State of PET filament printing

Posted by RRuser

|

Re: State of PET filament printing February 01, 2015 06:49AM |

Admin Registered: 11 years ago Posts: 3,096 |

The PETG I've received yesterday prints wonderfully, the settings are close to PLA, the bottom layer delaminated, probably need to set bed temp 10º higher to 70º and extruder temp had to be bumped up from 205º for PLA to 215~220º for PETG.

Will continue my tests.

http://www.marinusdebeer.nl/

Will continue my tests.

http://www.marinusdebeer.nl/

|

Re: State of PET filament printing February 01, 2015 07:09AM |

Registered: 11 years ago Posts: 195 |

|

Re: State of PET filament printing February 01, 2015 08:36AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

MPower

Your PETG was labeled 215+ degrees extruding temp?

Color Clear

Netto weight 1kg

Diameter 1.75mm +-0.05mm

Material PETG

Filament property Transparent

Printing temperature 190-220 °C

platform temperature 20-70 °C

Printing speed 15-150mm/s

Total weight 1.4kg

210º works well, but layer adhesion isn't super. So I'm bumping it up a little. Oozing is practically nonexistent, bridging is quite good too. Filament diameter is exactly 1.75 over the parts that I measured so far.

http://www.marinusdebeer.nl/

|

Re: State of PET filament printing February 01, 2015 08:57AM |

Registered: 11 years ago Posts: 195 |

|

Re: State of PET filament printing February 01, 2015 09:15AM |

Admin Registered: 11 years ago Posts: 3,096 |

Well, it depends on the mixture of course. PETG is PET with a Glycol modification.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: State of PET filament printing February 12, 2015 03:48PM |

Registered: 9 years ago Posts: 20 |

So anyone using PET from recycled drink bottles? if so whats your filament extruder temp and also what bed and hot end temps are you using?

| If You Can Read, Thank A Teacher. If You Can Read It In English, Thank A Veteran That's what you do in a herd: you look out for each other. - Manny from Ice Age |

|

New to 3D printing, not new to 3D or tinkering. LulzBot Taz 5 Generic Chinese 50w 300x500 Laser Cutter/Engraver (Ebay:171066211150) Corel X7, Photoshop CS6, Lightroom 4, Modo, Hexagon, Bryce, Poser |

|

Re: State of PET filament printing February 14, 2015 08:10AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

Wolfie

So anyone using PET from recycled drink bottles? if so whats your filament extruder temp and also what bed and hot end temps are you using?

A quick google search told me it is about 210º extrusion temp for PET plastic. However, recycled PET bottles have different consistencies as they are recycled.

Bed should be around 60º/70º.

http://www.marinusdebeer.nl/

|

Re: State of PET filament printing February 14, 2015 02:09PM |

Registered: 9 years ago Posts: 52 |

The issue with PET is that it's not exactly stable.

Polyethylene Tertpthalate reacts with water, especially at it's glass transition temperature.

When it reacts with water it crosslinks, meaning it reaches out and grabs other parts of the plastic on a molecular level.

The crosslinking has a number of effects that can be both a blessing and a curse, depending on what properties you're looking for in the plastic.

PET can be made optically clear. This is why it's used in soda bottles. If you want a cheap, optically clear plastic PET is an excellent choice, if there is a low amount of crosslinking. Crosslinked chains of PET form crystalline impurities that alter the way light travels through PET, which is why soda bottles have a maximum life cycle. The more often PET is reused or recycled, the more the crosslinking accumulates, and the worse the optical clarity of the plastic. This reduction in optical clarity is referred to as hazing.

Virgin PET has a relatively low melting temperature.

The thing about Crosslinking that is often overlooked, and the reason why old soda bottles still have a value after they cannot be seen through, is that highly crosslinked PET is exceptionally strong. It regularly competes with Nylon in the textile industry, and PET fibers have many similar characteristics of Nylon fiber, but at a much reduced cost.

Processing the highly crosslinked fiber does require higher temperatures, but they have superior mechanical characteristics.

So... the quick summary here is that PET has a range of properties because it reacts with water. The more it reacts with water the stronger the plastic will become, but it will loose it's optical clarity as it is processed and handled, and operating your printer in a humid environment, or allowing a roll of PET filament to sit in moist conditions, is going to alter the properties of that filament.

