Flexidrive is Flex3Drive Early Birds

Posted by Mutley3D

|

Re: Flexidrive is Flex3Drive Early Birds December 07, 2015 02:06AM |

Registered: 8 years ago Posts: 1 |

|

Re: Flexidrive is Flex3Drive Early Birds December 25, 2015 07:55AM |

Registered: 8 years ago Posts: 916 |

|

Re: Flexidrive is Flex3Drive Early Birds January 02, 2016 12:27PM |

Registered: 12 years ago Posts: 153 |

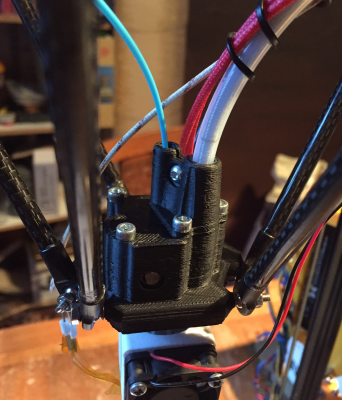

Hi nebbian, here's a pic of the flex3drive very recently installed on my kossell mini.

Pretty easy to fit as it is it's own effector (for the kossel mini at least,YMMV on other deltas) I just had to get some M3 studding to replace the existing six bolts holding on the diagonal rods. Mutley3d may well be including this studding in future kits now.

The existing web site instructions are for the old setup, now there is no need for backlash adjustment or lube of the gears.

You can see the flexdrive coming in on the right and blue filament feeding into the middle. I didn't use the fan shroud supplied (which attaches to the effector ) as I have a 24V setup so the supplied fan wouldn't work and the shroud was too small for my fan... but that's all just bonus stuff, the main deal is the flex drive itself. I'll add some sort of filament tube too once I have the reel mounting sorted, running it straight in over the top of the frame is ok when printing but can get a bit tangled when the printer homes afterwards and the slack filament tends to coil up a bit.

The driving motor is currently just sitting on the desk while I find the best place to mount it, seems to work OK like that

I run a smoothie board and have seen no problems with the 4000 odd E steps setting needed due to the smoothie's fixed microstepping and the drives geared down nature, lesser CPUs may need microstepping reduced.

I had a few questions during install and mutley3d was always swift and courteous to help out via PM on this forum.

I've not had any time to torture test it yet but will be breaking out the voronoi models soon

Pretty easy to fit as it is it's own effector (for the kossel mini at least,YMMV on other deltas) I just had to get some M3 studding to replace the existing six bolts holding on the diagonal rods. Mutley3d may well be including this studding in future kits now.

The existing web site instructions are for the old setup, now there is no need for backlash adjustment or lube of the gears.

You can see the flexdrive coming in on the right and blue filament feeding into the middle. I didn't use the fan shroud supplied (which attaches to the effector ) as I have a 24V setup so the supplied fan wouldn't work and the shroud was too small for my fan... but that's all just bonus stuff, the main deal is the flex drive itself. I'll add some sort of filament tube too once I have the reel mounting sorted, running it straight in over the top of the frame is ok when printing but can get a bit tangled when the printer homes afterwards and the slack filament tends to coil up a bit.

The driving motor is currently just sitting on the desk while I find the best place to mount it, seems to work OK like that

I run a smoothie board and have seen no problems with the 4000 odd E steps setting needed due to the smoothie's fixed microstepping and the drives geared down nature, lesser CPUs may need microstepping reduced.

I had a few questions during install and mutley3d was always swift and courteous to help out via PM on this forum.

I've not had any time to torture test it yet but will be breaking out the voronoi models soon

|

Re: Flexidrive is Flex3Drive Early Birds January 27, 2016 06:19PM |

Registered: 9 years ago Posts: 1 |

I'm very interested in this extruder but I use a lot the "pause at height" plugin in cura to change filaments while printing. After changing it I manually extrude until the filament comes out with the right color, manually meaning I spin the gears with my hand. How could I do the same with a flex3drive?

