Hot End Cooling with Heated Chamber

Posted by TFinleyosu

|

Hot End Cooling with Heated Chamber November 20, 2014 12:36PM |

Registered: 9 years ago Posts: 48 |

I'm curious if you need to change the cooling techniques if you use a heated build chamber. If you're blowing 50-60°C air over the heat sink instead of 18-20°C ambient air, I can imagine this is going to impact the performance of the hot end. If so, what performance related issues will come up? Will the hot end start clogging up because it starts melting too early? Should the top of the hot end be as cool as possible (with a water cooled option or something), or will that start to effect the temp of the hot end and cause problems too. I know it's a balancing act, but I'd like to hear some advice before I "learn the hard way"

Can someone help clarify this for me?

Cheers

Can someone help clarify this for me?

Cheers

|

Re: Hot End Cooling with Heated Chamber November 20, 2014 01:38PM |

Admin Registered: 11 years ago Posts: 3,096 |

Depends on what you're printing. I assume it's PLA, which I have no experience with.

ABS in a closed chamber worked fine for me. The cooling was less efficient, but the only reason why I cooled my PEEK part of the J-head was because I didn't want any heat to creep up to the X-carriage.

I imagine that if you do this with PLA, you would need to get colder air in from outside the box, but with PLA you don't really need to print with an enclosure, so it would be a waste of time trying to do that

http://www.marinusdebeer.nl/

ABS in a closed chamber worked fine for me. The cooling was less efficient, but the only reason why I cooled my PEEK part of the J-head was because I didn't want any heat to creep up to the X-carriage.

I imagine that if you do this with PLA, you would need to get colder air in from outside the box, but with PLA you don't really need to print with an enclosure, so it would be a waste of time trying to do that

http://www.marinusdebeer.nl/

|

Re: Hot End Cooling with Heated Chamber November 20, 2014 02:05PM |

Registered: 10 years ago Posts: 469 |

Every single heated build chamber I have seen that went over 50c people used either forced air cooling, or water cooling. I am investigating forced air through a silicone tube. Hopefully the silicone tube will withstand the 60-70c range I plan to experiment with. However I will try my luck with no cooling at all. I run my hot end with no cooling now, and prefer it that way. If I can get away with no cooling at all it will stay that way.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Hot End Cooling with Heated Chamber November 20, 2014 02:26PM |

Registered: 12 years ago Posts: 2,470 |

I have an enclosure that has usually 50-55C°. I only cool the extruder and the top of the Hotend with a normal fan, using the air inside of the enclosure. I don't print PLA with that machine, but it works fine for ABS and PET.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Hot End Cooling with Heated Chamber November 20, 2014 04:25PM |

Registered: 9 years ago Posts: 48 |

Initially I was considering going with an E3D V6 hot end, but I really didn't like the mounting options and now this might be a problem. However, now I'm considering making my own heat sink with a water cooler jacket for an electric motor like this: LINK. Could be a pretty elegant solution.

In that case I might only need to buy something like the J-head nozzle and screw it into my custom heat sink. I can easily turn down some aluminum to fit inside the water jacket and tap it to fit the nozzle. Do you guys see any poor logic behind that?

In that case I might only need to buy something like the J-head nozzle and screw it into my custom heat sink. I can easily turn down some aluminum to fit inside the water jacket and tap it to fit the nozzle. Do you guys see any poor logic behind that?

|

Re: Hot End Cooling with Heated Chamber November 20, 2014 10:14PM |

Registered: 10 years ago Posts: 580 |

I think it's a good idea.

I think you won't need a water jacket tho, since water cooling is so much more efficient.

I think just a strait through channel on one side of a block (similar to how a heater cartridge fits on one side of a j-head) should be enough.

I may use this instead of ducted cooling as I'm doing now. I have a left over radiator setup from a water cooled PC that might work. Hmmm...

Kind of like this:

Water Cooled Jhead

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I think you won't need a water jacket tho, since water cooling is so much more efficient.

