First (basic) attempt at a repstrap

Posted by greenarrow

|

First (basic) attempt at a repstrap August 06, 2007 08:06PM |

Registered: 16 years ago Posts: 161 |

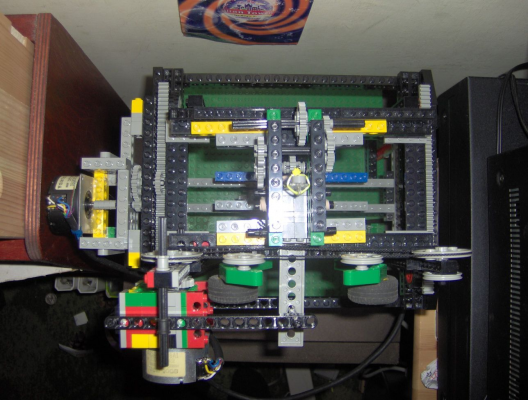

This is my first attempt at a repstrap, the whole thing is built from lego using added on stepper motors.

Both the motors and driver are from an old printer (i'm not using reprap electronics) with the driver connected to the parallel port. This means the software has to control every coil on the system individually which is annoying but it works. The software is written in python with a C backend to take care of the actual coil movements (which sped things up a lot).

At the moment i'm not using the reprap software due to incompatible hardware. I'm not really intending to get this up to being able to print reprap parts, it's more just for a learning experience until reprap can re-produce. Once i've added the extruder motor (for a syringe) i'm going to experiment with making basic shapes using either glue or filler.

The accuracy of the machine is surprisingly good. I gave it a small job (about 10 movements) to do,repeated it about 5 times and set it to return to the centre. The x axis drifted about 1 mm and the y axis about 10mm. I only got it hooked up the computer today and am pretty sure i can get the y axis better.

Both the motors and driver are from an old printer (i'm not using reprap electronics) with the driver connected to the parallel port. This means the software has to control every coil on the system individually which is annoying but it works. The software is written in python with a C backend to take care of the actual coil movements (which sped things up a lot).

At the moment i'm not using the reprap software due to incompatible hardware. I'm not really intending to get this up to being able to print reprap parts, it's more just for a learning experience until reprap can re-produce. Once i've added the extruder motor (for a syringe) i'm going to experiment with making basic shapes using either glue or filler.

The accuracy of the machine is surprisingly good. I gave it a small job (about 10 movements) to do,repeated it about 5 times and set it to return to the centre. The x axis drifted about 1 mm and the y axis about 10mm. I only got it hooked up the computer today and am pretty sure i can get the y axis better.

|

Re: First (basic) attempt at a repstrap September 01, 2007 04:58PM |

Registered: 16 years ago Posts: 161 |

Here's an update:

[www.flickr.com]

I've managed to do a five layer print of a letter 'I'. There is still a bit of distortion at the beginning of each line, i have found that extruding extra material st the start of every new line helps the material stick down better, but can result in the nozzle getting coated in excess material, my next idea is to suspend a piece of tissue outside of the print area so that the machine can clean it's nozzle between lines.

The print in the photo is printed at about a 1mm in both the x and y axis and layer thickness. The positioning system is much more accurate than this (probably about 0.2mm) but i'm extruding directly out of the syringe which has quite a wide nozzle. I've got some huge thick needles from ebay that are presumably for injecting elephants and such, when i get round to it i'm going to cut one down and try to get some higher resolutions.

At the moment i am still using my own custom electronics and software, but i've just ordered some pcbs from zach (thanks by the way) so i can move onto the official hardware. I will probably continue to develop my own python library on the official hardware as it will help me to learn how whole system works more thoroughly.

[www.flickr.com]

I've managed to do a five layer print of a letter 'I'. There is still a bit of distortion at the beginning of each line, i have found that extruding extra material st the start of every new line helps the material stick down better, but can result in the nozzle getting coated in excess material, my next idea is to suspend a piece of tissue outside of the print area so that the machine can clean it's nozzle between lines.