If I could extrude some filament using marlins interface... but as soon as I touch the button it resumes the print :/

If I could extrude some filament using marlins interface... but as soon as I touch the button it resumes the print :/

|

Re: Flexidrive is Flex3Drive Early Birds January 28, 2016 12:13PM |

Registered: 12 years ago Posts: 153 |

With the latest flex3drive the filament is clamped to the hobb by a quick release cam lever. So it's really easy to just flip the lever to unlock it and push filament through by hand, you don't need to turn anything.

I suppose you'd have to be careful not to move the carriage while doing that though.

Cheers,

Robin.

I suppose you'd have to be careful not to move the carriage while doing that though.

Cheers,

Robin.

|

Re: Flexidrive is Flex3Drive Early Birds January 31, 2016 02:24AM |

Registered: 9 years ago Posts: 425 |

Quote

The-Force

I'm very interested in this extruder but I use a lot the "pause at height" plugin in cura to change filaments while printing. After changing it I manually extrude until the filament comes out with the right color, manually meaning I spin the gears with my hand. How could I do the same with a flex3drive?

If I could extrude some filament using marlins interface... but as soon as I touch the button it resumes the print :/

As Zedsquared mentioned, the new designs have quick release cam lock tensioners. You can simply flick the tension lever up, remove old filament, push the new filament in so it come out of the nozzle, flick the cam lock back over and hit "resume". No need to manually feed filament or use special commands (except your pause at Z).

I have also changed filaments without stopping the print, if the infill area is big enough. Simply set printer to 10% speed, and do the above during the infill on the layer

|

Re: Flexidrive is Flex3Drive Early Birds February 17, 2016 03:27AM |

Registered: 8 years ago Posts: 2 |

I just put in an order for a flex3drive and wanted to thank Mutley3d for the quick responses and answering all my questions. Looking forward to upgrading to this and eliminating another unreliable part of my printer.

New to the world of 3d printing

Prusa i3 - cheap acrylic kit

Upgrades:

P3Steel frame

Leadscrews

Gecko tek build plate

Auto bed leveling sensor

Flex3drive (soon)

E3d v6 (soon)

New to the world of 3d printing

Prusa i3 - cheap acrylic kit

Upgrades:

P3Steel frame

Leadscrews

Gecko tek build plate

Auto bed leveling sensor

Flex3drive (soon)

E3d v6 (soon)

|

Re: Flexidrive is Flex3Drive Early Birds February 17, 2016 08:57PM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds March 17, 2016 05:54PM |

Registered: 8 years ago Posts: 338 |

|

Re: Flexidrive is Flex3Drive Early Birds March 18, 2016 02:01AM |

Registered: 9 years ago Posts: 425 |

Quote

Qdeathstar

Hello.

I was wondering if there are limitations in the types of material you can print. Also, what is the life expectancy of this product.. the gears are made of Nylon, how long do they last?

Hello Qdeathstar - There is no limitation on the materials you can print using the Flex3Drive. If wanting to use flexibles we do however suggest using 3mm feedstock since it is structurally stronger in its filament form. Otherwise all the extruders will run with 1.75mm and 3mm filaments.

The life expectancy of the product is very long term, Flex3Drive is designed as a fit and forget item. We have literally thousands of printing hours on some of the in-house units. The gears are injection molded using tools we own, and are made from a non-standard (and very expensive) engineering acetal polymer (not nylon) that includes both a structural infill and infused lubricant so these run without a wet lube. The drivetrain comes with a lifetime warranty.

