PLA vs ABS tough or not ?!

Posted by Rigor_M

|

PLA vs ABS tough or not ?! October 17, 2014 10:32AM |

Registered: 10 years ago Posts: 98 |

Ok, So I guess this topic was discussed multiple times on this forum but still, I can't wrap my head around it

Here is the scenario : If I print a thin wall (lets say 2mm think) horizontal layers going up. One in PLA and the other in ABS.

the ABS is so easy to break between layers when the PLA is much harder (will eventually break).

Everywhere i read that if you need something solid, print it in ABS.. but, personal experience, says to do it in PLA.

Am I missing something ? printing ABS at a to high temprature, to fast ?

Is there a rule a thumb ? or am i right is saying that ABS is not that tough ?!

ask away if i forgot to mention something ;-)

Thanks for any feedback..

J-F

Here is the scenario : If I print a thin wall (lets say 2mm think) horizontal layers going up. One in PLA and the other in ABS.

the ABS is so easy to break between layers when the PLA is much harder (will eventually break).

Everywhere i read that if you need something solid, print it in ABS.. but, personal experience, says to do it in PLA.

Am I missing something ? printing ABS at a to high temprature, to fast ?

Is there a rule a thumb ? or am i right is saying that ABS is not that tough ?!

ask away if i forgot to mention something ;-)

Thanks for any feedback..

J-F

|

Re: PLA vs ABS tough or not ?! October 17, 2014 11:48AM |

Registered: 10 years ago Posts: 869 |

Different materials have different physical characteristics. It's difficult to say without physical examination to determine why you had structural failure. It's possible your temperature extruder wasn't hot enough, your extrusion rate not suitable for your actual layer height, moving too fast, too rapid of cooling etc. IOW, poor bonding between layers.

Generally speaking, ABS is suppose to be tougher, more impact resistant (less brittle) with easier flexing. However if there's poor adhesion between layers then that becomes the weak link in the print.

Generally speaking, ABS is suppose to be tougher, more impact resistant (less brittle) with easier flexing. However if there's poor adhesion between layers then that becomes the weak link in the print.

|

Re: PLA vs ABS tough or not ?! October 17, 2014 12:10PM |

Registered: 10 years ago Posts: 98 |

|

Re: PLA vs ABS tough or not ?! October 17, 2014 12:19PM |

Registered: 10 years ago Posts: 1,401 |

Which is your bed temperature and it's your printer open or enclosed? Inter layer adhesion has more to do with those two factors than hotend temperature (within ABS acceptable temperatures).

PLA will be more solid but brittle. ABS will flex before it brakes.

Edited 2 time(s). Last edit at 10/17/2014 12:21PM by ggherbaz.

PLA will be more solid but brittle. ABS will flex before it brakes.

Edited 2 time(s). Last edit at 10/17/2014 12:21PM by ggherbaz.

|

Re: PLA vs ABS tough or not ?! October 17, 2014 12:42PM |

Registered: 10 years ago Posts: 98 |

|

Re: PLA vs ABS tough or not ?! October 17, 2014 04:50PM |

Registered: 10 years ago Posts: 439 |

I would use white dibond for the enclosure except the front. That way light is reflected inside for better viewing of prints.

Edited 1 time(s). Last edit at 10/17/2014 04:52PM by Ralph.Hilton.

Edited 1 time(s). Last edit at 10/17/2014 04:52PM by Ralph.Hilton.

|

Re: PLA vs ABS tough or not ?! October 17, 2014 08:39PM |

Registered: 10 years ago Posts: 240 |

If you get ABS right, it will be stronger than PLA, get it wrong and it's brittle as heck.

The problem is that ABS is VERY fickle about how it's printed:

Too little airflow and you lose definition, too high of airflow and it becomes brittle.

Allow the previous layer to cool too much before the next layer, and it won't stick. Allow it to stay heated too much and it will sag.

Heat your bed too little and it won't stick, too much and it effects layer cooling and gives your print an hourglass shape.

Higher speed, makes this an even bigger problem.

PLA... you can't over-cool it and as long as it's not burning, it's fine, making it very hard to mess up.

The problem is that ABS is VERY fickle about how it's printed:

Too little airflow and you lose definition, too high of airflow and it becomes brittle.

