Bowden questions

Posted by Ralph.Hilton

|

Bowden questions May 28, 2014 01:14AM |

Registered: 10 years ago Posts: 439 |

I'm building a second printer changing quite a few things as it slowly progresses. The new E3D v6 inspired me to to consider going for a Bowden extruder. I was wondering about optimum placement of the extruder motor and what people have had best results from. It would seem best to keep the tube as short as possible so was considering a swivel mount attached to the Z assembly that would go up and down with the X carriage. Does that sound feasible?

|

Re: Bowden questions May 28, 2014 12:00PM |

Registered: 13 years ago Posts: 2,947 |

It seems that consensuses on this is that shorter is better (under 700mm's).

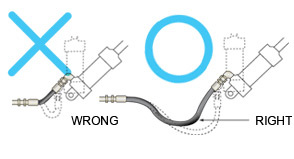

I have always found that a smooth curve with out changing direction is very important, just like in hydraulics with hoses. Otherwise the filament has to switch side of the tube mid way through which results in hysteresis.

I would also recommend using 3mm since you can retract and un-retract it at incredible speeds without it ever buckling and that means you can actually have good working retraction.

Edited 1 time(s). Last edit at 05/28/2014 12:01PM by Sublime.

I have always found that a smooth curve with out changing direction is very important, just like in hydraulics with hoses. Otherwise the filament has to switch side of the tube mid way through which results in hysteresis.

I would also recommend using 3mm since you can retract and un-retract it at incredible speeds without it ever buckling and that means you can actually have good working retraction.

Edited 1 time(s). Last edit at 05/28/2014 12:01PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden questions May 28, 2014 12:17PM |

Registered: 10 years ago Posts: 43 |

|

Re: Bowden questions May 28, 2014 12:58PM |

Registered: 11 years ago Posts: 1,049 |

You didn't say what printer, or what type of printer?

Filament is not hydraulic --- fluid vs solid.

I would disagree with even 90 deg bends with hydraulics.

The hotend (output nozzle) is always moving!

Sweeping bends in transit tubes in all areas, even supply to extruder.

Shortest route with large radius bends in all positions without twisting.

Run extruder without hotend for smooth, resistance free filament movement.

Extruder directly above the hot end midpoint.

Think of it as transfering the push of the extruder thru the bowden tube

----- with ALL force transfered to hotend tip!

Filament is not hydraulic --- fluid vs solid.

I would disagree with even 90 deg bends with hydraulics.

The hotend (output nozzle) is always moving!

Sweeping bends in transit tubes in all areas, even supply to extruder.

Shortest route with large radius bends in all positions without twisting.

Run extruder without hotend for smooth, resistance free filament movement.

Extruder directly above the hot end midpoint.

Think of it as transfering the push of the extruder thru the bowden tube

----- with ALL force transfered to hotend tip!

|

Re: Bowden questions May 28, 2014 02:21PM |

Registered: 10 years ago Posts: 43 |

|

Re: Bowden questions May 28, 2014 05:17PM |

Registered: 13 years ago Posts: 2,947 |

Quote

ejbantz

Sublime, for the 3mm you recommend... is that the filament diameter... or a retraction length?

Yes filament diameter

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden questions May 28, 2014 05:24PM |

Registered: 13 years ago Posts: 2,947 |

Quote

cozmicray

You didn't say what printer, or what type of printer?

Filament is not hydraulic --- fluid vs solid.

I would disagree with even 90 deg bends with hydraulics.

The hotend (output nozzle) is always moving!

Sweeping bends in transit tubes in all areas, even supply to extruder.

Shortest route with large radius bends in all positions without twisting.

Run extruder without hotend for smooth, resistance free filament movement.

Extruder directly above the hot end midpoint.

Think of it as transfering the push of the extruder thru the bowden tube

----- with ALL force transfered to hotend tip!

True it is not a fluid but the extra play around the filament will allow the filament to switch sides of the tube as the tube bends the opposite direction. If you look at some bowdens they form a peanut shape which results in the filament snaking from one side to the other and during retraction it then has to pull out more slack. If you look at Tantillus's Bowden which works perfectly for retractions it only forms one smooth curve and the filament always makes contact on the outside of the curve. So when you retract the pressure drops off immediately because it does not have to make up for the hysteresis from the filament snaking.

