McWire Successor

Posted by sircastor

|

Re: McWire Successor March 04, 2010 12:18PM |

Registered: 16 years ago Posts: 169 |

@ bjbsquared: I shamelessly stole your sketchup model of the Auger and played with making a cable drive to replace the McWire threaded rod. Iused the nema23 stepper you used but I think a 17 or even a 14 would be strong enough. Where did you find the sketchup file for the motor?

You'll still have to use your imagination to see the cable stretched from the drive rod to the pulley and it's attachement point under the platform and it's attachment location in the center of the platform area. I don't think I could draw the cable.

I shouldn't have any problem moving the platform without any binding because of the way the skate bearings ride on the electrical conduit rail. Only constrained to the sides.

Well, well, maybe! Dropbox came to my rescue! Just had to make a public link. Had to attach the sketchup file that way too. It's 732kb.

[dl.dropbox.com]

Edited 2 time(s). Last edit at 03/04/2010 12:24PM by Arvin.

You'll still have to use your imagination to see the cable stretched from the drive rod to the pulley and it's attachement point under the platform and it's attachment location in the center of the platform area. I don't think I could draw the cable.

I shouldn't have any problem moving the platform without any binding because of the way the skate bearings ride on the electrical conduit rail. Only constrained to the sides.

Well, well, maybe! Dropbox came to my rescue! Just had to make a public link. Had to attach the sketchup file that way too. It's 732kb.

[dl.dropbox.com]

Edited 2 time(s). Last edit at 03/04/2010 12:24PM by Arvin.

|

Re: McWire Successor March 04, 2010 01:47PM |

Registered: 14 years ago Posts: 34 |

@Arvin. This is very COOL! We need more people to get involved with the design and not just "arm chair" ideas. Doing spawns ideas spawns doing.

I got the model off of the Google library but had to shorten the body size for the motors I have. I used #23s for the McWire but I think #17 would do fine. I might order some and keep the #23s with my McWire for routing.

I'm hoping that others will dig in and attempt to design a belt+pulley and rack+ pinion forks or whatever.

You might be able to do the belt with the "Follow" command. It might not be worth doing at this point.

I have an idea for an easier to make drive screw that I will hopefully explore this weekend.

Keep up the good work!

B^2 : [replibot.blogspot.com]

~~ We Are The Factory ~~

I got the model off of the Google library but had to shorten the body size for the motors I have. I used #23s for the McWire but I think #17 would do fine. I might order some and keep the #23s with my McWire for routing.

I'm hoping that others will dig in and attempt to design a belt+pulley and rack+ pinion forks or whatever.

You might be able to do the belt with the "Follow" command. It might not be worth doing at this point.

I have an idea for an easier to make drive screw that I will hopefully explore this weekend.

Keep up the good work!

B^2 : [replibot.blogspot.com]

~~ We Are The Factory ~~

|

Re: McWire Successor March 05, 2010 05:39PM |

Registered: 14 years ago Posts: 53 |

I'm interested in opinions people have about some sort of modular design. What I mean in terms of modularity is a design that allows for different options depending on availability and cost. This is obvious in terms of an extruder or electronics. However, could we design a printer that could allow for easy swap-out the drive system (leadscrew/belt/rack)? or the linear rails (bjb's conduit-based rails, or drawer slides)

This kind of design would require a sort of common mount system. Would it be worth doing to allow people greater flexibility? Should that kind of effort be spent on furthering the RepRap, rather than working on a RepStrap?

This kind of design would require a sort of common mount system. Would it be worth doing to allow people greater flexibility? Should that kind of effort be spent on furthering the RepRap, rather than working on a RepStrap?

|

Re: McWire Successor March 05, 2010 05:51PM |

Registered: 14 years ago Posts: 380 |

sircastor,

I was thinking about modifying the wiki and/or pdf to have choices and subsections. Like for instance, the black iron pipe is easy to find anywhere, but all the pieces add up in cost. If you have access to tools, and know someone who can weld, it should be both cheaper and stronger to make the whole frame from one piece 1" square box tubing cut to lengths and welded together. Also some choices on screw drive, belt drive, or cable drive.

I currently feel the pdf drops the ball when it comes to the electronics and print heads. I don't know if these have so much variation that we should do several separate write ups, and just tell the reader at the end of the mechanical assembly to pick one from the list of electronics (plus software links), and one from the extruder list.

