Couple of issues with dual extruders - Ooze, Halt, Cracks

Posted by duckfriedrice

|

Couple of issues with dual extruders - Ooze, Halt, Cracks September 16, 2014 11:23PM |

Registered: 10 years ago Posts: 51 |

Hi reprapers,

Been playing with my prusa mendel i3 - single extruder for a year now,

Happy to say its print quality is excellent with relatively small and bulky objects

But no matter what, printing with single extruder is still weak at tackling overhang objects.

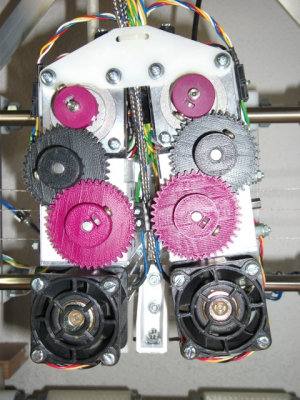

Few months ago, I have upgraded my i3 to dual extruder.

Hoping to print one head with ABS and the other with PLA as support material.

I have gathered some of the issues over the last few months,

wish to have some advice from reprapers here

Issues:-

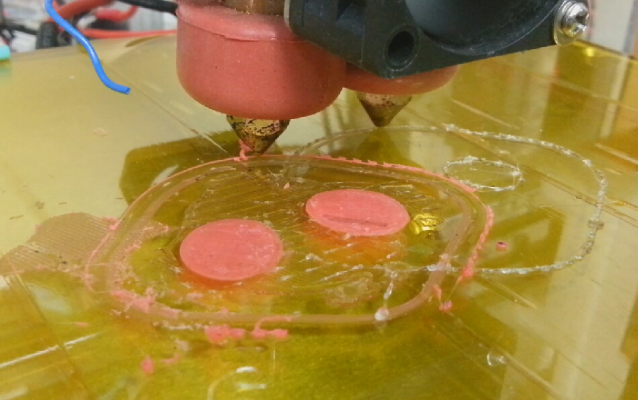

1. Ooze - while switching extruders, affecting the outer finishing of the model.

Found something very interesting from youtube, created by Nerdtron44

Anyone had any clues in how to control the servo or dc motor or stepper motor to switch heads.

I'm good on the mechanial side but not too familar with electronics and programming.

I'm only stuck on the electronics parts.

2. Halt - the print halts very often in the middle of the print.

The print does't stop, but halt in all direction. Like heavy lagging, XYZ are moving at very slow jerk moves.

Still cannot solve this problem.

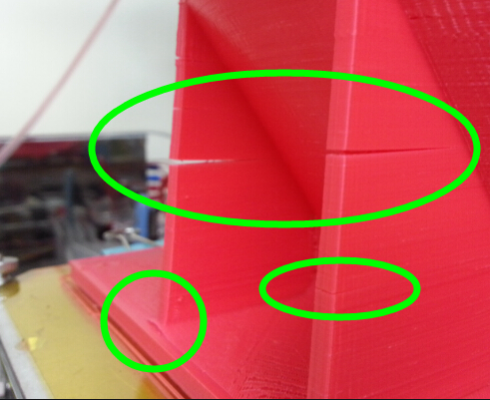

3. Cracks in tall large objects - this issue happens in both single and dual extruder printer.

Printing tall and large objects, corners and thicker volume areas tend to warp badly

In most case even forces the object to crack, especially with ABS (PLA also warp, but doesn't crack as often)

Do I need to build a heated chamber to avoid warping ?

Been playing with my prusa mendel i3 - single extruder for a year now,

Happy to say its print quality is excellent with relatively small and bulky objects

But no matter what, printing with single extruder is still weak at tackling overhang objects.

Few months ago, I have upgraded my i3 to dual extruder.

Hoping to print one head with ABS and the other with PLA as support material.

I have gathered some of the issues over the last few months,

wish to have some advice from reprapers here

Issues:-

1. Ooze - while switching extruders, affecting the outer finishing of the model.

Found something very interesting from youtube, created by Nerdtron44

Anyone had any clues in how to control the servo or dc motor or stepper motor to switch heads.

I'm good on the mechanial side but not too familar with electronics and programming.

I'm only stuck on the electronics parts.

2. Halt - the print halts very often in the middle of the print.

The print does't stop, but halt in all direction. Like heavy lagging, XYZ are moving at very slow jerk moves.

