new guy in the deep end

Posted by aparkin

|

new guy in the deep end December 31, 2014 09:09AM |

Registered: 9 years ago Posts: 43 |

hi im tony from the uk

and i have little to no engineering and design back ground but i love the idea of 3d printing and want to build a home self use 3d printer i believe with a little help and a lot more reading i can build a reprap Prusa i3 having read so many bad reports about bad kits i thought i would find and order all the parts i need my self.To start off with inexpensive materials 12 mm mdf for frame and upgrade later down the line if required

now ive been reading a lot on wiki as this forum is good at helping individual problems but i cart find any good build logs and i also cart find a new guys are induce your self part to the forum (oups off topic)

anyway i believe i still got a couple off weeks of reading to do about Prusa i3 building (anyone no of any build logs are anything remotely useful that would help please don't be shy link away many thanks in advance )

so i wanted to ask where can i skimp (save money) on bits and replace as i get more adventuress and what's best not to skimp on as it will save problems and more expensive in the future

p.s my son cart wait to design models of this beloved game's and book heroes he is 13 and well up for it

and i have little to no engineering and design back ground but i love the idea of 3d printing and want to build a home self use 3d printer i believe with a little help and a lot more reading i can build a reprap Prusa i3 having read so many bad reports about bad kits i thought i would find and order all the parts i need my self.To start off with inexpensive materials 12 mm mdf for frame and upgrade later down the line if required

now ive been reading a lot on wiki as this forum is good at helping individual problems but i cart find any good build logs and i also cart find a new guys are induce your self part to the forum (oups off topic)

anyway i believe i still got a couple off weeks of reading to do about Prusa i3 building (anyone no of any build logs are anything remotely useful that would help please don't be shy link away many thanks in advance )

so i wanted to ask where can i skimp (save money) on bits and replace as i get more adventuress and what's best not to skimp on as it will save problems and more expensive in the future

p.s my son cart wait to design models of this beloved game's and book heroes he is 13 and well up for it

|

Re: new guy in the deep end December 31, 2014 01:49PM |

Registered: 10 years ago Posts: 439 |

You might find this kit of interest for the Mendel90. [forums.reprap.org]

or, if you want an enclosure and LED display [www.think3dprint3d.com]

The build instructions are excellent. I haven't seen a bad report on the forums for either.

or, if you want an enclosure and LED display [www.think3dprint3d.com]

The build instructions are excellent. I haven't seen a bad report on the forums for either.

|

Re: new guy in the deep end December 31, 2014 06:41PM |

Registered: 11 years ago Posts: 1,592 |

|

Re: new guy in the deep end December 31, 2014 06:42PM |

Registered: 10 years ago Posts: 56 |

I'm gonna be completely honest: building a stock Prusa i3 is kinda a nightmare. I went for the Box Frame variant. It took me months, and I ended up with the wrong extruder, no method to level the bed, and a Y-Axis length of 100mm. I've since fixed it, and it's printing beautifully, but it was a pain. The number one kit that I'd recommend would be the Prusa i3v kit from Makerfarm. There's different sizes, but you shouldn't need anything above the 10" kit. If you're intent on building your own from scratch, I'd go with the Prusa i3 Rework, or, even better, the fully parametric Mendel90. There's a Python script for the 90 where you enter the dimensions and sizes you want, and the script spits out a full bill of materials and all the needed STL (3D model) files.

|

Re: new guy in the deep end December 31, 2014 08:40PM |

Registered: 9 years ago Posts: 43 |

thanks Waitaki great looking video save some reading time

@ solomondg

ive not considered many other options for 1 i don't really not the strengths and weakness of them except for what's posted on wiki and i have read a lot of night mare builds on the i3 ill look into the mendel90 at only a quick glance it looks prity much the same as the i3 ecept a little older and more basic (maybe a good place to start then )

thanks if you have any links to good build threads on the mendel90 would be gratefully revived and also would a e3d hot end fit a mendel90 as it seems people rave about them and sinces more people get put off by hot end problems than anything other on the build