Polyethylene Tertpthalate reacts with water, especially at it's glass transition temperature.

When it reacts with water it crosslinks, meaning it reaches out and grabs other parts of the plastic on a molecular level.

The crosslinking has a number of effects that can be both a blessing and a curse, depending on what properties you're looking for in the plastic.

PET can be made optically clear. This is why it's used in soda bottles. If you want a cheap, optically clear plastic PET is an excellent choice, if there is a low amount of crosslinking. Crosslinked chains of PET form crystalline impurities that alter the way light travels through PET, which is why soda bottles have a maximum life cycle. The more often PET is reused or recycled, the more the crosslinking accumulates, and the worse the optical clarity of the plastic. This reduction in optical clarity is referred to as hazing.

Virgin PET has a relatively low melting temperature.

The thing about Crosslinking that is often overlooked, and the reason why old soda bottles still have a value after they cannot be seen through, is that highly crosslinked PET is exceptionally strong. It regularly competes with Nylon in the textile industry, and PET fibers have many similar characteristics of Nylon fiber, but at a much reduced cost.

Processing the highly crosslinked fiber does require higher temperatures, but they have superior mechanical characteristics.

So... the quick summary here is that PET has a range of properties because it reacts with water. The more it reacts with water the stronger the plastic will become, but it will loose it's optical clarity as it is processed and handled, and operating your printer in a humid environment, or allowing a roll of PET filament to sit in moist conditions, is going to alter the properties of that filament.

|

Re: State of PET filament printing March 01, 2015 09:28PM |

Registered: 11 years ago Posts: 186 |

I have only tried the eSun PETG that Intservo sells. I print at 245C and my bed as been at 110 - though I see others are using less, so I may turn that down to save on warm up time. I am using 0.2mm layers, and am under the impression that it does not work optimally with much thinner layers.

I have no had any curl or cracking like I do with larger ABS objects. I even built a cabinet to help by ABS prints - but I don't like my motors and filament drive getting hot. I put two very high powered 24v fans on them and that seems to be good.

Does the PETG print as easily as PLA? Sort of, but slower. It takes longer for the bed to heat up, and they are saying to print at 30-60mm/sec. Because of this and the higher price (though eSun is only $32.40 on Amazon with that discount code), it does not obsolete PLA but I may not buy more ABS.

I print on glue stick - which is easier than tape, abs juice, hairspray, or Kapton for every filament, as far as I can tell. I am surprised that people are still using anything but glue. In fact I was surprised that my M2 came with a $20 roll of Kapton instead of a 50 cent glue stick that works better.

If PETG is inferior to XT or other polyesters, I would love to know and hope someone does a comparison. I will know a lot more in a few months but am buried with printing things that have to be printed.

[www.matter-replicator.com]

I have no had any curl or cracking like I do with larger ABS objects. I even built a cabinet to help by ABS prints - but I don't like my motors and filament drive getting hot. I put two very high powered 24v fans on them and that seems to be good.

Does the PETG print as easily as PLA? Sort of, but slower. It takes longer for the bed to heat up, and they are saying to print at 30-60mm/sec. Because of this and the higher price (though eSun is only $32.40 on Amazon with that discount code), it does not obsolete PLA but I may not buy more ABS.

I print on glue stick - which is easier than tape, abs juice, hairspray, or Kapton for every filament, as far as I can tell. I am surprised that people are still using anything but glue. In fact I was surprised that my M2 came with a $20 roll of Kapton instead of a 50 cent glue stick that works better.

If PETG is inferior to XT or other polyesters, I would love to know and hope someone does a comparison. I will know a lot more in a few months but am buried with printing things that have to be printed.

[www.matter-replicator.com]

|

Re: State of PET filament printing March 01, 2015 09:53PM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing March 02, 2015 04:16AM |

Admin Registered: 11 years ago Posts: 3,096 |

Clean up is similar to PLA, however, PLA breaks off easier. PETG is very flexible and tends to stretch out when you pull small strings off before breaking off. Also, sometimes you pull it into a thin thread so working with really tiny cutting pliers will be best. PETG is very flexible so it won't snap off so easily. If your layer adhesion is not so good, you can pull off the printed strings off of the printed part, it can delaminate in the reversed direction it was printed, this only happens if you print too cold.

