Want to build a Wallace.

Posted by GANNONBB

|

Want to build a Wallace. May 22, 2014 12:42PM |

Registered: 9 years ago Posts: 1 |

I am new to the forum and I am looking to build the Wallace version of the reprap.

The first thing I was looking for is if there was anyone on this forum that would print the parts for me since this would be my first 3d printer.

Cheers!

Edited 1 time(s). Last edit at 05/22/2014 04:34PM by GANNONBB.

The first thing I was looking for is if there was anyone on this forum that would print the parts for me since this would be my first 3d printer.

Cheers!

Edited 1 time(s). Last edit at 05/22/2014 04:34PM by GANNONBB.

|

Re: Want to build a Wallace. May 23, 2014 05:51AM |

Registered: 10 years ago Posts: 32 |

I've never really understood this design, or why the printrbot is so popular.

You're relying on the rigidity of the smooth rods for the stability of the entire x & z axis, it's basically a prusa design but without the frame.

That aside, post up your location and someone local is bound to be able to lend you a hand.

You're relying on the rigidity of the smooth rods for the stability of the entire x & z axis, it's basically a prusa design but without the frame.

That aside, post up your location and someone local is bound to be able to lend you a hand.

|

Re: Want to build a Wallace. May 23, 2014 04:10PM |

Registered: 10 years ago Posts: 240 |

Is there a reason you chose this particular model?

This model is still listed as experimental, even though it's well over 2 years old. We have come quite a ways since then in terms of cost, speed, reliability, and ease of use.

My advice is look for something that either has, or at least parts are available to make it auto level or calibrate. This will make your life much easier.

This model is still listed as experimental, even though it's well over 2 years old. We have come quite a ways since then in terms of cost, speed, reliability, and ease of use.

My advice is look for something that either has, or at least parts are available to make it auto level or calibrate. This will make your life much easier.

|

Re: Want to build a Wallace. May 23, 2014 07:18PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

sheepdog43

Is there a reason you chose this particular model?

This model is still listed as experimental, even though it's well over 2 years old. We have come quite a ways since then in terms of cost, speed, reliability, and ease of use.

My advice is look for something that either has, or at least parts are available to make it auto level or calibrate. This will make your life much easier.

Come on, you really don't need autoleveling, it's for lazy people. And for people who just like new things.

Every printer has worked well without autoleveling before, so I wouldn't bother.

But, if you really want a Wallace... Maybe in the sales forums there might be someone wanting to print you parts

|

Re: Want to build a Wallace. May 23, 2014 07:53PM |

Registered: 10 years ago Posts: 474 |

I agree Auto leveling is like a Band-Aid the real root of the problem is the machine is off or designed badly. It makes the little microprocessor work itself to death to me not a good idea build a machine that is straight flat and square.

Edited 1 time(s). Last edit at 05/23/2014 07:54PM by cnc dick.

Edited 1 time(s). Last edit at 05/23/2014 07:54PM by cnc dick.

|

Re: Want to build a Wallace. May 23, 2014 08:09PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Want to build a Wallace. May 24, 2014 05:28AM |

Registered: 10 years ago Posts: 240 |

Quote

Ohmarinus

Quote

sheepdog43

Is there a reason you chose this particular model?

This model is still listed as experimental, even though it's well over 2 years old. We have come quite a ways since then in terms of cost, speed, reliability, and ease of use.

My advice is look for something that either has, or at least parts are available to make it auto level or calibrate. This will make your life much easier.

Come on, you really don't need autoleveling, it's for lazy people. And for people who just like new things.

Every printer has worked well without autoleveling before, so I wouldn't bother.

Manual configuration of course works fine, my point was though, is that there are better, newer designs out there, auto level being a part of that.

You should know how to do it manually, and I would even recommend doing it at least once, but if you would rather use your printer than spend your time messing with it, auto level makes that task a whole lot faster and easier. On a printer such as the Wallace, I suspect you will be doing a lot of recalibrating.

Strength and stability is highly under-rated in the Reprap community in my opinion, particularly in older designs, both of which effect print quality and speed. Stability is something that design severely lacks (hello triangulation!), just look at the upper bracing on that. I'm not saying the Wallace is bad, or that no one should build it, just that if you were going to build your first printer, there are better, easier to build, more modern choices that will serve you a lot better, for a lot longer.

