State of PET filament printing

Posted by RRuser

|

Re: State of PET filament printing August 31, 2015 07:57AM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing August 31, 2015 11:01AM |

Registered: 8 years ago Posts: 430 |

|

Re: State of PET filament printing September 01, 2015 03:03AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: State of PET filament printing September 06, 2015 01:53PM |

Registered: 8 years ago Posts: 5,232 |

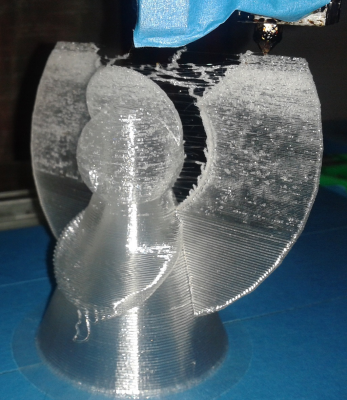

I just printed my first parts with my new Delta

Glass bed + blue painter tape + COLD bed + Brim = success

I wouldn´t have tried to print PETG without heated bed on my shake/rattle and hum Prusa I3, but with a steady bed ( or moving in z direction only ) it seems possible.

Who needs ABS anymore?

-Olaf

Glass bed + blue painter tape + COLD bed + Brim = success

I wouldn´t have tried to print PETG without heated bed on my shake/rattle and hum Prusa I3, but with a steady bed ( or moving in z direction only ) it seems possible.

Who needs ABS anymore?

-Olaf

|

Re: State of PET filament printing September 06, 2015 02:08PM |

Registered: 11 years ago Posts: 195 |

PETG is just slightly better then PLA and still inferior to ABS in terms of heat resistance.Quote

o_lampe

Who needs ABS anymore?

http://www.i3d.ro

|

Re: State of PET filament printing September 06, 2015 04:11PM |

Registered: 8 years ago Posts: 475 |

Unfortunately, this is not as simple as that.

The variability of PETG properties is important, and according different material datashets, the heat deflexion temperature varies from 69 to 99°C, which makes a huge difference.

This is why I am so worried that no PETG filament manufacturer supply datasheet. Is that so complex to carbon copy the producer datasheet ? That is really not acceptable.

The difference of hotend temperature I experienced between esun PETG and reprapper PETG is more than 20°C (the highest is esun, and in addition it is difficult to heat and have adhesion problems)

Sources for plastic properties :

[www.boedeker.com]

[www.matweb.com]

[www.matweb.com]

[www.thermoplasticprocesses.com]

Edited 1 time(s). Last edit at 09/06/2015 04:42PM by PRZ.

The variability of PETG properties is important, and according different material datashets, the heat deflexion temperature varies from 69 to 99°C, which makes a huge difference.

This is why I am so worried that no PETG filament manufacturer supply datasheet. Is that so complex to carbon copy the producer datasheet ? That is really not acceptable.

The difference of hotend temperature I experienced between esun PETG and reprapper PETG is more than 20°C (the highest is esun, and in addition it is difficult to heat and have adhesion problems)

Sources for plastic properties :

[www.boedeker.com]

[www.matweb.com]

[www.matweb.com]

[www.thermoplasticprocesses.com]

Edited 1 time(s). Last edit at 09/06/2015 04:42PM by PRZ.

|

Re: State of PET filament printing September 06, 2015 11:57PM |

Registered: 10 years ago Posts: 444 |

I'm now printing the eSun opaque black (which now is smooth filament; previous roll was textured), and it extrudes well at 245, but for small features that get hot, I'm trying cooling to 220 to reduce stringing.

I find the glass bed (no coatings at all) should be 100 first layer, and 80 or more afterwards. If 110 first layer, then it's very hard to remove (chipped some boro glass).

On cooling, the crackling starts at 50 or so. And at 30 it pops off.

Edited 1 time(s). Last edit at 09/07/2015 12:00AM by RRuser.

I find the glass bed (no coatings at all) should be 100 first layer, and 80 or more afterwards. If 110 first layer, then it's very hard to remove (chipped some boro glass).

On cooling, the crackling starts at 50 or so. And at 30 it pops off.

Edited 1 time(s). Last edit at 09/07/2015 12:00AM by RRuser.

|

Re: State of PET filament printing September 07, 2015 02:03AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: State of PET filament printing September 07, 2015 05:31AM |

Registered: 8 years ago Posts: 475 |

I print blue translucent and yellow translucent esun (edit: both textured).

