Makerspace kit printer

Posted by LoboCNC

|

Makerspace kit printer November 24, 2014 09:06PM |

Registered: 10 years ago Posts: 564 |

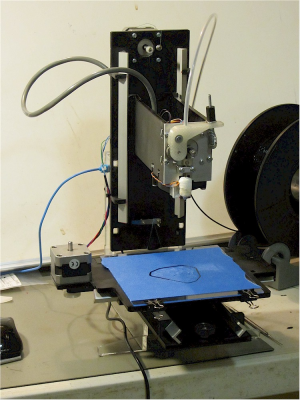

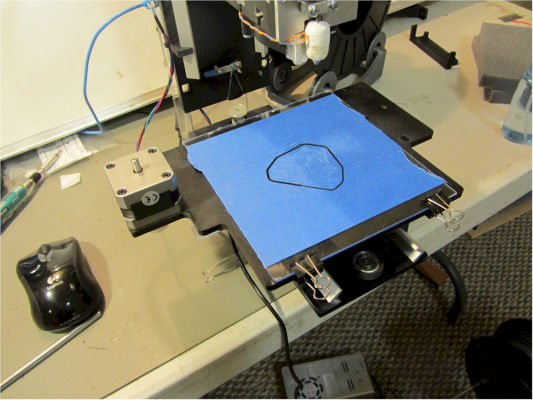

I've designed a new, very simple printer that my local makerspace (Bellingham Foundry) can manufacture and sell as a kit. They have a nice big laser cutter, so most of the parts can be cut out of 6mm acrylic, which is a lot faster than 3D printing parts. (Although there are also a couple of 3D printed parts as well.) There are 3 simple machined aluminum parts (hot-end nozzle, extruder plate, tube clamp) that will probably need to be made at a local shop. The complete material cost for plastic, motors, electronics, etc., should be around $150, so the idea is to sell fairly inexpensive kits and then also offer workshops for helping people put them together. It has moderately decent performance - the treefrog at the bottom was printed at ~70mm/sec. I'm particularly pleased with the Spectra fishing line Z-axis drive which seems very accurate. (The frog was printed with 0.08mm layers.) I'm hoping that other makespaces might also be interested. I should have a package of part files together shortly.

http://youtu.be/RkITj05fH5w

Printed at 0.08mm layer thickness

http://youtu.be/RkITj05fH5w

Printed at 0.08mm layer thickness

|

Re: Makerspace kit printer November 24, 2014 09:57PM |

Registered: 10 years ago Posts: 564 |

In the first video I posted above, I selected the option to let youtube stabilize the video, with pretty interesting results. Here's a copy of the video without stabilization:

http://youtu.be/Z0rfS4ym5Lc

I'm leaving the original one up because it makes the printer look way more sophisticated, with it's micro-articulated hot-end.

http://youtu.be/Z0rfS4ym5Lc

I'm leaving the original one up because it makes the printer look way more sophisticated, with it's micro-articulated hot-end.

|

Re: Makerspace kit printer November 25, 2014 01:28PM |

Registered: 10 years ago Posts: 26 |

|

Re: Makerspace kit printer November 25, 2014 02:20PM |

Registered: 10 years ago Posts: 564 |

|

Re: Makerspace kit printer November 25, 2014 06:23PM |

Registered: 11 years ago Posts: 313 |

|

Re: Makerspace kit printer November 25, 2014 07:49PM |

Registered: 10 years ago Posts: 564 |

|

Re: Makerspace kit printer November 25, 2014 08:51PM |

Registered: 10 years ago Posts: 105 |

|

Re: Makerspace kit printer November 25, 2014 09:06PM |

Registered: 10 years ago Posts: 564 |

Quote

runninfarmer

Are the axes just 608 bearings riding in aluminum angle? Or is the angle steel? I'm always on the hunt for different linear systems and like what you've done with the angle. Is there any play or binding with axes?

