Colour mixing now a reality

Posted by Xabbax

|

Colour mixing now a reality November 03, 2014 01:34PM |

Registered: 11 years ago Posts: 173 |

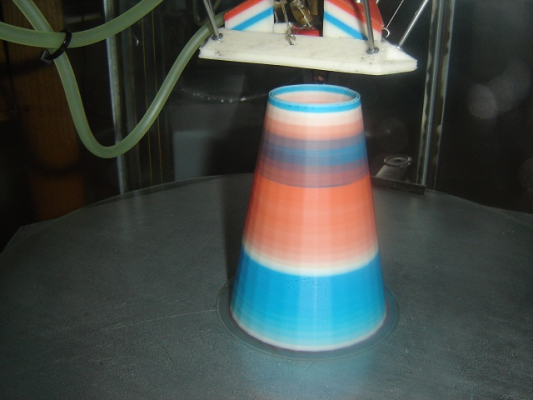

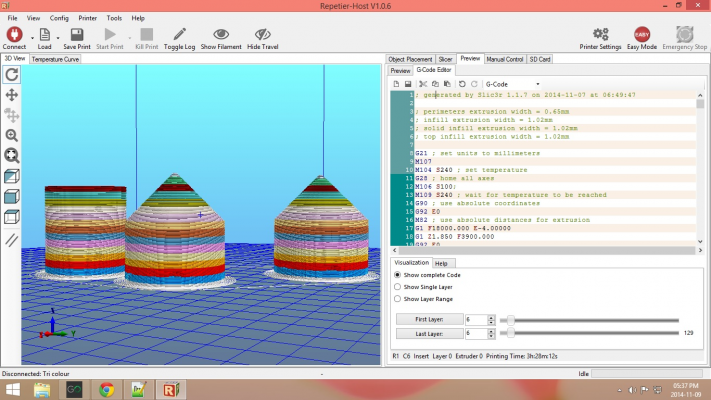

Colour mixing now a reality with Repetier's mixing extruder firmware (http://www.repetier.com/firmware/v092/index.html)

printing with a Tri-colour hotend. See the mixing extruder theory by Repetier at [github.com]

This allow you to print with 16 virtual extruders with as many filament feeds your printer can accommodate.

Two prints on my delta printer with a Tri-colour hotend.(http://deltaprinter.co.za/tri-colour/index.html)

You only learn when you change your mind.

[www.deltaprinter.co.za]

printing with a Tri-colour hotend. See the mixing extruder theory by Repetier at [github.com]

This allow you to print with 16 virtual extruders with as many filament feeds your printer can accommodate.

Two prints on my delta printer with a Tri-colour hotend.(http://deltaprinter.co.za/tri-colour/index.html)

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 03, 2014 01:47PM |

Registered: 10 years ago Posts: 140 |

|

Re: Colour mixing now a reality November 04, 2014 04:55AM |

Registered: 11 years ago Posts: 364 |

|

Re: Colour mixing now a reality November 04, 2014 08:43AM |

Registered: 11 years ago Posts: 173 |

I played around with the three basic colours yellow, blue and red.

A problem that I had was that the blue filament was a little smaller than the other two and I had to proportionally increase the feed of the blue not to under extrude the blue.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 04, 2014 09:45AM |

Registered: 9 years ago Posts: 49 |

|

Re: Colour mixing now a reality November 04, 2014 10:17AM |

Registered: 11 years ago Posts: 173 |

The hotend is my own design - an all metal Tri-colour hotend with water cooling for printing ABS in a heated chamber.

More info here - [deltaprinter.co.za]

Edited 1 time(s). Last edit at 11/05/2014 12:18AM by Xabbax.

You only learn when you change your mind.

[www.deltaprinter.co.za]

More info here - [deltaprinter.co.za]

Edited 1 time(s). Last edit at 11/05/2014 12:18AM by Xabbax.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 04, 2014 10:30AM |

Admin Registered: 11 years ago Posts: 3,096 |

I am speechless. You have achieved such a beautiful accomplishment. That hotend is beautifully engineered!

It reminds me of what the [www.fabbster.com] Fabbster printer does in terms of looks.

But it works with one hotend, one filament supply and you can only switch filaments per inserted piece. So with your solution you kind of have complete control

A friend of mine has this printer and it's not the best thing, but the multicolor play is nice, though kind of random.

See it here:

[youtu.be]

Edited 1 time(s). Last edit at 11/04/2014 10:31AM by Ohmarinus.

http://www.marinusdebeer.nl/

It reminds me of what the [www.fabbster.com] Fabbster printer does in terms of looks.

