|

Flexidrive is Flex3Drive Early Birds May 17, 2014 09:41PM |

Registered: 9 years ago Posts: 425 |

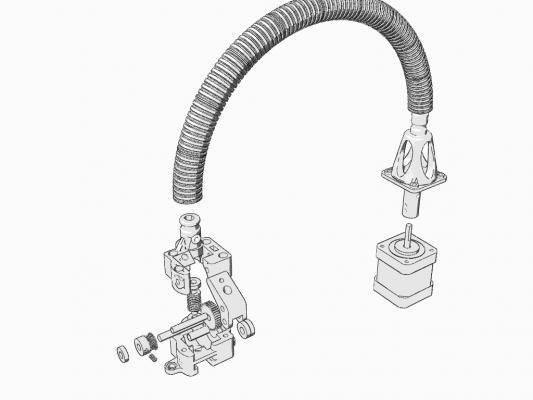

Introducing Flex3DriveTM – The Flexible Driveshaft Extruder solution for 3D Printers.

Hello, My name is Jason Perkes CEO of Mutley3D. I am a Product Design Engineer and Innovator, proficient in mechatronic systems and CAD with a strong and long standing interest in 3d printing in particular Reprap 3D Printers over the last 2 years.

I have just completed development of Flex3DriveTM.

Flex3DriveTM is a complete end to end, flexible driveshaft based extruder system offering several key advantages over other systems, including a lighter X carriage, faster print and travel speeds, reduced retraction distances, increased retract speeds to name but a few. The extruder motor is mounted remotely from the extruder itself and attached to the frame or X ends of a printer allowing the extruder to move faster with less vibrations. Flex3DriveTM is also fully compatible with Delta type machines.

Other features include compatibility with all groove-mount hot ends (JHead, E3D, Arcol, Hexagon etc...) and filament types ( Nylon, Ninjafllex, Taulman, Laywoo, Laybrick, PLA, ABS and more) in 1.75 or 3mm form without modification or change.

Flex3DriveTM is lightweight with a low height profile for increased Z axis clearance. Distance between hobbed pulley and hot end is less than 10mm helping to reduce ringing and other print artifacts.

Print speeds in excess of 400mms are achievable whilst producing great quality prints at these speeds.

A 40:1 gear reduction results in higher resolution of filament control per mm extruded. Higher accelerations are achieved and stepper motor loading is reduced. Gear tooling is owned in house, operated by a reliable moulding company. Overall driveshaft length is close to 900mm and encased within a PTFE support structure combining PTFE tubing, spring links. Wiring for the hot end and thermistor sensor, fan power etc, are attached and encased within a black conduit so it can be used for all sizes of machine.

Flex3DriveTM has gone through extensive development and in house testing and has entered a Beta testing phase whilst now being made available to pre-order for early bird customers at a discounted price. 40 units are being made available under this offer.

To give peace of mind, Flex3Drive also comes with a full 12 month warranty on the driveshaft and gear train components. If they fail they will be replaced.

[imgur.com]

The future for Flex3DriveTM is to continue development and produce dual and triple filament versions, whilst providing support for customers ranging from open source CAD files, exploded assembly diagrams through to benchmark settings for printers and slicing softwares. Flex3DriveTM will be made fully open source following the early bird offer and printable part CAD stl files will be made available on the website mutley3d.com shortly.

You can see more by going to the links [www.youtube.com] [www.youtube.com] [www.youtube.com] [www.youtube.com] to see videos of Flex3DriveTM in action, as well as the images in this gallery [imgur.com].

10 Beta units have been sold and are shipping now. I am offering the next 40 units for sale at £95 each + shipping costs (UK-£10, EU-£15, RoW-£20 . Just add motor and hot end.

The Flex3DriveTM early birds will receive a fully assembled item. Shipping times will range from 3-8 weeks (or less) depending on when you place your order. A couple of surplus early early bird development units are also available on shorter lead time (1 week dispatch).