The extrusion is not the problem, it is very easy at relatively low temperature.

The problem with esun is that if you are not sufficiently hot :

- The layer adhesion is poor

- The material is brittle

The material is difficult to heat and as soon as you have some flowrate, it cool down the filament and it makes like if the temperature is too low. With esun I am printing at a temperature 50°C over extrusion temperature, which is quite large. I could print 15°C lower, but at very low speed.

This is stringy, but with an agressive retract, the strings are very thin and that is ok.

In fact, my conclusion is that with esun, if it is not stringy, you are too low in temperature.

You have two easy indication of good temperature :

- The material shall be perfectly translucent and you shall see the former layer through the new deposited one

- Any beginning of filament whiting is an indication of insufficient temperature. it is interesting to look at, while accelerating. You see the filament becoming white if you increase the speed (by 20 to 30%). Immediate lost adhesion.

Printing opaque black prevent you to have those two indications and really I will not try to print this brand PETG in opaque filament.

In fact, it depends from your hotend. I have a Fisher, which does have an all-metal integral hotend, but with a standard heat zone length.

To print esun PETG, you need a quite long heating zone. With that, it will work at lower temperature.

My experience with reprapper PETG was very different, with a much lower temperature and a much better flowrate capability (maybe twice)

Edited 1 time(s). Last edit at 09/07/2015 05:34AM by PRZ.

The extrusion is not the problem, it is very easy at relatively low temperature.

The problem with esun is that if you are not sufficiently hot :

- The layer adhesion is poor

- The material is brittle

The material is difficult to heat and as soon as you have some flowrate, it cool down the filament and it makes like if the temperature is too low. With esun I am printing at a temperature 50°C over extrusion temperature, which is quite large. I could print 15°C lower, but at very low speed.

This is stringy, but with an agressive retract, the strings are very thin and that is ok.

In fact, my conclusion is that with esun, if it is not stringy, you are too low in temperature.

You have two easy indication of good temperature :

- The material shall be perfectly translucent and you shall see the former layer through the new deposited one

- Any beginning of filament whiting is an indication of insufficient temperature. it is interesting to look at, while accelerating. You see the filament becoming white if you increase the speed (by 20 to 30%). Immediate lost adhesion.

Printing opaque black prevent you to have those two indications and really I will not try to print this brand PETG in opaque filament.

In fact, it depends from your hotend. I have a Fisher, which does have an all-metal integral hotend, but with a standard heat zone length.

To print esun PETG, you need a quite long heating zone. With that, it will work at lower temperature.

My experience with reprapper PETG was very different, with a much lower temperature and a much better flowrate capability (maybe twice)

Edited 1 time(s). Last edit at 09/07/2015 05:34AM by PRZ.

|

Re: State of PET filament printing September 07, 2015 05:42AM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing September 07, 2015 06:18AM |

Registered: 8 years ago Posts: 475 |

DTA labs, who sells an adsjustable length hotend (Prometheus), have made a nice synthesis of an hotend adjustments:

[www.dta-labs.com]

Disclaimer: I bought a Prometheus, but it waits that I finish my new machine to be tested.

In short: long heating zone : strings , but if you don't have the long heat zone, you shall have very high temperature, so the strings are there in any case.

Another point is the retraction effectiveness.

High temperature decrease overhang capabilities

With my super high temperature, I am capable to do 40° overhangs, and I design my parts accordingly. The behaviour is a bit frightening, anyway, as you see the overhang displaced while the hotend is moving, but it is elastic and came back. In fact, as you shall not cool, the part remain quite flexible while you print and you see it moved by the hotend, but it print ok, anyway. Overhang shall have a minimum width of 2.5mm, if not, the pointy part will have problems.

A point I did not mentioned with esun. Absolutely NO cooling if you want proper adhesion. Not the smallest breathe.

With small parts, it could be delicate as they have no time to cool. I set in the slicer a minimum cooling time of 25 seconds between layers, and the absolute minimum shall be 20 sec. I think that is one tradeoff of the PETG.

Reprapper PETG, again, is more tolerant.

[www.dta-labs.com]

Disclaimer: I bought a Prometheus, but it waits that I finish my new machine to be tested.