The printed parts are very impact resistant and tend to 'bounce' off the floor when dropped. The walls are flexible, but can still break at random unexpected places when you bend them too far.

Printing on kapton works really well for me. Printing at 220º, bed at 70º for first layer and 55º for the rest of the layers.

Had a few times the filament would jam in my hotend, not sure why, the insulator was very cool and the filament didn't seem to form a plug. The power to the extruder drive is very strong and well balanced. It might be that the PETG has more friction with the PTFE liner of my bowden setup compared to PLA filament.

I couldn't find out much about the exact comparison in friction coefficient between PLA and PETG, of course the consistencies are different per manufacturer, but still there should be available numbers somewhere. I can only find it for PET and not for PETG.

The main property that stands out is the flexibility though, it's incredible, I have designed a few rings to be worn by someone and then I made them in PETG they felt better around my fingers because of the flex. Next up is a phone-clamp for on my race bike, I hope the flexibility will dampen the vibrations slightly, which is why I will built-in a spring-like holder topped with a rubber surface for extra grip and dampening.

http://www.marinusdebeer.nl/

The printed parts are very impact resistant and tend to 'bounce' off the floor when dropped. The walls are flexible, but can still break at random unexpected places when you bend them too far.

Printing on kapton works really well for me. Printing at 220º, bed at 70º for first layer and 55º for the rest of the layers.

Had a few times the filament would jam in my hotend, not sure why, the insulator was very cool and the filament didn't seem to form a plug. The power to the extruder drive is very strong and well balanced. It might be that the PETG has more friction with the PTFE liner of my bowden setup compared to PLA filament.

I couldn't find out much about the exact comparison in friction coefficient between PLA and PETG, of course the consistencies are different per manufacturer, but still there should be available numbers somewhere. I can only find it for PET and not for PETG.

The main property that stands out is the flexibility though, it's incredible, I have designed a few rings to be worn by someone and then I made them in PETG they felt better around my fingers because of the flex. Next up is a phone-clamp for on my race bike, I hope the flexibility will dampen the vibrations slightly, which is why I will built-in a spring-like holder topped with a rubber surface for extra grip and dampening.

http://www.marinusdebeer.nl/

|

Re: State of PET filament printing March 02, 2015 08:28AM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing March 02, 2015 10:52AM |

Registered: 9 years ago Posts: 20 |

Well. I got a Taz 5 instead of a Taz 4 and I am pretty ecstatic with it. The borosilicate glass bed covered with PEI upper surface requires (at least thus far) NO prep to print on. In fact the instruction maual recommends AGAINST most of the bed preps especially ABS juice.

So far I have printed with PLA, ABS, LayWood, Flex EcoPLA and 618 Nylon. In fact, the ABS adhears so well to the bed that I have broken a couple parts trying to get it OFF the bed. And of those I only failed to get adhesion of the Nylon. It wouldn't stick to the blue painter's tape nor would it stick to the bed. Have not tried PET yet. I will. I think there was some PET in the sampler pack I got from MakerGeeks but I haven't positively identified all the samples yet.

Personally I favor ABS so far. Yes it prints warmer. But you can acetone vapor smooth them for a glass finish. You can't do that with PLA without use of extremely toxic and hard to obtain chemicals. Don't know whats available to smooth PET, haven't researched it.

Edited 1 time(s). Last edit at 03/02/2015 10:55AM by Wolfie.

So far I have printed with PLA, ABS, LayWood, Flex EcoPLA and 618 Nylon. In fact, the ABS adhears so well to the bed that I have broken a couple parts trying to get it OFF the bed. And of those I only failed to get adhesion of the Nylon. It wouldn't stick to the blue painter's tape nor would it stick to the bed. Have not tried PET yet. I will. I think there was some PET in the sampler pack I got from MakerGeeks but I haven't positively identified all the samples yet.

Personally I favor ABS so far. Yes it prints warmer. But you can acetone vapor smooth them for a glass finish. You can't do that with PLA without use of extremely toxic and hard to obtain chemicals. Don't know whats available to smooth PET, haven't researched it.

