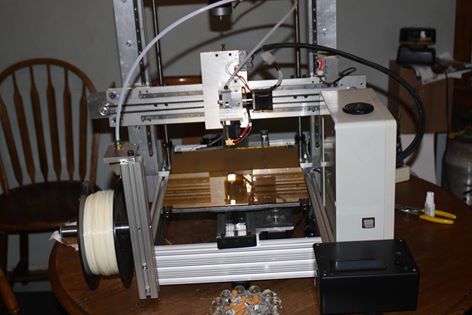

This is my latest design and build 3-D printer

Posted by cnc dick

|

This is my latest design and build 3-D printer May 27, 2014 04:20PM |

Registered: 10 years ago Posts: 474 |

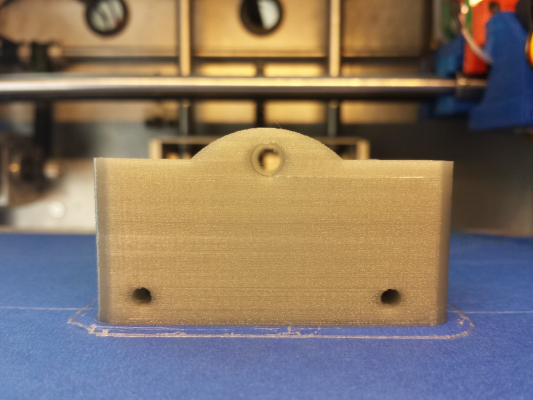

Here are a few pictures

|

Re: This is my latest design and build 3-D printer May 27, 2014 08:49PM |

Registered: 13 years ago Posts: 1,797 |

|

Re: This is my latest design and build 3-D printer May 28, 2014 08:27AM |

Registered: 10 years ago Posts: 474 |

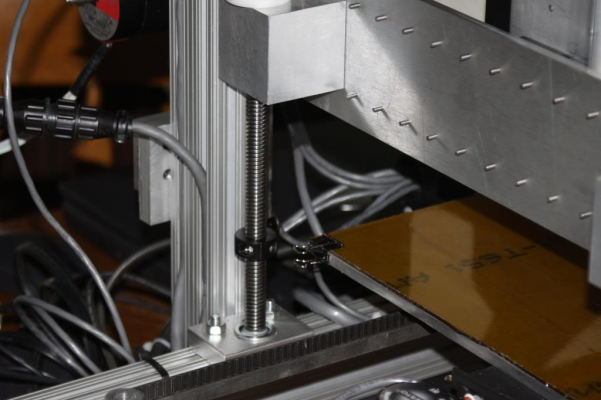

in my opinion the extruder is the most important part of 3-D printer needs to be tremendously reliable again this is a smaller version of one I built my large machine. It uses the same drive system which is a serrated drive wheel off a mig welder it's over an inch in diameter and that's driven by 100 to 1 gear motor. I don't seem to have any problems by letting it overhang that much I could've done it the other way around so that the hot end was feeding off the backside but I didn't like the spring pintch system the that way. Plus something I definitely wanted was my design of the sliding extruder only held down by gravity it slides on a little ball slide and the screw you see on top is for adjusting height. The large diameter of the drive wheel is the key many more teeth are engaged in the filament at a time if you click on the last picture it should be a link to a video the X carriage and the whole machine is very rigid and takes the overhang well . 90% of the materials and the components I had on hand I had the 8020 and the aluminum plate three of the four motors and the linear rails and bearings I bought the Arduino ramps LCD and E 3-D hot end one motor and two of the belts so I basically designed around what I had the XY and Z are 23'sQuote

jamesdanielv

how do you keep the chatter down on the z axis. you want the nozzle to be as near the center of z stage as possible. perhaps move the nozzle in another inch?

Edited 10 time(s). Last edit at 05/28/2014 09:36AM by cnc dick.

|

Re: This is my latest design and build 3-D printer May 29, 2014 02:29AM |

Registered: 11 years ago Posts: 364 |

|

Re: This is my latest design and build 3-D printer May 29, 2014 06:26AM |

Registered: 10 years ago Posts: 474 |

Nothing in particular I just went to eBay bought a mig welder serrated drive wheel and built the extruder around that. Like I said in a couple of other posts large diameter is the key because of the radius more teeth are engaged at any one time. But because of that you have to go quite high on the gear reduction. If You click on this issue be a link to a crappy video

Edited 1 time(s). Last edit at 05/29/2014 11:43AM by cnc dick.