Allow the previous layer to cool too much before the next layer, and it won't stick. Allow it to stay heated too much and it will sag.

Heat your bed too little and it won't stick, too much and it effects layer cooling and gives your print an hourglass shape.

Higher speed, makes this an even bigger problem.

PLA... you can't over-cool it and as long as it's not burning, it's fine, making it very hard to mess up.

|

Re: PLA vs ABS tough or not ?! October 17, 2014 09:25PM |

Registered: 10 years ago Posts: 1,401 |

Ok, since it is an open frame, do the following experiment:

1.- use a ceramic space heater in front of printer an set it to at least 75 to 80 degrees and slow fan setting.

2.- use a 200 watts incandescent bulb and put it close to the part you are printing (this method is the one I used all the time) be sure that the socket for the bulb is ceramic. The heat from the bulb keeps the small area in front really warm and moves the air around too.

Attached you can see a white ABS part I printed for a customer.

1.- use a ceramic space heater in front of printer an set it to at least 75 to 80 degrees and slow fan setting.

2.- use a 200 watts incandescent bulb and put it close to the part you are printing (this method is the one I used all the time) be sure that the socket for the bulb is ceramic. The heat from the bulb keeps the small area in front really warm and moves the air around too.

Attached you can see a white ABS part I printed for a customer.

|

Re: PLA vs ABS tough or not ?! October 18, 2014 10:15AM |

Registered: 10 years ago Posts: 98 |

Thank you all for the hands-on knowledge.

I did try one with 2x 100W bulbs, (one in front and the other in back). I wasn't sure it helped.

@sheepdog43:

Got any good values you use that I could play around with ?

@ggherbaz:

1. Do you have to shine the bulb at the current layer being printed or the part in general ?

2. Also, do I need both steps or just one ? (cause I don't have a ceramic heater).

I did try one with 2x 100W bulbs, (one in front and the other in back). I wasn't sure it helped.

@sheepdog43:

Got any good values you use that I could play around with ?

@ggherbaz:

1. Do you have to shine the bulb at the current layer being printed or the part in general ?

2. Also, do I need both steps or just one ? (cause I don't have a ceramic heater).

|

Re: PLA vs ABS tough or not ?! October 18, 2014 12:39PM |

Registered: 9 years ago Posts: 60 |

|

Re: PLA vs ABS tough or not ?! October 18, 2014 05:26PM |

Registered: 10 years ago Posts: 1,401 |

Either or, if you have a heater used it, the bulb is cheap and a ceramic socket too. You only put it facing the part you are printing within 6 inches. My printer is semi enclosed and the bulb is enough for the job, with an open frame you want to prevent from cold air to move around the printed part that's why a heater will be useful because will move hot air around the part.

|

Re: PLA vs ABS tough or not ?! October 18, 2014 05:31PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: PLA vs ABS tough or not ?! October 18, 2014 05:36PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: PLA vs ABS tough or not ?! October 18, 2014 11:07PM |

Registered: 10 years ago Posts: 98 |

|

Re: PLA vs ABS tough or not ?! October 18, 2014 11:10PM |

Registered: 10 years ago Posts: 98 |

|

Re: PLA vs ABS tough or not ?! October 19, 2014 01:10PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: PLA vs ABS tough or not ?! October 19, 2014 10:20PM |

Registered: 10 years ago Posts: 240 |

I do all I can to avoid ABS these days.Quote

Rigor_M

@sheepdog43:

Got any good values you use that I could play around with ?

Unfortunately, will all the changes we did to prep for the Griffin Pro, all my settings where in constant flux. I have no idea what state my ABS settings are in or where they are.

My best advice is print slow, and use walls to keep air out of the print area.

|

Re: PLA vs ABS tough or not ?! October 20, 2014 07:54AM |

Registered: 10 years ago Posts: 98 |

@ggherbaz :

i'll get some foamboard from the store after work. My Custom made printer is in form of a cube so should not be hard to close up all around. I know you said 3 sides, witch ones ? side to side, i would guess but the other one, backside or top ?

My office space is already at around 70F year round.. so ramping it up to 80 should be easy with a 200W bulb. especially if the printer is inclosed.. i'll try that first !

