Flexidrive is Flex3Drive Early Birds

Posted by Mutley3D

|

Re: Flexidrive is Flex3Drive Early Birds July 28, 2015 09:12AM |

Registered: 8 years ago Posts: 5 |

i've got mine installed on a delta (boots industries v2.5) and working for the most part.. but that might be just dumb luck on my part. i'm working on getting my stepping correct and the proper retract acceleration and speed. i think my retraction is keeping me from getting great surface finish results.. but than again i'm also getting little micro-pauses within each layer that give me over extrusion bumps... i think its all tuning on my end... but some more examples from people's slic3r profiles might help me

also is there anything about my stepper itself that i need to keep in mind?

Edited 2 time(s). Last edit at 07/28/2015 10:05AM by yenbadnosyt.

also is there anything about my stepper itself that i need to keep in mind?

Edited 2 time(s). Last edit at 07/28/2015 10:05AM by yenbadnosyt.

|

Re: Flexidrive is Flex3Drive Early Birds July 28, 2015 12:04PM |

Registered: 9 years ago Posts: 425 |

Quote

yenbadnosyt

i've got mine installed on a delta (boots industries v2.5) and working for the most part.. but that might be just dumb luck on my part. i'm working on getting my stepping correct and the proper retract acceleration and speed. i think my retraction is keeping me from getting great surface finish results.. but than again i'm also getting little micro-pauses within each layer that give me over extrusion bumps... i think its all tuning on my end... but some more examples from people's slic3r profiles might help me

also is there anything about my stepper itself that i need to keep in mind?

Hi, Glad to hear youve got it installed. For tuning, take the parameters below as a guideline starting point for your machine, bear in mind i dont know what electronics you are running on the machine...

Stepping rate: 1/8th Microstepping (whenever possible, some higher speed electronics wont allow changes to microstepping, but due to higher speed they can handle the higher pulse rates required...ie smoothie)

Steps per mm on E Axis: Will vary based on filament diameter, but start with 1900 and be prepared to crank up to 2100

E Axis Jerk: 0.1 (no need for additional tuning)

E Axis Accel: 10k (depending on your setup you may turn this down if its too high, but this should be ok on most systems)

E Axis Feed Max: 45mms (no need to tune)

Retract Length: Set to 1.8mm (optimal setting will deviate very little from this length)

Retract Speed: Set to 10mms (very low slow speed, can be turned up but start tuning with this value to achieve reliable retract)

Retract Accel: Set to 100mms^2 (this is slow but steady, turn up if you feel the need but start with this value to experiance full retract without issue, can be tuned lower if needs be)

The issue you describe with "micro-pauses" might be due to the retract acceleration being too high, it will attempt the retract but skip steps, then unretract successfully pushing out filament that should have been retracted but didnt, giving you the surface bumps.

When you have retract speeds and accels working correctly, you will be able to tell by the note of the motor sounding very "correct". A nice higher pitch smooth tone "beep beep" (<<Edited 1 time(s). Last edit at 07/28/2015 12:08PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds July 28, 2015 01:06PM |

Registered: 8 years ago Posts: 5 |

|

Re: Flexidrive is Flex3Drive Early Birds July 29, 2015 03:16PM |

Registered: 8 years ago Posts: 5 |

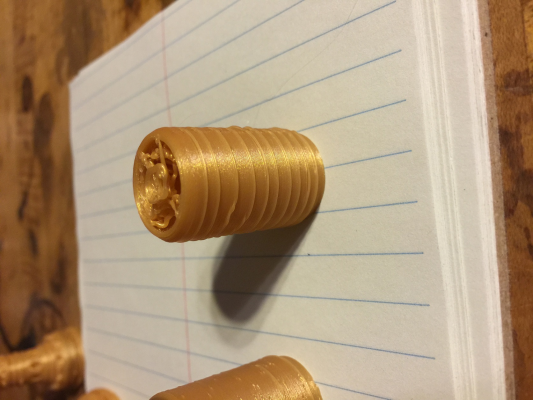

ok after a bit of tuning/testing and more tuning and testing I am getting much better results... i started with a major problem with holes in my perimeters but i was able to clear that up by lowing my retraction speed to 10mm/s like you suggested.

