Newbie Rep Strap

Posted by wednesday

|

Newbie Rep Strap June 28, 2014 03:27PM |

Registered: 9 years ago Posts: 46 |

Hello all,

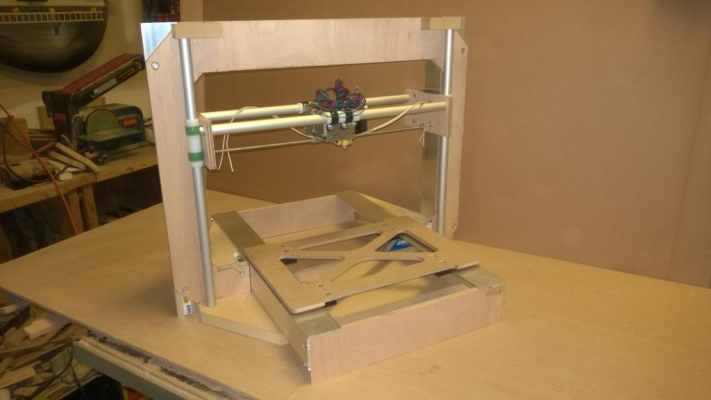

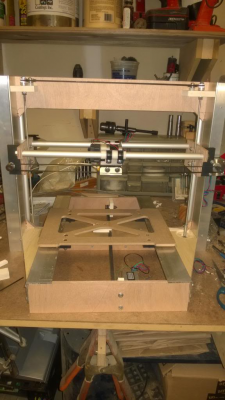

Wanted to share my adventure in building a repstrap printer (I guess it would be called a repstrap). It's an I3 design modified with a slightly larger heat bed and dual extruders.

The mechanical frame was made mostly from stuff I had in the shop plywood, MDF, and aluminum angle. For the slide bearings and shafting I poured through McMaster Carr

for low cost and creative alternatives in the way of UHMW and anodized alum. tubing.

I chose to use only one stepper for the Z axis which meant having to slave the dual threaded rods mechanically. Test motion on the axis has proven it to function

consistent and accurate so I am happy with the choice for now.

This machine is running an Azteeg X3 control board to allow for the dual extruder. I am very happy with the X3 and found it pretty straight forward to wire up.

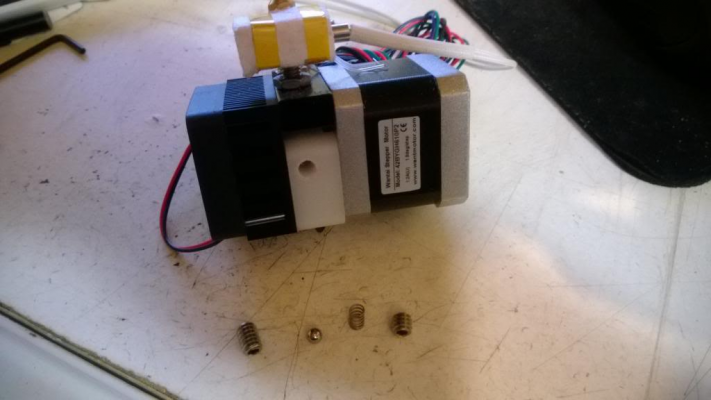

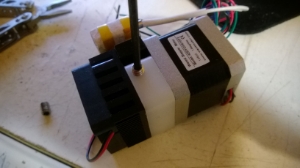

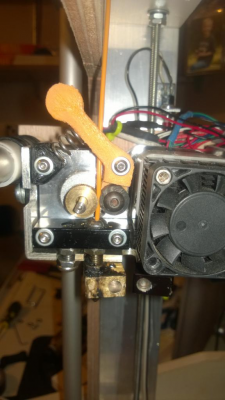

I went for dual MBE v9 extruders from (formerly) QU-BD originally to fit a printer design I wanted to develop. I have no comment as to how well or not they work as I have not made

it that far in my setting up and testing yet. I ordered directly from thier store online and recieved everything perfectly fine in good order. However from get go I felt there is an oversight on

the filament adjustment feature of the extruders design.

Arranging the extruders hot ends as close to each other as possible also routes the dual filament streams close together. This set up buries the filament adjustment screw on the side of

each extruder between them when mounted. Meaning they would have to come off the mount to make any adjustments to either. Here is my resulting attempt to make the filament adjustment

a hands free set up.