I think just a strait through channel on one side of a block (similar to how a heater cartridge fits on one side of a j-head) should be enough.

I may use this instead of ducted cooling as I'm doing now. I have a left over radiator setup from a water cooled PC that might work. Hmmm...

Kind of like this:

Water Cooled Jhead

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Hot End Cooling with Heated Chamber November 20, 2014 11:18PM |

Registered: 9 years ago Posts: 48 |

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 01:20AM |

Registered: 10 years ago Posts: 580 |

Yep, that is what it's for, the water will transfer the heat very well. The cooling block could be sized a bit bigger perhaps.

A couple of things to note:

If you use aluminum for the tube that connects the j-head to the rest, then that will transfer a LOT of heat - its a good conductor. You will have a lot harder time getting the hot end up to temp, and the thermal break will be a lot harder to cool.

It's better to use metal with lower thermal conductivity, you want a very sharp dropoff in temperature right above the j-head so filament does not soften there, but you do not want the cooling apparatus to cool the j-head itself - you do not want the cooler to be touching the j-head.

If you use a stainless tube, then you will need to find some with a smooth bore that is the right size, or ream it carefully (very slow RPM with Molly-Dee). Some stainless is very hard to machine (304), 303 is better.

For PLA they often use a Teflon tube as a liner also, because PLA softens a lot easier and sticks to the metal bore. A Teflon liner can help make the thermal break also. I've not made a hot-end like that tho.

You can insulate the J-Head by wrapping it with high temperature fiberglass tape.

Thermal conductivity:

Stainless <16

Brass 69-92

Aluminum 144 (Increases with heat)

Copper 213

Hope your build goes well!

A couple of things to note:

If you use aluminum for the tube that connects the j-head to the rest, then that will transfer a LOT of heat - its a good conductor. You will have a lot harder time getting the hot end up to temp, and the thermal break will be a lot harder to cool.

It's better to use metal with lower thermal conductivity, you want a very sharp dropoff in temperature right above the j-head so filament does not soften there, but you do not want the cooling apparatus to cool the j-head itself - you do not want the cooler to be touching the j-head.

If you use a stainless tube, then you will need to find some with a smooth bore that is the right size, or ream it carefully (very slow RPM with Molly-Dee). Some stainless is very hard to machine (304), 303 is better.

For PLA they often use a Teflon tube as a liner also, because PLA softens a lot easier and sticks to the metal bore. A Teflon liner can help make the thermal break also. I've not made a hot-end like that tho.

You can insulate the J-Head by wrapping it with high temperature fiberglass tape.

Thermal conductivity:

Stainless <16

Brass 69-92

Aluminum 144 (Increases with heat)

Copper 213

Hope your build goes well!

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 09:48AM |

Registered: 9 years ago Posts: 48 |

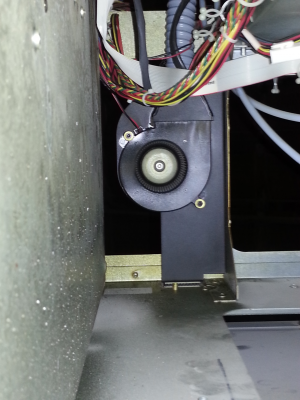

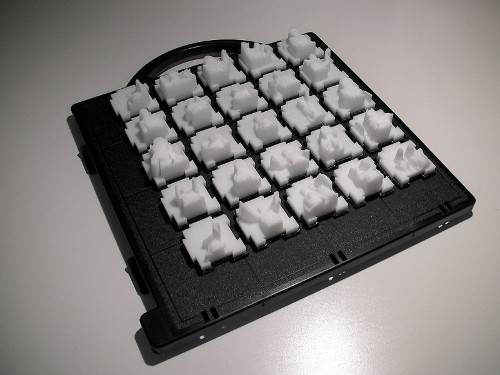

Now I feel like an idiot. I am rebuilding a scrapped industrial 3d printer and I didn't realize that it had forced ambient air onto the extruder. I hadn't pulled off the siding. I thought the grey tube was for electrical and the plastic difuser was on the bottom of the machine. I think I'll stick with this then. '

Thank you for your effort to help me out. Here is are some pics for someone in the future who needs to do an ambient forced air setup.