Mike

Team Open Air

Blog Team Open Air

rocket scientists think LIGHTYEARS outside the box!

I was thinking about modifying the wiki and/or pdf to have choices and subsections. Like for instance, the black iron pipe is easy to find anywhere, but all the pieces add up in cost. If you have access to tools, and know someone who can weld, it should be both cheaper and stronger to make the whole frame from one piece 1" square box tubing cut to lengths and welded together. Also some choices on screw drive, belt drive, or cable drive.

I currently feel the pdf drops the ball when it comes to the electronics and print heads. I don't know if these have so much variation that we should do several separate write ups, and just tell the reader at the end of the mechanical assembly to pick one from the list of electronics (plus software links), and one from the extruder list.

Mike

Team Open Air

Blog Team Open Air

rocket scientists think LIGHTYEARS outside the box!

|

Re: McWire Successor March 05, 2010 07:06PM |

Registered: 14 years ago Posts: 34 |

For myself, I don't feel the need for modular design. This may be something to tackle down the road but for now I think we need to get a base repStrap that is affordable, reliable and buildable by the "average" personal with an "average" maker skill set. Adding modularity would, at least at this point, be too confining the progress toward those attributes.

Also, the only reason that I can think of that could be a reason for a drive system change would be to drastically change the gearing. So, I see a modular system always having to drive threaded rod as the lower gearing option and one of the other drive systems or a larger pitch screw for the higher option.

B^2 : [replibot.blogspot.com]

~~ We Are The Factory ~~

Also, the only reason that I can think of that could be a reason for a drive system change would be to drastically change the gearing. So, I see a modular system always having to drive threaded rod as the lower gearing option and one of the other drive systems or a larger pitch screw for the higher option.

B^2 : [replibot.blogspot.com]

~~ We Are The Factory ~~

|

Re: McWire Successor March 07, 2010 11:49AM |

Registered: 14 years ago Posts: 34 |

sircastor Wrote:

.

> I'm not big on the DIY leadscrew, I think because

> it feels like a bit of a project itself....

I have come up with another way. I will be trying both out.

Threadless Drive Screw

B^2 : [replibot.blogspot.com]

~~ We Are The Factory ~~

.

> I'm not big on the DIY leadscrew, I think because

> it feels like a bit of a project itself....

I have come up with another way. I will be trying both out.

Threadless Drive Screw

B^2 : [replibot.blogspot.com]

~~ We Are The Factory ~~

|

Re: McWire Successor March 07, 2010 02:04PM |

Admin Registered: 16 years ago Posts: 13,884 |

... if you are searching for threadless linear drives, then maybe the Uhing-"rolling ring drive" is interesting too -simply press three bearings skewed on a shaft and it's pushing defined and with high precision ...

|

Re: McWire Successor March 08, 2010 12:28AM |

Registered: 16 years ago Posts: 438 |

VDX - I don't think I understand that. It seems that they must be using bearings with a larger ID than the shaft, and then offsetting a cocking them different ways to get the effect.

Since the shaft is smooth, I'd think you'd lose some repeatability, same way as with a V belt, or other smooth belt drive system.

Really cool effect though...

--

I'm building it with Baling Wire

Since the shaft is smooth, I'd think you'd lose some repeatability, same way as with a V belt, or other smooth belt drive system.

Really cool effect though...

--

I'm building it with Baling Wire

|

Re: McWire Successor March 08, 2010 12:59AM |

Registered: 14 years ago Posts: 53 |

So I've spent a few days working on a sketchup model of a McWire replacement. My work is mostly based on Stoffle15's Wulfstrap. I went with drawer slides because they're relatively cheap, and easily found, and pretty fault tolerant. A builder can simply screw them in, mount stages, and you're set.

Thoughts, criticisms, ideas, etc, are welcome. Sorry for poor design, I'm new to sketchup.

Model is too big to attach, so it can be gotten here:

RepStrap Model

Thoughts, criticisms, ideas, etc, are welcome. Sorry for poor design, I'm new to sketchup.

Model is too big to attach, so it can be gotten here:

RepStrap Model

|

Re: McWire Successor March 08, 2010 02:53AM |

Admin Registered: 17 years ago Posts: 1,791 |

Viktor, that three-rings thing looks awesome.