In short: long heating zone : strings , but if you don't have the long heat zone, you shall have very high temperature, so the strings are there in any case.

Another point is the retraction effectiveness.

High temperature decrease overhang capabilities

With my super high temperature, I am capable to do 40° overhangs, and I design my parts accordingly. The behaviour is a bit frightening, anyway, as you see the overhang displaced while the hotend is moving, but it is elastic and came back. In fact, as you shall not cool, the part remain quite flexible while you print and you see it moved by the hotend, but it print ok, anyway. Overhang shall have a minimum width of 2.5mm, if not, the pointy part will have problems.

A point I did not mentioned with esun. Absolutely NO cooling if you want proper adhesion. Not the smallest breathe.

With small parts, it could be delicate as they have no time to cool. I set in the slicer a minimum cooling time of 25 seconds between layers, and the absolute minimum shall be 20 sec. I think that is one tradeoff of the PETG.

Reprapper PETG, again, is more tolerant.

|

Re: State of PET filament printing September 07, 2015 06:40AM |

Registered: 8 years ago Posts: 475 |

I assume that a lower melting temperature filament does have a lower deflexion temperature, but without any manufacturer data, this is only a bet.

I think that, till filament manufacturers get their fingers off (sorry for that, but that upsets me), you shall assume a deflexion temperature of 69°C for PETG.

I think that, till filament manufacturers get their fingers off (sorry for that, but that upsets me), you shall assume a deflexion temperature of 69°C for PETG.

|

Re: State of PET filament printing September 07, 2015 07:12AM |

Registered: 8 years ago Posts: 475 |

Another note about the oozing and retract for PETG.

All-metal hotend manufacturers recommends to have a retract length lower than the transition zone. So, they recommend generally a retract not exceeding 2mm. That may be the need for a direct extruder, but that don't work for 'bowden tube' extruders.

I had a bowden tube extruder, which while short (460mm), was a bit tortured. This means that the compression of the filament (and extension of the tube) is significant. PETG is much more flexible than PLA and significantly compress in the bowden tube, even if the extrusion pressure is lower. This means that with a bowden, you shall increase the retract value with an estimated value of the compression.

I get much better results and significant string reduction while increasing the retract from 2mm to 3.5 mm and increasing the rectract speed. Also, I retract for each move.

With the direct drive, the retraction speed I set was 150mm/s. Now, with a geared extruder, I reduced it to 80mm/s (since, I reduced the bowden length to 390mm and its route is more direct).

All-metal hotend manufacturers recommends to have a retract length lower than the transition zone. So, they recommend generally a retract not exceeding 2mm. That may be the need for a direct extruder, but that don't work for 'bowden tube' extruders.

I had a bowden tube extruder, which while short (460mm), was a bit tortured. This means that the compression of the filament (and extension of the tube) is significant. PETG is much more flexible than PLA and significantly compress in the bowden tube, even if the extrusion pressure is lower. This means that with a bowden, you shall increase the retract value with an estimated value of the compression.

I get much better results and significant string reduction while increasing the retract from 2mm to 3.5 mm and increasing the rectract speed. Also, I retract for each move.

With the direct drive, the retraction speed I set was 150mm/s. Now, with a geared extruder, I reduced it to 80mm/s (since, I reduced the bowden length to 390mm and its route is more direct).

|

Re: State of PET filament printing September 09, 2015 12:26AM |

Registered: 8 years ago Posts: 430 |

|

Re: State of PET filament printing September 13, 2015 04:51AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: State of PET filament printing September 13, 2015 01:27PM |

Registered: 8 years ago Posts: 100 |

makergeeks just started producing there own PETG, they are US based, reasonably priced at 24.95 Don't have a ton of PETG options yet, but they seem to add more new stuff all the time.

makergeeks

I have some on order (there was a 20% off Labor Day sale) so I haven't used it yet, but I have had good luck with their ABS and free shipping.

Only downside is THIS time they didn't ship my order immediately. Last couple times it was shipped asap, this one had a 4-7 day wait. Not sure if they got swamped with Labor day sale orders or there is another issue. Will be contacting them to check.

makergeeks

I have some on order (there was a 20% off Labor Day sale) so I haven't used it yet, but I have had good luck with their ABS and free shipping.