Still cannot solve this problem.

3. Cracks in tall large objects - this issue happens in both single and dual extruder printer.

Printing tall and large objects, corners and thicker volume areas tend to warp badly

In most case even forces the object to crack, especially with ABS (PLA also warp, but doesn't crack as often)

Do I need to build a heated chamber to avoid warping ?

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 17, 2014 04:59PM |

Registered: 10 years ago Posts: 581 |

1. Ooze isn't necessarily going to be resolved by this design. I've had to play with the Slic3r settings quite a bit to minimise ooze. I'm getting reasonable results with Slic3r's skirt for wiping the ooze off, but had to up it to 5 loops to prevent it coming unstuck. setting the temperature variation to -40C has helped significantly. The standard setting of -5C just doesn't cut it.

Re the dual extruder, that looks like a servo with a rack and pinion setup to switch extruders, which is pretty cool. Here's a good post on adding servo support to Marlin (turns out it's built-in and you just need to do some configuring).

2. Halt - probably your stepper drivers or motors overheating. Check the heat as you print - are they getting really hot? If so you might need to wind down vref.

3. Fairly common with ABS. An enclosure will definitely help.

Edit: here's the reprap forum thread on the dual extruder in the video (thought I'd seen it somewhere).

Edited 1 time(s). Last edit at 09/17/2014 05:01PM by 3dkarma.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

Re the dual extruder, that looks like a servo with a rack and pinion setup to switch extruders, which is pretty cool. Here's a good post on adding servo support to Marlin (turns out it's built-in and you just need to do some configuring).

2. Halt - probably your stepper drivers or motors overheating. Check the heat as you print - are they getting really hot? If so you might need to wind down vref.

3. Fairly common with ABS. An enclosure will definitely help.

Edit: here's the reprap forum thread on the dual extruder in the video (thought I'd seen it somewhere).

Edited 1 time(s). Last edit at 09/17/2014 05:01PM by 3dkarma.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 19, 2014 12:11AM |

Registered: 10 years ago Posts: 51 |

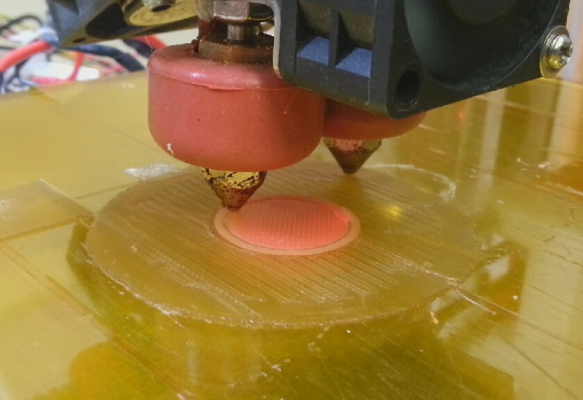

I've tried slic3r and cura to slice my models, but when the print gets to around third layer,

the printer will halt.

The printer continues to halt even if I kill print,

I had to disconnect and reconnect repetier or press the reset button on the ramps board,

in order to get the printer move normally again.

Otherwise the printer will continue to halt.

I'm using the most updated marlin

The following videos show the halt in action:

Repetier / Slic3r / Halt at third layer

Bear print A

Repetier / Cura / Halt at third layer

Mushroom print A

Edited 2 time(s). Last edit at 09/19/2014 12:17AM by duckfriedrice.

the printer will halt.

The printer continues to halt even if I kill print,

I had to disconnect and reconnect repetier or press the reset button on the ramps board,

in order to get the printer move normally again.

Otherwise the printer will continue to halt.

I'm using the most updated marlin

The following videos show the halt in action:

Repetier / Slic3r / Halt at third layer

Bear print A

Repetier / Cura / Halt at third layer

Mushroom print A

Edited 2 time(s). Last edit at 09/19/2014 12:17AM by duckfriedrice.

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 19, 2014 03:08AM |

Registered: 10 years ago Posts: 581 |

Have you checked the temperature of your stepper drivers and stepper motors to see if they're overheating?

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 19, 2014 06:24AM |

Registered: 10 years ago Posts: 240 |

Ooze

Retract speed is a big factor in ooze, as is nozzle size. I've heard .35mm is harder to stop oozing than larger nozzles. My advice, faster, longer retract, and lower your temp a bit. The lower temp will raise the viscosity a bit.

