PLEASE HELP - Snapped extruder tube during assembly

Posted by FLY-FAST

|

PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 03:38PM |

Registered: 9 years ago Posts: 30 |

I was finishing up my 3D printer that I purchased from eBay and ended up making a huge mistake. I didn't realize how fragile the tube in the extruder was, and, I over-tightened and snapped the thing in half. The seller is all the way in China and closed for another 10 days or so because of the holidays and I really want to do some printing / calibrating today.

Here are a few pictures of the aftermath:

[i.imgur.com]

and

[i.imgur.com]

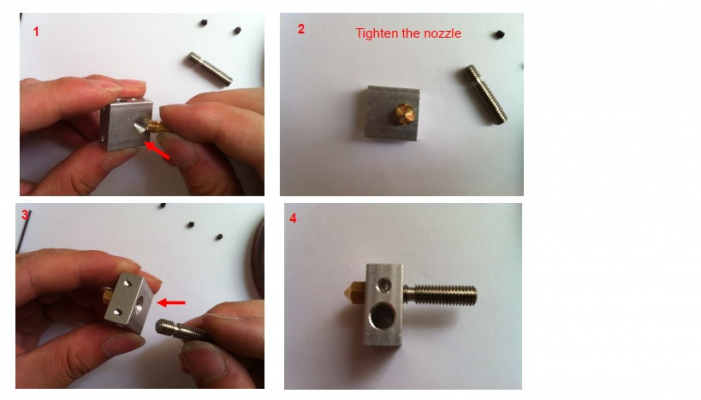

Here is a picture of the extruder components that came with the printer:

[i.imgur.com]

Another pic showing assembly:

[i.imgur.com]

So, it looks like I just need to replace the hollow tube in the picture. Is there ANY chance that I can pick something up from Home Depot that I can use here? It would be REALLY helpful if I could go get one locally. I googled around and using the same terms found in my printer I found:

[www.aliexpress.com]

I think that's it.

Thoughts on what to do now? I know, totally my fault here. But, everyone has to start somewhere.

Here are a few pictures of the aftermath:

[i.imgur.com]

and

[i.imgur.com]

Here is a picture of the extruder components that came with the printer:

[i.imgur.com]

Another pic showing assembly:

[i.imgur.com]

So, it looks like I just need to replace the hollow tube in the picture. Is there ANY chance that I can pick something up from Home Depot that I can use here? It would be REALLY helpful if I could go get one locally. I googled around and using the same terms found in my printer I found:

[www.aliexpress.com]

I think that's it.

Thoughts on what to do now? I know, totally my fault here. But, everyone has to start somewhere.

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 03:51PM |

Registered: 10 years ago Posts: 553 |

It's just a bolt or piece of threaded rod with a hole and notch cut into it. You'll need a lathe to do it right but it could be done other ways, I'd recommend all-thread because I don't believe the stuff Home Depot sells is hardened. Do not buy a Grade 8 bolt because you likely wont be able to drill it.

Please add your printer design to [reprap.org]

Please add your printer design to [reprap.org]

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 04:04PM |

Registered: 9 years ago Posts: 30 |

OK. I definitely don't have access to a lathe. What if I just cut the threaded rod to length, then drilled a hole through some stock that I have lying around, put the rod in the the hole (so perfect 90) and then drilled through the road via clamped down drillpress? Think this would work?

Any clue if I could buy something that already had the middle cut out or any other strategies?

Any clue if I could buy something that already had the middle cut out or any other strategies?

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 04:35PM |

Registered: 10 years ago Posts: 903 |

The part in question looks like the E3D hotend's stainless steel heat break. It is machined thin and fragile to act as an insulator between the heated block and cooling fins. If you replace it with anything else, your hotend will jam after a few minutes of running when the filament melt zone migrates into the cooling fins because the heat break will not be performing its job.

If that is an E3D hotend clone, you may get lucky and find that the genuine E3D part will fit it. Here's the assembly manual with pictures:

http://files.e3d-online.com/Drawings/E3Dv5_Assembly_Manual.pdf

According to E3D, the V5 and V6 use heat breaks that are not compatible with each other, so do your homework carefully if you decide to go this route.....

If that is an E3D hotend clone, you may get lucky and find that the genuine E3D part will fit it. Here's the assembly manual with pictures:

http://files.e3d-online.com/Drawings/E3Dv5_Assembly_Manual.pdf

According to E3D, the V5 and V6 use heat breaks that are not compatible with each other, so do your homework carefully if you decide to go this route.....

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 05:02PM |

Registered: 9 years ago Posts: 30 |

Another dumb question... So, I called my local hardware store to see if they happened to carry threaded rods. They do, but, do not have an M6 threaded rod - all their parts are fractional. Can I somehow use a fractional rod here? This would be a short-term solution to allow me to use the printer while a replacement is shipped from China?

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 05:12PM |

Registered: 9 years ago Posts: 30 |

Quote

vreihen

The part in question looks like the E3D hotend's stainless steel heat break. It is machined thin and fragile to act as an insulator between the heated block and cooling fins. If you replace it with anything else, your hotend will jam after a few minutes of running when the filament melt zone migrates into the cooling fins because the heat break will not be performing its job.

If that is an E3D hotend clone, you may get lucky and find that the genuine E3D part will fit it. Here's the assembly manual with pictures:

http://files.e3d-online.com/Drawings/E3Dv5_Assembly_Manual.pdf

According to E3D, the V5 and V6 use heat breaks that are not compatible with each other, so do your homework carefully if you decide to go this route.....

What if I was to file waaaay down the area that you can see exposed in picture 4 below? Would that work?

obligatory crappy pic:

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 07:49PM |

Registered: 11 years ago Posts: 1,049 |

Not so easy to bore a 1.75mm hole in a M6 threaded rod or bolt?

Not only a hole some 30mm long but a smooth hole

a ragged hole will just catch the filament

This is a stainless steel part for dimesional stability at 220deg C

The part you broke should be tighten against the brass nozzle when HOT

If not it will leak.

Get a replacement from E3D or QUBD

Not only a hole some 30mm long but a smooth hole

a ragged hole will just catch the filament

This is a stainless steel part for dimesional stability at 220deg C

The part you broke should be tighten against the brass nozzle when HOT

If not it will leak.

Get a replacement from E3D or QUBD

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 07:56PM |

Registered: 10 years ago Posts: 903 |

You will probably wind up making a bigger mess than if you just wait for the correct part to arrive.

This is the E3D v6 heat break. The v5 (likely what you have a clone of) is slightly different:

Sadly, neither of the USA-based E3D distributors have v5 heat breaks in stock.....

This is the E3D v6 heat break. The v5 (likely what you have a clone of) is slightly different:

Sadly, neither of the USA-based E3D distributors have v5 heat breaks in stock.....

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 03, 2015 10:52PM |

Registered: 9 years ago Posts: 30 |

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 04, 2015 02:28PM |

Registered: 9 years ago Posts: 61 |

|

Re: PLEASE HELP - Snapped extruder tube during assembly January 04, 2015 09:05PM |

Registered: 9 years ago Posts: 30 |

Those guys are GREAT. Thanks jrcaster

Sorry, only registered users may post in this forum.