But it looks like those rings need to be lathed/ground on the two inner faces.

I was hoping it could work with skate bearings.

Model is too big to attach, so it can be gotten here:

sircastor, Arvin, bjbsquared, fellow RepRappers, you guys are welcome to use the wiki to host images, repstrap candidates, post-mendel candidates, and so on. Also, don't forget you can use it as a dropbox for attachments instead of the forum.

In this case, you may want to paste the file and the render up on the WolfStrap page. (I think Wolfgang would be happy if you did so.)

Mike, you're quite welcome to edit/supplement/version the mcwire wiki page (as soon as it gets moved to the mediawiki in a few days).

I don't have a welding kit, but I like the idea of square beams myself:

[objects.reprap.org]

Edited 1 time(s). Last edit at 03/08/2010 02:56AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

But it looks like those rings need to be lathed/ground on the two inner faces.

I was hoping it could work with skate bearings.

Model is too big to attach, so it can be gotten here:

sircastor, Arvin, bjbsquared, fellow RepRappers, you guys are welcome to use the wiki to host images, repstrap candidates, post-mendel candidates, and so on. Also, don't forget you can use it as a dropbox for attachments instead of the forum.

In this case, you may want to paste the file and the render up on the WolfStrap page. (I think Wolfgang would be happy if you did so.)

Mike, you're quite welcome to edit/supplement/version the mcwire wiki page (as soon as it gets moved to the mediawiki in a few days).

I don't have a welding kit, but I like the idea of square beams myself:

[objects.reprap.org]

Edited 1 time(s). Last edit at 03/08/2010 02:56AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: McWire Successor March 08, 2010 04:16AM |

Admin Registered: 16 years ago Posts: 13,884 |

... for building static 'roll-ring-drives' which acts like normal threaded rods you can use normal bearings with fixed skewed positions on a steel-shaft.

The halfcylindric shaped inner ring in the images is needed if you want to change the 'threading' on the fly for changing the moving speeds and direction - the normal use for this drives is a constant rotating shaft and with changing the skewing angles the drive runs up and down the shaft with selectable speed and positioning accuracy ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The halfcylindric shaped inner ring in the images is needed if you want to change the 'threading' on the fly for changing the moving speeds and direction - the normal use for this drives is a constant rotating shaft and with changing the skewing angles the drive runs up and down the shaft with selectable speed and positioning accuracy ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: McWire Successor March 08, 2010 05:18AM |

Registered: 14 years ago Posts: 3,742 |

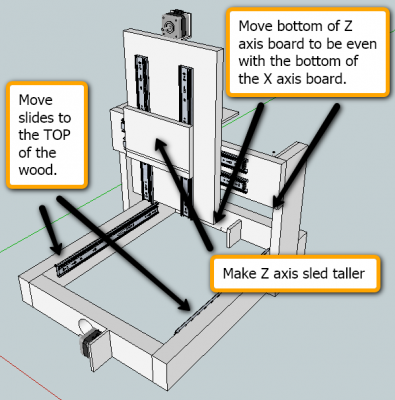

@sircastor: With that design you will only get about 3 cm in the Z direction before the bottom of the Z-stage destroys what you have printed! Better rethink your design.

Edited 1 time(s). Last edit at 03/08/2010 05:19AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Edited 1 time(s). Last edit at 03/08/2010 05:19AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: McWire Successor March 08, 2010 05:28AM |

Registered: 14 years ago Posts: 7,505 |

@sircastor

And the y-Axis cant move...

Edited 1 time(s). Last edit at 03/08/2010 05:28AM by Stoffel15.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

And the y-Axis cant move...

Edited 1 time(s). Last edit at 03/08/2010 05:28AM by Stoffel15.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: McWire Successor March 08, 2010 05:50AM |

Registered: 14 years ago Posts: 3,742 |

|

Re: McWire Successor March 08, 2010 05:58AM |

Registered: 14 years ago Posts: 7,505 |

The z-board has to the bottom edge

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: McWire Successor March 08, 2010 06:06AM |

Registered: 14 years ago Posts: 7,505 |

but i see... he get trouble with the stepper on top.. no place for the pulley.

