Belts on the Z-Axis

Posted by MrDoctorDIV

|

Belts on the Z-Axis August 05, 2014 08:04PM |

Registered: 10 years ago Posts: 790 |

In getting the gantry parts printed and fitted [temporarily, the final product will not be printed] I have moved on to the bed part of designing. I have a larger build area, about 650mm by 310mm, so keep in mind that weight is in play with the bed and heating/mounting parts. You can see the frame of my printer here.

Even beyond my specific build, what are the differences between rods and belts in driving the Z-Axis? I know the basics, that belts tend to drop when power is lost, rods are hit and miss with Z-wobble. I've got a mind and I've read plenty of forum posts, articles, and looked at plenty of printer designs. I don't need any more basics or speculations or ideas or thoughts. I need actual, factual, scientific, hands-on facts, evidences, and findings. I need in-depth things, again, I have a mind and I've read from plenty of others. What I haven't read are scientific or true comparisons with those who have effectively used both. I need information like A2's millions links, the design experience like nicholas.seward, etc.

More simply, don't give me common sense or speculation, give me actual, hard facts about belts vs rods. Hopefully this will help many in search, beyond myself. I just find this lack of straightforward information disturbing. I've seen both and I've seen people swear by both.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Even beyond my specific build, what are the differences between rods and belts in driving the Z-Axis? I know the basics, that belts tend to drop when power is lost, rods are hit and miss with Z-wobble. I've got a mind and I've read plenty of forum posts, articles, and looked at plenty of printer designs. I don't need any more basics or speculations or ideas or thoughts. I need actual, factual, scientific, hands-on facts, evidences, and findings. I need in-depth things, again, I have a mind and I've read from plenty of others. What I haven't read are scientific or true comparisons with those who have effectively used both. I need information like A2's millions links, the design experience like nicholas.seward, etc.

More simply, don't give me common sense or speculation, give me actual, hard facts about belts vs rods. Hopefully this will help many in search, beyond myself. I just find this lack of straightforward information disturbing. I've seen both and I've seen people swear by both.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Belts on the Z-Axis August 05, 2014 10:49PM |

Registered: 13 years ago Posts: 2,947 |

From my experience designing Tantillus with a threaded rod lead screw to start and then moving over to a cable I can give you a little real world feed back.

Threaded Rod cons on Tantillus:

1) The imperial threaded rod had to use layer heights that had minimal rounding errors and that limited the possible layer heights by a small amount (still had lots of choice).

2) To prevent Z banding you had to be sure the lead screw nut could move in X and Y to get the best results. If it did not move in X and Y there was very little you could do to prevent the banding.

3) Was not very fast at 15mm/s

Threaded rod pros on Tantillus:

1) Lots of torque allowing you to have a heavy bed or stiff bearings/bushings.

2) You could turn the single lead screw by hand during the first layer to get it perfect or when using a different thickness piece of glass.

Cable Z cons on Tantillus:

1) Very difficult to create a drum that ends up with an even steps per mm.

2) With the rounding errors created by the drum size you end up with a limited number of possible layer heights available to use.

3) Having the drum directly attached to the motor without any gearing the possible layer heights without large rounding errors is limited even further (My current profiles are 0.099, 0.149, 0.199, 0.258 and only the 0.149 I would consider to be without rounding errors (16nm per layer))(Gearing would help at the cost of possible backlash).

Cable Z pros on Tantillus:

1) If you use a layer height with a small rounding error it prints extremely consistently.

2) The bed drops when the print is complete so there is no worry of the hotend touching the print and melting a spot on it.

3) It's very quick (My Marlin settings are max_feedrate=300, max_accel=8000, default_accel=3000, jerk=10)

This thread is from a Tantillus user WillWorkForPlastic where he tried a metric threaded rod, then a ball screw and then a cable Z axis. He includes his testing and the results.

I also have a machine that is 250x500x750 that uses a print worm gear and drums for the Z and I do get banding. I believe it is because I am using two motors to turn the worm gear and they seem to fight each other regardless of what I do. Even tightening the grub screws after powering them up to ensure they are on the same step does not help where as unplugging one does. I plan on redesigning it to use a single motor on each axis. Its Marlin settings are max_feedrate=100, max_accel=1500, default_accel=2000, jerk=2

Here is the rendering of the big machines Z axis. I will try and get a picture of that actual machine after we are done moving.

Edited 1 time(s). Last edit at 08/05/2014 10:54PM by Sublime.

Threaded Rod cons on Tantillus:

1) The imperial threaded rod had to use layer heights that had minimal rounding errors and that limited the possible layer heights by a small amount (still had lots of choice).

2) To prevent Z banding you had to be sure the lead screw nut could move in X and Y to get the best results. If it did not move in X and Y there was very little you could do to prevent the banding.

3) Was not very fast at 15mm/s

Threaded rod pros on Tantillus:

1) Lots of torque allowing you to have a heavy bed or stiff bearings/bushings.