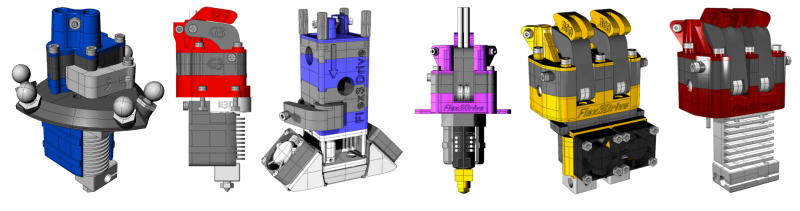

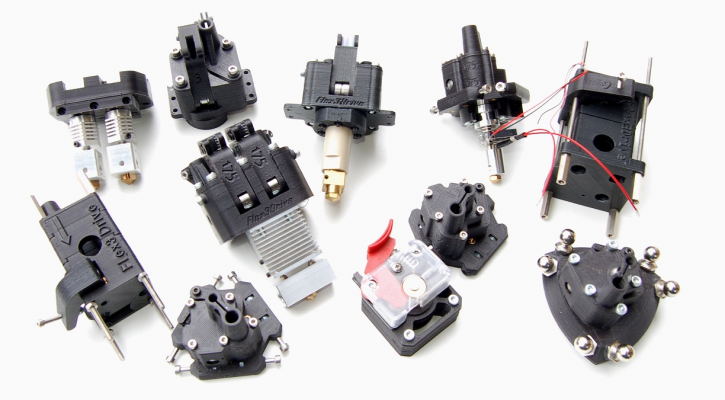

The 1st generation design shown on the website is no longer supplied. Several new designs are available for different printers (website is being rewritten to present this). We call these "2nd Generation" designs and they all include several useful features like quick release cam lock tensioners, very sharp durable hobbs, and compatibility with a wide range of hotends (JHead/E3D/Hexagon/Buda/Pico/Ultimaker and more). We are constantly working to increase this range, and have a number of dual drive designs ready for release aswell.

Edited 2 time(s). Last edit at 03/18/2016 02:13AM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds March 25, 2016 01:34PM |

Registered: 9 years ago Posts: 425 |

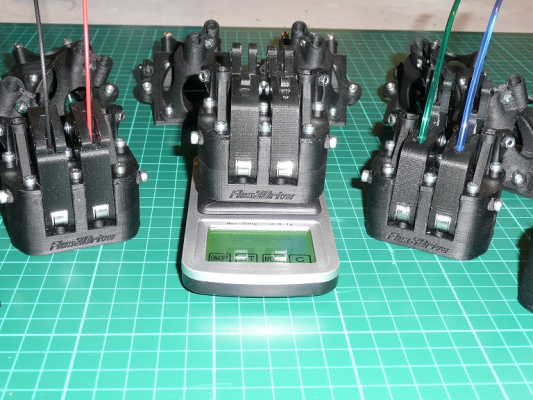

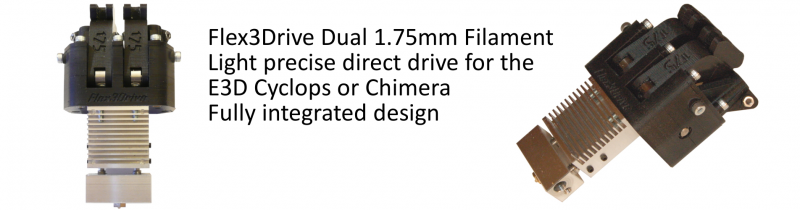

Pretty pleased with how this has turned out, G2Duo-CH (dual drive for a Chimera/Cyclops hotend)

And heres a link to the G+ post with more info

Edited 1 time(s). Last edit at 03/25/2016 10:58PM by Mutley3D.

And heres a link to the G+ post with more info

Edited 1 time(s). Last edit at 03/25/2016 10:58PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds March 26, 2016 09:13AM |

Registered: 9 years ago Posts: 425 |

Full assembly with all fasteners and tensioner arms bearings etc <100grammes

1.75mm on the left of center, 3mm on the right of center. or...1.75 and 3mm can be run in the same unit together.