i'm not 100% sure i know how to change the retraction acceleration or retraction jerk in repetier so that is staying whatever it currently is..

after getting retraction a lot closer, i was able to lower my extrussion steps/mm to 2050.. this seems to help a lot... i dont want to go much lower because i think that will be too far from my extrusion length measurements..

extrusion at 2250 steps/mm

extrusion at 2050steps/mm

anyway i think im going to lower my extraction distance to 1.6mm because i believe i am getting some small defects/holes at the start locations because of it.

any more suggestions? you've been so very helpful those far. the longer strings out the side kid of confuse me.. i'm not sure how come that would happen.. in a rather regular pattern at first and than much less with the lower extrusion rates

as a final note.. this is PLA printed @ 195C from repetier @ 60mm/s

|

Re: Flexidrive is Flex3Drive Early Birds July 29, 2015 06:06PM |

Registered: 9 years ago Posts: 425 |

Not sure about the rings on the outside, this appears to be a seperate mechanical issue perhaps, something loose perhaps? Z axis motion control issue? Is the hotend secure?

With regard to the retraction issue, you need to get this tuned correctly, especially the retract acceleration. Take a look through this thread to see if it gives you any clues [forums.reprap.org]

Note that if the retract operation is not working correctly, when the unretract occurs, it can push out a blob of plastic since the filament has not fully retracted. Equally if the retract works correctly and the unretract doesnt, it will leave a gap/hole.

HTH

With regard to the retraction issue, you need to get this tuned correctly, especially the retract acceleration. Take a look through this thread to see if it gives you any clues [forums.reprap.org]

Note that if the retract operation is not working correctly, when the unretract occurs, it can push out a blob of plastic since the filament has not fully retracted. Equally if the retract works correctly and the unretract doesnt, it will leave a gap/hole.

HTH

|

Re: Flexidrive is Flex3Drive Early Birds August 24, 2015 04:21PM |

Registered: 9 years ago Posts: 56 |

Got the flex3drive (G2 version) fitted this weekend, it works very nice so far

I used to use a bowden before, and the flex clearly makes a huge improvement in print quality and ease of setup, it's really the same as having the motor near the hotend

I was a bit afraid by the 40:1 reduction because my board doesn't allow to reduce motors microstepping, but actually the smoothieboard handles the needed ~4000steps/mm very well. Extruder motor is cool after 12 hours printing.

Here you can see a video of the first test print (not very interesting indeed ^^) : [www.youtube.com]

I used to use a bowden before, and the flex clearly makes a huge improvement in print quality and ease of setup, it's really the same as having the motor near the hotend

I was a bit afraid by the 40:1 reduction because my board doesn't allow to reduce motors microstepping, but actually the smoothieboard handles the needed ~4000steps/mm very well. Extruder motor is cool after 12 hours printing.

Here you can see a video of the first test print (not very interesting indeed ^^) : [www.youtube.com]

|

Re: Flexidrive is Flex3Drive Early Birds August 26, 2015 06:28PM |

Registered: 8 years ago Posts: 1 |

|

Re: Flexidrive is Flex3Drive Early Birds August 27, 2015 11:51PM |

Registered: 8 years ago Posts: 81 |

|

Re: Flexidrive is Flex3Drive Early Birds August 29, 2015 05:39PM |

Registered: 9 years ago Posts: 425 |

TPra - Great to hear you got it running, Awesome. Contact me if you need ongoing support

Abalosa - Im just clearing a couple of tasks and then ill be onto a Bootsv2.5 design (I have someone else after the same so demand rules )

)

Hephaustus000 - Great stuff Thank you

~To others who may not be aware. A lot of hard yards covered recently that result in some new designs.

The original design has been replaced by a 2nd Generation design aka Flex3Drive G2. An online album exists here [imgur.com]

The G2 design includes a cam based quick change filament tensioner, improved gear drive with fixed positioning and backlash adjustment removed. Gears are moulded with an improved exotic "lubricant infused" polymer that requires no additional lubrication. New mounting wings and incorporated physical clamp for the hotend. New filament guide arrangement from motor to print head extruder.

There is a Rostock version (v1 and v2) of the same above and can be seen in this online album [imgur.com] This version features the same as G2 above.