But it works with one hotend, one filament supply and you can only switch filaments per inserted piece. So with your solution you kind of have complete control

A friend of mine has this printer and it's not the best thing, but the multicolor play is nice, though kind of random.

See it here:

[youtu.be]

Edited 1 time(s). Last edit at 11/04/2014 10:31AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Colour mixing now a reality November 04, 2014 11:03AM |

Registered: 9 years ago Posts: 376 |

|

Re: Colour mixing now a reality November 04, 2014 11:17AM |

Registered: 11 years ago Posts: 364 |

|

Re: Colour mixing now a reality November 04, 2014 11:23AM |

Registered: 11 years ago Posts: 173 |

Can you direct me to a picture where you see the material.Quote

UkIan

Question for you: What is the clay like material you put around the hot bits? I've been looking for something like that and haven't found anything that likes hot temperatuers.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 04, 2014 11:41AM |

Registered: 11 years ago Posts: 173 |

Quote

ekaggrat

do the filaments mix properly or do you get a toothpaste effect like richard's 3 way extruder ?

With the naked eye I cannot see any toothpaste effect in the .35 mm layers - I am using a .65 mm nozzle. So yes, the colours are mixing properly. ( in the limited number of prints so far)

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 04, 2014 01:18PM |

Registered: 9 years ago Posts: 376 |

Quote

Xabbax

Can you direct me to a picture where you see the material.Quote

UkIan

Question for you: What is the clay like material you put around the hot bits? I've been looking for something like that and haven't found anything that likes hot temperatuers.

My mistake, it looks like it is actually where you have primed and then painted it. Had a sort of terracotta colour, so jumped to conclusions :/

|

Re: Colour mixing now a reality November 04, 2014 05:19PM |

Registered: 10 years ago Posts: 580 |

Ulkan,

I've used Autocrete- Hi-Temp Ceramic Adhesive when building my hot-end.

It worked very well.

I really like the tri-color hot-end. Great Job!

I am planning one for Raptosaur, and water cooling may work best.

Edited 1 time(s). Last edit at 11/04/2014 05:22PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I've used Autocrete- Hi-Temp Ceramic Adhesive when building my hot-end.

It worked very well.

I really like the tri-color hot-end. Great Job!

I am planning one for Raptosaur, and water cooling may work best.

Edited 1 time(s). Last edit at 11/04/2014 05:22PM by Paul Wanamaker.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Colour mixing now a reality November 04, 2014 05:35PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Paul Wanamaker

Ulkan,

I've used Autocrete- Hi-Temp Ceramic Adhesive when building my hot-end.

It worked very well.

I really like the tri-color hot-end. Great Job!

I am planning one for Raptosaur, and water cooling may work best.

Great stuff, but I got Firegum from Holts which is cheaper and works a bit differently I think. It sets from the heat and form a very hard material.

About the toothpaste effect, I think this has to to with the size of the melt-chamber. Keep it down to a minimum and you might not achieve high-speed extrusion, but also won't have the toothpaste effect as much.

Edited 1 time(s). Last edit at 11/04/2014 05:36PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Colour mixing now a reality November 04, 2014 06:08PM |

Registered: 11 years ago Posts: 205 |

In looking at this very interesting hot end it occurs to me that this is the perfect part to be 3D printed on a laser or electron beam sintering machine. Built that way you could do it in one piece with gently curved passages for the filament, passages for the cooling water etc. You'd probably need to clean up the external and internal threads and maybe extrude hone the filament passages and it would be done. You might even include a static mixing zone and you could include mounting bosses or holes to make using it easier. I wonder what company could do that if you sent a model?

|

Re: Colour mixing now a reality November 06, 2014 01:03PM |

Registered: 10 years ago Posts: 59 |

|

Re: Colour mixing now a reality November 11, 2014 10:40AM |

Registered: 11 years ago Posts: 173 |

A few more prints.

The g-code files and EEPROM settings available at [deltaprinter.co.za]

You only learn when you change your mind.

[www.deltaprinter.co.za]

The g-code files and EEPROM settings available at [deltaprinter.co.za]

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 12, 2014 03:29AM |

Registered: 9 years ago Posts: 257 |

|

Re: Colour mixing now a reality November 12, 2014 04:00AM |

Registered: 11 years ago Posts: 173 |

Quote

kimented_

Hi,

Your work is great and promising!

I see you only change the color by the Z axis. It is not possible to change the color on X-Y ? Are you already working at this stuff?