Edited 1 time(s). Last edit at 03/02/2015 10:55AM by Wolfie.

| If You Can Read, Thank A Teacher. If You Can Read It In English, Thank A Veteran That's what you do in a herd: you look out for each other. - Manny from Ice Age |

|

New to 3D printing, not new to 3D or tinkering. LulzBot Taz 5 Generic Chinese 50w 300x500 Laser Cutter/Engraver (Ebay:171066211150) Corel X7, Photoshop CS6, Lightroom 4, Modo, Hexagon, Bryce, Poser |

|

Re: State of PET filament printing March 02, 2015 11:13PM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing March 03, 2015 04:03AM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: State of PET filament printing March 03, 2015 05:58AM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing March 03, 2015 09:26AM |

Admin Registered: 11 years ago Posts: 3,096 |

Well, it's not about dissolving it completely, acetone cleans the bed enough for a next print. ABS gets completely dissolved when you talk about big parts of plastic. PLA gets cleaned off of your bed with acetone just fine.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: State of PET filament printing April 25, 2015 01:02PM |

Registered: 8 years ago Posts: 7 |

I couldn't agree more with RSilvers regarding Glue Stick. I've had my 3D printer for 1 1/2 years and have tried 'everything', and nothing beats Glue Stick, so far. I use the Elmer's Extreme I haven't had as good results with the disappearing purple - and tried a cheaper one and it was a joke.

I heat my bed to 110 (I have the Rostock Max that has the 12 volt bed heater - that used to take forever plus a whole day just to get to 90 deg, I added a second PC power supply and run the 12 volt from one supply in Serial with 5 volt from the other supply, gives 17 volts without load, but while heating falls to about 13-14 volts, now i can get up to 110 in about 60-90 seconds).

Using Glue Stick glue only works good for me when the bed is heated. ABS sticks real good to it. And, when the bed cools down, the parts just fall off. Literally. With PETG the parts stick when the bed is hot, and when it cools generally I have to bump them or use a razor to pop them off, but, no force.

The first time I used glue stick was before I added the second power supply and i could only get the bed to 90 deg. At that temp ABS would not stick to it. It was useless. Once I got the bed hotter, it works like magic.

Previously for ABS i was using either ABS juice or Liquitex Acrylic Medium. The ABS juice or the liquid Acrylic would work TOO good at gluing the ABS down. It was hell getting the parts off. In fact, I ruined one side of my Borosilicate glass as many times pieces of glass popped off with the parts. When I switched to using Glue Sticks, I also made the mistake of trying to pry the parts off while the bed was still hot. That is a no no. You HAVE to wait for the bed to cool, then the ABS just pops off by itself.

When I started printing with PETG it was before I had the second power supply, so I didn't have 110 bed. At the time I found blue tape + hair spray worked - sort of ok. But, the parts stuck so well, again, it was hell getting them off, and either i would have to replace the tape every print, or print with torn tape. When I tried the glue stick at 110 bed temp, i'll never use anything else. Parts stick like - glue - while the bed is hot and your printing, and when it cools down, PETG doesn't pop off automatically like ABS, but, a slight bump or razor and off it comes.

I coat the glass with the glue stick while the glass is cold. First time you take it to 110 it 'cures' the glue. But the hot temps allow it to adhere to hot plastic. When it cool it releases. I print anywhere from 20 to 50 or more prints on just one coat of glue stick. In fact, if you don't scrap it off, it lasts 100's of prints, as long as you let the glass cool down before trying to remove the parts. If you need to remove the glue, EASY, I put it in my sink and soak it, then it washes right off.

NOW, regarding printing with PETG. I get STRINGs like crazy.... I have retraction set to 7mm and it doesn't seem to help. I print a 244 deg I used to use WINBO PETG ordering directly from China from AliExpress but, I just bought eSun off of Amazon with Prime shipping, got it in 2 days. Seems fine.

Just, how do i control the Stringyness ????

I heat my bed to 110 (I have the Rostock Max that has the 12 volt bed heater - that used to take forever plus a whole day just to get to 90 deg, I added a second PC power supply and run the 12 volt from one supply in Serial with 5 volt from the other supply, gives 17 volts without load, but while heating falls to about 13-14 volts, now i can get up to 110 in about 60-90 seconds).

Using Glue Stick glue only works good for me when the bed is heated. ABS sticks real good to it. And, when the bed cools down, the parts just fall off. Literally. With PETG the parts stick when the bed is hot, and when it cools generally I have to bump them or use a razor to pop them off, but, no force.