@ solomondg

ive not considered many other options for 1 i don't really not the strengths and weakness of them except for what's posted on wiki and i have read a lot of night mare builds on the i3 ill look into the mendel90 at only a quick glance it looks prity much the same as the i3 ecept a little older and more basic (maybe a good place to start then )

thanks if you have any links to good build threads on the mendel90 would be gratefully revived and also would a e3d hot end fit a mendel90 as it seems people rave about them and sinces more people get put off by hot end problems than anything other on the build

|

Re: new guy in the deep end January 01, 2015 11:15PM |

Registered: 11 years ago Posts: 661 |

While there are some i3 kits where the quality is lacking, building an i3 in and of itself isn't too difficult. The important part is managing your expectations and knowing the limits of your experience. From you post it looks like you have that part covered. I'd suggest a kit from a well known source but you can also source your own. If you source your own use build docs/logs that are consistent and well documented. Find one you like a stick with it. As far as skimping on anything, I'd suggest building a smaller printer at first with a basic feature set as the way to save money rather than trying to get less expensive components of lesser quality. Often people will try to save on electronics or hotends only to find later the money they saved wasn't really a savings as they have to buy another.

|

Re: new guy in the deep end January 02, 2015 01:46AM |

Registered: 10 years ago Posts: 439 |

The Mendel90 build instructions are linked to at

[forums.reprap.org]

Here is one way to fit an E3D:

[www.thingiverse.com]

[forums.reprap.org]

Here is one way to fit an E3D:

[www.thingiverse.com]

|

Re: new guy in the deep end January 02, 2015 12:22PM |

Registered: 9 years ago Posts: 43 |

on the heat beds I'm going to use one of these

[www.ebay.co.uk]

I'm going for i3 box frame so ill use wood to make the bed then use the screw and springs to keep the hot bed off the wood (no fires please) but do i use a sheet of glass over the top of the hot bed are print onto the above hot bed

and do i need to cover the wood with heat proof substance are is that a step to far

[www.ebay.co.uk]

I'm going for i3 box frame so ill use wood to make the bed then use the screw and springs to keep the hot bed off the wood (no fires please) but do i use a sheet of glass over the top of the hot bed are print onto the above hot bed

and do i need to cover the wood with heat proof substance are is that a step to far

|

Re: new guy in the deep end January 02, 2015 01:46PM |

Registered: 9 years ago Posts: 43 |

apart from the above question I'm think I'm almost done with the build i except not actual done it yet but understand how to and have files and video stacked for when i do start now i need to look at software

i'm looking at free software to start off what's recommended any one found and use any nice programs out there yes i know i now get a lot more reading to do

i'm looking at free software to start off what's recommended any one found and use any nice programs out there yes i know i now get a lot more reading to do

|

Re: new guy in the deep end January 03, 2015 11:48AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

solomondg

I'm gonna be completely honest: building a stock Prusa i3 is kinda a nightmare. I went for the Box Frame variant. It took me months, and I ended up with the wrong extruder, no method to level the bed, and a Y-Axis length of 100mm. I've since fixed it, and it's printing beautifully, but it was a pain. The number one kit that I'd recommend would be the Prusa i3v kit from Makerfarm. There's different sizes, but you shouldn't need anything above the 10" kit. If you're intent on building your own from scratch, I'd go with the Prusa i3 Rework, or, even better, the fully parametric Mendel90. There's a Python script for the 90 where you enter the dimensions and sizes you want, and the script spits out a full bill of materials and all the needed STL (3D model) files.