There is also a Kossel Mini variant that can be seen here [imgur.com]

The Kossel Mini and Rostock variant can be arranged to fit other Delta style machines that use M3 bolts or studding to affix end effector to delta arms.

All the above come with fixture clamps that support Original JHeads, E3D and Hexagon hotends, along with the usual warranty and direct support.

If you have questions, special requests or other interest, just ping me a message.

Thanks again for all the support.

Edited 3 time(s). Last edit at 08/29/2015 05:44PM by Mutley3D.

Abalosa - Im just clearing a couple of tasks and then ill be onto a Bootsv2.5 design (I have someone else after the same so demand rules

)

)Hephaustus000 - Great stuff Thank you

~To others who may not be aware. A lot of hard yards covered recently that result in some new designs.

The original design has been replaced by a 2nd Generation design aka Flex3Drive G2. An online album exists here [imgur.com]

The G2 design includes a cam based quick change filament tensioner, improved gear drive with fixed positioning and backlash adjustment removed. Gears are moulded with an improved exotic "lubricant infused" polymer that requires no additional lubrication. New mounting wings and incorporated physical clamp for the hotend. New filament guide arrangement from motor to print head extruder.

There is a Rostock version (v1 and v2) of the same above and can be seen in this online album [imgur.com] This version features the same as G2 above.

There is also a Kossel Mini variant that can be seen here [imgur.com]

The Kossel Mini and Rostock variant can be arranged to fit other Delta style machines that use M3 bolts or studding to affix end effector to delta arms.

All the above come with fixture clamps that support Original JHeads, E3D and Hexagon hotends, along with the usual warranty and direct support.

If you have questions, special requests or other interest, just ping me a message.

Thanks again for all the support.

Edited 3 time(s). Last edit at 08/29/2015 05:44PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds September 04, 2015 01:23PM |

Registered: 8 years ago Posts: 5 |

@abalosa

i did a bunch of modifications to the two aluminum plates.. its not pretty but I actually have a design i am going to have CNC'd from aluminum plate soon to replace them.. I use two 3mm bolts to clamp the whole thing together.

@mutley3d

where can i find your stl files for the newer delta designs? i think i'd like to try and make a rostock mount work for the boots BIv2.5

i did a bunch of modifications to the two aluminum plates.. its not pretty but I actually have a design i am going to have CNC'd from aluminum plate soon to replace them.. I use two 3mm bolts to clamp the whole thing together.

@mutley3d

where can i find your stl files for the newer delta designs? i think i'd like to try and make a rostock mount work for the boots BIv2.5

|

Re: Flexidrive is Flex3Drive Early Birds September 04, 2015 01:25PM |

Registered: 8 years ago Posts: 5 |

|

Re: Flexidrive is Flex3Drive Early Birds September 07, 2015 03:55PM |

Registered: 12 years ago Posts: 153 |

I have a Kossel mini that I'm thinking of adding flex3drive to, it has the standard 5:1 geared down extruder motor on it at the moment, would that need to be replaced? If so, with what sort of motor?

I'm running everything from a smoothieboard, in case that makes any difference.

Cheers,

Robin.

I'm running everything from a smoothieboard, in case that makes any difference.

Cheers,

Robin.

|

Re: Flexidrive is Flex3Drive Early Birds September 08, 2015 04:35AM |

Registered: 9 years ago Posts: 425 |

@yenbadnosyt - I'll get some files emailed over to you in the next couple of days. There will also be a general public release coming soon, but i have to clear my decks of other related duties first. With regard to the graphite, yes you should apply sparingly  , admittedly its not an ideal lubricant to apply but it is the most effective for the gears since you will only need to do it once during initial commission. A light teflon based lube will also work but re-application maybe required after a few hundred hours printing time. DO NOT use a lubricant that has ceramic additives.

, admittedly its not an ideal lubricant to apply but it is the most effective for the gears since you will only need to do it once during initial commission. A light teflon based lube will also work but re-application maybe required after a few hundred hours printing time. DO NOT use a lubricant that has ceramic additives.