Thank you for your effort to help me out. Here is are some pics for someone in the future who needs to do an ambient forced air setup.

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 01:15PM |

Registered: 10 years ago Posts: 580 |

That's awesome.

Can you post what the blower model is, or post a pic of it's label?

Hope you don't mind if I have a few questions...

I'm looking for a lighter duct for mine, is there anything printed on the grey tube?

Can you describe it's diameter?

I'm wondering how stiff it is?

Does it have a metal or plastic ribbing?

Thanks!

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Can you post what the blower model is, or post a pic of it's label?

Hope you don't mind if I have a few questions...

I'm looking for a lighter duct for mine, is there anything printed on the grey tube?

Can you describe it's diameter?

I'm wondering how stiff it is?

Does it have a metal or plastic ribbing?

Thanks!

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 01:22PM |

Registered: 9 years ago Posts: 48 |

Happy to help or answer any question. I'll get the info tonight when I get home from work, but here are some more pics of the system that might answer your questions: [imgur.com]

I'm looking for a lighter duct for mine, is there anything printed on the grey tube? not that I can tell, but I'll look closer

Can you describe it's diameter? ~1", but I'll measure

I'm wondering how stiff it is? I dont have a good comparison.

Does it have a metal or plastic ribbing? I'll check

I'm looking for a lighter duct for mine, is there anything printed on the grey tube? not that I can tell, but I'll look closer

Can you describe it's diameter? ~1", but I'll measure

I'm wondering how stiff it is? I dont have a good comparison.

Does it have a metal or plastic ribbing? I'll check

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 01:24PM |

Registered: 9 years ago Posts: 48 |

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 01:26PM |

Registered: 10 years ago Posts: 580 |

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 03:07PM |

Registered: 9 years ago Posts: 48 |

Any chance you guys have a wiring diagram for a heated build chamber? I'm curious how its monitored and controlled? I'm new to this.

EDIT: I guess I'm really curious on the requirements of the hardware to connect a thermistor and hard it would be to adjust a firware configuration to monitor and control the heater and fans.

Edited 1 time(s). Last edit at 11/21/2014 03:25PM by TFinleyosu.

EDIT: I guess I'm really curious on the requirements of the hardware to connect a thermistor and hard it would be to adjust a firware configuration to monitor and control the heater and fans.

Edited 1 time(s). Last edit at 11/21/2014 03:25PM by TFinleyosu.

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 05:02PM |

Registered: 10 years ago Posts: 580 |

Right now I am only controlling the heat of the build plate, although I do have hardware thermostats on both the heated bed and in the chamber to protect against serious over temp.

I do plan on adding a thermistor for the chamber.There are extra thermistor inputs on my Rumba (although I plan on replacing that board with a Smoothie).

I do not know yet if my firmware (Repetier) can manage chamber temp. That would be the simplest.

It would be simple enough to program a separate Arduino to read the thermistor and have it do something if the temp goes over say 65C.

This is sparking all kinds of ideas. I like the idea of offloading it, then there can be a separate readout of the chamber temp, and an indication of what steps are being taken. It could turn off the heated bed with a relay, adjust the speed of an exhaust fan, etc.

Hmmm, more interesting things to think about.

I do plan on adding a thermistor for the chamber.There are extra thermistor inputs on my Rumba (although I plan on replacing that board with a Smoothie).

I do not know yet if my firmware (Repetier) can manage chamber temp. That would be the simplest.

It would be simple enough to program a separate Arduino to read the thermistor and have it do something if the temp goes over say 65C.