If you want to build it for fun, great, retro can be cool. If you want it as your first and/or only printer, I think it's a bad choice. Compared to what we have now, it's more of a Repstrap design.

|

Re: Want to build a Wallace. May 24, 2014 06:14AM |

Registered: 10 years ago Posts: 240 |

Complete and utter BS.Quote

cnc dick

I agree Auto leveling is like a Band-Aid the real root of the problem is the machine is off or designed badly. It makes the little microprocessor work itself to death to me not a good idea build a machine that is straight flat and square.

Go ahead and build it, make it perfectly true, particularly a Wallace. Move that Y axis and maybe the Z up and down once, and I bet you that thing wobbles all over. Also, just how precise can you get with manual calibration, .0002mm accuracy across the entire bed? I doubt it. Does your linear rail have a slight bend? gantry droop? Try dialing that out. Auto level can do it, and even tell you how far out it is and where.

Try building a delta, the system can calibrate itself and auto level itself in a fraction of the time you can, and to a higher degree of accuracy. If it doesn't tax the processor on a delta (it doesn't), there's no way it's going to tax the processor on a cartesian. I run my delta at over twice the speeds you run at and it handles it just fine with auto level and auto calibration. Matter of fact, I couldn't go the speeds I do until I got the higher accuracy.

You see it as a band-aid, I see it as a way to get better prints, easier and faster.

Edited 1 time(s). Last edit at 05/24/2014 06:16AM by sheepdog43.

|

Re: Want to build a Wallace. May 24, 2014 09:27AM |

Registered: 10 years ago Posts: 474 |

I agree the Wallace is not sturdy in fact most reprap printers are terrible as far as stability goes. That's the point I was trying to make if the machine is designed and built correctly and then it stays where it should be. I Don't have any experience building a Delta but he was not talking about a Delta he was talking about a Cartesian style

|

Re: Want to build a Wallace. May 24, 2014 11:54AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

Does your linear rail have a slight bend? gantry droop? Try dialing that out. Auto level can do it, and even tell you how far out it is and where.

Which firmware does this? Looking at Marlin it seems to just model the bed as an inclined plane even if it probes a grid.

[www.hydraraptor.blogspot.com]

|

Re: Want to build a Wallace. May 24, 2014 06:42PM |

Registered: 10 years ago Posts: 240 |

It's checking the distance from probe to bed in every place it checks and remembers it.Quote

nophead

Quote

Does your linear rail have a slight bend? gantry droop? Try dialing that out. Auto level can do it, and even tell you how far out it is and where.

Which firmware does this? Looking at Marlin it seems to just model the bed as an inclined plane even if it probes a grid.

You can get a readout of those numbers and see the high and low spots. Granted this doesn't directly tell you if it's the gantry or the bed itself, but will tell you if there is a change in that dimension. I've even seen at least one person put the numbers into a chart and model it in 3d.

Marlin and Repeteir both can do it, though I have yet to use the latter and I hear it's more difficult.

|

Re: Want to build a Wallace. May 24, 2014 06:57PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes but it doesn't do anything to compensate for it like you implied. I think Marlin only compensates for the bed being not level or the Z height varying, the same as I implemented on HydraRaptor.

There are lots of ways a machine can be out of true that probing the bed cannot compensate for or even detect. For example the axes not being perpendicular to each other or the towers of a delta not being perfectly spaced, parallel and orthogonal to the bed. That is why I designed the Mendel90 even though I had already implemented auto levelling.

[www.hydraraptor.blogspot.com]

There are lots of ways a machine can be out of true that probing the bed cannot compensate for or even detect. For example the axes not being perpendicular to each other or the towers of a delta not being perfectly spaced, parallel and orthogonal to the bed. That is why I designed the Mendel90 even though I had already implemented auto levelling.

[www.hydraraptor.blogspot.com]