@sheepdog43:

I know, I try to avoid it like the plege. But my last order was suppose to be 4x spools of PLA and 1x spools of ABS, to order was botched-up and got 4x ABS and 1xPLA. I tried to sell it locally but the didn't work so i'm stuck with it.. might has well make the most out of it.

Also, i'm upgrading my old Prusa mendel i2 to a Prusa i3 and i'm building a custom shroud around the hotend so, I need some ABS for that part.

i'll get some foamboard from the store after work. My Custom made printer is in form of a cube so should not be hard to close up all around. I know you said 3 sides, witch ones ? side to side, i would guess but the other one, backside or top ?

My office space is already at around 70F year round.. so ramping it up to 80 should be easy with a 200W bulb. especially if the printer is inclosed.. i'll try that first !

@sheepdog43:

I know, I try to avoid it like the plege. But my last order was suppose to be 4x spools of PLA and 1x spools of ABS, to order was botched-up and got 4x ABS and 1xPLA. I tried to sell it locally but the didn't work so i'm stuck with it.. might has well make the most out of it.

Also, i'm upgrading my old Prusa mendel i2 to a Prusa i3 and i'm building a custom shroud around the hotend so, I need some ABS for that part.

|

Re: PLA vs ABS tough or not ?! October 20, 2014 08:16AM |

Registered: 10 years ago Posts: 1,401 |

Sorry, I meant sides, back and top. Just leave front open and few perforations on one side for flow. Heat tends to go up and stay there until it cools down, so on the front side put a little strip 2 or 3 inches high to prevent the heat to escape from the top and the perforations on the side put them low to force cold air out.

|

Re: PLA vs ABS tough or not ?! October 20, 2014 12:03PM |

Registered: 10 years ago Posts: 98 |

Great thanks, i'll try to close up ASAP :-)

Do you guys also insulate the bed ?

For me, I have a 3mm glass, under is a 3mm aluminium plate and a 500W/120V silicon heat pad stuck under the aluminium

glass & aluminium is 270mmx340mm and the heatpad is centered with a 230mmx300mm. Should I isolate the bed ?

Do you guys also insulate the bed ?

For me, I have a 3mm glass, under is a 3mm aluminium plate and a 500W/120V silicon heat pad stuck under the aluminium

glass & aluminium is 270mmx340mm and the heatpad is centered with a 230mmx300mm. Should I isolate the bed ?

|

Re: PLA vs ABS tough or not ?! October 20, 2014 12:17PM |

Registered: 10 years ago Posts: 439 |

|

Re: PLA vs ABS tough or not ?! October 20, 2014 12:45PM |

Registered: 10 years ago Posts: 98 |

Quote

Ralph.Hilton

Insulation under the bed helps. I use cardboard covered in reflective metallic tape.

If your order gets botched the seller should correct it surely?

I don't know about putting cardboard under the silicon pad.. that thing is pretty powerful.

i'm sure that if I close up the printer, that alone should raise the heat inside the box at a pretty good level.. coupled with a 200W bulb, well.. I just hope that I don't over shoot ! LOL

Yes, I got a refund and said to keep the plastic. :-)

the seller wasn't at fault.. he gave me a great service and follow-up.

The distributor was the one at fault ( order was shipped directly from the distributor).

Edited 2 time(s). Last edit at 10/20/2014 12:46PM by Rigor_M.

|

Re: PLA vs ABS tough or not ?! October 20, 2014 02:17PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: PLA vs ABS tough or not ?! October 21, 2014 07:54AM |

Registered: 10 years ago Posts: 98 |

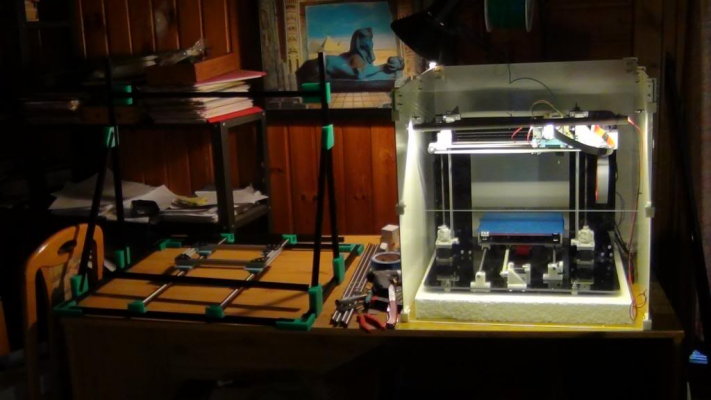

So, I did the closeup on my printer.. here is the before and after images.

