Dat gap

Posted by UkIan

So I've been playing with 3d printing since,... summer? I forget. I started with PLA, then switched to ABS a while a go, and just came back to PLA. I had forgotten everything and my first PLA prints made me immediately assume I had duff filament. It wasn't, it was a duff me.

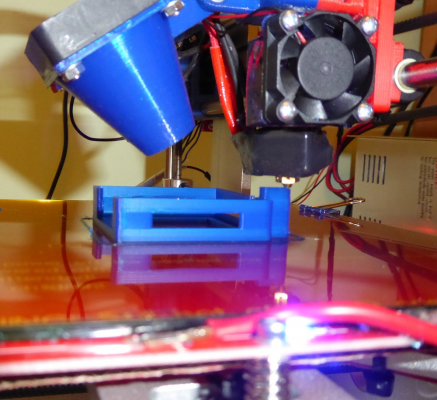

So I have some questions: I needed a print fan and as you can see in the picture below I've got a 40mm one funnelling its woeful output onto my print. As you can also see, look at that bridging!! How clean is that??

The thing being printed, besides having amazing bridging, is for a radial "blower" fan. Why don't any of these little fans blow?? I've got 25,30,40,50 and 60mm fans, none of them produce anything like the gale I was hoping for.

Do they make fans that blow? I'm just not getting it.

So I have some questions: I needed a print fan and as you can see in the picture below I've got a 40mm one funnelling its woeful output onto my print. As you can also see, look at that bridging!! How clean is that??

The thing being printed, besides having amazing bridging, is for a radial "blower" fan. Why don't any of these little fans blow?? I've got 25,30,40,50 and 60mm fans, none of them produce anything like the gale I was hoping for.

Do they make fans that blow? I'm just not getting it.

|

Re: Dat gap January 04, 2015 03:35PM |

Registered: 13 years ago Posts: 1,797 |

it is likely they work fine. you will want to look for fans that have a high CFM (cubic feet per minute) air flow. my guess is the average is about Air Flow: 6.7 CFM, also use the term "HIGH-VELOCITY'

something like this may work, [www.allelectronics.com]

it has 19.7 CFM,

as a side note, I find that cooling with a duct that surrounds the extruder provides the best results, because the reason for the need for the high flow is to cool the pla that is far away on the other side, otherwise it would never get cool air. I do fall to the fact that it is easier to put a high speed fan in place, that to have a 360 deg duct survive long term.

Edited 2 time(s). Last edit at 01/04/2015 03:40PM by jamesdanielv.

something like this may work, [www.allelectronics.com]

it has 19.7 CFM,

as a side note, I find that cooling with a duct that surrounds the extruder provides the best results, because the reason for the need for the high flow is to cool the pla that is far away on the other side, otherwise it would never get cool air. I do fall to the fact that it is easier to put a high speed fan in place, that to have a 360 deg duct survive long term.

Edited 2 time(s). Last edit at 01/04/2015 03:40PM by jamesdanielv.

|

Re: Dat gap January 04, 2015 04:31PM |

Registered: 9 years ago Posts: 376 |

That's quite cool actually (no pun intended). I've got a 60X20 fan which has a throughput of 19cfm, but even that didn't feel particularly pushy. I wonder how heavy the motor in a hand held dyson weighs... Probably a lot thinking about it

I'm designing a 360 degree duct at the moment, which will go onto the new X carriage I'm (also) designing. Think3dPrint3d have a modified Mendel 90 version that will fit an e3d v6 (hotend I'm currently using) which I considered hacking, but it's quite an interesting design to pull off in OpenScad

I'm designing a 360 degree duct at the moment, which will go onto the new X carriage I'm (also) designing. Think3dPrint3d have a modified Mendel 90 version that will fit an e3d v6 (hotend I'm currently using) which I considered hacking, but it's quite an interesting design to pull off in OpenScad

|

Re: Dat gap January 04, 2015 10:35PM |

Registered: 10 years ago Posts: 564 |

In general, blowers work much better with ducting than fans. They generate less airflow but at higher pressures, so when you create a lot of back pressure with the duct, it forces a high velocity stream out of a small opening. With a fan, the CFM airflow drops off quite rapidly as the back pressure increases. This post has more discussion of using a duct with a blower.

Sorry, only registered users may post in this forum.