The supply chain is on standby and ready to facilitate product release into the market space. A majority of the items are already in stock. Revenues from early bird sales will be committed straight back into ongoing development to move towards mixed filament and multi colour capabilities through a single hot end within a few months. The groundwork for this has also been completed. Currently all development has been funded in house by myself and the early bird offer will allow its progression by way of direct unit sales so there is no associated risk. Additional early bird funded work will also fund CAD work to complete stl's for additional X cars X ends and Delta End Effectors.

Please contact me with any questions, leave a post below or email me >> mutleys.crew@gmail.com

I would like to take this opportunity to sincerely thank the open source 3d community for all their support and encouragement, and in particular the first 10 beta testers that enabled the final stretch of development to be completed by making their very trusting and committed early early bird purchases which are shipping 18/05/14. Thank you for your time in reading this and....happy Flexing

Mutley

Edited 10 time(s). Last edit at 05/18/2014 09:05PM by Mutley3D.

Hello, My name is Jason Perkes CEO of Mutley3D. I am a Product Design Engineer and Innovator, proficient in mechatronic systems and CAD with a strong and long standing interest in 3d printing in particular Reprap 3D Printers over the last 2 years.

I have just completed development of Flex3DriveTM.

Flex3DriveTM is a complete end to end, flexible driveshaft based extruder system offering several key advantages over other systems, including a lighter X carriage, faster print and travel speeds, reduced retraction distances, increased retract speeds to name but a few. The extruder motor is mounted remotely from the extruder itself and attached to the frame or X ends of a printer allowing the extruder to move faster with less vibrations. Flex3DriveTM is also fully compatible with Delta type machines.

Other features include compatibility with all groove-mount hot ends (JHead, E3D, Arcol, Hexagon etc...) and filament types ( Nylon, Ninjafllex, Taulman, Laywoo, Laybrick, PLA, ABS and more) in 1.75 or 3mm form without modification or change.

Flex3DriveTM is lightweight with a low height profile for increased Z axis clearance. Distance between hobbed pulley and hot end is less than 10mm helping to reduce ringing and other print artifacts.

Print speeds in excess of 400mms are achievable whilst producing great quality prints at these speeds.

A 40:1 gear reduction results in higher resolution of filament control per mm extruded. Higher accelerations are achieved and stepper motor loading is reduced. Gear tooling is owned in house, operated by a reliable moulding company. Overall driveshaft length is close to 900mm and encased within a PTFE support structure combining PTFE tubing, spring links. Wiring for the hot end and thermistor sensor, fan power etc, are attached and encased within a black conduit so it can be used for all sizes of machine.

Flex3DriveTM has gone through extensive development and in house testing and has entered a Beta testing phase whilst now being made available to pre-order for early bird customers at a discounted price. 40 units are being made available under this offer.

To give peace of mind, Flex3Drive also comes with a full 12 month warranty on the driveshaft and gear train components. If they fail they will be replaced.

[imgur.com]

The future for Flex3DriveTM is to continue development and produce dual and triple filament versions, whilst providing support for customers ranging from open source CAD files, exploded assembly diagrams through to benchmark settings for printers and slicing softwares. Flex3DriveTM will be made fully open source following the early bird offer and printable part CAD stl files will be made available on the website mutley3d.com shortly.

You can see more by going to the links [www.youtube.com] [www.youtube.com] [www.youtube.com] [www.youtube.com] to see videos of Flex3DriveTM in action, as well as the images in this gallery [imgur.com].

10 Beta units have been sold and are shipping now. I am offering the next 40 units for sale at £95 each + shipping costs (UK-£10, EU-£15, RoW-£20 . Just add motor and hot end.

The Flex3DriveTM early birds will receive a fully assembled item. Shipping times will range from 3-8 weeks (or less) depending on when you place your order. A couple of surplus early early bird development units are also available on shorter lead time (1 week dispatch).