The print in the photo is printed at about a 1mm in both the x and y axis and layer thickness. The positioning system is much more accurate than this (probably about 0.2mm) but i'm extruding directly out of the syringe which has quite a wide nozzle. I've got some huge thick needles from ebay that are presumably for injecting elephants and such, when i get round to it i'm going to cut one down and try to get some higher resolutions.

At the moment i am still using my own custom electronics and software, but i've just ordered some pcbs from zach (thanks by the way) so i can move onto the official hardware. I will probably continue to develop my own python library on the official hardware as it will help me to learn how whole system works more thoroughly.

|

Re: First (basic) attempt at a repstrap September 01, 2007 06:42PM |

Registered: 16 years ago Posts: 82 |

|

Re: First (basic) attempt at a repstrap September 02, 2007 01:13AM |

Registered: 16 years ago Posts: 235 |

I was going to suggest you post the details of exactly which lego kits and parts you used but then I re-read your post and as you're probably not going to evolve it into a reprap it may not be worth the bother (I think it would probably be a lot of work to document from looking at the pictures).

Having said that, I for one would be interested in having a closer look at your support structure to see if I can do anything similar as I'm starting to get to the point where I'm going to have to come up with my own ideas or get RP parts.

I'm much better at fine-tuning other peoples ideas rather than coming up with my own

Having said that, I for one would be interested in having a closer look at your support structure to see if I can do anything similar as I'm starting to get to the point where I'm going to have to come up with my own ideas or get RP parts.

I'm much better at fine-tuning other peoples ideas rather than coming up with my own

|

Re: First (basic) attempt at a repstrap September 02, 2007 04:46AM |

Registered: 16 years ago Posts: 161 |

Samuel Wrote:

-------------------------------------------------------

> Looks great. Nice job using Lego. Hopefully it can

> successfully print the reprap parts you need. I

> can't wait to see more pictures.

>

> -Samuel

Thanks

reece.arnott Wrote:

-------------------------------------------------------

> I was going to suggest you post the details of

> exactly which lego kits and parts you used but

> then I re-read your post and as you're probably

> not going to evolve it into a reprap it may not be

> worth the bother (I think it would probably be a

> lot of work to document from looking at the

> pictures).

>

> Having said that, I for one would be interested in

> having a closer look at your support structure to

> see if I can do anything similar as I'm starting

> to get to the point where I'm going to have to

> come up with my own ideas or get RP parts.

>

> I'm much better at fine-tuning other peoples ideas

> rather than coming up with my own

I am now considering taking it further as i have been very pleased with the results so far. If the casting method of making extruders is successful then i will have a go at putting a plastic extruder onto the machine. Otherwise i will have to re-design it to take a heavier aluminium extruder.

I will try and do some better photos using a tripod, and of the different parts of the machine disassembled so that it will be easier to see how it is built. The motors are not made my lego, they are just standard stepper motors, but it's not too hard to connect them up if you have a few lego pieces to sacrifice and some decent glue.

As for what lego kits i used, the bulk of it is:

[www.brickset.com]

and

[www.brickset.com]

but i have a lot of pieces from other places too

-------------------------------------------------------

> Looks great. Nice job using Lego. Hopefully it can

> successfully print the reprap parts you need. I

> can't wait to see more pictures.

>

> -Samuel

Thanks

reece.arnott Wrote:

-------------------------------------------------------

> I was going to suggest you post the details of

> exactly which lego kits and parts you used but

> then I re-read your post and as you're probably

> not going to evolve it into a reprap it may not be

> worth the bother (I think it would probably be a

> lot of work to document from looking at the

> pictures).

>

> Having said that, I for one would be interested in

> having a closer look at your support structure to

> see if I can do anything similar as I'm starting

> to get to the point where I'm going to have to

> come up with my own ideas or get RP parts.

>

> I'm much better at fine-tuning other peoples ideas

> rather than coming up with my own

I am now considering taking it further as i have been very pleased with the results so far. If the casting method of making extruders is successful then i will have a go at putting a plastic extruder onto the machine. Otherwise i will have to re-design it to take a heavier aluminium extruder.

I will try and do some better photos using a tripod, and of the different parts of the machine disassembled so that it will be easier to see how it is built. The motors are not made my lego, they are just standard stepper motors, but it's not too hard to connect them up if you have a few lego pieces to sacrifice and some decent glue.