|

Re: Want to build a Wallace. May 24, 2014 07:56PM |

Registered: 11 years ago Posts: 205 |

|

Re: Want to build a Wallace. May 24, 2014 09:05PM |

Registered: 10 years ago Posts: 474 |

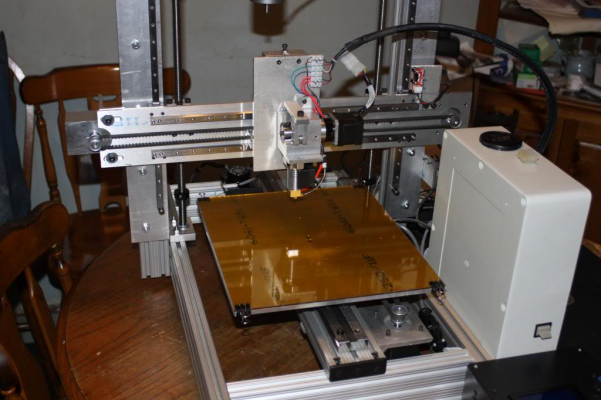

On my latest build I designed a couple little things to make it easier adjust nozzle and bed this is not a standard it is my own design of a printer. First there is a little ball linear slide mounted vertically to the extruder mounting plate and a little 10x32 stop screw is how you set the nozzle to bed height. Second the build plate is quarter inch 6061 jig plate I picked a piece I had that was not particularly flat and mounted Connors bowed down attached it just in the center with two 8x32 screws close together if I remember right one half an inch but then added four 6x32 setscrews in a 3 in. square patern so by tightening the setscrews I can equal out all four corners if there's a little hollow in the middle the glass takes care of that

at

Edited 4 time(s). Last edit at 05/24/2014 09:13PM by cnc dick.

Edited 4 time(s). Last edit at 05/24/2014 09:13PM by cnc dick.

|

Re: Want to build a Wallace. May 24, 2014 09:29PM |

Registered: 9 years ago Posts: 210 |

Quote

garyhlucas

Probing the bed won't produce flat objects. It'll make the layers parallel to whatever the surface of the bed is. So if your bed is bowl shaped your parts will be bowl shaped, even if all your axis are dead straight and square.

Not necessarily. The firmware could potentially even out the surface in the first few layers by varying the height.

I found this video interesting where the print isn't actually skewed but gets tilted and printed right: [www.youtube.com]

|

Re: Want to build a Wallace. May 25, 2014 09:40AM |

Registered: 10 years ago Posts: 553 |

I think what Gary is saying is that if your build surface is not planar you will not get flat prints even with a probe.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Want to build a Wallace. May 25, 2014 10:56AM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Want to build a Wallace. May 25, 2014 03:48PM |

Registered: 12 years ago Posts: 258 |

Quote

Ohmarinus

Quote

gmh39

I think what Gary is saying is that if your build surface is not planar you will not get flat prints even with a probe.

Exactly.

Heh, I thought it was all servo adjusting. Here's the code: [github.com]

Depending on AUTO_BED_LEVELING_GRID It either calculates a transformation matrix based on a plane derived from three probed points ( [github.com] ) or on the least-squares best fit plane through a set of more than three points ( [github.com] )

Autolevel's least-squares operation reduces even a dense grid of points into 3-value description of the best fit plane, for eventual use at [github.com]

Explicitly dealing with cupping and droop would take more than a simple rotation. You'd need at least 6 more values for translation and scaling.

You might think of the grid method as handling droop to some extent in that if you have a lot of samples in the middle, droopier part, they'd try to balance out the stiffer measurements near the edges. However, since the least squares method will weight the extremes more than the values closer to the mean, it probably biases the result more towards the outer edge measurement than the inner measurements.

|

Re: Want to build a Wallace. May 25, 2014 05:14PM |

Admin Registered: 17 years ago Posts: 7,879 |

Not only that but I think the maths in Marlin that converts the plane normal to a rotation matrix is incorrect. I.e. [github.com]

In my original code I pick an arbitrary vector along the plane parallel to the X axis and cross that with the plane's normal to get a third axis orthogonal to both. Marlin just picks a second arbitrary vector along the plane parallel to the Y axis. If the plane is inclined in both X and Y then you can't have both the object's X and Y axes parallel to the machine's X and Y, only one can be. At least that is my understanding, I am waiting for somebody to confirm it is wrong.

[www.hydraraptor.blogspot.com]

In my original code I pick an arbitrary vector along the plane parallel to the X axis and cross that with the plane's normal to get a third axis orthogonal to both. Marlin just picks a second arbitrary vector along the plane parallel to the Y axis. If the plane is inclined in both X and Y then you can't have both the object's X and Y axes parallel to the machine's X and Y, only one can be. At least that is my understanding, I am waiting for somebody to confirm it is wrong.

[www.hydraraptor.blogspot.com]

|

Re: Want to build a Wallace. May 25, 2014 11:24PM |

Registered: 12 years ago Posts: 258 |

Sorry, only registered users may post in this forum.