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: McWire Successor March 08, 2010 06:41AM |

Registered: 14 years ago Posts: 3,742 |

|

Re: McWire Successor March 08, 2010 06:51AM |

Registered: 14 years ago Posts: 7,505 |

|

Re: McWire Successor March 08, 2010 06:58AM |

Registered: 14 years ago Posts: 7,505 |

the bridge of the X-axis must more in the middle

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: McWire Successor March 08, 2010 07:05AM |

Registered: 14 years ago Posts: 3,742 |

Stoffel15 Wrote:

-------------------------------------------------------

> the bridge of the X-axis must more in the middle

No problem - under the sled, the height of the slides determines the amount of space available for the belt (wire, rod) or whatever he is going to use to drive it.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

-------------------------------------------------------

> the bridge of the X-axis must more in the middle

No problem - under the sled, the height of the slides determines the amount of space available for the belt (wire, rod) or whatever he is going to use to drive it.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: McWire Successor March 08, 2010 07:19AM |

Registered: 14 years ago Posts: 7,505 |

ok, let him change ist

i made the machine without any drawing... out of the brain into the wood

Mfg

Wolfgang

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

i made the machine without any drawing... out of the brain into the wood

Mfg

Wolfgang

| Aller Anfang war schwer - Wolfstrap | Reprap-fab.org |  |

Erfahrungen kann man leider schlecht weiter geben, die muss man selber machen.

|

Re: McWire Successor March 08, 2010 11:37AM |

Registered: 14 years ago Posts: 53 |

I was concerned about the Drawer slides not operating properly being mounted on the top of the frame. The slides are constructed to have the weight bear vertically, so the force is resting against the ball-bearings. If the slides are engineered in such a way that it doesn't matter, than fixing it is now issue. Otherwise, I thought they could be mounted as they would be in a drawer and we could use L brackets to mount to the stage.

Everything else everyone has pointed out is spot on. Thanks for the notes. I'm inclined to go for a linear screw drive rather than a belt for the z-access, in spite of my model showing otherwise. I figure for z, a screw isn't too slow. Any opinions about this?

Everything else everyone has pointed out is spot on. Thanks for the notes. I'm inclined to go for a linear screw drive rather than a belt for the z-access, in spite of my model showing otherwise. I figure for z, a screw isn't too slow. Any opinions about this?

|

Re: McWire Successor March 08, 2010 11:42AM |

Registered: 14 years ago Posts: 3,742 |

sircastor Wrote:

-------------------------------------------------------

> I figure for z, a screw isn't too slow. Any

> opinions about this?

Threaded bar drive for the Z-axis is fine.

For the Y-axis you need to at least lower the back board if you mount the slides as shown otherwise it won't go anywhere!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

-------------------------------------------------------

> I figure for z, a screw isn't too slow. Any

> opinions about this?

Threaded bar drive for the Z-axis is fine.

For the Y-axis you need to at least lower the back board if you mount the slides as shown otherwise it won't go anywhere!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: McWire Successor March 08, 2010 11:53AM |

Registered: 14 years ago Posts: 7,505 |

|

Re: McWire Successor March 08, 2010 01:50PM |

Registered: 15 years ago Posts: 264 |

Having nice small steps for the z-axis is very helpful as you can set the layer thickness precisely. So a threaded rod drive there is a good idea.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

|

Re: McWire Successor March 08, 2010 02:53PM |

Registered: 14 years ago Posts: 105 |

|

Re: McWire Successor March 08, 2010 03:18PM |

I am Building a MCwire. And i can say cost is not the issue with the MCwire. i am sitting hear looking at all the parts for under $100. 20 for the pipe, 10 for the boards, 40 for the channel and angle, that leaves me 30 for the bolts and screws. Mins the electronics which should cost around 200.

Performance, and more importinly documentation is the issue with mcwire.

The guides for the mc wire are good, but not grate. for the boards that need to be cut out. it just assume you buy them, or get them laser. would be nice to have the demotions for the boards. anytime it tells you to drill a hole it forgets to tell you how big of a hole. i know sometime it depends on what size of bolt, or screw your going to use. But it tells you which screw to use. So it should tell you what size of hole.

I am pointing this out because this is the frustration that i am getting rapstraping with the mcwire.

As far as the performance i don't know i am just putting it all together. Speed is going to be an issue, but will reliability ? as far as i know it's the extruder that will jam/clog/fail then the mcwire.