The first time I used glue stick was before I added the second power supply and i could only get the bed to 90 deg. At that temp ABS would not stick to it. It was useless. Once I got the bed hotter, it works like magic.

Previously for ABS i was using either ABS juice or Liquitex Acrylic Medium. The ABS juice or the liquid Acrylic would work TOO good at gluing the ABS down. It was hell getting the parts off. In fact, I ruined one side of my Borosilicate glass as many times pieces of glass popped off with the parts. When I switched to using Glue Sticks, I also made the mistake of trying to pry the parts off while the bed was still hot. That is a no no. You HAVE to wait for the bed to cool, then the ABS just pops off by itself.

When I started printing with PETG it was before I had the second power supply, so I didn't have 110 bed. At the time I found blue tape + hair spray worked - sort of ok. But, the parts stuck so well, again, it was hell getting them off, and either i would have to replace the tape every print, or print with torn tape. When I tried the glue stick at 110 bed temp, i'll never use anything else. Parts stick like - glue - while the bed is hot and your printing, and when it cools down, PETG doesn't pop off automatically like ABS, but, a slight bump or razor and off it comes.

I coat the glass with the glue stick while the glass is cold. First time you take it to 110 it 'cures' the glue. But the hot temps allow it to adhere to hot plastic. When it cool it releases. I print anywhere from 20 to 50 or more prints on just one coat of glue stick. In fact, if you don't scrap it off, it lasts 100's of prints, as long as you let the glass cool down before trying to remove the parts. If you need to remove the glue, EASY, I put it in my sink and soak it, then it washes right off.

NOW, regarding printing with PETG. I get STRINGs like crazy.... I have retraction set to 7mm and it doesn't seem to help. I print a 244 deg I used to use WINBO PETG ordering directly from China from AliExpress but, I just bought eSun off of Amazon with Prime shipping, got it in 2 days. Seems fine.

Just, how do i control the Stringyness ????

|

Re: State of PET filament printing April 25, 2015 01:20PM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing April 25, 2015 07:36PM |

Registered: 11 years ago Posts: 195 |

eSun PETG seems a little bit stringy and kinda brittle, at least compared to other vendors. However, the stringiness is minor, just occasional hair lines when the printed object has 2 separate areas and the hotend has to travel in between.

Never had to heat the bed up to 100+ degrees. I usually print small parts with no heated bed (room temperature) and larger parts at 50-60 (as a just in case measure, room is only 20 degrees or so; probably it wouldn't warp at lower bed temp either).

http://www.i3d.ro

Never had to heat the bed up to 100+ degrees. I usually print small parts with no heated bed (room temperature) and larger parts at 50-60 (as a just in case measure, room is only 20 degrees or so; probably it wouldn't warp at lower bed temp either).

http://www.i3d.ro

|

Re: State of PET filament printing April 27, 2015 04:41AM |

Registered: 9 years ago Posts: 104 |

|

Re: State of PET filament printing April 27, 2015 08:30AM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing April 27, 2015 01:51PM |

Registered: 9 years ago Posts: 104 |

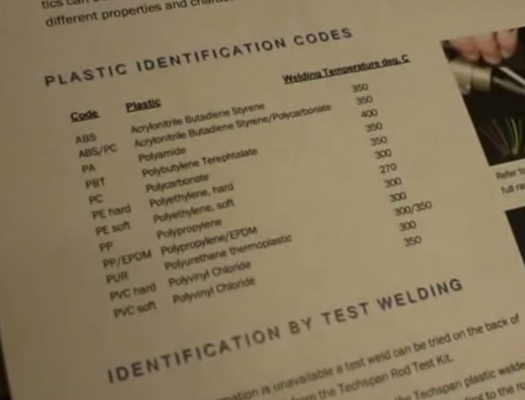

Oh cool, I hadn't heard about plastic welding. I found a video from 2010 with very many varieties of welding rods, perhaps ABS was commonly available because it's good for motorbike and car panels. found this. i don't know why the temperatures are so high, probably because it's a hot air welding.

Edited 1 time(s). Last edit at 04/27/2015 01:52PM by skynetprinter.