The supply chain is on standby and ready to facilitate product release into the market space. A majority of the items are already in stock. Revenues from early bird sales will be committed straight back into ongoing development to move towards mixed filament and multi colour capabilities through a single hot end within a few months. The groundwork for this has also been completed. Currently all development has been funded in house by myself and the early bird offer will allow its progression by way of direct unit sales so there is no associated risk. Additional early bird funded work will also fund CAD work to complete stl's for additional X cars X ends and Delta End Effectors.

Please contact me with any questions, leave a post below or email me >> mutleys.crew@gmail.com

I would like to take this opportunity to sincerely thank the open source 3d community for all their support and encouragement, and in particular the first 10 beta testers that enabled the final stretch of development to be completed by making their very trusting and committed early early bird purchases which are shipping 18/05/14. Thank you for your time in reading this and....happy Flexing

Mutley

Edited 10 time(s). Last edit at 05/18/2014 09:05PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds May 18, 2014 12:29AM |

Registered: 10 years ago Posts: 1,381 |

With a few modifications to the worm gear housing it could be useful for other 3d printer purposes, and markets, and potentially generate alternate sale revenues for you.

If you allow the output shaft of the worm wheel to exit the housing (add a through hole) it could be used to drive a GT2 pulley + belt (5 mm pulley bore, or 8 mm for 608 bearing shaft). If the input housing (guide to the flex shaft) was removable, the worm gear bore modified to fit a NEMA 17 shaft (5 mm), and a few holes added, you could mount a stepper motor directly to the worm gear, these mods would make it useful for other applications.

If you allow the output shaft of the worm wheel to exit the housing (add a through hole) it could be used to drive a GT2 pulley + belt (5 mm pulley bore, or 8 mm for 608 bearing shaft). If the input housing (guide to the flex shaft) was removable, the worm gear bore modified to fit a NEMA 17 shaft (5 mm), and a few holes added, you could mount a stepper motor directly to the worm gear, these mods would make it useful for other applications.

|

Re: Flexidrive is Flex3Drive Early Birds May 18, 2014 05:18AM |

Registered: 9 years ago Posts: 425 |

A2,

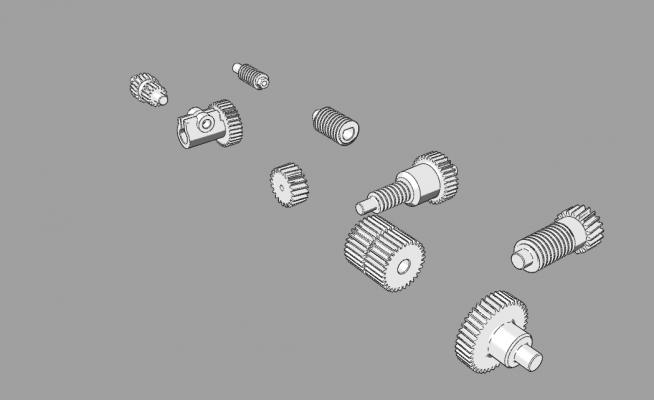

Thank you very much for your response. Yes Agreed there are a variety of 3D Printer / RepRap / Robotic applications and ideas that can stem from these gears. Additionally there are other gears within the tool suite as per the diagram below including two types of friction based slip clutches. Ultimately it is all down to time and resource, good organisation, helping hands etc in which to push out all the possibiities and provide any required support but i see many. I may start another thread as i would wish to keep this thread specifically for Flex3DriveTM however...

One example is to be able to remove one of the Z motors on Cartesian style machines by using a pair of worms on the end of a cross shaft underneath or on top of the machine connected to the Z screws, driven by one motor. Just a teaser to get your mind thinking about the possibilities. All of these gears are in stock and available. They are also incredibly strong in the standard material compound, and the tools can be run with different material compounds also.

Mutley

Edited 2 time(s). Last edit at 05/18/2014 06:12AM by Mutley3D.