Only downside is THIS time they didn't ship my order immediately. Last couple times it was shipped asap, this one had a 4-7 day wait. Not sure if they got swamped with Labor day sale orders or there is another issue. Will be contacting them to check.

|

Re: State of PET filament printing September 16, 2015 11:16PM |

Registered: 10 years ago Posts: 444 |

|

Re: State of PET filament printing September 18, 2015 09:57PM |

Registered: 8 years ago Posts: 100 |

Quote

RRuser

I wonder if their Dark As Glass is opaque black.

I guess not the best time to order from them. So apparently their 20% labor day sale caused them to sell 800+ spools in no time, now they are backed up. Sent a message out to customers saying they are working 12hr shifts to get caught back up.

|

Re: State of PET filament printing May 28, 2016 03:17AM |

Registered: 8 years ago Posts: 3,525 |

I just bought a roll of PET/PETG?? to try [www.technologyoutlet.co.uk] but I am having a nightmare printing with it.

It stops extruding after 6-10 mins. Easy enough to clear this jam I just heat the extruder and pull the filament out, cut it then refeed it. But I haven't been able to print anything more than a test cube. I've tried hotend temps from 220-270. Bed temp 80 deg C and getting really amazing adhesion so no issues there.

I'm using a Kossel Mini, e3d V5 hotend, all metal throat, e3d titan extruder 'flying' so just 10cm bowden tube. I was printing abs on this setup before loading the PET without issue.

Any suggestions?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

It stops extruding after 6-10 mins. Easy enough to clear this jam I just heat the extruder and pull the filament out, cut it then refeed it. But I haven't been able to print anything more than a test cube. I've tried hotend temps from 220-270. Bed temp 80 deg C and getting really amazing adhesion so no issues there.

I'm using a Kossel Mini, e3d V5 hotend, all metal throat, e3d titan extruder 'flying' so just 10cm bowden tube. I was printing abs on this setup before loading the PET without issue.

Any suggestions?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: State of PET filament printing May 28, 2016 02:43PM |

Registered: 8 years ago Posts: 475 |

Your retract shall be quite low, especially with a very short Bowden. PET/PETG are more compressible than PLA, but they flow very easily, so with low compression force, you may need less retract.

I don't know if you can install a Volcano on a V5, but that is better for PET/PETG

Temperature may need to be very high, the max till you have oozing.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

I don't know if you can install a Volcano on a V5, but that is better for PET/PETG

Temperature may need to be very high, the max till you have oozing.

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

|

Re: State of PET filament printing May 28, 2016 02:46PM |

Registered: 8 years ago Posts: 3,525 |

The material oozes at around 200 deg C, but it jams very quickly at 220. At 250 it takes a little longer to jam. I am using only 1.2mm retract at high speed 150mm/s perhaps I should try slower retract?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: State of PET filament printing May 28, 2016 06:35PM |

Registered: 8 years ago Posts: 475 |

No, 1.2mm is ok and speed shall be the fastest possible, so 150mm/sec is ok (while some disagree with that)

Check when you are doing retracts, sometimes, too many retract are problematic, you may avoid retract on layer change and also avoid crossing perimeters.

Anyway, test at 280°C

For information, I have a PETG which needs 290°C, while others needs only 255°C

PET temperature may be similar to PETG, or slightly higher.

What is the flowrate (mm3/s) you are using (HxWx speed).

Check your hot-end fan, it may have problems. If you can, measure the hotend fins temperature

Once on PETG, I get repeated jams on a part after 20~30 min, which I got difficulties to avoid. The problem was there was a lot of retracts and the speed was unsufficient (too small part). so heat was going up in the hotend. I was baby-sitting the print and pushing manually the filament while extruder was skipping (direct drive extruder, so a bit weak).

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

Check when you are doing retracts, sometimes, too many retract are problematic, you may avoid retract on layer change and also avoid crossing perimeters.

Anyway, test at 280°C

For information, I have a PETG which needs 290°C, while others needs only 255°C

PET temperature may be similar to PETG, or slightly higher.

What is the flowrate (mm3/s) you are using (HxWx speed).

Check your hot-end fan, it may have problems. If you can, measure the hotend fins temperature

Once on PETG, I get repeated jams on a part after 20~30 min, which I got difficulties to avoid. The problem was there was a lot of retracts and the speed was unsufficient (too small part). so heat was going up in the hotend. I was baby-sitting the print and pushing manually the filament while extruder was skipping (direct drive extruder, so a bit weak).