1.75mm on the left of center, 3mm on the right of center. or...1.75 and 3mm can be run in the same unit together.

|

Re: Flexidrive is Flex3Drive Early Birds March 26, 2016 11:48AM |

Registered: 8 years ago Posts: 93 |

|

Re: Flexidrive is Flex3Drive Early Birds April 15, 2016 05:50AM |

Registered: 8 years ago Posts: 776 |

hi Mutley3D,

looks really good - a rock-solid design. i'm doing a folding, portable corexy printer that fits into carry-on luggage size called the sandwich200, and i'm looking to push things to the limit. what you've come up with looks absolutely great: i like neither the bowden nor the direct extruders - this concept of working off the back of decades of proven manufacturing in flexible drive shafts seems inordinately sensible to me, as does the idea of greatly increasing the gear ratios. so i'd like to order one from you to try out: i've sent you a "contact" message via the website.

couple of question though: my current printhead is an E3Dv6 *bowden* style 3mm hotend, meaning that there will be a huge 6mm OD hole in the top where the 3mm filament would drop in. what you reckon: just make something up, a simple ring, that drops in the top and reduces the diameter from 6mm to 3mm? other than that, is there anything else you can think of that might be a "fly in the ointment"? height differences etc.?

second question: as a folding printer into quite a low-profile space, the extruder top - in this case the flex3drive - would be protruding quite a way up into space that would otherwise mean increasing the stowed box depth. is there anything unreasonable that you can think of about the idea of creating a quick-release system for the entire extruder assembly, so that it can be popped off the carriage and stowed elsewhere in the box?

Edited 1 time(s). Last edit at 04/15/2016 07:33AM by lkcl.

looks really good - a rock-solid design. i'm doing a folding, portable corexy printer that fits into carry-on luggage size called the sandwich200, and i'm looking to push things to the limit. what you've come up with looks absolutely great: i like neither the bowden nor the direct extruders - this concept of working off the back of decades of proven manufacturing in flexible drive shafts seems inordinately sensible to me, as does the idea of greatly increasing the gear ratios. so i'd like to order one from you to try out: i've sent you a "contact" message via the website.

couple of question though: my current printhead is an E3Dv6 *bowden* style 3mm hotend, meaning that there will be a huge 6mm OD hole in the top where the 3mm filament would drop in. what you reckon: just make something up, a simple ring, that drops in the top and reduces the diameter from 6mm to 3mm? other than that, is there anything else you can think of that might be a "fly in the ointment"? height differences etc.?

second question: as a folding printer into quite a low-profile space, the extruder top - in this case the flex3drive - would be protruding quite a way up into space that would otherwise mean increasing the stowed box depth. is there anything unreasonable that you can think of about the idea of creating a quick-release system for the entire extruder assembly, so that it can be popped off the carriage and stowed elsewhere in the box?

Edited 1 time(s). Last edit at 04/15/2016 07:33AM by lkcl.

|

Re: Flexidrive is Flex3Drive Early Birds April 16, 2016 12:51AM |

Registered: 9 years ago Posts: 425 |

asbo - err yea sorry about that  But yes I am very pleased with how this design has ultimately panned out. With a few variants of this design completed there is a good range of hotend and printer compatibility.

But yes I am very pleased with how this design has ultimately panned out. With a few variants of this design completed there is a good range of hotend and printer compatibility.

lkcl - Not quite sure in my minds eye what you are describing regarding the 6mm hole, however it doesnt sound like anything overly difficult to cater for if it isnt already. As for quick release mounting, this shouldnt be too difficult either. The mounting arrangement would lend itself to a baseplate that the extruder assembly is bolted to, and then the baseplate can have the requisite features to interface with the quick fit/release arrangment. Alternatively the mounting wings on the side of the extruder base could be modified to interface with such an arrangement. Ill send you a PM regarding this.

But yes I am very pleased with how this design has ultimately panned out. With a few variants of this design completed there is a good range of hotend and printer compatibility.