Thank you very much for your response. Yes Agreed there are a variety of 3D Printer / RepRap / Robotic applications and ideas that can stem from these gears. Additionally there are other gears within the tool suite as per the diagram below including two types of friction based slip clutches. Ultimately it is all down to time and resource, good organisation, helping hands etc in which to push out all the possibiities and provide any required support but i see many. I may start another thread as i would wish to keep this thread specifically for Flex3DriveTM however...

One example is to be able to remove one of the Z motors on Cartesian style machines by using a pair of worms on the end of a cross shaft underneath or on top of the machine connected to the Z screws, driven by one motor. Just a teaser to get your mind thinking about the possibilities. All of these gears are in stock and available. They are also incredibly strong in the standard material compound, and the tools can be run with different material compounds also.

Mutley

Edited 2 time(s). Last edit at 05/18/2014 06:12AM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds May 18, 2014 06:29AM |

Registered: 10 years ago Posts: 1,381 |

Quote

Mutley3D

One example is to be able to remove one of the Z motors on Cartesian style machines by using a pair of worms on the end of a cross shaft underneath or on top of the machine connected to the Z screws, driven by one motor. Just a teaser to get your mind thinking about the possibilities.

I'm designing a Z-axis dual worm drive with a belt that potentially can lift 200 lbs, that's why I brought it up

Here is an example of a worm gear applied to the Z-axis: [www.youtube.com]

If there was an inexpensive plastic housing for the worm gear drive (none exist) it would make it easier to incorporate, eliminate the cross shaft, and give the device cleaner lines.

|

Anonymous User

Re: Flexidrive is Flex3Drive Early Birds May 18, 2014 09:01AM |

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 05:09AM |

Registered: 11 years ago Posts: 72 |

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 06:47AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

radus

You made easy X carriage and get more speed on X.

But Y axis with heat bed remains heavy and poor quality on Y.

The solution would be:

- ultralight heatbed without any height-settings available to keep materials used to a minimum

- autoleveling on hotend

Or....... put the Z-axis on the heatbed and make an Ultimaker kind of setup. I think the Ultimaker setup would be ideal for this Flex3Drive.

|

Re: Flexidrive is Flex3Drive Early Birds - shipping May 19, 2014 02:22PM |

Registered: 9 years ago Posts: 425 |

Final Assembly stages of the first beta batches near on ready for shipping. This is part of a batch of 10 ordered 4 weeks ago. Shipping for these will be complete by midweek. Work will then commence on the next 40 of batch of early bird product and will ship progressively on a first come first served basis. A lot of care and attention goes into the assembly which is labour intensive. Order early for a shorter waiting time and in doing so you will help decrease lead times for everyone.  Many thanks for all your support out there.

Many thanks for all your support out there.

Many thanks for all your support out there.

Many thanks for all your support out there.|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 02:30PM |

Registered: 9 years ago Posts: 425 |

Quote

radus

You made easy X carriage and get more speed on X.

But Y axis with heat bed remains heavy and poor quality on Y.

Radus Hi,

I have done the Y Axis aswell, it is lighter than the original, but heavier than X yes i agree however, the issue given the working envelope of torque and power that can be transmitted through a Nema17 and toothed belt is limited by the tension of the belt. The new Y axis uses only one Ali plate, a low profile rigid print surface mount system, spread and raised Y rods with a low profile and room to put electronics and PSU underneat inside with cooling.

Both X and Y axis can run 500mms 10k accels Jerk 15. Due to high accelerations it is no longer a requirement to try and set jerk any higher. In fact low Jerk and high accelerations means smoother running machine with less vibrations also.

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 02:32PM |

Registered: 9 years ago Posts: 425 |

Quote

Ohmarinus

Quote

radus

You made easy X carriage and get more speed on X.

But Y axis with heat bed remains heavy and poor quality on Y.

The solution would be:

- ultralight heatbed without any height-settings available to keep materials used to a minimum

- autoleveling on hotend

Or....... put the Z-axis on the heatbed and make an Ultimaker kind of setup. I think the Ultimaker setup would be ideal for this Flex3Drive.