This is sparking all kinds of ideas. I like the idea of offloading it, then there can be a separate readout of the chamber temp, and an indication of what steps are being taken. It could turn off the heated bed with a relay, adjust the speed of an exhaust fan, etc.

Hmmm, more interesting things to think about.

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 05:32PM |

Registered: 9 years ago Posts: 48 |

Quote

Paul Wanamaker

Right now I am only controlling the heat of the build plate, although I do have hardware thermostats on both the heated bed and in the chamber to protect against serious over temp.

I do plan on adding a thermistor for the chamber.There are extra thermistor inputs on my Rumba (although I plan on replacing that board with a Smoothie).

I do not know yet if my firmware (Repetier) can manage chamber temp. That would be the simplest.

It would be simple enough to program a separate Arduino to read the thermistor and have it do something if the temp goes over say 65C.

This is sparking all kinds of ideas. I like the idea of offloading it, then there can be a separate readout of the chamber temp, and an indication of what steps are being taken. It could turn off the heated bed with a relay, adjust the speed of an exhaust fan, etc.

Hmmm, more interesting things to think about.

That's exactly what I was thinking about. Make it a subsystem with it's own arduino. You could choose to integrate it to the master controler, or not. the arduino could run a nice PID controller to get the turning. You could use the logic and controls from a Sous Vide cooker program with nice readouts. here is a tutorial. [learn.adafruit.com]

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 06:07PM |

Registered: 10 years ago Posts: 580 |

|

Re: Hot End Cooling with Heated Chamber November 21, 2014 10:12PM |

Registered: 9 years ago Posts: 35 |

I've thought about this for a while. Confucious says, "Don't kill a mosquitoe with a cannon ball." I look at the fundamental thermodynamic problem and see a simple solution. It's easy to add exotic cooling systems to your build and fix the problem, because so many of the hot ends on the market are reliant on fans.

If you have a hot end that isn't reliant on a fan in the first place, you don't need to worry about it. You have active cooling and passive cooling. Being that the vast majority of hot ends rely on active cooling (fans) to cool the hot end, the natural inclination is to add more fans. But the real question is, how do you make a hot end work, in a heated environment, without a fan?

I added an insulating chamber to one of my printers with a passively cooled hot end and I never had a problem with it. So the real problem in your solution is... why are you trying to solve a problem where fans don't work... with more fans?

If you have a hot end that isn't reliant on a fan in the first place, you don't need to worry about it. You have active cooling and passive cooling. Being that the vast majority of hot ends rely on active cooling (fans) to cool the hot end, the natural inclination is to add more fans. But the real question is, how do you make a hot end work, in a heated environment, without a fan?

I added an insulating chamber to one of my printers with a passively cooled hot end and I never had a problem with it. So the real problem in your solution is... why are you trying to solve a problem where fans don't work... with more fans?

|

Re: Hot End Cooling with Heated Chamber November 22, 2014 12:05AM |

Registered: 9 years ago Posts: 48 |

|

Re: Hot End Cooling with Heated Chamber November 24, 2014 11:47PM |

Registered: 9 years ago Posts: 48 |

Quote

Paul Wanamaker

I like it.

Thanks for sharing the link.

Paul,

What I found interesting is that the Stratasys printer did not use a heated bed. It just used a heated chamber at ~55°C and would not start printing until everything was up to temp.

Have you ever tried using just the heated chamber and not the heated bed?

|

Re: Hot End Cooling with Heated Chamber November 25, 2014 12:27AM |

Registered: 10 years ago Posts: 580 |

I believe the reason they could do this is because they used a special foam block to print on, so there is no problem with adhesion.

Of course they got to charge quite a bit for every one. The bottom of the print would not be smooth however.

Another thread here had info on this, and using a specific foam available from Home Depot.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Of course they got to charge quite a bit for every one. The bottom of the print would not be smooth however.