But yes I am very pleased with how this design has ultimately panned out. With a few variants of this design completed there is a good range of hotend and printer compatibility.lkcl - Not quite sure in my minds eye what you are describing regarding the 6mm hole, however it doesnt sound like anything overly difficult to cater for if it isnt already. As for quick release mounting, this shouldnt be too difficult either. The mounting arrangement would lend itself to a baseplate that the extruder assembly is bolted to, and then the baseplate can have the requisite features to interface with the quick fit/release arrangment. Alternatively the mounting wings on the side of the extruder base could be modified to interface with such an arrangement. Ill send you a PM regarding this.

|

Re: Flexidrive is Flex3Drive Early Birds April 16, 2016 04:58AM |

Registered: 8 years ago Posts: 776 |

Quote

Mutley3D

lkcl - Not quite sure in my minds eye what you are describing regarding the 6mm hole, however it doesnt sound like anything overly difficult to cater for if it isnt already. As for quick release mounting, this shouldnt be too difficult either. The mounting arrangement would lend itself to a baseplate that the extruder assembly is bolted to, and then the baseplate can have the requisite features to interface with the quick fit/release arrangment. Alternatively the mounting wings on the side of the extruder base could be modified to interface with such an arrangement. Ill send you a PM regarding this.

appreciated. yeah it's actually an 8mm hole to a depth of about... 9mm, because there has to be space for the bowden tube's clip. i'm sure i can arrange something to fill that in if needed. i also took the opportunity to download the flex3drive CAD drawings and i feel it'll be fine, as well.

|

Re: Flexidrive is Flex3Drive Early Birds May 09, 2016 10:00AM |

Registered: 10 years ago Posts: 17 |

|

Re: Flexidrive is Flex3Drive Early Birds May 09, 2016 03:44PM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds May 24, 2016 05:13PM |

Registered: 8 years ago Posts: 776 |

hi i just wanted to say thank you to mutley3d as i have the Flex3Drive installed and tested, you've been extremely helpful in getting it up and running in what is an experimental printer, even adapting parts to fit. using 2.85mm filament with a 0.6mm nozzle and an E3Dv6 "volcano" upgrade i ran tests at up to 400mm/s printing speeds, a layer height of 0.3mm, which resulted in cura 15.04 reporting a maximum extrusion rate of 90mm3/s which is enormous. at that speed the filament was only just beginning to lose its shine, but it was not breaking up. reducing the speed to 200mm/s (still a whopping 45mm3/s) gave the shine back.

it is a pity that there is a design mistake that i made in the sandwich200v2 by using vertical carriage-rods: this however is nothing to do with the Flex3Drive. i will update once i have some better results and a reliable replacement kinematics arrangement in place, but i wanted people to get an inkling of what can be achieved by using a Flex3Drive, and to say thank you to mutley3d for going out of your way to help me get up and running.

-- sandwich200: compact portable folding corexy printer [reprap.org]

it is a pity that there is a design mistake that i made in the sandwich200v2 by using vertical carriage-rods: this however is nothing to do with the Flex3Drive. i will update once i have some better results and a reliable replacement kinematics arrangement in place, but i wanted people to get an inkling of what can be achieved by using a Flex3Drive, and to say thank you to mutley3d for going out of your way to help me get up and running.

-- sandwich200: compact portable folding corexy printer [reprap.org]

|

Re: Flexidrive is Flex3Drive Early Birds June 04, 2016 11:16AM |

Registered: 7 years ago Posts: 1 |

|

Re: Flexidrive is Flex3Drive Early Birds June 21, 2016 03:13AM |

Registered: 8 years ago Posts: 2 |

|

Re: Flexidrive is Flex3Drive Early Birds June 21, 2016 09:12AM |

Registered: 9 years ago Posts: 425 |

|

Re: Flexidrive is Flex3Drive Early Birds June 29, 2016 12:26AM |

Registered: 9 years ago Posts: 142 |

Hello Reprap!

So i've gotten my Flex3Drive up and running. And all i can say is wow. I absolutely Love it.