Hi Ohmarinus

This is effectively what i have done, there is also no need for levelling since with this design if something is not level on the bed, either the Z screws need a small tweak to level the gantry which is easily enough done by eye, otherwise something is bent which wont be the case unless the machine is dropped or the Dog pulls it of the table

No need for Z levelling probes.

No need for Z levelling probes.

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 02:44PM |

Registered: 10 years ago Posts: 790 |

And where does one purchase this magical device?

Edit: mutley3d.com opens blank

Also, is it possible, within reasonable added cost, to get a longer one? Say 1100mm shaft?

Edited 2 time(s). Last edit at 05/19/2014 02:55PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Edit: mutley3d.com opens blank

Also, is it possible, within reasonable added cost, to get a longer one? Say 1100mm shaft?

Edited 2 time(s). Last edit at 05/19/2014 02:55PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 03:31PM |

Registered: 9 years ago Posts: 425 |

Quote

MrDoctorDIV

And where does one purchase this magical device?

Edit: mutley3d.com opens blank

Also, is it possible, within reasonable added cost, to get a longer one? Say 1100mm shaft?

Hi MrDoctorDIV

The website is offline at this time while it is being updated and secured. Meanwhile if you wish to order one, pls do send me a PM and i can give you the details to make a paypal payment and secure your order.

I am looking at different lengths of shaft with suppliers at this time, however only the 900mm version is available. When longer shafts are available if you should choose to increase your driveshaft length, it will be a two minute job

. Many thanks

. Many thanks

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 03:56PM |

Registered: 10 years ago Posts: 790 |

What's the response like? What's the delay between motor movement and end movement? Flexing compared to bowden?

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 06:02PM |

Registered: 9 years ago Posts: 425 |

Quote

MrDoctorDIV

What's the response like? What's the delay between motor movement and end movement? Flexing compared to bowden?

Hi, I believe you are referring to something often described as "backlash". This can be caused in different ways depending on the mechanical element of the machine that has this "lash". Play between gears, toothed belt and pulley mesh, belt tension and so on.

In the Flex3Drive there is a highly geared mechanism with a gear ratio of 40:1as opposed to the traditional 7:1 thru 9.5:1 (or thereabouts) gearing of traditional extruder gearing mechanisms. This widely used gearing ratio ball park, puts a tremendous load on the stepper motor and although it is able to handle this power, we do often hear of the motors and stepper drivers getting very hot, print freezes due to overheating electronics and so on.

In using such a high gearing ratio you dramatically decrease the load on the motor whilst at the same time getting it to run faster, this means less energy is used holding or driving the motor resulting in less heat however this is simply an effect of the low torque requirment to drive the 40:1 gearing system at higher speeds. You may take note that upon installing your flex3drive you will in fact need to increase your E axis steps by a factor of 4 or more (or reduce microstepping rates, or a combination of both). In turn this gives you a higher number of steps per mm of extruded filament but the point being, due to the reduced load required to drive the gear train there is less torsional twisting load on the driveshaft itself, therefore the drive becomes transferred without any noticeable or measurable loss or delay. I should add, where traditionally my E motors were very warm at best if not burning hot, they are now simply at room temp, if only a couple of degrees higher.

Flex3Drive provides many additional benefits over and beyond the sheer loss of weight on the extruder assembly. I have discovered that i can drive filament faster for longer without slippage or stripping, fewer grinds etc (in fact none) and there is strong evidence to suggest (when analysed) that there is in fact a traction control effect going on in driving the filamnet, in so far as a smoother acceleration with more control seems to reduce the initial "fracturing" event at a magnifying glass level of the filament material that leads to a breakdown of the filament structure we often see and is known as a filament "grind".