Just wanted to say, this is a very subjective experience. I've seen plenty of people not having any trouble with building the Prusa i3 box frame.

http://www.marinusdebeer.nl/

|

Re: new guy in the deep end January 08, 2015 05:50AM |

Registered: 9 years ago Posts: 43 |

quick question i was just putting together a shopping list of parts to go and buy but it seem that the Prusa i3 has different lengths for the rods no 2 build instructions are the same can any shed any light on this

and if any has any good suppliers of smooth rods please share all i can find is alli express and ebay

THANKS IN ADVANCE

and if any has any good suppliers of smooth rods please share all i can find is alli express and ebay

THANKS IN ADVANCE

|

Re: new guy in the deep end January 11, 2015 05:46PM |

Registered: 9 years ago Posts: 43 |

stepper motors anyone got any recommendations for the i3 model are dose it have to be the 1.2amp 43n seem a little hard to find with buying them in packs of ten and being in the uk ill get hit for 30 quid custom charges

any help here would be great are do i have a little scope on the motors would these do the job for instance

[www.banggood.com]

any help here would be great are do i have a little scope on the motors would these do the job for instance

[www.banggood.com]

|

Re: new guy in the deep end January 12, 2015 10:59PM |

Registered: 9 years ago Posts: 120 |

Hi aparkin,

NEMA17 motors with around 40 N/cm of torque are the sort that I got, and they are probably the most recommended sort (more on the RepRap wiki). I can buy them for 5 for 48 USD total on eBay- and that's where I got a set. Highly recommend scooping some of those.

I started out with Slic3r as my slicer, Pronterface as my interface, and Marlin as my firmware. They have worked quite well for me. I would go and check out their websites to learn more about what they do. (Lots of explanation is probably better explained there.)

I enjoy the 3D modeling quite a bit, and I would surely recommend OpenSCAD as the CAD editor of choice. It took me very little time to pick up, it's intuitive, and I'd put money on it that your son could start to design things with it easily. If he's ever worked with programming it should come naturally, and otherwise it's still very simple.

Let me know what happens

Blue Ice

blog at [contemporarymaker.com]

NEMA17 motors with around 40 N/cm of torque are the sort that I got, and they are probably the most recommended sort (more on the RepRap wiki). I can buy them for 5 for 48 USD total on eBay- and that's where I got a set. Highly recommend scooping some of those.

Quote

aparkin

when i do start now i need to look at software

i'm looking at free software to start off what's recommended any one found and use any nice programs out there yes i know i now get a lot more reading to do

I started out with Slic3r as my slicer, Pronterface as my interface, and Marlin as my firmware. They have worked quite well for me. I would go and check out their websites to learn more about what they do. (Lots of explanation is probably better explained there.)

I enjoy the 3D modeling quite a bit, and I would surely recommend OpenSCAD as the CAD editor of choice. It took me very little time to pick up, it's intuitive, and I'd put money on it that your son could start to design things with it easily. If he's ever worked with programming it should come naturally, and otherwise it's still very simple.

Let me know what happens

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 13, 2015 10:13AM |

Registered: 9 years ago Posts: 124 |

I'm one of the new guys and I'm ankle deep right now getting all the pieces together for my Prusa I3 Rework. I didn't buy a kit - I've been buying everything pieces at a time. I have the majority of the parts with the exception of the endstops, heatbed, hotend and thermistors.

One question I have (of many I'm sure) concerns the extruder assembly of the printed parts I purchased. I have attached some pictures of the part I'm referring to. It looks like I will have to cut the highlighted areas away in order to fit the idler assembly on the main extruder body. Is this correct?

I'm pretty sure I need to, but I want to knwo if anyone else has had to do this with the printed part. Many thanks in advance.

One question I have (of many I'm sure) concerns the extruder assembly of the printed parts I purchased. I have attached some pictures of the part I'm referring to. It looks like I will have to cut the highlighted areas away in order to fit the idler assembly on the main extruder body. Is this correct?

I'm pretty sure I need to, but I want to knwo if anyone else has had to do this with the printed part. Many thanks in advance.

|

Re: new guy in the deep end January 13, 2015 10:40AM |

Registered: 9 years ago Posts: 329 |

Quote

One question I have (of many I'm sure) concerns the extruder assembly of the printed parts I purchased. I have attached some pictures of the part I'm referring to. It looks like I will have to cut the highlighted areas away in order to fit the idler assembly on the main extruder body. Is this correct?