Edited 1 time(s). Last edit at 05/29/2014 11:43AM by cnc dick.

|

Re: This is my latest design and build 3-D printer May 30, 2014 03:57PM |

Admin Registered: 11 years ago Posts: 3,096 |

Well, I don't agree with what you are saying about gear diameter. I am using a MK8 and If I'm not mistaken, has a ID of 5mm and OD of 7mm and it has never jammed on me, and has a grip that makes your seat go up.

The quality of the grip-lines in the gear is very important. When they can't get clogged, the gear will perform way better. And with a small OD, the force that the motor has to output to move the filament is very low.

The quality of the grip-lines in the gear is very important. When they can't get clogged, the gear will perform way better. And with a small OD, the force that the motor has to output to move the filament is very low.

|

Re: This is my latest design and build 3-D printer May 31, 2014 09:11AM |

Registered: 10 years ago Posts: 474 |

I'm glad you never have any problems but if you just think of it in your mind the diameter with teeth directly on centerline where your idler wheel is .If you push the filament into the tooth it's lined up on the centerline X amount of distance on a very small wheel it has to go in father for teeth to touch the filament above and below with other teeth but with a larger diameter it has to push less into the filament less because of the radius. I think you definitely need more than one tooth at a time driving the filament the more the better. When I first decided to build a 3-D printer I checked and most people had problems with extruders and hot ends my first machine was meant to run 24 hours a day for days and I could not rely on anything that was out there at the time. So the first thing I built and tested was the extruder and hot end and worked with it until it was happy with it currently there's some nice all metal hot ends out there even I bought one for my last build. A lot of people use Bowden style extruders now so weight is not a factor

Edited 3 time(s). Last edit at 05/31/2014 09:14AM by cnc dick.

Edited 3 time(s). Last edit at 05/31/2014 09:14AM by cnc dick.

|

Re: This is my latest design and build 3-D printer May 31, 2014 03:59PM |

Registered: 10 years ago Posts: 162 |

The amount of filament that gets driven per revolution is equal to the circumference of the drive gear... so for a smaller diameter drive gear, your motor doesn't have to work as hard to push the filament. I think this is probably more important for a bowden setup (due to the extra friction from the tube) than non-bowden, which is why you are likely to be able to get away with a range of drive gear diameters.

If it works, go with it. But I don't think this is a one size fits all situation.

If it works, go with it. But I don't think this is a one size fits all situation.

|

Re: This is my latest design and build 3-D printer May 31, 2014 05:29PM |

Registered: 13 years ago Posts: 643 |

It never is one size fits all, but the current normal setup of a tiny drive wheel is probably sub-optimal. If the extruder can tear through the filament without stalling the motor, then we have torque we could be using to extrude faster or push through jams that would stall existing extruders. If the motor stalls before stripping the filament, then we know that we can use all the torque the motor has to offer.

|

Re: This is my latest design and build 3-D printer May 31, 2014 06:40PM |

Registered: 10 years ago Posts: 474 |

this is where gearing comes in I personally run 100 to 1 gear motor the drive wheel is approximately 26 mm diameter. With 16 micro step it's 3200 steps per millimeter very accurate. And like I said many times before you have the picture it in your mind little teeth in the small diameter it's not a good scenario but even the Pro machines use a small drive wheel which I think is wrong the more teeth engaging the better you can do anything you want with gearing and get whatever resolution you wantQuote

iquizzle

The amount of filament that gets driven per revolution is equal to the circumference of the drive gear... so for a smaller diameter drive gear, your motor doesn't have to work as hard to push the filament. I think this is probably more important for a bowden setup (due to the extra friction from the tube) than non-bowden, which is why you are likely to be able to get away with a range of drive gear diameters.

If it works, go with it. But I don't think this is a one size fits all situation.

Edited 3 time(s). Last edit at 05/31/2014 06:44PM by cnc dick.

|

Re: This is my latest design and build 3-D printer May 31, 2014 07:19PM |

Registered: 10 years ago Posts: 790 |

I've thought about a tank track type grip, but that's unnecessarily complex. Just a thought.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: This is my latest design and build 3-D printer June 03, 2014 10:35AM |

Registered: 11 years ago Posts: 47 |

|

Re: This is my latest design and build 3-D printer June 03, 2014 10:52AM |

Registered: 10 years ago Posts: 790 |

You've shown your printer and extruder, but I don't believe I've seen prints you've done.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: This is my latest design and build 3-D printer June 03, 2014 02:50PM |

Registered: 10 years ago Posts: 474 |

I just did a Dragon I got off thingaverse in ABS.not that high of a resolution I used a .2985 layer height came out very good little cleanup and I just sprayed some clear lacquer on it now when it's dry post a picture of it was a six-hour print when I was cleaning it up I did snap the tale myself not when it was printing but while I was cleaningQuote

MrDoctorDIV

You've shown your printer and extruder, but I don't believe I've seen prints you've done.

