex3Drive Early Birds

Posted by Mutley3D

|

Re: Flexidrive is Flex3Drive Early Birds October 20, 2014 03:31PM |

Registered: 10 years ago Posts: 790 |

Any updates on duel extrusion model?

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds October 21, 2014 06:18AM |

Registered: 9 years ago Posts: 376 |

|

Re: Flexidrive is Flex3Drive Early Birds October 21, 2014 11:58PM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds October 31, 2014 10:39AM |

Registered: 9 years ago Posts: 376 |

|

Re: Flexidrive is Flex3Drive Early Birds November 17, 2014 08:33PM |

Registered: 11 years ago Posts: 20 |

I was toying with the idea of an extruder driven by a flexible shaft back in late 2012, but was convinced hysteresis could prove a problem. I'm happy to see that there's a way to make it work. Does the design do anything to counter hysteresis?

|

Re: Flexidrive is Flex3Drive Early Birds November 19, 2014 05:26PM |

Registered: 9 years ago Posts: 425 |

Quote

zachnfine

I'm happy to see that there's a way to make it work. Does the design do anything to counter hysteresis?

Hi Zachnfine, A combination of correct shaft specification, ptfe tubing and support structure, high ratio gearing within the extruder head, and extremely short filament forcepath allow even the most flexible materials to be printed without any evident hysteresis

|

Re: Flexidrive is Flex3Drive Early Birds December 01, 2014 12:01AM |

Registered: 9 years ago Posts: 3 |

|

Re: Flexidrive is Flex3Drive Early Birds January 18, 2015 10:53PM |

Registered: 9 years ago Posts: 6 |

|

Re: Flexidrive is Flex3Drive Early Birds February 07, 2015 04:45PM |

Registered: 9 years ago Posts: 2 |

|

Re: Flexidrive is Flex3Drive Early Birds February 13, 2015 01:06AM |

Registered: 9 years ago Posts: 425 |

OK so its been real busy at this end which has pulled me in many directions. Thankfully ive cleared a LOT of stuff and am now back on to core design work, so lets see what the next few days bring.

SuperSurfer, there is a way to get Flex3Drive onto your UMO - There are a couple of user designs on youmagine.com. It would be very easy to convert a standard Flex3Drive to a UMO - I also have a UMO variant in the pipeline (all based on same parts) so I guess the short answer is Yes!

Krizzap, without making promises, let me see how the next few days pan out - There is a reconfiguration of the design midway through to enable an effecitve kossel mini variant. The reconfiguration of parts was the hard part (done) now just have to complete the printed part designs - 80% done but as we know, the last 5% is often the hardest yard.

Firmly back in this saddle and some interesting things are a brewing.

SuperSurfer, there is a way to get Flex3Drive onto your UMO - There are a couple of user designs on youmagine.com. It would be very easy to convert a standard Flex3Drive to a UMO - I also have a UMO variant in the pipeline (all based on same parts) so I guess the short answer is Yes!

Krizzap, without making promises, let me see how the next few days pan out - There is a reconfiguration of the design midway through to enable an effecitve kossel mini variant. The reconfiguration of parts was the hard part (done) now just have to complete the printed part designs - 80% done but as we know, the last 5% is often the hardest yard.

Firmly back in this saddle and some interesting things are a brewing.

|

Re: Flexidrive is Flex3Drive Early Birds February 13, 2015 11:36AM |

Registered: 9 years ago Posts: 2 |

Hi Jason,

I have seen this design: [www.youmagine.com] and: [www.youmagine.com]

Neither will fit my UMO+ because of different hot ends.

Can you please point me in the direction of a design that would fit the UMO+?

Are you supplying all components like worm gear and such?

Kind regards,

I have seen this design: [www.youmagine.com] and: [www.youmagine.com]

Neither will fit my UMO+ because of different hot ends.

Can you please point me in the direction of a design that would fit the UMO+?

Are you supplying all components like worm gear and such?

Kind regards,

|

Re: Flexidrive is Flex3Drive Early Birds February 13, 2015 06:51PM |

Registered: 9 years ago Posts: 425 |

SuperSurfer,

I presume you are referring to the original UM hotend and associated parts?

I have completed UM2 version which is now in last stages of running extended print and retraction torture tests and looking very suweet. UM Original version is part of current design activities and is at advanced stage. This will be running in next few days using same core components.

I presume you are referring to the original UM hotend and associated parts?