Before

After

Here is a partial result print (mind that it did not fail, I stoped the print)

Look at the bottom and the last upper layers.. what could do that ?

I got a small ceramic heater heater from my local big box store. but.. I could not use it as the internal temp was going at 124F++.

with the bed alone, the temp was at 119F constant

I inserted a thermometer on the top of the box to check temp variations.

is 119F too much ? would I need to make some hole on the top to let some hot air escape ? Could the 119F have made the small ripples on the bottom of the print ?

Its where i'm at now :-)

Before

After

Here is a partial result print (mind that it did not fail, I stoped the print)

Look at the bottom and the last upper layers.. what could do that ?

I got a small ceramic heater heater from my local big box store. but.. I could not use it as the internal temp was going at 124F++.

with the bed alone, the temp was at 119F constant

I inserted a thermometer on the top of the box to check temp variations.

is 119F too much ? would I need to make some hole on the top to let some hot air escape ? Could the 119F have made the small ripples on the bottom of the print ?

Its where i'm at now :-)

|

Re: PLA vs ABS tough or not ?! October 21, 2014 10:24AM |

Registered: 10 years ago Posts: 1,401 |

Ok, 119 isn't bad, I keep mine at 110.

First thing you need to do is to lowered your extrusion temperature a bit and increase your retraction settings. Since you have a chamber now, the ABS will stay softer longer.

Regarding the picture, it might be 3 things:

1 Air trapped in the filament.

2 excessive infill to perimeter overlap.

3 loose belt (since your printer is now enclosed, temperature will affect your plastic and rubber parts)

Do not perforate the top, you will defeat the purpose of the enclosure, if you want you can put a fan in a exhaust mode on the side as low as you can to help circulation.

Edited 1 time(s). Last edit at 10/21/2014 10:41AM by ggherbaz.

First thing you need to do is to lowered your extrusion temperature a bit and increase your retraction settings. Since you have a chamber now, the ABS will stay softer longer.

Regarding the picture, it might be 3 things:

1 Air trapped in the filament.

2 excessive infill to perimeter overlap.

3 loose belt (since your printer is now enclosed, temperature will affect your plastic and rubber parts)

Do not perforate the top, you will defeat the purpose of the enclosure, if you want you can put a fan in a exhaust mode on the side as low as you can to help circulation.

Edited 1 time(s). Last edit at 10/21/2014 10:41AM by ggherbaz.

|

Re: PLA vs ABS tough or not ?! October 21, 2014 10:47AM |

Registered: 10 years ago Posts: 98 |

hum.. i see... well.. I printed the part @ 240C.. maybe I could go down to 230C.

The bed is at 110C. I did not get any warping yet.. (bet there was some time left . I'm using hairspray on kapton tape

maybe 105C would make the temp in the chamber at around 110F

I have to play around..

So, from the look of things, I don't need the ceramic heater ?

The bed is at 110C. I did not get any warping yet.. (bet there was some time left . I'm using hairspray on kapton tape

maybe 105C would make the temp in the chamber at around 110F

I have to play around..

So, from the look of things, I don't need the ceramic heater ?

|

Re: PLA vs ABS tough or not ?! October 21, 2014 12:40PM |

Registered: 10 years ago Posts: 1,401 |

I print at 225~230, 240 is on the high side. If your enclosure is keeping the temperature well, you don't need to add more heat but you need to add flow, see heat from heater bed just goes up, it will move parallel to your part and will keep it at temperature but you want to have some of that heat hitting the part perpendicular to the surface to help layer bonding. Best option will be to lower some your bed temperature (not by much) and use the heater to introduce the flow and compensate the temperature.

|

Re: PLA vs ABS tough or not ?! October 21, 2014 01:03PM |

Registered: 10 years ago Posts: 98 |

|

Re: PLA vs ABS tough or not ?! October 21, 2014 01:38PM |

Registered: 10 years ago Posts: 1,401 |

Sorry, only registered users may post in this forum.