@Zedsquared - Essentially any standard NEMA17 with 200 steps per revolution (1.8 degree step angle) will work. DO NOT use 400 steps per revolutio (0.9 degree step angle) motors.Take a look at this link [reprap.org] on the wiki, I would suggest something with a rated torque over 30Ncm and a "can" (motor body) length of 40mm+. Some of the motors listed on the wiki page show shorter motors but these will usually have a lower torque rating. The higher torque rating will ensure fast reliable retract operation. With regard to running on a Smoothie board, there will be no issue here but note you will run e-steps at around 3800-4200 since microstepping is fixed at 1/16th microsteps. Due to smoothie's high processor speed this wont be an issue.

HTH

M

, admittedly its not an ideal lubricant to apply but it is the most effective for the gears since you will only need to do it once during initial commission. A light teflon based lube will also work but re-application maybe required after a few hundred hours printing time. DO NOT use a lubricant that has ceramic additives.

, admittedly its not an ideal lubricant to apply but it is the most effective for the gears since you will only need to do it once during initial commission. A light teflon based lube will also work but re-application maybe required after a few hundred hours printing time. DO NOT use a lubricant that has ceramic additives.@Zedsquared - Essentially any standard NEMA17 with 200 steps per revolution (1.8 degree step angle) will work. DO NOT use 400 steps per revolutio (0.9 degree step angle) motors.Take a look at this link [reprap.org] on the wiki, I would suggest something with a rated torque over 30Ncm and a "can" (motor body) length of 40mm+. Some of the motors listed on the wiki page show shorter motors but these will usually have a lower torque rating. The higher torque rating will ensure fast reliable retract operation. With regard to running on a Smoothie board, there will be no issue here but note you will run e-steps at around 3800-4200 since microstepping is fixed at 1/16th microsteps. Due to smoothie's high processor speed this wont be an issue.

HTH

M

|

Re: Flexidrive is Flex3Drive Early Birds September 11, 2015 09:25PM |

Registered: 9 years ago Posts: 52 |

I bought one of these, found the problem that made me think I needed to upgrade and am happy with my current set up. I think I paid about $175.00 by the time it got to the good old USA. Would anyone like to make an offer on it, including shipping, I can send photos, never installed, only opened and placed under the bench...

Kengineer

Diablorougerules@outlook.com

Kengineer

Diablorougerules@outlook.com

|

Re: Flexidrive is Flex3Drive Early Birds September 23, 2015 06:41PM |

Registered: 8 years ago Posts: 81 |

|

Re: Flexidrive is Flex3Drive Early Birds September 23, 2015 07:48PM |

Registered: 9 years ago Posts: 425 |

Yes I am now shipping all outstanding orders, You will receive item via DHL Express by end of week. Due to a hard drive failure there has been an unexpected and somewhat testing delay, but im back in the saddle with a good gallop on  . All affected orders will receive complimentary print surfaces with their shipment as a gesture to compensate for the unforeseen delays. My apologies to those affected.

. All affected orders will receive complimentary print surfaces with their shipment as a gesture to compensate for the unforeseen delays. My apologies to those affected.

Thanks,

Jason

PS Kengineer - If you do sell on, please advise your buyer that your unused item will come with my full support, alternatively if you decide to keep it you can upgrade to the new 2nd Generation design just by printing the parts, or to the dual drive when it comes out in the coming weeks. Please send me an email and will forward onto you the print files ahead of public release.

Edited 3 time(s). Last edit at 09/23/2015 09:13PM by Mutley3D.

. All affected orders will receive complimentary print surfaces with their shipment as a gesture to compensate for the unforeseen delays. My apologies to those affected.

. All affected orders will receive complimentary print surfaces with their shipment as a gesture to compensate for the unforeseen delays. My apologies to those affected.Thanks,

Jason

PS Kengineer - If you do sell on, please advise your buyer that your unused item will come with my full support, alternatively if you decide to keep it you can upgrade to the new 2nd Generation design just by printing the parts, or to the dual drive when it comes out in the coming weeks. Please send me an email and will forward onto you the print files ahead of public release.

Edited 3 time(s). Last edit at 09/23/2015 09:13PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds October 02, 2015 01:55PM |

Registered: 8 years ago Posts: 11 |

I am interested in incorperating the Flexidrive into my next Kossel.