Edited 2 time(s). Last edit at 06/03/2014 02:52PM by cnc dick.

|

Re: This is my latest design and build 3-D printer June 03, 2014 04:39PM |

Registered: 10 years ago Posts: 474 |

Okay here is a few pictures of the Dragon I printed

|

Re: This is my latest design and build 3-D printer June 03, 2014 05:31PM |

Registered: 10 years ago Posts: 790 |

Ooooo, yeah I definitely am going to keep my plans to paint my prints with special techniques. Also, I'm pretty sure I'm going to kill my plans to speed up my Solidoodle. Slow and steady really does win the race.

My recent quality test seems to be near the best I can get, which is low enough as it is, adding in speed would make it pointless.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

My recent quality test seems to be near the best I can get, which is low enough as it is, adding in speed would make it pointless.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:02PM |

Registered: 10 years ago Posts: 474 |

There is a few people here that hate to see me post this picture but since you did here is one I did on my big floorstanding machine

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:08PM |

Registered: 11 years ago Posts: 47 |

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:23PM |

Registered: 10 years ago Posts: 474 |

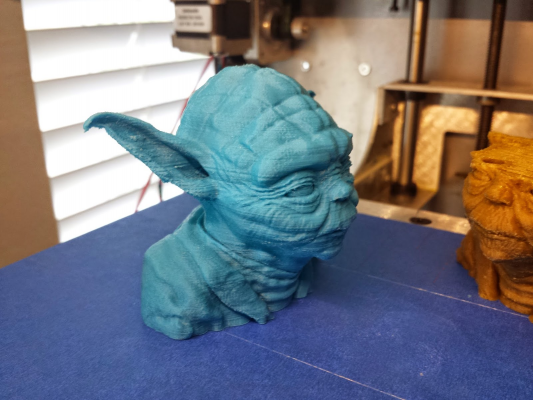

sorry I have thrown a little 20 mm test cubes away this is how you set the machine up yes it produces accurate straight walls if you think printing a square cube is easier than printing something like the Dragon I just printed your out of your mind if it's not set up exactly it will knock the legs off before they are attached to the body the tail will come out terribly never mind the wings I've done Stratis gliders which are difficult because there only one layer thick wings. I've done the screw cap Bottle test and multiple squares but obviously I didn't hold onto these. And the Yoda was printed on a larger machine that I made a couple years agoQuote

tkole

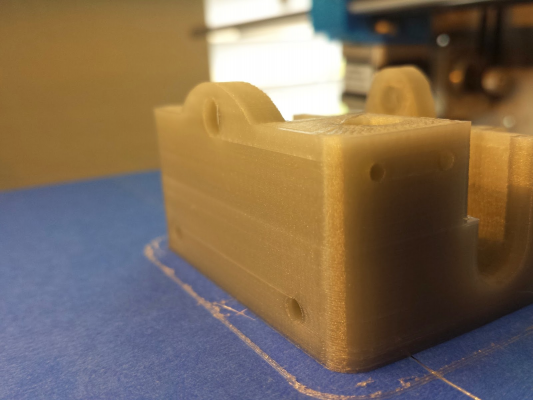

The yoda is definitely nice, but these objects don't give a good measure of a printer's capability in my opinion. I want to see an object with flat vertical faces and sharp corners. All of the curves and irregular borders mask the limitations of the printer.

Edited 1 time(s). Last edit at 06/03/2014 06:26PM by cnc dick.

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:27PM |

Registered: 10 years ago Posts: 790 |

I base my quality solely on vertical faces and holes, the most challenging of any printer [besides unsupported bridging, maybe?] to get perfect. Here's my self rating piece:

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:31PM |

Registered: 11 years ago Posts: 47 |

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:37PM |

Registered: 10 years ago Posts: 474 |

Looks like you have set your printer up pretty good but I think you mainly print in PLA I mainly print it ABS I never worried about putting a drill in a hole after printing I just built the printer so I haven't printed any thing structural yet except for the test pieces and some screw cap Bottles to check fit. The large floorstanding printer printer I built a couple years ago was all structural parts where I worked. Try to print the the Dragon it will tell you if you got it right it's a fairly good size and if you have any kind of over extrusion or over prime it will knock the pieces off before that connected

Edited 3 time(s). Last edit at 06/03/2014 09:22PM by cnc dick.