The pipe is not needed. this could be made out of MDF. Just a simple box frame.

What we have is good, just need more polish. We should update the guide. add in the missing information. Add in a belt drive, with the threaded rod.

Its the simple things that stop someone from finishing a project. Not wanting to drill the wrong hole. Cutting something to the wrong size. Destroying the investment. Not counting thing like real life, time, and money. If we want as many people to get in to this. Then we could make the hurdles a little smaller.

Performance, and more importinly documentation is the issue with mcwire.

The guides for the mc wire are good, but not grate. for the boards that need to be cut out. it just assume you buy them, or get them laser. would be nice to have the demotions for the boards. anytime it tells you to drill a hole it forgets to tell you how big of a hole. i know sometime it depends on what size of bolt, or screw your going to use. But it tells you which screw to use. So it should tell you what size of hole.

I am pointing this out because this is the frustration that i am getting rapstraping with the mcwire.

As far as the performance i don't know i am just putting it all together. Speed is going to be an issue, but will reliability ? as far as i know it's the extruder that will jam/clog/fail then the mcwire.

The pipe is not needed. this could be made out of MDF. Just a simple box frame.

What we have is good, just need more polish. We should update the guide. add in the missing information. Add in a belt drive, with the threaded rod.

Its the simple things that stop someone from finishing a project. Not wanting to drill the wrong hole. Cutting something to the wrong size. Destroying the investment. Not counting thing like real life, time, and money. If we want as many people to get in to this. Then we could make the hurdles a little smaller.

|

Re: McWire Successor March 08, 2010 04:01PM |

Registered: 14 years ago Posts: 53 |

okay, design revision number two. A lot of Wolfgang's design decisions make sense

The sketchup file for this can be found at:

[objects.reprap.org]

The sketchup file for this can be found at:

[objects.reprap.org]

|

Re: McWire Successor March 08, 2010 05:32PM |

Registered: 14 years ago Posts: 380 |

Sebastien,

In my inflated ego, I am thinking of calling my revision of the McWire with wire cable drive instead of threaded rod the "MikeWire". It should speed it up to what ever speed the extruder can handle, and should make it about as fast as a Mendel. I still have a Regional Robotics Competition to mentor this weekend, then I will work on building and documenting my version of the McWire. I am also going to track down all costs and sources to give a solid purchase price, in the US at least. To reduce cost for first time 3D printer fans, I am also looking at making a single controller board for the whole machine, with a graphic that can be printed on a laser printer, ironed onto double sided copper board, etched, stuffed with mostly through hole devices bought from Digikey or Mouser, and then connected to the stepper motors and extruder heater. If I am lucky, get total parts cost down to $250 to $300.

Mike

Team Open Air

Blog Team Open Air

rocket scientists think LIGHTYEARS outside the box!

In my inflated ego, I am thinking of calling my revision of the McWire with wire cable drive instead of threaded rod the "MikeWire". It should speed it up to what ever speed the extruder can handle, and should make it about as fast as a Mendel. I still have a Regional Robotics Competition to mentor this weekend, then I will work on building and documenting my version of the McWire. I am also going to track down all costs and sources to give a solid purchase price, in the US at least. To reduce cost for first time 3D printer fans, I am also looking at making a single controller board for the whole machine, with a graphic that can be printed on a laser printer, ironed onto double sided copper board, etched, stuffed with mostly through hole devices bought from Digikey or Mouser, and then connected to the stepper motors and extruder heater. If I am lucky, get total parts cost down to $250 to $300.

Mike

Team Open Air

Blog Team Open Air

rocket scientists think LIGHTYEARS outside the box!

|

Re: McWire Successor March 08, 2010 05:38PM |

Admin Registered: 17 years ago Posts: 1,791 |

Thanks sircastor!

I've updated WolfStrap to point to the file:

[objects.reprap.org]

I may rename this thread the "WolfStrap (bootstrap RepRap) Group Design Party " in a day or so.

" in a day or so.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

I've updated WolfStrap to point to the file:

[objects.reprap.org]

I may rename this thread the "WolfStrap (bootstrap RepRap) Group Design Party

" in a day or so.

" in a day or so.-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

Sorry, only registered users may post in this forum.