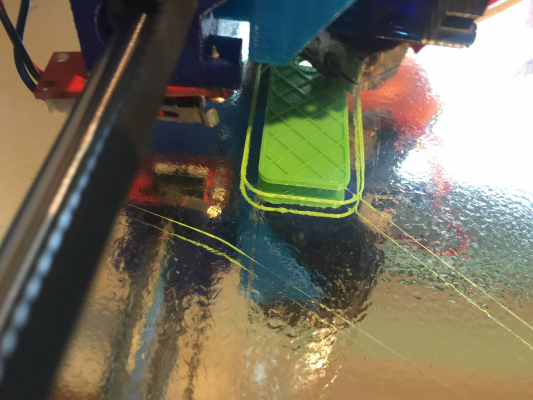

I got the GT2 Version running on a CoreXY with a buildarea of 300x300, and it prints wonderfully and reliant!

The support that Jason From Mutley3D Is offering, is out of this world. I had a brocken shaft, because something was overtigthened - which he replaced in no time and with no quibble! He helped me tune in my printer for it. He even helped me improve the overall quality of the print!

He's a guy thats truly not in it for the money - but for the sake of the product and the customers.

The extruder it self is the best i've tried.

I am using 1.75mm filament, and i've always had difficulties printing with flexible filament. However, with Flex3drive i can print it easily at 40mm/s - and it can probably go faster when i get comfortable with it! Thats really amazing imo!

The image below shows infill being printed at 40mm/s.

I was running a bowden setup prior to switching to Flex3Drive. This was giving me quite a bit of a head scratch because of all the blobs it brought with it. (I know alot can be helped by wiping and coasting - been there tried that)

The Flex3Drive also basically took that away...

So if your considering getting a flex3drive, i'd say go for it Its the best upgrade i've bought for my printers ever. Brings both speed and quality and was a HUGE improvement for me.

Its the best upgrade i've bought for my printers ever. Brings both speed and quality and was a HUGE improvement for me.

And thank you, Mutley3D! For your amazing suppot, patience and help all the way through

So i've gotten my Flex3Drive up and running. And all i can say is wow. I absolutely Love it.

I got the GT2 Version running on a CoreXY with a buildarea of 300x300, and it prints wonderfully and reliant!

The support that Jason From Mutley3D Is offering, is out of this world. I had a brocken shaft, because something was overtigthened - which he replaced in no time and with no quibble! He helped me tune in my printer for it. He even helped me improve the overall quality of the print!

He's a guy thats truly not in it for the money - but for the sake of the product and the customers.

The extruder it self is the best i've tried.

I am using 1.75mm filament, and i've always had difficulties printing with flexible filament. However, with Flex3drive i can print it easily at 40mm/s - and it can probably go faster when i get comfortable with it! Thats really amazing imo!

The image below shows infill being printed at 40mm/s.

I was running a bowden setup prior to switching to Flex3Drive. This was giving me quite a bit of a head scratch because of all the blobs it brought with it. (I know alot can be helped by wiping and coasting - been there tried that)

The Flex3Drive also basically took that away...

So if your considering getting a flex3drive, i'd say go for it

Its the best upgrade i've bought for my printers ever. Brings both speed and quality and was a HUGE improvement for me.

Its the best upgrade i've bought for my printers ever. Brings both speed and quality and was a HUGE improvement for me.And thank you, Mutley3D! For your amazing suppot, patience and help all the way through

|

Re: Flexidrive is Flex3Drive Early Birds July 05, 2016 11:01AM |

Registered: 7 years ago Posts: 1 |

Hi Guys!

Finally got to play with Flex3Drive - after learning a wee bit more about my E-Axis (thanks Jason!), especially start speed and acceleration, I'm now getting really great builds

I was able to mount it on a delta (CZ1-2.0 from ConstructionZone) without any modifications.

This is a great piece of engineering and really fun to work with!