I have completed UM2 version which is now in last stages of running extended print and retraction torture tests and looking very suweet. UM Original version is part of current design activities and is at advanced stage. This will be running in next few days using same core components.

|

Re: Flexidrive is Flex3Drive Early Birds February 14, 2015 03:13AM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds March 01, 2015 02:48PM |

Registered: 9 years ago Posts: 2 |

Need Some Suggestion

Recently I install Flex3Drive on my Prusa I3 .

I have some difficulty fine tuning it , problem is the infill , made a couple of test with different step per mm , it doesn't seems to change a lot .

Accuracy of the model is there , first layers of the infill barely stick on the bottom layer .

Printer was set at slow , I tried different software for slicing , slicer , Cura , kisslicer, simplify3d. All had the same result with the 20 mm hollow box 20%infill.

My guess was under extrusion , here's some pic of my problem .

I remove the flex3drive for now to be able to print some part , I need a better fan duct , and some way to hold the fan a bit closer to the aluminum heat sink. This was my second guess ,bad cooling .

If you guys seen this kind of behaviour before , I would greatly appreciate any suggestion , solution .

Thanks .

Edited 1 time(s). Last edit at 03/01/2015 02:49PM by Mort-O-RaT.

Recently I install Flex3Drive on my Prusa I3 .

I have some difficulty fine tuning it , problem is the infill , made a couple of test with different step per mm , it doesn't seems to change a lot .

Accuracy of the model is there , first layers of the infill barely stick on the bottom layer .

Printer was set at slow , I tried different software for slicing , slicer , Cura , kisslicer, simplify3d. All had the same result with the 20 mm hollow box 20%infill.

My guess was under extrusion , here's some pic of my problem .

I remove the flex3drive for now to be able to print some part , I need a better fan duct , and some way to hold the fan a bit closer to the aluminum heat sink. This was my second guess ,bad cooling .

If you guys seen this kind of behaviour before , I would greatly appreciate any suggestion , solution .

Thanks .

Edited 1 time(s). Last edit at 03/01/2015 02:49PM by Mort-O-RaT.

|

Re: Flexidrive is Flex3Drive Early Birds March 03, 2015 06:49PM |

Registered: 9 years ago Posts: 425 |

Hi Mort-O-Rat

Sorry to hear your having an issue there. Definately something not correctly setup but easily resolved. There are a couple of things to check and consider, so some initial questions to help me help you

1. Is the hot end secure in its mounting.

2. Is it a new filament or have you printed with it before (as opposed to a new spool) - PLA or ABS (looks like PLA)

3. What filament diameter (3mm or 1.75) and what temp settings are used?

4. What esteps and microstepping are you running with - have you set them to 1750 esteps with 1/8 microstepping on 3mm filament?

5. What retraction settings are you running (acceleration, retract distance and retract speed)?

M

Sorry to hear your having an issue there. Definately something not correctly setup but easily resolved. There are a couple of things to check and consider, so some initial questions to help me help you

1. Is the hot end secure in its mounting.

2. Is it a new filament or have you printed with it before (as opposed to a new spool) - PLA or ABS (looks like PLA)

3. What filament diameter (3mm or 1.75) and what temp settings are used?

4. What esteps and microstepping are you running with - have you set them to 1750 esteps with 1/8 microstepping on 3mm filament?

5. What retraction settings are you running (acceleration, retract distance and retract speed)?

M

|

Re: Flexidrive is Flex3Drive Early Birds March 07, 2015 08:25PM |

Registered: 9 years ago Posts: 2 |

Hi Mutley3D

Thanks for your response , sorry if I could not reply earlier .

to answer your question

1) Yes hotend was secure real tight in its mounting

2) No , I have use this filament before , no problem before , Black ABS .

3) Filament diameter is 1.75mm printed at 230C hotend , 100C Heatbed.

4)Set the E-step at start 1700 to 2000 throughout a couple of print , 1/8 Microstepping on 1.75mm filament

5) retraction setting a: accel E10000 , b: Retract Distance 2mm c: retract speed 10mm/sec

Here's my start g-code

M92 E(1700-2000)

M201 X3000 Y3000 E10000

M203 X500 Y500 E1500

M204 S2000 T200

M205 X15 E1

Cura Speed

40 Print speed

40 infill

30 outher perimeter

35 inner perimeter

I made the purchase of an E3D-V6 hotend . 1,75mm which took care of my fan problem , also took the time to make a nice fan duct for the turbo cooling fan use for cooling the print . The new hotend give me really great result , it is very light , it also made me realize how bad the oem hotend quality was , which im pretty sure didn't help at all to achieve acceptable result .