Yes. These are supports that facilitated printing the raised portions of the part.

-David

Find me online at:

Thingiverse

Instructables.com

Check out my FolgerTech Prusa i3 (plexi) at MindRealm.net

|

Re: new guy in the deep end January 13, 2015 02:52PM |

Registered: 9 years ago Posts: 124 |

|

Re: new guy in the deep end January 13, 2015 02:59PM |

Registered: 9 years ago Posts: 120 |

Yep, I ran into this too. Only after looking at pictures of the finished part did I realize that these parts can get pulled off. I believe there are also support pieces on the Extruder Idler that can be removed.

Blue Ice

blog at [contemporarymaker.com]

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 13, 2015 05:39PM |

Registered: 9 years ago Posts: 124 |

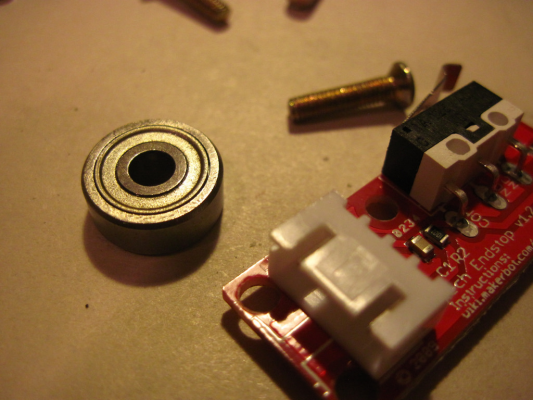

OOPS!! I think I messed up on the X-End idler assembly.

The bearing was putting too much outward pressure on the printed part and I didn't want it to split, so I removed the tapered inner rings. I had to do this for the Y-Axis idler to get it to fit, so I figured the same for this part.

Unfortunately, the bearing didn't sit centered like I thought it should. Back to the instructions and.... I thought a 608ZZ bearing went there! WRONG!

I was supposed to put a 624ZZ bearing there!! OKAY, let's try that then.... Uhhh.. it looks like the hardware kit I got doesn't have a 624ZZ bearing. Instead I have 2 623ZZ bearings.

In my searches I found that the different builds on the printed parts effected the rod length, but I thought the bearings would be the same throughout the different builds. My mistake again.

I went ahead and put both 623ZZ bearings in place of the one 624ZZ bearing and temporarily put one of the M3 screws on to see how well it fit. Both of the 623ZZ bearings seem to fit really good, however I don't have the right length M3 screw. Shouldn't be too hard to find one. Does anyone see a problem with using the two 623ZZ bearings in place of the one 624ZZ bearing. It seems that the main difference is the diameter of screw needed to hold it centered in place...

Edited 1 time(s). Last edit at 01/14/2015 07:53AM by psneddon.

The bearing was putting too much outward pressure on the printed part and I didn't want it to split, so I removed the tapered inner rings. I had to do this for the Y-Axis idler to get it to fit, so I figured the same for this part.

Unfortunately, the bearing didn't sit centered like I thought it should. Back to the instructions and.... I thought a 608ZZ bearing went there! WRONG!

I was supposed to put a 624ZZ bearing there!! OKAY, let's try that then.... Uhhh.. it looks like the hardware kit I got doesn't have a 624ZZ bearing. Instead I have 2 623ZZ bearings.

In my searches I found that the different builds on the printed parts effected the rod length, but I thought the bearings would be the same throughout the different builds. My mistake again.

I went ahead and put both 623ZZ bearings in place of the one 624ZZ bearing and temporarily put one of the M3 screws on to see how well it fit. Both of the 623ZZ bearings seem to fit really good, however I don't have the right length M3 screw. Shouldn't be too hard to find one. Does anyone see a problem with using the two 623ZZ bearings in place of the one 624ZZ bearing. It seems that the main difference is the diameter of screw needed to hold it centered in place...