Yes, they are plain 608 bearings running in anodized aluminum angle. The attached photo shows the carriage holding the bearings. I've laser cut parallelogram flexures into the mounting points for two of the bearings so they end up spring-loaded against one of the rails. They are very smooth with zero play and no binding at all. They are not hugely stiff, but they seem stiff enough to produce pretty nice prints at reasonable acceleration values.

|

Re: Makerspace kit printer November 26, 2014 06:15AM |

Registered: 9 years ago Posts: 47 |

|

Re: Makerspace kit printer November 27, 2014 05:58AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Makerspace kit printer November 27, 2014 11:41AM |

Registered: 10 years ago Posts: 564 |

Quote

A2

Is that an aluminum nozzle, Nichrome wire heated hot end, and Teflon tape wrapped? How did you connected the nozzle to the tubing?

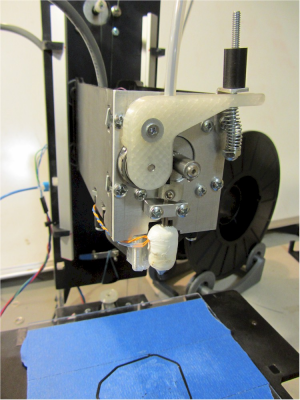

Yes, exactly - aluminum nozzle, wrapped with 2 layers of kapton tape, nichrome wire heater and with PTFE pipe tape overwrap. At some point, I'd like to try using hard anodized aluminum and see if I can eliminate the first layer of kapton tape.

The stainless tube is press fit into the nozzle. The tube is nominal 0.125" OD, 0.100 ID from McMaster-Carr, and is just slightly oversized. Using a 0.126" dia reamer, I get a nice press fit. I've made other nozzles the same way but where I've glued the tube in with JB Weld.

|

Re: Makerspace kit printer December 01, 2014 01:01PM |

Registered: 10 years ago Posts: 105 |

|

Re: Makerspace kit printer December 01, 2014 01:34PM |

Registered: 10 years ago Posts: 564 |

Quote

runninfarmer

Cool hotend, I like it. Does it work well with PLA? I couldn't see from the pics but does it have a fan cooling it? What diameter and length of nichrome wire did you use? Thanks for your info!

Yes, I mostly print with PLA. The stainless steel tube has a PTFE liner, so the PLA feeds smoothly. The aluminum plate holding the motor and the clamp for the stainless tube acts as a big heat sink. You can't see it very well but underneath there is a blower with a duct concentrating the air on the nozzle, but the duct also has a small port blowing air up onto the aluminum plate. This old post has a discussion of this setup.

I am using 30ga nichrome wire with a 12 ohm resistance. This works out to about 18" of wire.

|

Re: Makerspace kit printer December 01, 2014 02:44PM |

Registered: 10 years ago Posts: 869 |

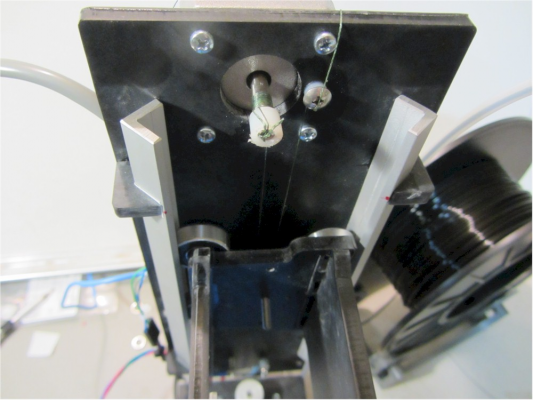

What happens when the fishing line breaks? Or power is interrupted?Quote

LoboCNC

Thanks. The nice thing about this drive is that there are no components (couplers, pulleys, screws, etc.) that can introduce the periodic errors that would result in Z axis banding. And the drive train components only cost about $0.35.

|

Re: Makerspace kit printer December 01, 2014 03:11PM |

Registered: 10 years ago Posts: 564 |

Quote

cdru

What happens when the fishing line breaks? Or power is interrupted?

If the fishing line breaks, all hell breaks loose. However, the carriage weights about 1lb and is supported by 2 strands of 30# braided fishing line. You should be able to tolerate a significant amount of fraying (which is visible) before it breaks altogether.

If the power is interrupted, not much happens because the unpowered detent torque of the stepper is enough to support the weight of the carriage.

Sorry, only registered users may post in this forum.