In relation to the actual meshing of the gear train, there is minimal if any backlash with properly adjusted gears and you can achieve effective and clean retracts and unretracts at very high speeds, and very short distances, such as 1mm at 100mms. The overall increase in performance and general "sound" of the machine may also seem far more deliberate and natural to the design of the printer as a whole sum. The only thing you may notice is a slight "twitch" of the driveshaft assembly during retract, accopnied by a rather pleasant sounding

chirp from the motor. Pleasant insofar as the sound almost confirms how nicely it is running.

chirp from the motor. Pleasant insofar as the sound almost confirms how nicely it is running.Whilst this could have been quite a short answer, i think it is important to bring to light the knock-on effect of the Flex3Drive upon the printer as a whole.

Edited 1 time(s). Last edit at 05/19/2014 06:11PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds May 19, 2014 06:53PM |

Registered: 10 years ago Posts: 790 |

I've got 1:1 direct drive and never had even a warm motor [I've got a heatsink and fan, though]. Retracts around 80-100mm/s at 3.2mm distance. But you answered my question. I'm definitely a future buyer.Quote

Mutley3D

we do often hear of the motors and stepper drivers getting very hot, print freezes due to overheating electronics and so on.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds May 20, 2014 02:51PM |

Registered: 11 years ago Posts: 334 |

I just ordered one to test out, after some testing I will share my experiences.

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

WWW.ZATOPA.COM - Your Place for high quality 3D Printing Filament and accessories

|

Re: Flexidrive is Flex3Drive Early Birds May 20, 2014 02:57PM |

Registered: 10 years ago Posts: 790 |

Here's another question: What's the horizontal distance that can be reache? It's a 900mm shaft, but with how things move and collide I can't imagine you'd get a movement range of any more than 5-600mm. Of course, I have no idea how in/flexible it is.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Flexidrive is Flex3Drive Early Birds May 20, 2014 03:00PM |

Registered: 11 years ago Posts: 117 |

|

Re: Flexidrive is Flex3Drive Early Birds May 20, 2014 04:51PM |

Registered: 10 years ago Posts: 1,381 |

Area Moment of Inertia, also known as Second Moment of Inertia - I, is a property of shape that is used to predict deflection, bending and stress in beams.

Note: the "Area Moment of Inertia" is analogous to the "Polar Moment of Inertia" as a measure of a beam's ability to resist torsion - which is required to calculate the twist of a beam subjected to torque

the "Section Modulus" is defined as W = I / y, where I is Area Moment of Inertia and y is the distance from the neutral axis to any given fibre

[www.engineeringtoolbox.com]

Second moment of area

[en.wikipedia.org]

Note: the "Area Moment of Inertia" is analogous to the "Polar Moment of Inertia" as a measure of a beam's ability to resist torsion - which is required to calculate the twist of a beam subjected to torque

the "Section Modulus" is defined as W = I / y, where I is Area Moment of Inertia and y is the distance from the neutral axis to any given fibre

[www.engineeringtoolbox.com]

Second moment of area

[en.wikipedia.org]

|

Re: Flexidrive is Flex3Drive Early Birds May 21, 2014 09:35AM |

Registered: 11 years ago Posts: 117 |

|

Re: Flexidrive is Flex3Drive Early Birds May 23, 2014 03:05PM |

Registered: 11 years ago Posts: 973 |

ive ordered one and ill do my best to keep u all updated but cant wait

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Flexidrive is Flex3Drive Early Birds May 24, 2014 05:02PM |

Registered: 9 years ago Posts: 425 |

Quote

jkoljo

Nice and interesting design. What's the second moment of area for the drive shaft?

I will endeavour to get this information from the shaft supplier for the second moment of Area. I can confirm the delta between in and out is Zero and why this shaft was chosen.

My focus is on implementing and executing what is in the innovative minds eye backed up by nearly two decades of experience within the automotive sector with high grade world renown performance brands.

For a moment i had thought you were talking about something else (thats in the pipeline)

A Very good question though and I would be happy to work with you to assess this in greater depth to eeek out any additional performance gains that may be possible based on the theory side of things.