As for what lego kits i used, the bulk of it is:

[www.brickset.com]

and

[www.brickset.com]

but i have a lot of pieces from other places too

|

Anonymous User

Re: First (basic) attempt at a repstrap September 02, 2007 06:47AM |

Hi there,

> I will probably

> continue to develop my own python library on the

> official hardware as it will help me to learn how

> whole system works more thoroughly.

since I am not familiar with Java (Reprap soft language), but I am with Python, I'd love to see your progress in the library!

> I will probably

> continue to develop my own python library on the

> official hardware as it will help me to learn how

> whole system works more thoroughly.

since I am not familiar with Java (Reprap soft language), but I am with Python, I'd love to see your progress in the library!

|

Re: First (basic) attempt at a repstrap September 02, 2007 08:46AM |

Admin Registered: 17 years ago Posts: 7,879 |

|

Re: First (basic) attempt at a repstrap September 02, 2007 12:21PM |

Registered: 16 years ago Posts: 161 |

arturo Wrote:

-------------------------------------------------------

> Hi there,

>

> > I will probably

> > continue to develop my own python library on

> the

> > official hardware as it will help me to learn

> how

> > whole system works more thoroughly.

>

> since I am not familiar with Java (Reprap soft

> language), but I am with Python, I'd love to see

> your progress in the library!

Yeah i've never used java either. At the moment my library controls motors over the parallel port but as soon as i have my reprap electronics built i will change over to controlling that. At the moment there is a C library wrapped for python that deals with all the low level motor control, then there is another library ontop of that which deals with what the machine is doing, where the head is etc, then specific programs to do stuff such as print from bitmaps use that library. I'm in the process of switching from tkinter to wxpython but once that is done i will post some code.

-------------------------------------------------------

> Hi there,

>

> > I will probably

> > continue to develop my own python library on

> the

> > official hardware as it will help me to learn

> how

> > whole system works more thoroughly.

>

> since I am not familiar with Java (Reprap soft

> language), but I am with Python, I'd love to see

> your progress in the library!

Yeah i've never used java either. At the moment my library controls motors over the parallel port but as soon as i have my reprap electronics built i will change over to controlling that. At the moment there is a C library wrapped for python that deals with all the low level motor control, then there is another library ontop of that which deals with what the machine is doing, where the head is etc, then specific programs to do stuff such as print from bitmaps use that library. I'm in the process of switching from tkinter to wxpython but once that is done i will post some code.

|

Anonymous User

Re: First (basic) attempt at a repstrap September 02, 2007 12:24PM |

|

Re: First (basic) attempt at a repstrap September 02, 2007 12:28PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: First (basic) attempt at a repstrap September 02, 2007 02:06PM |

Registered: 16 years ago Posts: 246 |

|

Anonymous User

Re: First (basic) attempt at a repstrap September 02, 2007 04:12PM |

|

Anonymous User

Re: First (basic) attempt at a repstrap September 02, 2007 08:11PM |

And now that I think about it, reprapping something akin to a lego brick might not be such a bad idea. If more the the frame structure of the reprap could be made of small, printable peices instead of materials from building suppliers, the machine would be that much closer to the goal of self-replication.

|

Re: First (basic) attempt at a repstrap September 03, 2007 03:38AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes, but the design of Darwin is such that it can print things almost as big as itself so you only need to break the frame into pieces that are half the full span, you don't need to make them any smaller.

The main advantage of RepRap is that you can print custom shapes rather than having to assemble things from stock items.

Having said that, it would take a very long time to extrude something as big as a frame, so it might make sense to extrude a few molds and then cast a larger number of modular components. The frame is pretty symmetrical and as each axis needs to be divided into at lease two you would need at least four items per face, in the same way the original bed was divided into four before it got replaced with a sheet of MDF plus four corners. That would mean for a cube you could have 24 instances of one piece, making molding worth while.

[www.hydraraptor.blogspot.com]

The main advantage of RepRap is that you can print custom shapes rather than having to assemble things from stock items.