Edited 1 time(s). Last edit at 01/14/2015 07:53AM by psneddon.

|

Re: new guy in the deep end January 14, 2015 02:15AM |

Registered: 9 years ago Posts: 288 |

I'm just working my way through ooznest's Prusa i3 kit.

and so far I'm inputted as the wiring is all terminated in connectors that can only go in one way.

The only problem I have is that I am struggling to handle the hex socket M3 bolts as I'm struggling to hold the tiny allen key supplied (two thin for me to keep hold.)

and so far I'm inputted as the wiring is all terminated in connectors that can only go in one way.

The only problem I have is that I am struggling to handle the hex socket M3 bolts as I'm struggling to hold the tiny allen key supplied (two thin for me to keep hold.)

|

Re: new guy in the deep end January 14, 2015 06:58AM |

Registered: 9 years ago Posts: 43 |

Quote

GRAYWOLF

I'm just working my way through ooznest's Prusa i3 kit.

and so far I'm inputted as the wiring is all terminated in connectors that can only go in one way.

The only problem I have is that I am struggling to handle the hex socket M3 bolts as I'm struggling to hold the tiny allen key supplied (two thin for me to keep hold.)

?? use pliers are swop them out for cross head screws 3m screws are easy to find

are buy hex screw drivers

[www.ebay.co.uk]

[www.ebay.co.uk]

|

Re: new guy in the deep end January 14, 2015 08:01AM |

Registered: 9 years ago Posts: 43 |

Quote

Blue Ice

I started out with Slic3r as my slicer, Pronterface as my interface, and Marlin as my firmware. They have worked quite well for me. I would go and check out their websites to learn more about what they do. (Lots of explanation is probably better explained there.)

I enjoy the 3D modeling quite a bit, and I would surely recommend OpenSCAD as the CAD editor of choice. It took me very little time to pick up, it's intuitive, and I'd put money on it that your son could start to design things with it easily. If he's ever worked with programming it should come naturally, and otherwise it's still very simple.

Let me know what happens

hi the slicer is great just what i was missing ive had a 5 minuet go on openSCAD but for me it seem very windows 98 style with its interface i do like the simplistic of [tinkercad.com] its very simply and child like so ill keep looking for a good C A D p.s ill sit down and spend a few hours going over openscad and see if gets any better but from what i have read its all type in commands hopefully ill find something more intuitive

but thanks for the help ive found a stepper motor in germany for 48 quid (no import tax from with in the E,U there 1.7 amps and 40n so all should be good i do have 1 last question which is the easiest filament to start off with

|

Re: new guy in the deep end January 14, 2015 11:44AM |

Registered: 9 years ago Posts: 124 |

Any idea what size hobbed bolt this extruder takes? All of the build lists I've looked at don't give any lengths or information where the hobbed portion begins.

[forums.reprap.org]

[forums.reprap.org]

|

Re: new guy in the deep end January 14, 2015 12:10PM |

Registered: 9 years ago Posts: 120 |

Quote

aparkin

hi the slicer is great just what i was missing ive had a 5 minuet go on openSCAD but for me it seem very windows 98 style with its interface

Yeah, I know what you mean. It's pretty formulaic at first, but after using it for quite a while, I'm convinced that this format is the best way to lay things out. I've used other FOSS CAD editros and had quite a bit of experience with 3D design, so I understand that it seems a little imposing for someone starting out.

Quote

aparkin

i do like the simplistic of [tinkercad.com] its very simply and child like so ill keep looking for a good C A D

I just took a peek at TinkerCAD and it looks like an excellent place to start.

Quote

aparkin

p.s ill sit down and spend a few hours going over openscad and see if gets any better but from what i have read its all type in commands hopefully ill find something more intuitive

Yep, it's all type in commands.

Quote

aparkin

but thanks for the help ive found a stepper motor in germany for 48 quid (no import tax from with in the E,U there 1.7 amps and 40n so all should be good i do have 1 last question which is the easiest filament to start off with

PLA is definitely the easiest filament to start out with. Pick out a color that isn't white or black (hard to see close up imperfections) and look for a 1kg spool. Also make sure that the diameter (1.75 or 3 mm) matches your hotend.