To change colour on X-Y will require a purge of the previous colour outside the print area.(or in an infill) - No I have not tried that out but it can be done if you fiddle around with the g-code.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 12, 2014 04:22AM |

Admin Registered: 11 years ago Posts: 3,096 |

So, if you manage to mix two colors, do you get a new color if you are using three primary colors as base filament? That way it theoretically *should* be possible to output RGB values.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Colour mixing now a reality November 12, 2014 05:00AM |

Registered: 10 years ago Posts: 329 |

Printing with 3 primary colours, an RGB printer in effect, would in theory allow sophisticated multi coloured art work or lettering to be incorporated within the print if the software was capable of it. This would be a game changer.

Xabbax, after your earlier post I started to source the bits to make a hotend myself. I have not got very far yet. It is a fairly complicated assembly that needs to be silver soldered together. Any plans to sell them? or as garyhlucas suggested getting a version metal printed that you can mass produce and put on the market?

Does having 5 tubes going into the hotend present any particular problems? Did you need to beef up the motors or slow the print down?

Xabbax, after your earlier post I started to source the bits to make a hotend myself. I have not got very far yet. It is a fairly complicated assembly that needs to be silver soldered together. Any plans to sell them? or as garyhlucas suggested getting a version metal printed that you can mass produce and put on the market?

Does having 5 tubes going into the hotend present any particular problems? Did you need to beef up the motors or slow the print down?

|

Re: Colour mixing now a reality November 12, 2014 07:10AM |

Registered: 11 years ago Posts: 173 |

Yes you can build your own colour scheme. I used the basic red, yellow and blue(Not RGQuote

Ohmarinus

So, if you manage to mix two colors, do you get a new color if you are using three primary colors as base filament? That way it theoretically *should* be possible to output RGB values.

In the image below I started off with red then added 10% yellow and decreased the red with 10% in stages until pure yellow then did the same with blue until pure blue and then again with red until pure red.

Then printed pure yellow,red,yellow,blue, yellow and then added red and blue to the yellow in the same percentage (printing all three colours at the same time at different percentages) to the top.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 12, 2014 07:28AM |

Admin Registered: 17 years ago Posts: 7,879 |

You need the secondary colours, i.e. cyan, magenta and yellow when mixing pigments that absorb and reflect light as they are subtractive. The primary colours are used for processes where the colours add.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Colour mixing now a reality November 12, 2014 07:35AM |

Registered: 11 years ago Posts: 173 |

Quote

dave3d

Printing with 3 primary colours, an RGB printer in effect, would in theory allow sophisticated multi coloured art work or lettering to be incorporated within the print if the software was capable of it. This would be a game changer.

Xabbax, after your earlier post I started to source the bits to make a hotend myself. I have not got very far yet. It is a fairly complicated assembly that needs to be silver soldered together. Any plans to sell them? or as garyhlucas suggested getting a version metal printed that you can mass produce and put on the market?

Does having 5 tubes going into the hotend present any particular problems? Did you need to beef up the motors or slow the print down?

I do not use tools other than drill, dremel, and handy gas flame to make the hotends. The tricky part is the silver solder. You have to be careful not to over heat the stainless tubes.

5 or 6 tubes into the hotend should not be a problem. For that you will need a board that can accommodate 8 or 9 steppers. The other problem will be to have the motors attached to the hotend to drive the filament.

I use 76 ounce nema 17 steppers.

The g-code settings for speed and other settings for the following print:

; avoid_crossing_perimeters = 0

; bed_size = 200,200

; bed_temperature = 0

; bridge_acceleration = 0

; bridge_fan_speed = 100

; bridge_flow_ratio = 1

; brim_width = 5

; complete_objects = 0

; cooling = 1

; default_acceleration = 0

; disable_fan_first_layers = 1

; duplicate_distance = 6

; end_gcode = M104 S0 ; turn off temperature\nM106 S0;\nM400;\nG28; home all axes\nM84 ; disable motors

; external_perimeters_first = 0

; extruder_clearance_height = 20

; extruder_clearance_radius = 20

; extruder_offset = 0x0

; extrusion_axis = E

; extrusion_multiplier = 1

; fan_always_on = 0

; fan_below_layer_time = 60

; filament_diameter = 1.65

; first_layer_acceleration = 0

; first_layer_bed_temperature = 0

; first_layer_extrusion_width = 200%

; first_layer_speed = 50%

; first_layer_temperature = 240

; g0 = 0

; gcode_arcs = 0

; gcode_comments = 0

; gcode_flavor = reprap

; infill_acceleration = 0

; infill_first = 0

; layer_gcode =

; max_fan_speed = 100

; min_fan_speed = 35

; min_print_speed = 10

; min_skirt_length = 0

; notes =

; nozzle_diameter = 0.65

; only_retract_when_crossing_perimeters = 0

; ooze_prevention = 0

; output_filename_format = [input_filename_base].gcode

; perimeter_acceleration = 0

; post_process =

; print_center = 0,0

; resolution = 0

; retract_before_travel = 2

; retract_layer_change = 1

; retract_length = 4

; retract_length_toolchange = 10

; retract_lift = 1.5

; retract_restart_extra = 1

; retract_restart_extra_toolchange = 0

; retract_speed = 300

; skirt_distance = 6

; skirt_height = 1

; skirts = 1

; slowdown_below_layer_time = 30

; spiral_vase = 0

; standby_temperature_delta = -5

; start_gcode = G28 ; home all axes\nM106 S100;