I agree with the others on 2 and 3... Pretty common with ABS and sounds like the steppers or stepper drivers are overheating. Printed gears add quite a bit of drag.

Retract speed is a big factor in ooze, as is nozzle size. I've heard .35mm is harder to stop oozing than larger nozzles. My advice, faster, longer retract, and lower your temp a bit. The lower temp will raise the viscosity a bit.

I agree with the others on 2 and 3... Pretty common with ABS and sounds like the steppers or stepper drivers are overheating. Printed gears add quite a bit of drag.

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 19, 2014 08:31AM |

Registered: 10 years ago Posts: 51 |

I've checked the temperature of the stepper drivers, they are at good temp while printing.

I have a strong 80mm fan blowing right over the ramps 1.4

Temp on the ramps should not be a problem

i'm using a 0.4mm nozzle, retraction speed at 35mm/s, retraction length at 7mm

Both hotends are bowden system

I have a strong 80mm fan blowing right over the ramps 1.4

Temp on the ramps should not be a problem

i'm using a 0.4mm nozzle, retraction speed at 35mm/s, retraction length at 7mm

Both hotends are bowden system

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 19, 2014 05:13PM |

Registered: 10 years ago Posts: 240 |

35mm/s retract speed is really low from what I've seen, try doubling it (you may get skipped steps, if so, slow it down until that stops).

Your steppers motors themselves can get too hot and stop, too.

Are you printing with a computer, or from an LCD. If it's from a computer, that can be a problem. Make sure you turn off as much as you can, anti-virus included. If you are using Windows, open Task Manager, find your host software and give it a higher priority (right click, change priority).

Your steppers motors themselves can get too hot and stop, too.

Are you printing with a computer, or from an LCD. If it's from a computer, that can be a problem. Make sure you turn off as much as you can, anti-virus included. If you are using Windows, open Task Manager, find your host software and give it a higher priority (right click, change priority).

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 19, 2014 09:08PM |

Registered: 10 years ago Posts: 51 |

Cool thx, I'll try to speed up the retraction speed later

I've installed heatsink and 40mm fan at the back of X and Y stepper motors

Room temperature at around 20C

I've tried to print with both computer and LCD2004, but no matter how simple the model is,

the print would begin to halt at around layer 3

Last night I've tried printing the object with no support

The printer can print the whole object without problem.

P.S. My extruder 1 is ABS as print material, and my extruder 2 is PLA as support material.

I'm still stuck at layer 3 when I'm printing with dual material.

Is my electronics faulty ? Or my slicer is not set well ?

I've installed heatsink and 40mm fan at the back of X and Y stepper motors

Room temperature at around 20C

I've tried to print with both computer and LCD2004, but no matter how simple the model is,

the print would begin to halt at around layer 3

Last night I've tried printing the object with no support

The printer can print the whole object without problem.

P.S. My extruder 1 is ABS as print material, and my extruder 2 is PLA as support material.

I'm still stuck at layer 3 when I'm printing with dual material.

Is my electronics faulty ? Or my slicer is not set well ?

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 20, 2014 02:50AM |

Registered: 10 years ago Posts: 581 |

There's a clue - if you're not printing support, you're only heating one extruder and the power demands are significantly lower. Perhaps your power supply is not rated high enough to keep dual extruders and a heated bed running all at the same time.

What kind of power supply do you have and what is it rated for?

Try running the print with support but without heating the bed.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

What kind of power supply do you have and what is it rated for?

Try running the print with support but without heating the bed.

[3DKarma.com] - suppliers of quality, affordable 3D printer kits and filament for the UK market.

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 21, 2014 10:42PM |

Registered: 10 years ago Posts: 51 |

|

Re: Couple of issues with dual extruders - Ooze, Halt, Cracks September 23, 2014 10:06AM |

Registered: 10 years ago Posts: 51 |

Nope, tried to replace the 50a psu with another one

but still halt in the middle of the print,

happened at around layer 6

I then uploaded the previous marlin that was set to single extruder

and guess what, wohoo

it worked with single extruder firmware

I'm struggling with this dual extruder T_T

but still halt in the middle of the print,

happened at around layer 6

I then uploaded the previous marlin that was set to single extruder

and guess what, wohoo

it worked with single extruder firmware

I'm struggling with this dual extruder T_T

Sorry, only registered users may post in this forum.