Belts for Z Axis

Posted by RC-CnC

|

Belts for Z Axis July 29, 2014 12:06PM |

Registered: 10 years ago Posts: 87 |

|

Re: Belts for Z Axis July 29, 2014 12:48PM |

Registered: 10 years ago Posts: 439 |

|

Re: Belts for Z Axis July 29, 2014 01:32PM |

Registered: 10 years ago Posts: 87 |

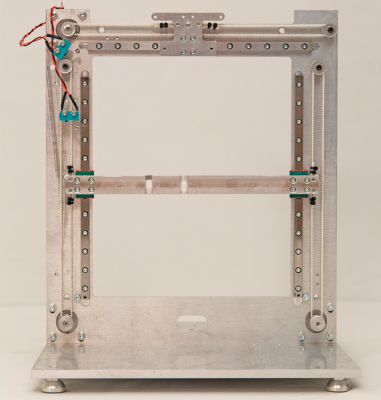

I've been debating on what to use on my build. Z axis with acme screws is going to be easier to keep level. Z axis with belts is going to require to level the Z axis every time you power up the machine also when you remove power to the steppers the z axis can fall from the weight. I'd rather not mix belt and acme rod, just my preference. I suppose I could design to be entirely acme screw driven. Any thoughts??

|

Re: Belts for Z Axis July 29, 2014 01:59PM |

Registered: 10 years ago Posts: 439 |

|

Re: Belts for Z Axis July 29, 2014 02:34PM |

Registered: 10 years ago Posts: 87 |

|

Re: Belts for Z Axis July 29, 2014 03:24PM |

Registered: 10 years ago Posts: 439 |

|

Re: Belts for Z Axis July 29, 2014 03:51PM |

Registered: 10 years ago Posts: 87 |

Quote

Ralph.Hilton

I think any engineer who knows their stuff does that too :-) I would ask as the first question - what do you want to make with the printer?

You don't need great expense to get zero Z wobble so there is a sweet spot between healthy over-engineering and overkill.

Absolutely...

I also look at the ease of calibration on all axes. Upfront cost on mechanical components are not at the top on my list. I'd rather build something and have it be right the first time.

I also look at the ease of calibration on all axes. Upfront cost on mechanical components are not at the top on my list. I'd rather build something and have it be right the first time.

|

Re: Belts for Z Axis July 30, 2014 11:20AM |

Registered: 10 years ago Posts: 869 |

While it's fine to have a preference, why do you have that preference? Just aesthetics of having them all match? Most would give up some aesthetics for better quality and faster speeds.Quote

RC-CnC

Z axis with belts is going to require to level the Z axis every time you power up the machine also when you remove power to the steppers the z axis can fall from the weight. I'd rather not mix belt and acme rod, just my preference.

It all comes down the mechanical advantage of the system. For how they typically are used for 3D printers, belts move faster where acme rods can hold position better. Presuming a XY bed design, the X and Y axes move far more than the Z axis, so having faster movements that don't need a lot of holding power is desired, where the Z-axis needs to be able to hold position very well but doesn't need to move fast, so acme/threaded rod gets used there.

|

Re: Belts for Z Axis July 30, 2014 11:26AM |

Registered: 10 years ago Posts: 87 |

Quote

cdru

While it's fine to have a preference, why do you have that preference? Just aesthetics of having them all match? Most would give up some aesthetics for better quality and faster speeds.Quote

RC-CnC

Z axis with belts is going to require to level the Z axis every time you power up the machine also when you remove power to the steppers the z axis can fall from the weight. I'd rather not mix belt and acme rod, just my preference.

It all comes down the mechanical advantage of the system. For how they typically are used for 3D printers, belts move faster where acme rods can hold position better. Presuming a XY bed design, the X and Y axes move far more than the Z axis, so having faster movements that don't need a lot of holding power is desired, where the Z-axis needs to be able to hold position very well but doesn't need to move fast, so acme/threaded rod gets used there.

Good point

That is very true

That is very true

|

Re: Belts for Z Axis July 31, 2014 12:34PM |

Registered: 13 years ago Posts: 2,947 |

Tantillus, Ingentis, Up by Afina, Printxl, all deltas and a few others use Belts or cables on Z and NEVER have z wobble and do not require any special tuning to not have Z wobble. Where as lead screw machines are hit and miss and most people do have to fight it and find a way to eliminate it. This shows up far more when printing layer heights less than 0.3 and more as you go even lower.

You do not need to relevel the bed as long as both belts are connected with a shaft. If you use two separate motors then you will have the same issues as with a Prusa where the motors go out of sync. You would also have the issue of the driver not being made to run two motors which causes the microstepping to not work as designed.

The bed dropping on a machine where the bed only moves in Z is a feature not an issue. You want your part to move away from the hotend when done and that is what happens. I let my bed drop every time and never had it break anything. You could use cushions or springs to catch it if you are worried.

Edited 1 time(s). Last edit at 07/31/2014 08:48PM by Sublime.

You do not need to relevel the bed as long as both belts are connected with a shaft. If you use two separate motors then you will have the same issues as with a Prusa where the motors go out of sync. You would also have the issue of the driver not being made to run two motors which causes the microstepping to not work as designed.

The bed dropping on a machine where the bed only moves in Z is a feature not an issue. You want your part to move away from the hotend when done and that is what happens. I let my bed drop every time and never had it break anything. You could use cushions or springs to catch it if you are worried.

Edited 1 time(s). Last edit at 07/31/2014 08:48PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Belts for Z Axis August 03, 2014 06:32AM |

Registered: 12 years ago Posts: 227 |

|

Re: Belts for Z Axis August 03, 2014 07:17AM |

Registered: 10 years ago Posts: 1,381 |

Quote

Sublime

You would also have the issue of the driver not being made to run two motors which causes the microstepping to not work as designed.

Can you provide more details about the disadvantages of this, and how it's configured. I've read this a few times but I don't have clear notes about it.

Tks.

|

Re: Belts for Z Axis August 03, 2014 12:17PM |

Registered: 13 years ago Posts: 2,947 |

Quote

A2

Quote

Sublime

You would also have the issue of the driver not being made to run two motors which causes the microstepping to not work as designed.

Can you provide more details about the disadvantages of this, and how it's configured. I've read this a few times but I don't have clear notes about it.

Tks.

My understanding of it is not all that great either. I know it has to do with EMF between the motors. Also the fact that you are now running the motors in either parallel which decreases the resistance and increases the current draw on the chip which is often being run at its maximum so the result is half the current to each motor that you would have to one motor normally. Then if you run them in series you double the resistance so the current can only reach half the amount given the same voltage and step pulse time.

I am sure someone with a better understanding will correct what I have said.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.