I swapped out the original set screw with a shorter one, adding a stainless ball bearing and spring to keep pressure on the ball. To set the initial tension I inserted a 1.5mm allen wrench

between the hobbed drive gear and the bearing ball, inserted the spring and installed the shorter set screw. With the allen wrench in the tension is set snug then an 1/8th turn. With the wrench

removed the filament then pushes in easily yet firmly by hand.

The machine has been wired and running for several weeks as I have been struggling my way through learning the programming and tuning. All is working to my liking except for the Z axis endstop and I haven't begun my configure H tuning for these extruders. Any assistance on either would be greatly appreciated.

I am trying to home the Z to the max (mechanical) endstop and have the minimum set by the software. The Z axis works as I want it to but the max endstop switch doesn't work. I have swapped out switches and played with the configure h settings until they are completely buggered and still no switch activation yet the axis moves fine. Can anyone guide me a bit on this? here is the current config h for the endstops and xyz movement using repetier firmware.

Last but not least is there anyone running the dual MBE v9's that is willing to share thier config h settings for these extruders?

Thanks all hope you like what I've got so far.

Mike

Wanted to share my adventure in building a repstrap printer (I guess it would be called a repstrap). It's an I3 design modified with a slightly larger heat bed and dual extruders.

The mechanical frame was made mostly from stuff I had in the shop plywood, MDF, and aluminum angle. For the slide bearings and shafting I poured through McMaster Carr

for low cost and creative alternatives in the way of UHMW and anodized alum. tubing.

I chose to use only one stepper for the Z axis which meant having to slave the dual threaded rods mechanically. Test motion on the axis has proven it to function

consistent and accurate so I am happy with the choice for now.

This machine is running an Azteeg X3 control board to allow for the dual extruder. I am very happy with the X3 and found it pretty straight forward to wire up.

I went for dual MBE v9 extruders from (formerly) QU-BD originally to fit a printer design I wanted to develop. I have no comment as to how well or not they work as I have not made

it that far in my setting up and testing yet. I ordered directly from thier store online and recieved everything perfectly fine in good order. However from get go I felt there is an oversight on

the filament adjustment feature of the extruders design.

Arranging the extruders hot ends as close to each other as possible also routes the dual filament streams close together. This set up buries the filament adjustment screw on the side of

each extruder between them when mounted. Meaning they would have to come off the mount to make any adjustments to either. Here is my resulting attempt to make the filament adjustment

a hands free set up.

I swapped out the original set screw with a shorter one, adding a stainless ball bearing and spring to keep pressure on the ball. To set the initial tension I inserted a 1.5mm allen wrench

between the hobbed drive gear and the bearing ball, inserted the spring and installed the shorter set screw. With the allen wrench in the tension is set snug then an 1/8th turn. With the wrench

removed the filament then pushes in easily yet firmly by hand.

The machine has been wired and running for several weeks as I have been struggling my way through learning the programming and tuning. All is working to my liking except for the Z axis endstop and I haven't begun my configure H tuning for these extruders. Any assistance on either would be greatly appreciated.

I am trying to home the Z to the max (mechanical) endstop and have the minimum set by the software. The Z axis works as I want it to but the max endstop switch doesn't work. I have swapped out switches and played with the configure h settings until they are completely buggered and still no switch activation yet the axis moves fine. Can anyone guide me a bit on this? here is the current config h for the endstops and xyz movement using repetier firmware.

Quote

// ################ Endstop configuration #####################

#define ENDSTOP_PULLUP_X_MIN true

#define ENDSTOP_X_MIN_INVERTING true

#define MIN_HARDWARE_ENDSTOP_X true

#define ENDSTOP_PULLUP_Y_MIN true

#define ENDSTOP_Y_MIN_INVERTING true

#define MIN_HARDWARE_ENDSTOP_Y true

#define ENDSTOP_PULLUP_Z_MIN true

#define ENDSTOP_Z_MIN_INVERTING true

#define MIN_HARDWARE_ENDSTOP_Z true

#define ENDSTOP_PULLUP_X_MAX true

#define ENDSTOP_X_MAX_INVERTING true

#define MAX_HARDWARE_ENDSTOP_X true

#define ENDSTOP_PULLUP_Y_MAX true

#define ENDSTOP_Y_MAX_INVERTING true

#define MAX_HARDWARE_ENDSTOP_Y true

#define ENDSTOP_PULLUP_Z_MAX true

#define ENDSTOP_Z_MAX_INVERTING true

#define MAX_HARDWARE_ENDSTOP_Z true

#define max_software_endstop_r true

#define min_software_endstop_x false

#define min_software_endstop_y false

#define min_software_endstop_z true

#define max_software_endstop_x false

#define max_software_endstop_y false

#define max_software_endstop_z false

#define ENDSTOP_X_BACK_MOVE 0

#define ENDSTOP_Y_BACK_MOVE 0

#define ENDSTOP_Z_BACK_MOVE 0

#define ENDSTOP_X_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_Y_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_Z_RETEST_REDUCTION_FACTOR 3