Having said that, it would take a very long time to extrude something as big as a frame, so it might make sense to extrude a few molds and then cast a larger number of modular components. The frame is pretty symmetrical and as each axis needs to be divided into at lease two you would need at least four items per face, in the same way the original bed was divided into four before it got replaced with a sheet of MDF plus four corners. That would mean for a cube you could have 24 instances of one piece, making molding worth while.

[www.hydraraptor.blogspot.com]

|

Re: First (basic) attempt at a repstrap September 03, 2007 01:54PM |

Registered: 16 years ago Posts: 246 |

|

Re: First (basic) attempt at a repstrap November 24, 2007 03:39PM |

Registered: 16 years ago Posts: 91 |

I've been following reprap for a while now and one of these days I'd really like to start building one. (especially after Makezine, which I think will finally motivate me to start tinkering) So I'm still new to all this so bear with me.

I'm sure smarter and more knowledgeable people then me have thought about this before, but it seems much more logical to me that the structure be composed of small interlocking "blocks" like legos if its supposed to really replicate itself. When I think of a self replicating reprap I imagine something more like the replicators from Stargate. Made out of lots of simple similar shapes which are easy to fabricate and that can be combined to make new shapes. Something like burr puzzle blocks [www.mathematische-basteleien.de] or the way furniture was made before there were nails with dovetail joints between pieces [en.wikipedia.org]

Made out of lots of simple similar shapes which are easy to fabricate and that can be combined to make new shapes. Something like burr puzzle blocks [www.mathematische-basteleien.de] or the way furniture was made before there were nails with dovetail joints between pieces [en.wikipedia.org]

Looking at the current Darwin design, it seems to me that only a small fraction of the structure is being replicated, mostly just hinges and connectors, whereas the majority of the structure is composed of screws, nuts, bolts, and metal bars that it can't make. (and of course the electronics and motors which I understand part of which could be replicated eventually) Plus all the tools needed like hack saws, drills, files, etc. to assemble it all. The BoM and AssemblingDarwinMachinery page on the wiki is pretty overwhelming.

There seems to be a lot of interest in what people are calling Repstraps, but it looks to me that the Darwin design is just a repstrap as well, only a lot harder to make. Not to be so negative, but it says you guys hope to announce self-replication in 2008, but if less then 50% of it is being replicated, is it really self-replicating or am I missing something?

I'm sure smarter and more knowledgeable people then me have thought about this before, but it seems much more logical to me that the structure be composed of small interlocking "blocks" like legos if its supposed to really replicate itself. When I think of a self replicating reprap I imagine something more like the replicators from Stargate.

Made out of lots of simple similar shapes which are easy to fabricate and that can be combined to make new shapes. Something like burr puzzle blocks [www.mathematische-basteleien.de] or the way furniture was made before there were nails with dovetail joints between pieces [en.wikipedia.org]

Made out of lots of simple similar shapes which are easy to fabricate and that can be combined to make new shapes. Something like burr puzzle blocks [www.mathematische-basteleien.de] or the way furniture was made before there were nails with dovetail joints between pieces [en.wikipedia.org]Looking at the current Darwin design, it seems to me that only a small fraction of the structure is being replicated, mostly just hinges and connectors, whereas the majority of the structure is composed of screws, nuts, bolts, and metal bars that it can't make. (and of course the electronics and motors which I understand part of which could be replicated eventually) Plus all the tools needed like hack saws, drills, files, etc. to assemble it all. The BoM and AssemblingDarwinMachinery page on the wiki is pretty overwhelming.

There seems to be a lot of interest in what people are calling Repstraps, but it looks to me that the Darwin design is just a repstrap as well, only a lot harder to make. Not to be so negative, but it says you guys hope to announce self-replication in 2008, but if less then 50% of it is being replicated, is it really self-replicating or am I missing something?

|

Re: First (basic) attempt at a repstrap November 24, 2007 03:58PM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi gr0k,

... for this i'm so interested in other mechanical concepts, as my much easier to replicate and assemble tripod-repstrap (look at the parts and assembling: [builders.reprap.org] ) or elastic/morphing structures, as tentacles and bending strouts ...

It's obviously harder to control, then a 'plain orthogonal' cartesic robot, but there was some progres in the last years, so the software is on the way - and once written, it could be copied and adapted easily.