Edited 1 time(s). Last edit at 05/28/2014 06:33PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden questions May 28, 2014 05:26PM |

Registered: 13 years ago Posts: 2,947 |

Quote

ejbantz

So should the output of the extruder pointing straight up in the air and then arch 180 back down to the x-carriage?

This can cause the bowden to form the peanut shape I descibed in the last reply. On Tantillus I have the extruder facing back and then the tube forms a 270 degree turn and always forms a smooth curve.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Bowden questions May 28, 2014 05:34PM |

Registered: 9 years ago Posts: 425 |

Quote

Ralph.Hilton

I'm building a second printer changing quite a few things as it slowly progresses. The new E3D v6 inspired me to to consider going for a Bowden extruder. I was wondering about optimum placement of the extruder motor and what people have had best results from. It would seem best to keep the tube as short as possible so was considering a swivel mount attached to the Z assembly that would go up and down with the X carriage. Does that sound feasible?

Hi Ralph,

Just to let you know in case you were not aware there is now another alterntive to the Bowden setup and that is a flexible driveshaft solution. I dont wish to dive into your thread with all the details so here is a link to another post on the forum with more information [forums.reprap.org]

I hope your new build goes well in any case

|

Re: Bowden questions May 28, 2014 11:09PM |

Registered: 10 years ago Posts: 162 |

|

Re: Bowden questions May 29, 2014 09:04AM |

Registered: 10 years ago Posts: 43 |

|

Re: Bowden questions May 29, 2014 04:37PM |

Registered: 10 years ago Posts: 439 |

Mutley3D - I looked at the flexible driveshaft and your design looks very workable. However what puts me off is the price. I was wondering if something like [www.bunnings.com.au] could be hacked for the purpose. I think I'll try with the ptfe tube approach first as it is so much cheaper then investigate more expensive options if it doesn't work.

Cozmicray - I might try it out on my Mendel90 first but I'm really looking at it for my in progress openbeam cartesian printer with a bigger platform 315 x 215 x 200+. I took it apart for redesign a couple of days ago so nothing to take photos of. Putting the extruder above the X carriage midpoint doesn't seem workable but that might be a lacking in my visualizations. Have you got a working bowden setup to show?

Sublime - thanks for all the ideas :-) The Tantillus looks like a well thought out machine.

I am looking at an implementation which would have a total curve of 90 to 135 degrees and be 450mm long. I had considered mounting it on the X axis support which would have made it shorter but that got complex.

Rather than try people's patience with quite possibly unworkable theory I'll have to wait for some bowden tubing to arrive so that I can test it in practice. Living in an Alpine village means that wandering into the local hardware store gets one a rather blank look when one talks about 3D printer parts so it will be a week or so.

After I have a light X carriage then there is still the Y carriage to work out.

This might appear utterly insane but I'm considering building a Y platform from M3 threaded rod. With a combination of optimumly angled rod and printed parts a very light carriage might be makeable without expensive options such as carbon fibre.

.

Edited 1 time(s). Last edit at 05/29/2014 04:38PM by Ralph.Hilton.

Cozmicray - I might try it out on my Mendel90 first but I'm really looking at it for my in progress openbeam cartesian printer with a bigger platform 315 x 215 x 200+. I took it apart for redesign a couple of days ago so nothing to take photos of. Putting the extruder above the X carriage midpoint doesn't seem workable but that might be a lacking in my visualizations. Have you got a working bowden setup to show?

Sublime - thanks for all the ideas :-) The Tantillus looks like a well thought out machine.

I am looking at an implementation which would have a total curve of 90 to 135 degrees and be 450mm long. I had considered mounting it on the X axis support which would have made it shorter but that got complex.

Rather than try people's patience with quite possibly unworkable theory I'll have to wait for some bowden tubing to arrive so that I can test it in practice. Living in an Alpine village means that wandering into the local hardware store gets one a rather blank look when one talks about 3D printer parts so it will be a week or so.

After I have a light X carriage then there is still the Y carriage to work out.

This might appear utterly insane but I'm considering building a Y platform from M3 threaded rod. With a combination of optimumly angled rod and printed parts a very light carriage might be makeable without expensive options such as carbon fibre.

.

Edited 1 time(s). Last edit at 05/29/2014 04:38PM by Ralph.Hilton.

Sorry, only registered users may post in this forum.