Edited 1 time(s). Last edit at 04/27/2015 01:52PM by skynetprinter.

|

Re: State of PET filament printing May 21, 2015 05:31PM |

Registered: 10 years ago Posts: 439 |

|

Re: State of PET filament printing May 29, 2015 09:50AM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing July 22, 2015 07:50AM |

Registered: 8 years ago Posts: 475 |

I am now printing PETG on a Fisher Delta (from RepRapPro). I face a few problems, but globally it works quite well.

I think there shall be no confusion between PET and PETG, they are not the same material. Sadly, the own variablility of PETG properties is huge and as usual, there is no data from manufacturer except recommended temperature. My spool is from RepRapper.

The temperature I use are quite high (note: my machine temperature is NOT calibrated, I have not measured the real temp).

I am using a temperature above 260°C (manufacturer tells from 210 to 260°C). I have made high speed tests with temperature up to 275°C. This is a bit too high and I think 270°C shall not be excedeed. 250°C was not working (delamination) but for this test my extrusion coefficient was too low. I'm still experimenting, but 260°C seems the lower limit.

I am printing on BuildTak. The adhesion on BuildTak is quite good if you impose a minimal width (I use 200% for the first layer, with 0.35 mm height) . Default width with Slic3R had NO adhesion at all. Speed 20 mm/s for the first layer.

No fan, and the main problem is it cools way fast.

Filament is quite flexible and I had to increase the extrusion coefficient compared to PLA. Yet I am using 1.08, but I shall test higher coef. [edit]

This does extrude very well but the hotend is leaky. I have no oozing however.

I use a bowden tube and I have yet to make tests on the retract, which I hope wil help with leaks.

The main problem is that as it harden very fast, you tend to have hard blobs which creates scratching. I use a high Z uplift (0.6), easy on a delta. Also, the leaks tend to accumulate on the hotend and you sometimes have relatively large filament remains which detach from the hotend and may creates incidents.

The Fisher do have a very special bed system, which makes it move easily under relatively light load and then reposition very accurately while the load disappear. This is a feature of great help with PETG. In fact, without that feature, I shall have lost most of my parts.

The dimensions are relatively accurate due to the fast cooling but the finition is not the best (it does not 'flatten').

Large hole size are well controlled, but it is quite difficult to get small hole size. It seems that the fast cooling tend to 'drag' the filament, hence cutting corners.

No warping at all (and I have no heatbed).

The speed shall not be too low (except first layer) and go below 50mm/s. speed below 80mm/s are more tolerant to incidents.

max speed tested : 180 mm/s for infill, 130mm/s for periphery. That works, but any deposition incident will end badly. If noticed (you hear the 'scratching'), a speed slowing may help recover the problem. Yet the 'safe' speed is around 80mm/s for 0.25 mm layer. Could be higher for thicker layer.

Smaller layer height are more difficult to manage (I assume this is because small filament section cools too fast) and speed shall be reduced on smaller height.

With proper temperature, the material cohesion is excellent et the resistance is very good.

It shall be noted that the fisher hotend is specific and works quite well. The nozzle and heatbreak are a unique piece, so there is no risk of leaks on the hotend. On the fisher, you shall disassemble the duct to remove part cooling (that's easy, one screw only).

I will try to add kapton on my hotend to limit the blob adhesion.

This is still very much a work in progress but I have began to compile data and define 'rules', though I am afraid they shall be quite machine specific.

If I can control the leaks and avoid the building of blobs on the hotend, it will be a superb material for engineering.

Regards, Pierre

Edited 1 time(s). Last edit at 07/22/2015 08:03AM by PRZ.

I think there shall be no confusion between PET and PETG, they are not the same material. Sadly, the own variablility of PETG properties is huge and as usual, there is no data from manufacturer except recommended temperature. My spool is from RepRapper.

The temperature I use are quite high (note: my machine temperature is NOT calibrated, I have not measured the real temp).

I am using a temperature above 260°C (manufacturer tells from 210 to 260°C). I have made high speed tests with temperature up to 275°C. This is a bit too high and I think 270°C shall not be excedeed. 250°C was not working (delamination) but for this test my extrusion coefficient was too low. I'm still experimenting, but 260°C seems the lower limit.