However, I am planning to use balls and magnets for the arms (and end effector) and probably using a E3D or Pico Hot-end.

I am a bit confused on what is included in Flexidrive package and what I will need to design / purchase if the included parts don't fit my needs.

However, I am planning to use balls and magnets for the arms (and end effector) and probably using a E3D or Pico Hot-end.

I am a bit confused on what is included in Flexidrive package and what I will need to design / purchase if the included parts don't fit my needs.

|

Re: Flexidrive is Flex3Drive Early Birds October 03, 2015 03:27PM |

Registered: 9 years ago Posts: 425 |

Quote

SleepyPrince

I am interested in incorperating the Flexidrive into my next Kossel.

However, I am planning to use balls and magnets for the arms (and end effector) and probably using a E3D or Pico Hot-end.

I am a bit confused on what is included in Flexidrive package and what I will need to design / purchase if the included parts don't fit my needs.

Hi SleepyPrince

Take a look at this link [imgur.com] (hotend not included). High quality printed parts, gears, bearings, hobbed wheel, PTFE tube and driveshaft, motor mount, machined shafts all included along with warranty.

The end effector is an integrated part of the Kossel Mini Flex3Drive design and 3mm rods go through the end effector plate. If you require something a little different from this to accomodate the magnetic ball joints, ill be happy to work with you to provide a solution if they (the ball joints) dont mount via the 3mm rods. Just send me a PM if you wish and we can go from there.

|

Re: Flexidrive is Flex3Drive Early Birds October 03, 2015 06:10PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Flexidrive is Flex3Drive Early Birds October 03, 2015 07:12PM |

Registered: 9 years ago Posts: 425 |

Quote

MechaBits

Whats the difference with the flex drive, and the other method of pushing the filament down the ptfe tube(bowden/wade?), doesnt the spinning flexishaft create forces that you dont want, effecting print?

The difference is a light weight "direct drive" extruder. The spinning shaft does not create a torque on the end effector. This is accomplished within the design.

|

Re: Flexidrive is Flex3Drive Early Birds October 03, 2015 07:53PM |

Registered: 8 years ago Posts: 1,671 |

Saw this project sometime back, assume direct drive performs a little better as the filament has no chance to bend over long distances, quicker reactions & retractions? But from what I've seen the other bowden types seem to perform ok, but then I've not heard about the weak points. I was thinking of using flexicables(dremel) to drive my X-axis, or later for drill head, so I could keep the weight down there, but went ahead without testing the idea.

|

Re: Flexidrive is Flex3Drive Early Birds October 04, 2015 12:07AM |

Registered: 9 years ago Posts: 425 |

Hello Mechabits,

A bowden arrangement is compromised by its fundamental approach, however it is a workaround to a problem of removing mass from a print head. It comes with penalties. It was the only offered solution available to the original problem being resolved. As for weaknesses, you have already mentioned a couple of the key points in your earlier post. Bowdens work ok, but can be difficult to tune. If ok is good enough, then....ok

Flex3Drive is developed and offered as a superior solution. It has far better performance than a bowden, and dare I say traditional extruders.

A lot of the output one gets from a printer is down to user skill and ability. If you can do ok with a bowden, you will do far more than ok with a Flex3Drive. It is that simple. More info is available at mutley3d.com that explains how that is achieved.

A bowden arrangement is compromised by its fundamental approach, however it is a workaround to a problem of removing mass from a print head. It comes with penalties. It was the only offered solution available to the original problem being resolved. As for weaknesses, you have already mentioned a couple of the key points in your earlier post. Bowdens work ok, but can be difficult to tune. If ok is good enough, then....ok

Flex3Drive is developed and offered as a superior solution. It has far better performance than a bowden, and dare I say traditional extruders.