Edited 1 time(s). Last edit at 05/24/2014 07:39PM by Mutley3D.

|

Re: Flexidrive is Flex3Drive Early Birds May 24, 2014 05:09PM |

Registered: 9 years ago Posts: 425 |

Quote

MrDoctorDIV

Here's another question: What's the horizontal distance that can be reache? It's a 900mm shaft, but with how things move and collide I can't imagine you'd get a movement range of any more than 5-600mm. Of course, I have no idea how in/flexible it is.

Another great question....In the current arrangement 600mm is safely achievable and possibly a bit more. With some clever thought into mounting locations you could probably reach 1200mm with this particular shaft and a central position about the moving axis. I know of few printers however in the common market space that have such dimensions. That being said I can and am happy to support custom applications.

Longer shafts can also be used, or even two shafts linked together. Should you wish to consider and test such a deployment i would be happy to assist and provide any CAD related work in order to help you.

|

Anonymous User

Re: Flexidrive is Flex3Drive Early Birds May 27, 2014 10:43AM |

|

Re: Flexidrive is Flex3Drive Early Birds May 27, 2014 01:33PM |

Registered: 11 years ago Posts: 973 |

Reper what machine you putting it on?

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Flexidrive is Flex3Drive Early Birds May 28, 2014 04:37AM |

Registered: 12 years ago Posts: 227 |

|

Re: Flexidrive is Flex3Drive Early Birds May 28, 2014 03:43PM |

Registered: 9 years ago Posts: 425 |

Quote

karabas

What is the exact weight?

Karabas, thank you for your question and a very good point to raise...

Mass of the single filament extruder assembly is...

60.61grammes with JHead Mkv-B

39.22grammes without hotend

+-5%

The dual drive version will be less than 80 grammes (+ hot-end) noting that the internal drivetrain components can be swapped from the single to the dual drive when it arrives. Thereby making it cheaper to upgrade.

|

Re: Flexidrive is Flex3Drive Early Birds May 29, 2014 05:33PM |

Registered: 12 years ago Posts: 227 |

|

Re: Flexidrive is Flex3Drive Early Birds May 31, 2014 10:26AM |

Registered: 9 years ago Posts: 425 |

Quote

karabas

Quote

Mutley3D

Quote

karabas

What is the exact weight?

39.22grammes without hotend

Including flexible shaft?

Hi Karabas,

Perhaps i should have mentioned that the Flexible Drive Shaft effectively floats back and forth with the extruder and X carriage assembly adding very little weight if any (in the order of 10grammes possibly but little more if at all). I do intend to check this value precisely once i have acquired a set of digigtal scales that are small enough to mount onto the X carriage. Also, the degree of resistance created by the flex shaft is also negligable as th structure of indeed very flexible and follows the natural curve of the PTFE tube that is a (positive) result of the way the PTFE tube material is packaged and formed so it is indeed worked to the advantage of the design. Please note also the driveshaft diameter is 3mm in comparison the 6-10mm diameter of other driveshafts that some have asked would be compatible or usable such as those for driving dremmel tools.

|

Re: Flexidrive is Flex3Drive Early Birds May 31, 2014 04:07PM |

Registered: 12 years ago Posts: 227 |

What is your retract settings?

If f.e. Torsional Deflection = 6(12) degrees per ft per lb and effective diameter of hobbed bolt = 8 mm and stepper max torque = 4.4kg/cm

for 900mm shaft and 40:1 reductor

we get about max 0.125 - 0.3 mm e-feed error.

I wonder if it is acceptable. It seems it's better than bowden.

Edited 1 time(s). Last edit at 05/31/2014 05:19PM by karabas.

If f.e. Torsional Deflection = 6(12) degrees per ft per lb and effective diameter of hobbed bolt = 8 mm and stepper max torque = 4.4kg/cm

for 900mm shaft and 40:1 reductor

we get about max 0.125 - 0.3 mm e-feed error.

I wonder if it is acceptable. It seems it's better than bowden.

Edited 1 time(s). Last edit at 05/31/2014 05:19PM by karabas.

Sorry, only registered users may post in this forum.