I am printing on BuildTak. The adhesion on BuildTak is quite good if you impose a minimal width (I use 200% for the first layer, with 0.35 mm height) . Default width with Slic3R had NO adhesion at all. Speed 20 mm/s for the first layer.

No fan, and the main problem is it cools way fast.

Filament is quite flexible and I had to increase the extrusion coefficient compared to PLA. Yet I am using 1.08, but I shall test higher coef. [edit]

This does extrude very well but the hotend is leaky. I have no oozing however.

I use a bowden tube and I have yet to make tests on the retract, which I hope wil help with leaks.

The main problem is that as it harden very fast, you tend to have hard blobs which creates scratching. I use a high Z uplift (0.6), easy on a delta. Also, the leaks tend to accumulate on the hotend and you sometimes have relatively large filament remains which detach from the hotend and may creates incidents.

The Fisher do have a very special bed system, which makes it move easily under relatively light load and then reposition very accurately while the load disappear. This is a feature of great help with PETG. In fact, without that feature, I shall have lost most of my parts.

The dimensions are relatively accurate due to the fast cooling but the finition is not the best (it does not 'flatten').

Large hole size are well controlled, but it is quite difficult to get small hole size. It seems that the fast cooling tend to 'drag' the filament, hence cutting corners.

No warping at all (and I have no heatbed).

The speed shall not be too low (except first layer) and go below 50mm/s. speed below 80mm/s are more tolerant to incidents.

max speed tested : 180 mm/s for infill, 130mm/s for periphery. That works, but any deposition incident will end badly. If noticed (you hear the 'scratching'), a speed slowing may help recover the problem. Yet the 'safe' speed is around 80mm/s for 0.25 mm layer. Could be higher for thicker layer.

Smaller layer height are more difficult to manage (I assume this is because small filament section cools too fast) and speed shall be reduced on smaller height.

With proper temperature, the material cohesion is excellent et the resistance is very good.

It shall be noted that the fisher hotend is specific and works quite well. The nozzle and heatbreak are a unique piece, so there is no risk of leaks on the hotend. On the fisher, you shall disassemble the duct to remove part cooling (that's easy, one screw only).

I will try to add kapton on my hotend to limit the blob adhesion.

This is still very much a work in progress but I have began to compile data and define 'rules', though I am afraid they shall be quite machine specific.

If I can control the leaks and avoid the building of blobs on the hotend, it will be a superb material for engineering.

Regards, Pierre

Edited 1 time(s). Last edit at 07/22/2015 08:03AM by PRZ.

|

Re: State of PET filament printing August 30, 2015 06:18AM |

Registered: 10 years ago Posts: 444 |

Update:

Non-warping, no smell, PET filament:

No shrinking or warping.

No smell.

No enclosure required.

Build plate can be heated or not (depends on brand).

Can be printed on glass without any glue*

Does not absorb water or moisture from air, so no storage container needed.

Clear color is the most transparent of all filament materials.

Is much "tougher" that PLA or ABS; will bend before breaking.

Uses about the same extruder temps as ABS.

Does not need a print cooling fan like PLA does.

Also known as Polyester, PETG, PETT, PET+

Is what most soda pop bottles are made of.

Does not degrade in water.

FDA approved in the USA for for food contact.

Not brittle.

Is the most recycled plastic.

Prices are coming down, and some are about the same as ABS.

Test model: [www.thingiverse.com]

Printing video: [vid.me]

Result video: [vid.me]

Current places carrying PET:

eSun - from Intservo, in North Carolina USA:

[intservo.com]

*opaque black is tested to print onto glass without any glue at all;

stays attached above 80C, and pops off at room temp.

eSun - from Intservo on Ebay, in North Carolina USA:

[www.ebay.com]

Alchement - from New Jersey, USA (choose PET from the menu):

[www.ebay.com]

RepRapperTech in Hong Kong:

[www.reprappertech.com]

Made Solid - from California USA:

[shop.madesolid.com]

Made Solid - from Matter Hackers, in California USA:

[www.matterhackers.com]

Made Solid - from Design Box, in Ohio USA:

[designbox3d.com]

Made Solid - From Australia:

[thinglab.com.au]

Colorfabb XT - from Netherlands:

[colorfabb.com]

Colorfabb XT - from Printed Solid, in Delaware USA:

[www.printedsolid.com]