#define ENDSTOP_X_BACK_ON_HOME 1

#define ENDSTOP_Y_BACK_ON_HOME 1

#define ENDSTOP_Z_BACK_ON_HOME 1

#define ALWAYS_CHECK_ENDSTOPS 1

// ################# XYZ movements ###################

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define DISABLE_X 0

#define DISABLE_Y 0

#define DISABLE_Z 0

#define DISABLE_E 0

#define INVERT_X_DIR 0

#define INVERT_Y_DIR 1

#define INVERT_Z_DIR 0

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR 1

#define X_MAX_LENGTH 306

#define Y_MAX_LENGTH 226

#define Z_MAX_LENGTH 180

#define X_MIN_POS 0

#define Y_MIN_POS 0

#define Z_MIN_POS -180

Last but not least is there anyone running the dual MBE v9's that is willing to share thier config h settings for these extruders?

Thanks all hope you like what I've got so far.

Mike

|

Re: Newbie Rep Strap June 28, 2014 04:24PM |

Registered: 11 years ago Posts: 296 |

Qoute: "I am trying to home the Z to the max (mechanical) endstop and have the minimum set by the software"

If you use Zmax for homing you do not need Zmin, as you suggest your self this is calculated in sw as Z=0 when max printsize has been decided..

Maybe this is confusing your controller.

If you use Zmax for homing you do not need Zmin, as you suggest your self this is calculated in sw as Z=0 when max printsize has been decided..

Maybe this is confusing your controller.

|

Re: Newbie Rep Strap June 28, 2014 08:03PM |

Registered: 10 years ago Posts: 474 |

|

Re: Newbie Rep Strap June 29, 2014 08:09PM |

Registered: 9 years ago Posts: 46 |

@ curious; yeah turns out it wasn't the controller that was being confused. Think I identified the issue as purely operator error. I'll test out my epiphany of oversight a bit later.

@ cnc; thanks man, it just has to work decent enough to print its own replacement frame parts at least. Its been a really fun build and its hard to be patient in getting it finished and running prints.

Still hoping someone might chime in with a crib sheet (working config h) for the extruders. It would be cool to have a rough but closer place to start out at when I get to tuning mine.

Mike.

@ cnc; thanks man, it just has to work decent enough to print its own replacement frame parts at least. Its been a really fun build and its hard to be patient in getting it finished and running prints.

Still hoping someone might chime in with a crib sheet (working config h) for the extruders. It would be cool to have a rough but closer place to start out at when I get to tuning mine.

Mike.

|

Re: Newbie Rep Strap November 14, 2014 10:00PM |

Registered: 9 years ago Posts: 46 |

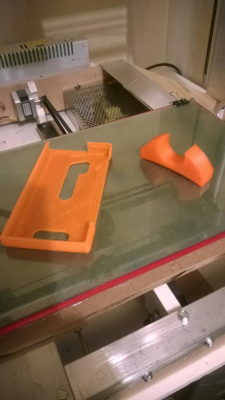

What a Fun-strating project this has been!!. I have encountered many many pitfalls and several real triumphs throughout the past nine or so months and am grateful to have this community to learn from. To be honest the machine I have now is not what I wanted to build originally but its existence has been inspiring.

In the coming weeks I hope to share the real test of my "strap" by having it print its own upgraded mech frame (and by extension offspring). In the meantime I wanted to share a few pics and vids of some successful testing so far.

MC.

[youtu.be]

[youtu.be]

[youtu.be]

In the coming weeks I hope to share the real test of my "strap" by having it print its own upgraded mech frame (and by extension offspring). In the meantime I wanted to share a few pics and vids of some successful testing so far.

MC.

[youtu.be]

[youtu.be]

[youtu.be]

Sorry, only registered users may post in this forum.