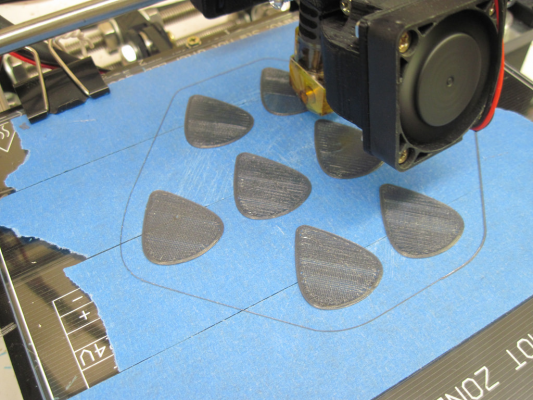

PLA is easy because it doesn't require a heated bed if it is printed on blue painter's tape (which it sticks to quite well). It's easier to start small when you begin using your printer for the first time. Here is a print that I did with this method when I started with my printer:

After you feel comfortable with this, you can start using the heated bed at about 70 degrees and have the printer print on the bare glass with PLA. Gives you nice shiny bottoms on your parts.

ABS is a whole different beast. I kept with PLA for 3 months before I even touched the stuff

By the way, make sure that the glass for the heated bed is at least 3mm thick and preferably borosilicate. Standard glass may crack with all of the heating and cooling. I got my borosilicate glass panel for about $40 USD.

Good luck!

Edited 2 time(s). Last edit at 01/14/2015 12:31PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 14, 2015 12:30PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

OOPS!! I think I messed up on the X-End idler assembly.

The bearing was putting too much outward pressure on the printed part and I didn't want it to split, so I removed the tapered inner rings. I had to do this for the Y-Axis idler to get it to fit, so I figured the same for this part.

Unfortunately, the bearing didn't sit centered like I thought it should. Back to the instructions and.... I thought a 608ZZ bearing went there! WRONG!

I was supposed to put a 624ZZ bearing there!! OKAY, let's try that then.... Uhhh.. it looks like the hardware kit I got doesn't have a 624ZZ bearing. Instead I have 2 623ZZ bearings.

In my searches I found that the different builds on the printed parts effected the rod length, but I thought the bearings would be the same throughout the different builds. My mistake again.

I went ahead and put both 623ZZ bearings in place of the one 624ZZ bearing and temporarily put one of the M3 screws on to see how well it fit. Both of the 623ZZ bearings seem to fit really good, however I don't have the right length M3 screw. Shouldn't be too hard to find one. Does anyone see a problem with using the two 623ZZ bearings in place of the one 624ZZ bearing. It seems that the main difference is the diameter of screw needed to hold it centered in place...

Yes, I think it does pose a problem. The two bearings together may keep the rotating outer rings of the bearings pressed up against the walls of the part, causing them not to spin. You can just use one of those bearings, but I would really just do it right the first time and order a replacement or call your kit manufacturer. It'll be a pain to loosen the belt and take off the part off the leadscrews once you want to put in the right bearing in the future.

This is what my setup looks like- as you can see the bearing is properly sized for the screw and it is not squeezed in the part. I would just order one- the wait will be worth the avoidance of the pain of fixing a bad build later.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 14, 2015 12:55PM |

Registered: 9 years ago Posts: 43 |

thankyou blue ice

i did not even think about the glass ill ask my local glass cutter what he's got in stock i'm not rushing and most of my bits are on order from china and 28 postage days away ill keep you posted and keep reading and learning thanks for all your help to you and everyone that's answered my question

i did not even think about the glass ill ask my local glass cutter what he's got in stock i'm not rushing and most of my bits are on order from china and 28 postage days away ill keep you posted and keep reading and learning thanks for all your help to you and everyone that's answered my question

|

Re: new guy in the deep end January 14, 2015 06:14PM |

Registered: 9 years ago Posts: 124 |

Thanks again for the feedback. I'll have to see if the seller would sell me just that part. I'm getting a lot of good information and advice from your answers to everyone.