On a sidepath i try to get the fingers on a 'neural-network-simulator', which is capable of 'self-learning' with error-feedback, so a complex mechanic and a 'nn-brain' could solve all the controlling issues on it's own ...

Viktor

... for this i'm so interested in other mechanical concepts, as my much easier to replicate and assemble tripod-repstrap (look at the parts and assembling: [builders.reprap.org] ) or elastic/morphing structures, as tentacles and bending strouts ...

It's obviously harder to control, then a 'plain orthogonal' cartesic robot, but there was some progres in the last years, so the software is on the way - and once written, it could be copied and adapted easily.

On a sidepath i try to get the fingers on a 'neural-network-simulator', which is capable of 'self-learning' with error-feedback, so a complex mechanic and a 'nn-brain' could solve all the controlling issues on it's own ...

Viktor

|

Re: First (basic) attempt at a repstrap November 24, 2007 03:58PM |

Registered: 16 years ago Posts: 246 |

The idea is to make as much of it from scratch as possible. Screws and such, if I remember the argument, are so ubiquitous that it's cheaper to buy them than to machine them special. The same goes for most of the other structure. The electronics are something a lot of us would like to see made from scratch, but the technology isn't there yet.

A lego fabricator that makes things out of legos is limited by the supply of lego bricks. A plastic extruding reprap is limited by the supply of suitable plastic. Plastic, be it thermo-plastic or some photo-cured, thermo-cured, or binary plastic, is much more widely available and can be worked into a much wider range of shapes, at all scales.

A lego fabricator that makes things out of legos is limited by the supply of lego bricks. A plastic extruding reprap is limited by the supply of suitable plastic. Plastic, be it thermo-plastic or some photo-cured, thermo-cured, or binary plastic, is much more widely available and can be worked into a much wider range of shapes, at all scales.

|

Re: First (basic) attempt at a repstrap November 24, 2007 04:03PM |

Registered: 16 years ago Posts: 622 |

gr0k,

The pieces for the real RepRap are, essentially, small, interlocking pieces. All those plastic pieces make up--I read somewhere in the forums--about 60% of the RepRap. Someone correct me if I'm wrong. Also, I read somewhere else on the forum that Lego blocks have to be pretty darn accurate to work well so there may be a problem there in replication.

In the current design we cannot fabricate metal parts. However, Viktor and others are working on laser sintering solutions that could yield metal structures in future versions. Remember, this is an iterative process so give us time.

As for Darwin being harder to make than a RepStrap...sure it is, but the parts that need to be bought in are--hoped to be--universal. I can buy most things in the States but people in India may have trouble finding a Lowes or a Home Depot. As long as only simple parts need to be bought we are good.

The issue of weather this can "actually" be called a self-replicating machine has been much discussed. Essentially it boils down to your POV. Take what you like and throw the rest out.

Cheers!

Demented

The pieces for the real RepRap are, essentially, small, interlocking pieces. All those plastic pieces make up--I read somewhere in the forums--about 60% of the RepRap. Someone correct me if I'm wrong. Also, I read somewhere else on the forum that Lego blocks have to be pretty darn accurate to work well so there may be a problem there in replication.

In the current design we cannot fabricate metal parts. However, Viktor and others are working on laser sintering solutions that could yield metal structures in future versions. Remember, this is an iterative process so give us time.

As for Darwin being harder to make than a RepStrap...sure it is, but the parts that need to be bought in are--hoped to be--universal. I can buy most things in the States but people in India may have trouble finding a Lowes or a Home Depot. As long as only simple parts need to be bought we are good.

The issue of weather this can "actually" be called a self-replicating machine has been much discussed. Essentially it boils down to your POV. Take what you like and throw the rest out.

Cheers!

Demented

|

Re: First (basic) attempt at a repstrap November 24, 2007 04:42PM |

Registered: 16 years ago Posts: 91 |

Viktor, yeah I saw that tripod design. It's visually impressive looking. I can't wait to see it in action. Reminds me of a flux capacitor!