Disassembling the Flex3Drive was almost a good thing , I found the 3mm nut bolt of the idler arm inside the top of the hotend cooling chamber , this is why I had such difficulty fitting the filament inside (argggg!! lol) . Back at the time I thought it as fall somewhere on the floor as usual , search for it for about an hour , gave up , took another m3 nut since I got plenty ! Mistake . Im also pretty sure this didn't help to achieve acceptable result .

Since I got a bit of time tonight and tomorrow I will put back to Flex3Drive with the addition of the E3D-V6 hotend back on the printed carriage especially made for the Prusa I3 , its a bit worn since i drill a bunch of hole to fit some fan and option for z auto level , but its still sturdy enough to make some tryout , I am in process of learning some cad software to be able to design some mod or adjustment when needed , slow process , lack of time . but eventually ill know. for now ill go with what i have .

Also Mutley3D suggested that my PFTE tube was inserted maybe too far inside Flex3Drive , I remember putting a lot of pressure before securing the lock screw for that tube , so I will release about 1 to 2 mm off that tube from the Flex3Drive . Also pretty sure that didn't help to achieve acceptable result .

For the next set of tryout , I will increase the speed a bit since the flex3drive perform better at regular or faster speed i believe .

Now simple question , how to make sure i am right on for the e-step (is the measuring filament before the extruder hotend , extruding X amount , check if difference is accurate , is a good method)

Also should I put 1/8 micro-stepping for 1.75mm filament since you precise 1/8 on 3mm filament ?

If all goes well Ill post some picture progress soon enough

Thanks for your help , Flex3Drive I can wait to make you work .

M-O-R. (first language =French , sorry about my poor written english hopefully it is understandable

Thanks for your response , sorry if I could not reply earlier .

to answer your question

1) Yes hotend was secure real tight in its mounting

2) No , I have use this filament before , no problem before , Black ABS .

3) Filament diameter is 1.75mm printed at 230C hotend , 100C Heatbed.

4)Set the E-step at start 1700 to 2000 throughout a couple of print , 1/8 Microstepping on 1.75mm filament

5) retraction setting a: accel E10000 , b: Retract Distance 2mm c: retract speed 10mm/sec

Here's my start g-code

M92 E(1700-2000)

M201 X3000 Y3000 E10000

M203 X500 Y500 E1500

M204 S2000 T200

M205 X15 E1

Cura Speed

40 Print speed

40 infill

30 outher perimeter

35 inner perimeter

I made the purchase of an E3D-V6 hotend . 1,75mm which took care of my fan problem , also took the time to make a nice fan duct for the turbo cooling fan use for cooling the print . The new hotend give me really great result , it is very light , it also made me realize how bad the oem hotend quality was , which im pretty sure didn't help at all to achieve acceptable result .

Disassembling the Flex3Drive was almost a good thing , I found the 3mm nut bolt of the idler arm inside the top of the hotend cooling chamber , this is why I had such difficulty fitting the filament inside (argggg!! lol) . Back at the time I thought it as fall somewhere on the floor as usual , search for it for about an hour , gave up , took another m3 nut since I got plenty ! Mistake . Im also pretty sure this didn't help to achieve acceptable result .

Since I got a bit of time tonight and tomorrow I will put back to Flex3Drive with the addition of the E3D-V6 hotend back on the printed carriage especially made for the Prusa I3 , its a bit worn since i drill a bunch of hole to fit some fan and option for z auto level , but its still sturdy enough to make some tryout , I am in process of learning some cad software to be able to design some mod or adjustment when needed , slow process , lack of time . but eventually ill know. for now ill go with what i have .

Also Mutley3D suggested that my PFTE tube was inserted maybe too far inside Flex3Drive , I remember putting a lot of pressure before securing the lock screw for that tube , so I will release about 1 to 2 mm off that tube from the Flex3Drive . Also pretty sure that didn't help to achieve acceptable result .

For the next set of tryout , I will increase the speed a bit since the flex3drive perform better at regular or faster speed i believe .

Now simple question , how to make sure i am right on for the e-step (is the measuring filament before the extruder hotend , extruding X amount , check if difference is accurate , is a good method)

Also should I put 1/8 micro-stepping for 1.75mm filament since you precise 1/8 on 3mm filament ?

If all goes well Ill post some picture progress soon enough

Thanks for your help , Flex3Drive I can wait to make you work .