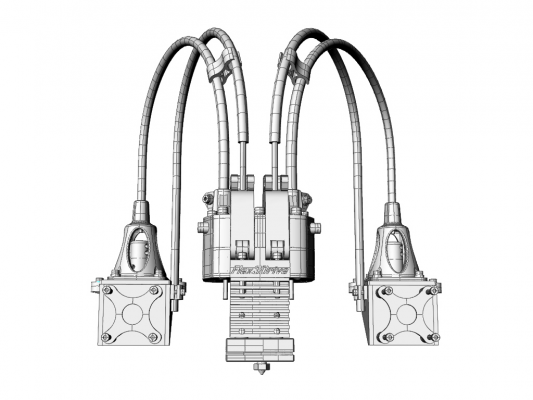

I'd love to see a 3x Flex3Drive for multicolor printing - something ongoing in that direction?

Finally got to play with Flex3Drive - after learning a wee bit more about my E-Axis (thanks Jason!), especially start speed and acceleration, I'm now getting really great builds

I was able to mount it on a delta (CZ1-2.0 from ConstructionZone) without any modifications.

This is a great piece of engineering and really fun to work with!

I'd love to see a 3x Flex3Drive for multicolor printing - something ongoing in that direction?

|

Re: Flexidrive is Flex3Drive Early Birds August 06, 2016 06:25AM |

Registered: 8 years ago Posts: 81 |

|

Re: Flexidrive is Flex3Drive Early Birds August 20, 2016 04:12AM |

Registered: 7 years ago Posts: 17 |

|

Re: Flexidrive is Flex3Drive Early Birds August 20, 2016 07:09AM |

Registered: 11 years ago Posts: 973 |

it can use both 1.75 and 3mm, just recommended with flexible material 3mm

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Flexidrive is Flex3Drive Early Birds August 21, 2016 04:49PM |

Registered: 7 years ago Posts: 1 |

|

Re: Flexidrive is Flex3Drive Early Birds September 22, 2016 12:48AM |

Registered: 9 years ago Posts: 425 |

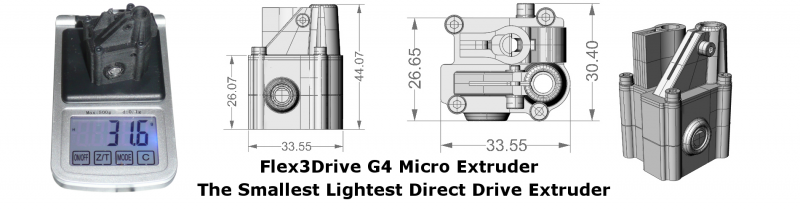

It has been a long road, and a lot of hard work.

I hope you find it of interest and of use, please do share it about. Got a plan, sticking to it, and now a page turns.

Below is just a selection of what is available. www.flex3drive.com is the new home where you can find out more.

There is also a pre-release program running for the Chimera/Cyclops dual drive Flex3Drive, which includes a code for participants that provides a 10% discount on a new Cyclops/Chimera hotend. If the program gets maxed out (which it nearly is) a further 10% discount is applied on the cost of the Flex3Drive Cyclops Duo extruder. You can see more at this link here

And if your going to the TCT show in Birmingham next week, maybe pop over and say hello. It would be great to meet some of you in person.

I hope you find it of interest and of use, please do share it about. Got a plan, sticking to it, and now a page turns.

Below is just a selection of what is available. www.flex3drive.com is the new home where you can find out more.

There is also a pre-release program running for the Chimera/Cyclops dual drive Flex3Drive, which includes a code for participants that provides a 10% discount on a new Cyclops/Chimera hotend. If the program gets maxed out (which it nearly is) a further 10% discount is applied on the cost of the Flex3Drive Cyclops Duo extruder. You can see more at this link here

And if your going to the TCT show in Birmingham next week, maybe pop over and say hello. It would be great to meet some of you in person.

|

Re: Flexidrive is Flex3Drive Early Birds September 22, 2016 07:35AM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.