I'm still waiting for my smooth and threaded rods to come in the mail. As I mentioned in a previous post, I have the majority of the parts, however I still need to get a hot end, heated bed, glass (or painters tape) thermistors and end stops - not counting some PLA.

The build calls for a J Head hot end. I know there are different hole sizes, but I'm at a loss as to which one or type/brand to buy. By my understanding, PLA is generally 1.75 mm in diameter and the hole in the hot end can be anywhere from 0.3mm to 0.5mm - correct?

What hot end would you recommend for the first time builder and what size hole? I was expecting to pay around $30 to $40 - is that a reasonable expectation?

As an example, I saw one like this listed for sale :

[www.ebay.com]

I don't want to buy junk that will cause problems or something that won't fit.

Edited 1 time(s). Last edit at 01/14/2015 06:16PM by psneddon.

I'm still waiting for my smooth and threaded rods to come in the mail. As I mentioned in a previous post, I have the majority of the parts, however I still need to get a hot end, heated bed, glass (or painters tape) thermistors and end stops - not counting some PLA.

The build calls for a J Head hot end. I know there are different hole sizes, but I'm at a loss as to which one or type/brand to buy. By my understanding, PLA is generally 1.75 mm in diameter and the hole in the hot end can be anywhere from 0.3mm to 0.5mm - correct?

What hot end would you recommend for the first time builder and what size hole? I was expecting to pay around $30 to $40 - is that a reasonable expectation?

As an example, I saw one like this listed for sale :

[www.ebay.com]

I don't want to buy junk that will cause problems or something that won't fit.

Edited 1 time(s). Last edit at 01/14/2015 06:16PM by psneddon.

|

Re: new guy in the deep end January 14, 2015 06:31PM |

Registered: 9 years ago Posts: 43 |

For me in the UK it has to be this 1[e3d-online.com]. I know its expencive but it has great reviews and this is the part that is going to make are break your machine don't skimp on motors are hot end the rest can be up graded as you work and learn I'm sure some 1 can point you at a good 1 on your side of the pond

Edited 1 time(s). Last edit at 01/14/2015 06:32PM by aparkin.

Edited 1 time(s). Last edit at 01/14/2015 06:32PM by aparkin.

|

Re: new guy in the deep end January 14, 2015 09:10PM |

Registered: 9 years ago Posts: 120 |

Quote

aparkin

thankyou blue ice

i did not even think about the glass ill ask my local glass cutter what he's got in stock i'm not rushing and most of my bits are on order from china and 28 postage days away ill keep you posted and keep reading and learning thanks for all your help to you and everyone that's answered my question

No problem! Glad you are getting things worked out.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 14, 2015 10:18PM |

Registered: 9 years ago Posts: 120 |

Quote

psneddon

Thanks again for the feedback. I'll have to see if the seller would sell me just that part. I'm getting a lot of good information and advice from your answers to everyone.

I'm still waiting for my smooth and threaded rods to come in the mail. As I mentioned in a previous post, I have the majority of the parts, however I still need to get a hot end, heated bed, glass (or painters tape) thermistors and end stops - not counting some PLA.

You're welcome

You will need glass either way, even if you use the painter's tape. It's pretty crucial to getting smooth prints.

You will need glass either way, even if you use the painter's tape. It's pretty crucial to getting smooth prints.Are you using Marlin for your firmware? You might want to pick out a thermistor in the table to make it easier on yourself. I use Marlin and it works fantastically- so just let me know what you are doing and I can explain for you.

Quote

psneddon

The build calls for a J Head hot end. I know there are different hole sizes, but I'm at a loss as to which one or type/brand to buy. By my understanding, PLA is generally 1.75 mm in diameter and the hole in the hot end can be anywhere from 0.3mm to 0.5mm - correct?

PLA comes in both 1.75mm and 3mm, as do most filaments. If you want a direct drive extruder (explanation of how a direct drive and bowden extruder work), then I would recommend 3mm. It's better for filaments that need constant pressure to get in the extruder. If you want a bowden drive extruder, then I would get 1.75mm. It's better for when you want to feed in filament from a longer distance.