M-O-R. (first language =French , sorry about my poor written english hopefully it is understandable

|

Re: Flexidrive is Flex3Drive Early Birds April 08, 2015 12:10PM |

Registered: 9 years ago Posts: 7 |

|

Re: Flexidrive is Flex3Drive Early Birds April 09, 2015 02:21AM |

Registered: 9 years ago Posts: 425 |

Quote

Rogue Scholar

Quote

krizzap

Any headway in adapting the feed mechanism to the kossel effector?

Did not see a response to this, but I was wondering the same thing. I was thinking this might work well for adding multiple extruders for a delta.

Rogue Scholar, Hello Sir

There is a Kossel Mini version available, I just havent had a chance to put it up on the website as yet. From what i understand it will also work with other "mini" delta variants although there maybe a need to adjust the "end effector radius" in firmware. A very small tweak for such a large gain

There is a Kossel Mini version available, I just havent had a chance to put it up on the website as yet. From what i understand it will also work with other "mini" delta variants although there maybe a need to adjust the "end effector radius" in firmware. A very small tweak for such a large gain

Someone is running and testing it at the moment, PM me to get involved with bonus

BTW BIG Shout out to Joem_ for his help and excellent CAD work on this whilst ive been tied up on another Flex related project for someone else. Thank you Joe

Edited 1 time(s). Last edit at 04/09/2015 02:31AM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds April 09, 2015 02:28AM |

Registered: 9 years ago Posts: 425 |

Mort-O-RaT

Are you back from your winter hibernation yet? Set your retract acceleration from 10000 to 100 as a safe value and run a couple of test prints and report back the results, if it works then you can start to turn up your retract acceleration back up in increments of 50 or 100 to find a safe optimal value. Your retract speed and distance setting is ok so dont touch these for now. I suspect you are skipping steps on retract. Also use 1900-2000 for esteps when set to 1/8 microstepping.

Let me now how you get along

Are you back from your winter hibernation yet? Set your retract acceleration from 10000 to 100 as a safe value and run a couple of test prints and report back the results, if it works then you can start to turn up your retract acceleration back up in increments of 50 or 100 to find a safe optimal value. Your retract speed and distance setting is ok so dont touch these for now. I suspect you are skipping steps on retract. Also use 1900-2000 for esteps when set to 1/8 microstepping.

Let me now how you get along

|

Re: Flexidrive is Flex3Drive Early Birds May 23, 2015 10:19AM |

Registered: 8 years ago Posts: 26 |

|

Re: Flexidrive is Flex3Drive Early Birds May 23, 2015 01:36PM |

Registered: 9 years ago Posts: 425 |

Quote

Laurent04FR

Hi,

I ordered a Flex3Drive on mutley3d dot com few days ago, and I would like to know how long is it to get it shipped (I paid 10 days ago and I only received one thing so far, the Paypal payment mail ;-) ).

Other buyers, how long was it for you ?

Thanks,

Laurent

Hi Laurent, your item will ship early next week. There is usually a 5-10 day lead time before shipping. At the moment its closer to 10 days due to other Flex3Drive activities going on behind the scenes

After this lead times will be shorter.

After this lead times will be shorter.M

Edited 1 time(s). Last edit at 05/23/2015 01:37PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds May 24, 2015 07:59AM |

Registered: 8 years ago Posts: 26 |

Hi,

Thanks, that's great ! By the same time, I should have received to my Volcano from E3D.

I read you advise not to use more than 1/8 for microstepping.

I planned to use an azteeg X5 I already have (32 bit cpu, DRV8825 onboard). Problem is I have to use 1/32 microstepping with this board.

Do you think I can try with 1/32 or it's useless so I have to go with another board ?

Regards,

Laurent

Edited 1 time(s). Last edit at 05/24/2015 09:00AM by Laurent04FR.

Thanks, that's great ! By the same time, I should have received to my Volcano from E3D.

I read you advise not to use more than 1/8 for microstepping.

I planned to use an azteeg X5 I already have (32 bit cpu, DRV8825 onboard). Problem is I have to use 1/32 microstepping with this board.

Do you think I can try with 1/32 or it's useless so I have to go with another board ?

Regards,

Laurent

Edited 1 time(s). Last edit at 05/24/2015 09:00AM by Laurent04FR.

|

Re: Flexidrive is Flex3Drive Early Birds June 20, 2015 04:16PM |

Registered: 9 years ago Posts: 6 |

|

Re: Flexidrive is Flex3Drive Early Birds June 23, 2015 02:50PM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds June 23, 2015 08:54PM |

Registered: 11 years ago Posts: 334 |

any updated or improvements to the design so far?