Edited 3 time(s). Last edit at 06/03/2014 09:22PM by cnc dick.

|

Re: This is my latest design and build 3-D printer June 03, 2014 06:42PM |

Registered: 11 years ago Posts: 47 |

It's not so much for the hole as it is for the inertia check. You can unmask many acceleration issues by throwing a hole in the path of a vertical wall. With the mass of your xcarriage and bed, I imagine printing this piece would be very telling. I'm not sure why PLA vs. ABS has anything to do with the discussion.

|

Re: This is my latest design and build 3-D printer June 03, 2014 07:28PM |

Registered: 10 years ago Posts: 790 |

PLA vs ABS can sometimes tell a different story. I am exclusively PLA, but upon certain need for one customer I will be getting another material, not sure yet which one.

Where's the file for the dragon? I'd love to print that out for test. Did you print with supports?

My speed was 60mm/s, acceleration was 5000, and I think my firmware has a jerk of 20, but I can't remember since I just left the default value for that one, I've had no bumpy curves and therefore no need to change it.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Where's the file for the dragon? I'd love to print that out for test. Did you print with supports?

My speed was 60mm/s, acceleration was 5000, and I think my firmware has a jerk of 20, but I can't remember since I just left the default value for that one, I've had no bumpy curves and therefore no need to change it.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: This is my latest design and build 3-D printer June 03, 2014 07:42PM |

Registered: 10 years ago Posts: 474 |

Of course it does it shrinks twice as much this a little glider I made the grandkids played with it for two weekends now it's broke now and I don't have a macro lens this is a good one to test print this you might be able to see the top layers on the fuselage and you possibly can see the square sides

|

Re: This is my latest design and build 3-D printer June 03, 2014 07:49PM |

Registered: 10 years ago Posts: 474 |

I got off thingaverse I don't remember what they called it something like a singing Dragon no supportsQuote

MrDoctorDIV

PLA vs ABS can sometimes tell a different story. I am exclusively PLA, but upon certain need for one customer I will be getting another material, not sure yet which one.

Where's the file for the dragon? I'd love to print that out for test. Did you print with supports?

My speed was 60mm/s, acceleration was 5000, and I think my firmware has a jerk of 20, but I can't remember since I just left the default value for that one, I've had no bumpy curves and therefore no need to change it.

Edited 1 time(s). Last edit at 06/03/2014 07:49PM by cnc dick.

|

Re: This is my latest design and build 3-D printer June 03, 2014 08:22PM |

Registered: 10 years ago Posts: 272 |

|

Re: This is my latest design and build 3-D printer June 03, 2014 09:04PM |

Registered: 10 years ago Posts: 474 |

I agree I think most problems with the reprap printers is exactly what you said throwing the mass around that's why you have to build the system sturdy enough to take the acceleration and deceleration of the X or light enough which I don't agree with because the extruder and hot end is the most important thing I don't like Bowden personally. I think The main problem with most reprap designs is z guide system and the frame. This is another picture that people hate to see here this was done on my large floorstanding machine I made a couple years ago very strong very accurate all ballscrews. I did print one of these these on my new little machine with belts and it didn't come out anywhere near as good as this but still better than most i gave it away to somebody that was at my house the picture is from the large machine URL=http://s1333.photobucket.com/user/richard_nelson1/media/IMG_7886_zps7e95bf6e.jpg.html] [/URL]my large machine with ballscrews look at the layersQuote

tkole

It's not so much for the hole as it is for the inertia check. You can unmask many acceleration issues by throwing a hole in the path of a vertical wall. With the mass of your xcarriage and bed, I imagine printing this piece would be very telling. I'm not sure why PLA vs. ABS has anything to do with the discussion.

Edited 3 time(s). Last edit at 06/04/2014 05:11AM by cnc dick.

|

Re: This is my latest design and build 3-D printer June 04, 2014 08:18AM |

Registered: 10 years ago Posts: 790 |

Ball/leadscrew driven axis produce extreme stability, and I've honestly thought about getting 8mm pitch screws for my axis, but I do like speed for certain applications. I might make a single printer amongst many, but my main will definitely be belt driven.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: This is my latest design and build 3-D printer June 04, 2014 02:02PM |

Registered: 10 years ago Posts: 474 |

You Can get ballscrews in any pitch you want the ones I used on the big machine I built our approximately 16mm per turn they are SAE. But I do have a couple nice short ones in my inventory that I was going use on the small machine I just built but I wanted to try to belts just see how bad they would perform. The two I was planning on using for the little machine 30 mm per turn

Edited 1 time(s). Last edit at 06/04/2014 02:04PM by cnc dick.

Edited 1 time(s). Last edit at 06/04/2014 02:04PM by cnc dick.

Sorry, only registered users may post in this forum.