I would go for 3mm filament- it allows you to print bendy materials like nylon and ninjaflex/filaflex more easily, and the filament is easier to deal with because it is thicker. I'm also using it right now, because the Prusa i3 (Rework and standard) were designed for it. In the end, though, it's not a huge deal which one you pick, 1.75mm or 3mm. There's no difference in how they look or print in the end.

The hole in the hotend is usually about that size. 0.35 to 0.45 mm provides a good balance between layer details and print speed.

Quote

psneddon

What hot end would you recommend for the first time builder and what size hole? I was expecting to pay around $30 to $40 - is that a reasonable expectation?

As an example, I saw one like this listed for sale :

[www.ebay.com]

I don't want to buy junk that will cause problems or something that won't fit.

Quote

aparkin

For me in the UK it has to be this 1[e3d-online.com]. I know its expencive but it has great reviews and this is the part that is going to make are break your machine don't skimp on motors are hot end the rest can be up graded as you work and learn I'm sure some 1 can point you at a good 1 on your side of the pond

I've heard great things about that hotend. I would have bought one of those instead of a J-Head if I could have when I got my kit. Really, I would just get that one and stick with it- there's no reason to get an inferior hotend. It also allows you to print at ridiculously high temperatures, which leaves room for you to experiment with other materials in the future.

Edited 2 time(s). Last edit at 01/14/2015 10:20PM by Blue Ice.

Blue Ice

blog at [contemporarymaker.com]

|

Re: new guy in the deep end January 14, 2015 11:47PM |

Registered: 9 years ago Posts: 124 |

More great info! Many thanks.

Yes, I'm using Marlin firmware. I was looking it over and seems to be one of the standard firmwares for 3d printing. I was able to test out my Ramps 1.4 and stepper motors and have managed to get Pronterface working the motors without having anything else hooked up - still dabbling and piecing it all together.

I also purchased a RepRap Full Graphic LCD 12864 display but it's not working properly. I found that a lot of people were having problems with this display on their I3's - unfortunately, I didn't know that until after I bought it.

I was finally able to get the display to come on properly and I was able to access the first submenu, but the scroll knob doesn't work. So, I've put that aside for now and am waiting on my rods to arrive so I can get down to business building my I3 Rework.

The hot end you recommend is like this I believe?

[www.ebay.com]

Unfortunately, the ones I find are all Bowden versions and I think I need to get a Wade style. I know it's probably one of the better hot ends out there right now, but were there any major problems using a standard J head with your printer? I expect a huge learning curve getting the printer to print properly and I also want to start with 1.75mm and work up to 3mm maybe later.

So, a .4mm hole for the extruder head would be a good selection then?

Thanks again for the feedback and information!

Yes, I'm using Marlin firmware. I was looking it over and seems to be one of the standard firmwares for 3d printing. I was able to test out my Ramps 1.4 and stepper motors and have managed to get Pronterface working the motors without having anything else hooked up - still dabbling and piecing it all together.

I also purchased a RepRap Full Graphic LCD 12864 display but it's not working properly. I found that a lot of people were having problems with this display on their I3's - unfortunately, I didn't know that until after I bought it.

I was finally able to get the display to come on properly and I was able to access the first submenu, but the scroll knob doesn't work. So, I've put that aside for now and am waiting on my rods to arrive so I can get down to business building my I3 Rework.

The hot end you recommend is like this I believe?

[www.ebay.com]

Unfortunately, the ones I find are all Bowden versions and I think I need to get a Wade style. I know it's probably one of the better hot ends out there right now, but were there any major problems using a standard J head with your printer? I expect a huge learning curve getting the printer to print properly and I also want to start with 1.75mm and work up to 3mm maybe later.

So, a .4mm hole for the extruder head would be a good selection then?

Thanks again for the feedback and information!

Sorry, only registered users may post in this forum.