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Flexidrive is Flex3Drive Early Birds June 25, 2015 02:23AM |

Registered: 9 years ago Posts: 6 |

Kossel mini, with a regular traxxas joints. I was actually considering another option for when I eventually upgrade to an E3D v6, which would be to mount the majority of the hotend (i.e. heatsink) above the effector plate, with the nozzle protruding below. This would save a little build height while also making more room to mount a flexidrive unit, away from the diagonal rods.Quote

Mutley3D

Quote

krizzap

Has anyone gotten this to work on any sort of delta printer? I'm still itching to put one of these on my Kossel but I lack the CAD skill to properly integrate the base into an effector..

Hi Krizzap,

Kossel Mini or Standard Kossel?

|

Re: Flexidrive is Flex3Drive Early Birds June 27, 2015 10:53AM |

Registered: 9 years ago Posts: 425 |

Quote

krizzap

Kossel mini, with a regular traxxas joints. I was actually considering another option for when I eventually upgrade to an E3D v6, which would be to mount the majority of the hotend (i.e. heatsink) above the effector plate, with the nozzle protruding below. This would save a little build height while also making more room to mount a flexidrive unit, away from the diagonal rods.Quote

Mutley3D

Quote

krizzap

Has anyone gotten this to work on any sort of delta printer? I'm still itching to put one of these on my Kossel but I lack the CAD skill to properly integrate the base into an effector..

Hi Krizzap,

Kossel Mini or Standard Kossel?

Krizzap,

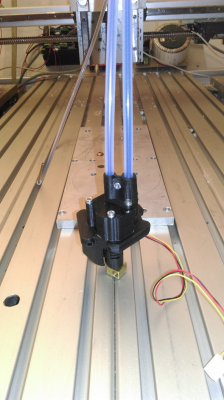

Check this out for a Kossel Mini

Now a completed design. The rest of the album can be seen here [imgur.com]

Now a completed design. The rest of the album can be seen here [imgur.com]|

Re: Flexidrive is Flex3Drive Early Birds June 28, 2015 12:35AM |

Registered: 10 years ago Posts: 15 |

Quote

Mutley3D

Krizzap,

Check this out for a Kossel MiniNow a completed design. The rest of the album can be seen here [imgur.com]

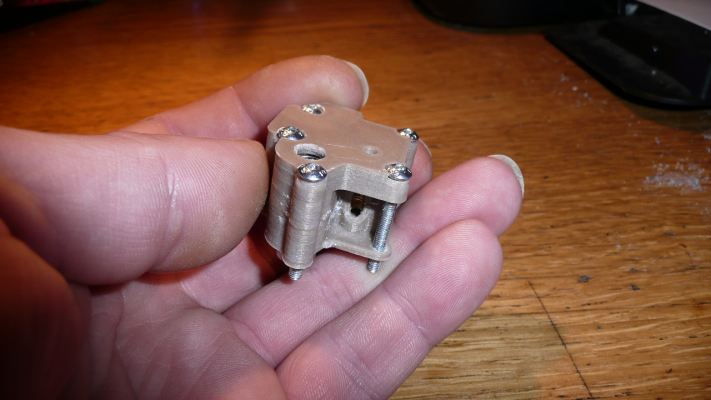

The finished part looks good, very compact (only the idler is a bit of a mistery), is great that you're making progress with the Delta compatibility.

It seems that right now there is no space for a probe but i'm sure that once the design will be available we'll be able to fit one in.

I'll probably order a Flex3Drive next week, just a few quick question:

1-When do you plan on releasing the stl file for the Delta? (right now i'll use the Flex3Drive on my i3 but i plan on building a delta really soon).

2-I Guess the internal components for the delta design are the same inside the regular block, so is just a matter of print the new part -> disassemble the old block -> install the internal components in the new one?

3-What kind of lead time (for EU region) can i expect in this period?

Congratulation and Keep up the good work!

Edited 1 time(s). Last edit at 06/28/2015 12:38AM by Nova.

|

Re: Flexidrive is Flex3Drive Early Birds July 05, 2015 02:53PM |

Registered: 9 years ago Posts: 6 |

|

Re: Flexidrive is Flex3Drive Early Birds July 12, 2015 03:06AM |

Registered: 8 years ago Posts: 312 |

Sorry, only registered users may post in this forum.