A lot of the output one gets from a printer is down to user skill and ability. If you can do ok with a bowden, you will do far more than ok with a Flex3Drive. It is that simple. More info is available at mutley3d.com that explains how that is achieved.

|

Re: Flexidrive is Flex3Drive Early Birds October 20, 2015 06:51AM |

Registered: 8 years ago Posts: 81 |

|

Re: Flexidrive is Flex3Drive Early Birds October 20, 2015 11:23AM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds October 22, 2015 01:21AM |

Registered: 8 years ago Posts: 81 |

|

Re: Flexidrive is Flex3Drive Early Birds December 03, 2015 10:28PM |

Registered: 8 years ago Posts: 2 |

|

Re: Flexidrive is Flex3Drive Early Birds December 03, 2015 10:43PM |

Registered: 9 years ago Posts: 425 |

truthbetold, you created an anonymous account and posted something that was pretty innacurate, you have not contacted me about this, you clearly have something to hide otherwise you would not be anonymous in your posting.

The Flex3Drive does work as intended and advertised. I suggest you have made an error in assembly, but without contacting me how can you learn what you didnt do correctly?

If you have a problem then i suggest you contact me and I will resolve the issue for you. There are many of these working out in the field with no problem, so yes clearly you are looking outside to blame rather than looking at what you have done wrong.

I did also contact you via PM but you dont respond, so it appears you are just out to try and do some damage to my reputation on this product. What version do you have and where did you get it from, was it directly from me or another source?

If you need a replacement shaft, then contact me, and i will replace, its warranty. Because you have failed to get it working correctly does not mean it is a bad product, it means you have made an error somewhere! And even under your error, i will still replace!

Edited 2 time(s). Last edit at 12/03/2015 11:20PM by Mutley3D.

The Flex3Drive does work as intended and advertised. I suggest you have made an error in assembly, but without contacting me how can you learn what you didnt do correctly?

If you have a problem then i suggest you contact me and I will resolve the issue for you. There are many of these working out in the field with no problem, so yes clearly you are looking outside to blame rather than looking at what you have done wrong.

I did also contact you via PM but you dont respond, so it appears you are just out to try and do some damage to my reputation on this product. What version do you have and where did you get it from, was it directly from me or another source?

If you need a replacement shaft, then contact me, and i will replace, its warranty. Because you have failed to get it working correctly does not mean it is a bad product, it means you have made an error somewhere! And even under your error, i will still replace!

Edited 2 time(s). Last edit at 12/03/2015 11:20PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds December 04, 2015 01:19AM |

Registered: 11 years ago Posts: 10 |

Going to poke in here and give my info on the Flex3Drive. I did a similar review on the PrintBite a while back and have been meaning to write one here as well.

I have been using the Flex3Drive for some time now and started using the original generic version after seeing some chit chat in the reprap irc channel. It looked like a good concept at the time and I took the risk based on the limited users info. I am glad I did and when I found out that the v2 had been released I purchased that one as well.

The original version I did have a few issues at first, though to be fair I compounded issues by putting it on a freshly built printer with a smoothieboard that I had not ever used before. The whole time Mutley was willing to walk me through troubleshooting and very willing to help me tune the printer, even took time to learn some of the smoothieboard along with me as I did. None of that stuff was things I expected but his willingness to help impacted me quite a bit with how dedicated he is to making sure people have a good experience with his product. I live in the US as well, and quite frequently he was available when I am pretty confident it must have been middle of the night for him.

I did have a few issues on the original with the adjustable backlash screws until I got a feel for how those should be set, and I frequently over tightened the tube that the flex cable rides in pinching it on the original version. Nothing that ever would prevent it from working and all entirely my fault starting off, but if you had a keen eye you could see some of the effects in the prints or hear the gears whining from being underlubricated and overtightened. [i.imgur.com] One time I even used the wrong lubricant for the gears and chewed them up pretty badly. Mutley sent me a replacement set no issues whatsoever he just wanted to know what lubricant I used so he could make sure to suggest against it with others(for the record he now sends lubricant he suggests using with the units so this is a non issue. I was using some teflon based stuff at the time that had cerflon ceramic in it and am pretty sure its the ceramic stuff that caused the damage)