I get that this is an iterative process and read that one of the goals of version 2, Mendel is to reduce the number of external parts. Just seems to me that version 1 should be a real repstrap, like the McWire design, very simple and even cheaper with a lot less parts. Then once you can start making things, replace parts with things it can make and increase precision until it can make the majority of itself... Darwin is like a hybrid already requiring fabricated parts + a ton of external parts. More like a version 2 then a version 1.

I would think someone in India that can get ahold of the motors and electronics, should have little trouble getting ahold of some pipe, aluminum rails, and roler skate bearings without a Home Depot...?

I get that this is an iterative process and read that one of the goals of version 2, Mendel is to reduce the number of external parts. Just seems to me that version 1 should be a real repstrap, like the McWire design, very simple and even cheaper with a lot less parts. Then once you can start making things, replace parts with things it can make and increase precision until it can make the majority of itself... Darwin is like a hybrid already requiring fabricated parts + a ton of external parts. More like a version 2 then a version 1.

I would think someone in India that can get ahold of the motors and electronics, should have little trouble getting ahold of some pipe, aluminum rails, and roler skate bearings without a Home Depot...?

|

Re: First (basic) attempt at a repstrap November 24, 2007 05:02PM |

Registered: 16 years ago Posts: 622 |

gr0k,

Possibly, but I think we are selling the harder to get components--except the steppers though they are working on that. Keep in mind, too, that we are in the project before it has actually launched. When self-replication happens consistently and reliably then they won't have to buy any of this other stuff, only the electronics and motors and such. The frame components that can be replicated will be and the project will spread from hand to hand. Much nicer than buying parts even if you can find them.

Not that I don't, in some respects, agree with you. The McWire design is much cleaner than the Darwin. And Viktor's tripod setup is cleaner still. I'm a fan but I don't mind the design path the Darwin is taking because I see that it fills a niche.

Demented

Possibly, but I think we are selling the harder to get components--except the steppers though they are working on that. Keep in mind, too, that we are in the project before it has actually launched. When self-replication happens consistently and reliably then they won't have to buy any of this other stuff, only the electronics and motors and such. The frame components that can be replicated will be and the project will spread from hand to hand. Much nicer than buying parts even if you can find them.

Not that I don't, in some respects, agree with you. The McWire design is much cleaner than the Darwin. And Viktor's tripod setup is cleaner still. I'm a fan but I don't mind the design path the Darwin is taking because I see that it fills a niche.

Demented

|

Re: First (basic) attempt at a repstrap November 24, 2007 05:07PM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi gr0k,

... i think it's no fault, to present many different ideas and concepts for repstrap and have the rrrf-shop with kits and complete sets to start.

Most people not so skilled with handcrafting can buy the complete set, if someone wants to play around, he can do 'his' way.

As the software is open, it's maybe more interesting to optimize the software to fit to any repstrap-system - be it cartesic, polar or others ...

When i asked Zach in the summer about a 'lathe-LOM'-approach, he couldn't really help me, so i'm trying several parallel directions and methods on my own.

When there would be some progress or a simpler way to a reprap with noncartesic mechanics (i'm expermenting with 'bionic' setups too), i'll post it in the blog.

I think, sometimes there is a fair chance to stick some morphing reprap-made plastic parts together, connect them to an aquarium-air-pump and a PC and have a working 'bionic'-reprap ready for starting the next sequence ...

Viktor

... i think it's no fault, to present many different ideas and concepts for repstrap and have the rrrf-shop with kits and complete sets to start.

Most people not so skilled with handcrafting can buy the complete set, if someone wants to play around, he can do 'his' way.

As the software is open, it's maybe more interesting to optimize the software to fit to any repstrap-system - be it cartesic, polar or others ...

When i asked Zach in the summer about a 'lathe-LOM'-approach, he couldn't really help me, so i'm trying several parallel directions and methods on my own.

When there would be some progress or a simpler way to a reprap with noncartesic mechanics (i'm expermenting with 'bionic' setups too), i'll post it in the blog.

I think, sometimes there is a fair chance to stick some morphing reprap-made plastic parts together, connect them to an aquarium-air-pump and a PC and have a working 'bionic'-reprap ready for starting the next sequence ...

Viktor

Sorry, only registered users may post in this forum.