Another thread here had info on this, and using a specific foam available from Home Depot.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Hot End Cooling with Heated Chamber November 25, 2014 12:33AM |

Registered: 9 years ago Posts: 48 |

The printer I have used a removable plastic bed that clipped into the platform

I think the trick might have been that they always printed a layer of the support material down prior to the ABS.

I think the trick might have been that they always printed a layer of the support material down prior to the ABS.

|

Re: Hot End Cooling with Heated Chamber November 30, 2014 06:42AM |

Registered: 14 years ago Posts: 351 |

Quote

Paul Wanamaker

I do plan on adding a thermistor for the chamber.There are extra thermistor inputs on my Rumba (although I plan on replacing that board with a Smoothie).

I do not know yet if my firmware (Repetier) can manage chamber temp. That would be the simplest.

When you move to Smoothieboard, adding heated chamber control will be as simple as adding a few lines to your configuration file.

Smoothie supports an arbitrary number of temperature control modules, just declare them in config : [smoothieware.org]

|

Re: Hot End Cooling with Heated Chamber November 30, 2014 02:54PM |

Registered: 10 years ago Posts: 580 |

Thanks Arthur. Good to know.

I'm really looking forward to the a smoothie type controller after I do a few other changes.

I just had to re-flash the USB chip for a second time on my Rumba, and I have problems with the processor being too slow, so I'm over it...

I would really rather buy a smoothie except that I want the higher voltage drivers in the Azteeg x5.

I'm really looking forward to the a smoothie type controller after I do a few other changes.

I just had to re-flash the USB chip for a second time on my Rumba, and I have problems with the processor being too slow, so I'm over it...

I would really rather buy a smoothie except that I want the higher voltage drivers in the Azteeg x5.

|

Re: Hot End Cooling with Heated Chamber November 30, 2014 03:00PM |

Registered: 14 years ago Posts: 351 |

Hey.

Azteeg X5 supports the same voltage as Smoothieboard ( we advertise 12-24V because it's what's most common, but I've run Smoothieboard at 32V and azteeg says 12-30V )

If you are reffering to current, be careful : Smoothieboard has 2A drivers -and- can actually handle up to 2A due to having a large cooling area. The azteeg X5 is quite small, so I'm not sure it can handle the rated 2.5A ( I recommend you check that with Panacutt ).

Cheers.

Azteeg X5 supports the same voltage as Smoothieboard ( we advertise 12-24V because it's what's most common, but I've run Smoothieboard at 32V and azteeg says 12-30V )

If you are reffering to current, be careful : Smoothieboard has 2A drivers -and- can actually handle up to 2A due to having a large cooling area. The azteeg X5 is quite small, so I'm not sure it can handle the rated 2.5A ( I recommend you check that with Panacutt ).

Cheers.

|

Re: Hot End Cooling with Heated Chamber November 30, 2014 05:17PM |

Registered: 10 years ago Posts: 580 |

Thank you Arthur,

I think it will work fine.

I have a smoothie in the cart... But I'm wondering what kind of display with SD card slot is available/supported like the Reprap Discount Smart LCD controller?

I want to be able to run it off an SD card. What I'd really like is a SmoothiePanel.

I think it will work fine.

I have a smoothie in the cart... But I'm wondering what kind of display with SD card slot is available/supported like the Reprap Discount Smart LCD controller?

I want to be able to run it off an SD card. What I'd really like is a SmoothiePanel.

|

Re: Hot End Cooling with Heated Chamber November 30, 2014 05:25PM |

Registered: 14 years ago Posts: 351 |

Hi !

Smoothie supports the RRD GLCD : [smoothieware.org]

You can actually get an adapter board for it at robotseed.com if you want to plug it easily into your Smoothieboard.

Also, Smoothiepanel is coming, soon

Smoothie supports the RRD GLCD : [smoothieware.org]

You can actually get an adapter board for it at robotseed.com if you want to plug it easily into your Smoothieboard.

Also, Smoothiepanel is coming, soon

Sorry, only registered users may post in this forum.