2) You could turn the single lead screw by hand during the first layer to get it perfect or when using a different thickness piece of glass.

Cable Z cons on Tantillus:

1) Very difficult to create a drum that ends up with an even steps per mm.

2) With the rounding errors created by the drum size you end up with a limited number of possible layer heights available to use.

3) Having the drum directly attached to the motor without any gearing the possible layer heights without large rounding errors is limited even further (My current profiles are 0.099, 0.149, 0.199, 0.258 and only the 0.149 I would consider to be without rounding errors (16nm per layer))(Gearing would help at the cost of possible backlash).

Cable Z pros on Tantillus:

1) If you use a layer height with a small rounding error it prints extremely consistently.

2) The bed drops when the print is complete so there is no worry of the hotend touching the print and melting a spot on it.

3) It's very quick (My Marlin settings are max_feedrate=300, max_accel=8000, default_accel=3000, jerk=10)

This thread is from a Tantillus user WillWorkForPlastic where he tried a metric threaded rod, then a ball screw and then a cable Z axis. He includes his testing and the results.

I also have a machine that is 250x500x750 that uses a print worm gear and drums for the Z and I do get banding. I believe it is because I am using two motors to turn the worm gear and they seem to fight each other regardless of what I do. Even tightening the grub screws after powering them up to ensure they are on the same step does not help where as unplugging one does. I plan on redesigning it to use a single motor on each axis. Its Marlin settings are max_feedrate=100, max_accel=1500, default_accel=2000, jerk=2

Here is the rendering of the big machines Z axis. I will try and get a picture of that actual machine after we are done moving.

Edited 1 time(s). Last edit at 08/05/2014 10:54PM by Sublime.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Belts on the Z-Axis August 06, 2014 06:15AM |

Registered: 13 years ago Posts: 7,616 |

Quote

MrDoctorDIV

rods are hit and miss with Z-wobble.

Only when not done properly. As Sublime wrote, these rods need some movement freedom in X and Y, like a flexible coupling to the motor shaft. Most simple way to get this: coupling with a fabric-reinforces piece of rubber hose. E.g. gasoline hose from cars.

I operate a WolfStrap with M8 rods on all three axes and while the sliders aren't exactly stiff, there is no noticeable wobbling.

Quote

Sublime

1) The imperial threaded rod had to use layer heights that had minimal rounding errors and that limited the possible layer heights by a small amount (still had lots of choice).

If you'd print at imperial layer heights, there were no such problem :-)

And the rounding errors are reeeeally small. Like less than a micrometer. Mathematically, this can't really be a problem (less than 1% error even on 0.1 mm layers), so I'm pretty sure there's something else responsible.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Belts on the Z-Axis August 06, 2014 12:58PM |

Registered: 10 years ago Posts: 790 |

Quote

Sublime

Cable Z cons on Tantillus:

1) Very difficult to create a drum that ends up with an even steps per mm.

2) With the rounding errors created by the drum size you end up with a limited number of possible layer heights available to use.

3) Having the drum directly attached to the motor without any gearing the possible layer heights without large rounding errors is limited even further (My current profiles are 0.099, 0.149, 0.199, 0.258 and only the 0.149 I would consider to be without rounding errors (16nm per layer))(Gearing would help at the cost of possible backlash).

So by using GT2 belts and a 4-to-1 belt path:

I could remove those cons?

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Belts on the Z-Axis August 06, 2014 07:53PM |

Registered: 13 years ago Posts: 2,947 |

Quote

MrDoctorDIV

Quote

Sublime

Cable Z cons on Tantillus:

1) Very difficult to create a drum that ends up with an even steps per mm.

2) With the rounding errors created by the drum size you end up with a limited number of possible layer heights available to use.

3) Having the drum directly attached to the motor without any gearing the possible layer heights without large rounding errors is limited even further (My current profiles are 0.099, 0.149, 0.199, 0.258 and only the 0.149 I would consider to be without rounding errors (16nm per layer))(Gearing would help at the cost of possible backlash).

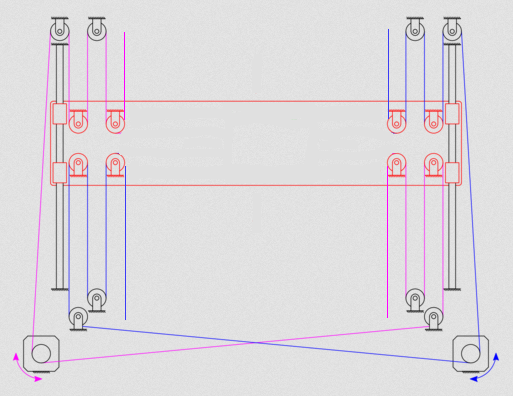

So by using GT2 belts and a 4-to-1 belt path:

[attachment 37888 ModifiedNSCoreXZ.png]

I could remove those cons?

As long as the final steps per mm work out then yes. Also because of the 4:1 gearing it would still give you a lot of choice even if you have some rounding errors.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.