; temperature = 240

; threads = 2

; toolchange_gcode =

; travel_speed = 65

; use_firmware_retraction = 0

; use_relative_e_distances = 0

; vibration_limit = 0

; wipe = 0

; z_offset = 0

; dont_support_bridges = 1

; extrusion_width = 0

; first_layer_height = 100%

; infill_only_where_needed = 0

; interface_shells = 0

; layer_height = 0.35

; raft_layers = 0

; seam_position = aligned

; support_material = 0

; support_material_angle = 0

; support_material_enforce_layers = 0

; support_material_extruder = 1

; support_material_extrusion_width = 0

; support_material_interface_extruder = 1

; support_material_interface_layers = 0

; support_material_interface_spacing = 0

; support_material_interface_speed = 100%

; support_material_pattern = rectilinear

; support_material_spacing = 2.5

; support_material_speed = 30

; support_material_threshold = 0

; bottom_solid_layers = 3

; bridge_speed = 40

; external_perimeter_speed = 70%

; extra_perimeters = 1

; fill_angle = 45

; fill_density = 30%

; fill_pattern = rectilinear

; gap_fill_speed = 15

; infill_every_layers = 1

; infill_extruder = 1

; infill_extrusion_width = 0

; infill_speed = 40

; overhangs = 1

; perimeter_extruder = 1

; perimeter_extrusion_width = 0

; perimeter_speed = 25

; perimeters = 3

; small_perimeter_speed = 25

; solid_fill_pattern = rectilinear

; solid_infill_below_area = 70

; solid_infill_every_layers = 0

; solid_infill_extrusion_width = 0

; solid_infill_speed = 40

; thin_walls = 1

; top_infill_extrusion_width = 0

; top_solid_infill_speed = 35

; top_solid_layers = 4

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 12, 2014 08:03AM |

Registered: 11 years ago Posts: 173 |

Quote

nophead

You need the secondary colours, i.e. cyan, magenta and yellow when mixing pigments that absorb and reflect light as they are subtractive. The primary colours are used for processes where the colours add.

Thank you for the input Nophead - Appreciate the expert advice - your colour mixing blog led me to experiment and try and get mine to work.

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 12, 2014 08:28AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think you confuse me with RichRap. I have never done any colour mixing since mixing paints at school!

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Colour mixing now a reality November 12, 2014 09:32AM |

Registered: 10 years ago Posts: 466 |

Quote

nophead

You need the secondary colours, i.e. cyan, magenta and yellow when mixing pigments that absorb and reflect light as they are subtractive. The primary colours are used for processes where the colours add.

you would also need black and white filaments for color mixing to create the proper shade.

|

Re: Colour mixing now a reality November 12, 2014 09:37AM |

Registered: 11 years ago Posts: 173 |

My apologies for the confusion!!Quote

nophead

I think you confuse me with RichRap. I have never done any colour mixing since mixing paints at school!

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Colour mixing now a reality November 12, 2014 10:04AM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

cat.farmer

Quote

nophead

You need the secondary colours, i.e. cyan, magenta and yellow when mixing pigments that absorb and reflect light as they are subtractive. The primary colours are used for processes where the colours add.

you would also need black and white filaments for color mixing to create the proper shade.

Yes you will certainly need white as well because in 2D printing you get white by not printing anything and letting the paper show but that doesn't work in 3D. In theory cyan + magenta + yellow makes black. In practice black is used as well to save ink and get a more accurate black.

[www.hydraraptor.blogspot.com]

|

Re: Colour mixing now a reality November 17, 2014 06:24AM |

Registered: 11 years ago Posts: 173 |

Not only vertical colour mixing but also horizontal colour mixing possible.

I designed the article in Openscad, exported the different colour components in .amf format,

then used Slic3r 1.1.7 file --> Combine multi-material STL files... to re-assemble the colour .amf files exported from Openscad

to build a complete .amf file. I then used Slic3r 1.2.1 to slice the files to a g-code file that was used to print.

(I tried Slic3r 1.1.7 for the slice but gave up because the layers were all messed up)

I printed the infill before the perimeters to purge the previous colour in the infill.

You only learn when you change your mind.

[www.deltaprinter.co.za]

Sorry, only registered users may post in this forum.