Pierre

- Safety [reprap.org]

- Embedded help system for Duet and RepRap Firmware [forums.reprap.org]

- Enclosed delta printers Lily [rouzeau.net] and Lily Big [rouzeau.net]

- OpenScad delta printer simulator [github.com]

- 3D printing on my site [www.rouzeau.net]

|

Re: State of PET filament printing May 29, 2016 07:13AM |

Registered: 8 years ago Posts: 3,525 |

Thanks for the info it's really helpful. I switched back to abs to test the printer and it prints beautiful precise parts in this material. I needed to print some functional parts straightaway. Its works perfectly.

So it's some setting that's wrong. I can go to much higher temperatures I have an all metal hot end throat. So I will try hotter. My hot end fan is a sunon maglev unit and its the best fan I've ever used so I don't think it's that. I don't have thermal imaging (would like one though) but the hotend heatsink is cool to touch.

I've tried slow printing and faster printing to see if it makes a difference - not much.

The parts I'm printing are not that heavy on retracts anyway. The manufacturers details for this filament are on this listing [www.technologyoutlet.co.uk]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

So it's some setting that's wrong. I can go to much higher temperatures I have an all metal hot end throat. So I will try hotter. My hot end fan is a sunon maglev unit and its the best fan I've ever used so I don't think it's that. I don't have thermal imaging (would like one though) but the hotend heatsink is cool to touch.

I've tried slow printing and faster printing to see if it makes a difference - not much.

The parts I'm printing are not that heavy on retracts anyway. The manufacturers details for this filament are on this listing [www.technologyoutlet.co.uk]

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: State of PET filament printing June 02, 2016 06:28AM |

Registered: 10 years ago Posts: 40 |

I've just been doing some tests with a spool of PET-G from RS Components. It prints very at my normal PLA temperatures (hot end 200, heated bed 57). I've been printing directly on glass as I do with PLA with no problems of the job not sticking. As far as I can see there is no reason not to use it, and I've just ordered some more spools.

I use nothing on my glass bed, but I do give it a good clean at room temperature every time before printing. My method of cleaning is a technique that I have been using very successfully for nearly a year now. I spray the bed with small quantity of Antiqwax Mirror and Glass Cleaner (no connection!) which I get from my local hardware shop, and rub this solution all over the bed with a clean tissue until it 'squeeks', I then dry the surface with another clean tissue.

I use nothing on my glass bed, but I do give it a good clean at room temperature every time before printing. My method of cleaning is a technique that I have been using very successfully for nearly a year now. I spray the bed with small quantity of Antiqwax Mirror and Glass Cleaner (no connection!) which I get from my local hardware shop, and rub this solution all over the bed with a clean tissue until it 'squeeks', I then dry the surface with another clean tissue.

|

Re: State of PET filament printing June 02, 2016 08:48AM |

Registered: 8 years ago Posts: 3,525 |

I think one of the challenges with the filament I have above is that its sold as PET-G but labelled PET on the spool. So its a little unclear what it actually is (I am sure this applies to most filaments though). Perhaps I will return to it later or try it in a different machine.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: State of PET filament printing June 02, 2016 04:58PM |

Registered: 8 years ago Posts: 88 |

|

Re: State of PET filament printing September 15, 2016 05:54AM |

Registered: 8 years ago Posts: 4 |

Quote

SlowFoot

I just tried some PETG from RepRap.me, My impression is that it takes a lot of energy to melt. The hot end temperature take a noticeable dip when the printing starts and at higher temperatures it struggle to keep up. Anyone noticed something similar?

EDIT: I print on unheated BuildTak and it stick reasonably well but not as good as PLA,

Cheers!

Insulate your hot end - ideally a wrap of ceramic wool and kapton tape will give you MUCH more control over the hotend temp, and it will maintain much better - this is especially the case when using a print fan or any other draft is blowing on the hotend, and this effect is more marked at lower layer height, as the air from the fan doesn't normally have anywhere else to go but up!

Cheers!

Andy

:-)

Sorry, only registered users may post in this forum.

) for my son. It worked perfectly on the first try (250 hotend, 100 bed). Not important, it was the blue translucent flavor.

) for my son. It worked perfectly on the first try (250 hotend, 100 bed). Not important, it was the blue translucent flavor.