Taulman T-Glase - from Matter Hackers, in California USA:

[www.matterhackers.com]

Taulman T-Glase - from MakerGeeks, in Missouri USA:

[www.makergeeks.com]

Taulman T-Glase - from Imprinte 3D, in France:

[www.imprimante3dfrance.com]

Eco PETG - from China (must email to order):

[www.ecoreprap.com]

Reprap PET - from Denmark:

[reprap.me]

Gizmo Dorks - in Los Angeles, USA:

[gizmodorks.com]

Various:

[www.microcenter.com]

3D Prima, from Sweden:

[www.3dprima.com]

Non-warping, no smell, PET filament:

No shrinking or warping.

No smell.

No enclosure required.

Build plate can be heated or not (depends on brand).

Can be printed on glass without any glue*

Does not absorb water or moisture from air, so no storage container needed.

Clear color is the most transparent of all filament materials.

Is much "tougher" that PLA or ABS; will bend before breaking.

Uses about the same extruder temps as ABS.

Does not need a print cooling fan like PLA does.

Also known as Polyester, PETG, PETT, PET+

Is what most soda pop bottles are made of.

Does not degrade in water.

FDA approved in the USA for for food contact.

Not brittle.

Is the most recycled plastic.

Prices are coming down, and some are about the same as ABS.

Test model: [www.thingiverse.com]

Printing video: [vid.me]

Result video: [vid.me]

Current places carrying PET:

eSun - from Intservo, in North Carolina USA:

[intservo.com]

*opaque black is tested to print onto glass without any glue at all;

stays attached above 80C, and pops off at room temp.

eSun - from Intservo on Ebay, in North Carolina USA:

[www.ebay.com]

Alchement - from New Jersey, USA (choose PET from the menu):

[www.ebay.com]

RepRapperTech in Hong Kong:

[www.reprappertech.com]

Made Solid - from California USA:

[shop.madesolid.com]

Made Solid - from Matter Hackers, in California USA:

[www.matterhackers.com]

Made Solid - from Design Box, in Ohio USA:

[designbox3d.com]

Made Solid - From Australia:

[thinglab.com.au]

Colorfabb XT - from Netherlands:

[colorfabb.com]

Colorfabb XT - from Printed Solid, in Delaware USA:

[www.printedsolid.com]

Taulman T-Glase - from Matter Hackers, in California USA:

[www.matterhackers.com]

Taulman T-Glase - from MakerGeeks, in Missouri USA:

[www.makergeeks.com]

Taulman T-Glase - from Imprinte 3D, in France:

[www.imprimante3dfrance.com]

Eco PETG - from China (must email to order):

[www.ecoreprap.com]

Reprap PET - from Denmark:

[reprap.me]

Gizmo Dorks - in Los Angeles, USA:

[gizmodorks.com]

Various:

[www.microcenter.com]

3D Prima, from Sweden:

[www.3dprima.com]

|

Re: State of PET filament printing August 30, 2015 09:06AM |

Registered: 8 years ago Posts: 5,232 |

I got mine from winbo-tech.com

Pretty happy with the flexibility of the parts, but a lot more cleaning is necessary after the print is done, compared to PLA.

I had little warping without brim sometimes.

-Olaf

Pretty happy with the flexibility of the parts, but a lot more cleaning is necessary after the print is done, compared to PLA.

I had little warping without brim sometimes.

-Olaf

|

Re: State of PET filament printing August 30, 2015 10:43AM |

Registered: 9 years ago Posts: 425 |

|

Re: State of PET filament printing August 30, 2015 12:05PM |

Registered: 8 years ago Posts: 150 |

I just tried some PETG from RepRap.me, My impression is that it takes a lot of energy to melt. The hot end temperature take a noticeable dip when the printing starts and at higher temperatures it struggle to keep up. Anyone noticed something similar?

EDIT: I print on unheated BuildTak and it stick reasonably well but not as good as PLA,

Cheers!

Edited 1 time(s). Last edit at 08/30/2015 12:08PM by SlowFoot.

EDIT: I print on unheated BuildTak and it stick reasonably well but not as good as PLA,

Cheers!

Edited 1 time(s). Last edit at 08/30/2015 12:08PM by SlowFoot.

Sorry, only registered users may post in this forum.