The v2(I think he calls it G2) is a big step up and its obvious Mutley has listened to his feedback from users. Backlash adjustment is gone(YAY) and the flex cable tube no longer uses grub screws to clamp, it uses a better clamping method that makes it pretty much impossible to overtighten and pinch the cable. The extruder body can be disassembled without unmounting it from the machine, and the hot end retainer is pretty nifty with the integrated fan mount. I have abused this feature into making something I like to call a "hotend module". When I change hotends now the fan and shroud goes with the hotend entirely and a new one just pops right into place(http://i.imgur.com/PPqrDLp.jpg). Finally this new one has a new filament tension mechanism. He calls it a cam lock but I am pretty sure it should just be called sliced bread. There is pretty much nothing I can say to explain how great this tensioner is. No springs, no screws, just flip it open feed in your filament, and flip it closed till it clicks onto its self, period. Done. I can pause mid print and swap filament in approximately 5 seconds, possibly 10 seconds if I am being slow with this. [i.imgur.com] (ignore the wire mess in that pic, I was experimenting with some cooling fan setups) There are even different cams for different filament diameters and types to ensure the best tension for the job.

I can attest that this thing will run, even on a fast printer and high stepping rates. The smoothieboard defaults to 1/16 microstepping and is "locked" in at that rate. There are a few ways to change this but it affects all the drivers on the board so not something you want to go in there changing light heartedly. Between the smoothie and the flex I had no issues topping 100mm/s printing speeds on a .4mm nozzle and .3mm layers. I eventually ended up cutting a trace to the extruder driver on the smoothie to bring it down to 1/4 stepping, which has made the stepping rates a bit more sane. I have even had the flex printing a .6mm nozzle at .5mm layers with 60mm/s to 80mm/s printing speeds no problem. [i.imgur.com] (using the original flex too)

All in all, I would completely recommend a Flex3Drive. After I had worked out all the kinks on the new printer its self, and figured out the smoothieboard there really was not much to do with the Flex3Drive its self in terms of needing to make adjustments to get it working. And standing side by side from my old printer and how much work went into setting up that geared extruder there is really no more or less work involved and similar to the geared extruder, once I have things dialed in I have not really ever had to go back to it to change anything. Everyone that has seen it in action at printer meetups has been pretty impressed by it and a few people have even noted it as their next choice upgrade for their own printers after seeing it running. All in all, very happy with the Flex3Drive. If a v3 is released in the future I will be buying that one too.

Finally, here are a couple videos of the v2 in action [www.youtube.com] and [www.youtube.com] they are from around a month ago now though. I have since made a few additional adjustments to the smoothie config that have helped prints as well mostly with acceleration. The channel has a few other videos as well of the original unit printing as well, it should relatively noticeable which version is which by the lack of the cam tensioner on the top in the videos(some of the older ones are at 1/16 stepping as well).

I have been using the Flex3Drive for some time now and started using the original generic version after seeing some chit chat in the reprap irc channel. It looked like a good concept at the time and I took the risk based on the limited users info. I am glad I did and when I found out that the v2 had been released I purchased that one as well.

The original version I did have a few issues at first, though to be fair I compounded issues by putting it on a freshly built printer with a smoothieboard that I had not ever used before. The whole time Mutley was willing to walk me through troubleshooting and very willing to help me tune the printer, even took time to learn some of the smoothieboard along with me as I did. None of that stuff was things I expected but his willingness to help impacted me quite a bit with how dedicated he is to making sure people have a good experience with his product. I live in the US as well, and quite frequently he was available when I am pretty confident it must have been middle of the night for him.

I did have a few issues on the original with the adjustable backlash screws until I got a feel for how those should be set, and I frequently over tightened the tube that the flex cable rides in pinching it on the original version. Nothing that ever would prevent it from working and all entirely my fault starting off, but if you had a keen eye you could see some of the effects in the prints or hear the gears whining from being underlubricated and overtightened. [i.imgur.com] One time I even used the wrong lubricant for the gears and chewed them up pretty badly. Mutley sent me a replacement set no issues whatsoever he just wanted to know what lubricant I used so he could make sure to suggest against it with others(for the record he now sends lubricant he suggests using with the units so this is a non issue. I was using some teflon based stuff at the time that had cerflon ceramic in it and am pretty sure its the ceramic stuff that caused the damage)

The v2(I think he calls it G2) is a big step up and its obvious Mutley has listened to his feedback from users. Backlash adjustment is gone(YAY) and the flex cable tube no longer uses grub screws to clamp, it uses a better clamping method that makes it pretty much impossible to overtighten and pinch the cable. The extruder body can be disassembled without unmounting it from the machine, and the hot end retainer is pretty nifty with the integrated fan mount. I have abused this feature into making something I like to call a "hotend module". When I change hotends now the fan and shroud goes with the hotend entirely and a new one just pops right into place(http://i.imgur.com/PPqrDLp.jpg). Finally this new one has a new filament tension mechanism. He calls it a cam lock but I am pretty sure it should just be called sliced bread. There is pretty much nothing I can say to explain how great this tensioner is. No springs, no screws, just flip it open feed in your filament, and flip it closed till it clicks onto its self, period. Done. I can pause mid print and swap filament in approximately 5 seconds, possibly 10 seconds if I am being slow with this. [i.imgur.com] (ignore the wire mess in that pic, I was experimenting with some cooling fan setups) There are even different cams for different filament diameters and types to ensure the best tension for the job.

I can attest that this thing will run, even on a fast printer and high stepping rates. The smoothieboard defaults to 1/16 microstepping and is "locked" in at that rate. There are a few ways to change this but it affects all the drivers on the board so not something you want to go in there changing light heartedly. Between the smoothie and the flex I had no issues topping 100mm/s printing speeds on a .4mm nozzle and .3mm layers. I eventually ended up cutting a trace to the extruder driver on the smoothie to bring it down to 1/4 stepping, which has made the stepping rates a bit more sane. I have even had the flex printing a .6mm nozzle at .5mm layers with 60mm/s to 80mm/s printing speeds no problem. [i.imgur.com] (using the original flex too)

All in all, I would completely recommend a Flex3Drive. After I had worked out all the kinks on the new printer its self, and figured out the smoothieboard there really was not much to do with the Flex3Drive its self in terms of needing to make adjustments to get it working. And standing side by side from my old printer and how much work went into setting up that geared extruder there is really no more or less work involved and similar to the geared extruder, once I have things dialed in I have not really ever had to go back to it to change anything. Everyone that has seen it in action at printer meetups has been pretty impressed by it and a few people have even noted it as their next choice upgrade for their own printers after seeing it running. All in all, very happy with the Flex3Drive. If a v3 is released in the future I will be buying that one too.

Finally, here are a couple videos of the v2 in action [www.youtube.com] and [www.youtube.com] they are from around a month ago now though. I have since made a few additional adjustments to the smoothie config that have helped prints as well mostly with acceleration. The channel has a few other videos as well of the original unit printing as well, it should relatively noticeable which version is which by the lack of the cam tensioner on the top in the videos(some of the older ones are at 1/16 stepping as well).

|

Re: Flexidrive is Flex3Drive Early Birds December 04, 2015 04:43AM |

Admin Registered: 12 years ago Posts: 2,569 |

Quote

truthbetold

I posted expressing my negative opinion of the flex3drive and it was deleted. The flex3drive does not work as Mutley says, buyer beware

I don't know what was in your post which was deleted, but here are a few guidelines to avoid it in the future :

- It is ok to report your bad experience with a product, but don't make it look like a crusade by spamming it everywhere.

- Keep it to facts, calmly describing what is the technical problem you're experiencing. The seller might actually help you solve it !

- Provide detailed facts to support your claim. "It does not work" is not sufficient.

- Do not accuse the seller of negative intentions - like lying or being a fraud etc - if you didn't try to solve the problem by communicating with him first.

- If you are in any way affiliated to someone producing or selling a product that might be considered a competitor, mention it.

- Do not create an account for the sole purpose of posting your claims. Having multiple accounts here is forbidden, and posting some negative comments as soon you register might look suspicious to everyone.

Again, I have no idea if any of those entries applied to your post, just mentioning what might lead to it being moderated.

Edited 1 time(s). Last edit at 12/04/2015 04:44AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Flexidrive is Flex3Drive Early Birds December 04, 2015 06:34AM |

Registered: 10 years ago Posts: 23 |

I just want to add my experiences here, I bought one of the first versions of Flex3Drive when it was released, I've found "Mutley" to be incredibly helpful, often responding to emails within minutes at 11pm on a Saturday night. He has also replaced parts at no charge even when they were most likely out of warranty. He is clearly very passionate about his products and looks after his customers.

Paul

Paul

Sorry, only registered users may post in this forum.