Tear Drop Holes.

Posted by KeithSloan

|

Tear Drop Holes. May 19, 2010 10:14AM |

Registered: 13 years ago Posts: 137 |

|

Re: Tear Drop Holes. May 19, 2010 10:21AM |

Registered: 15 years ago Posts: 199 |

|

Re: Tear Drop Holes. May 19, 2010 10:27AM |

Registered: 13 years ago Posts: 137 |

JohnWasser Wrote:

-------------------------------------------------------

> The top of a horizontal hole has no support.

> Putting a "roof" on the hole reduces the maximum

> overhang angle to 45 degrees.

Thanks. So its an issue of ability of part to be printed, rather than being required for Mendel construction. i.e. When inserting rods etc.

-------------------------------------------------------

> The top of a horizontal hole has no support.

> Putting a "roof" on the hole reduces the maximum

> overhang angle to 45 degrees.

Thanks. So its an issue of ability of part to be printed, rather than being required for Mendel construction. i.e. When inserting rods etc.

|

Re: Tear Drop Holes. May 19, 2010 10:43AM |

Registered: 14 years ago Posts: 689 |

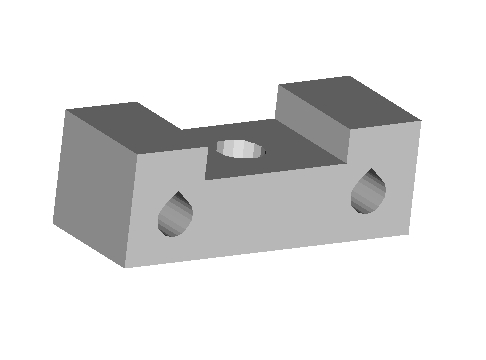

Exactly. That's why there is no teardrops in the x+y plane, as illustrated here:

|

Re: Tear Drop Holes. May 19, 2010 11:09AM |

Registered: 13 years ago Posts: 78 |

|

Re: Tear Drop Holes. May 19, 2010 02:44PM |

Registered: 13 years ago Posts: 1 |

|

Re: Tear Drop Holes. May 20, 2010 02:16AM |

Registered: 13 years ago Posts: 52 |

|

Re: Tear Drop Holes. May 20, 2010 02:28AM |

Registered: 13 years ago Posts: 137 |

|

Re: Tear Drop Holes. May 20, 2010 02:39AM |

Registered: 14 years ago Posts: 3,742 |

The RepRap Logo

Adrian Bowyer came up with the name RepRap, and Ed Sells came up with the logo. The teardrop shape is the profile of a cylinder with 45o angles above. Our commercial FDM machine can make a 45o overhang without support material, so - if you want a horizontal hole to put a cylinder through - the teardrop profile gets made without support. This is both faster and neater. And for the vast majority of cases it doesn't matter that it is not completely round.

The teardrop is also an important example of the fact that, with this technology, complexity of shape costs nothing.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Adrian Bowyer came up with the name RepRap, and Ed Sells came up with the logo. The teardrop shape is the profile of a cylinder with 45o angles above. Our commercial FDM machine can make a 45o overhang without support material, so - if you want a horizontal hole to put a cylinder through - the teardrop profile gets made without support. This is both faster and neater. And for the vast majority of cases it doesn't matter that it is not completely round.

The teardrop is also an important example of the fact that, with this technology, complexity of shape costs nothing.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Tear Drop Holes. May 20, 2010 03:54AM |

Registered: 13 years ago Posts: 83 |

|

Re: Tear Drop Holes. May 20, 2010 06:42AM |

Registered: 13 years ago Posts: 137 |

"The teardrop is also an important example of the fact that, with this technology, complexity of shape costs nothing."

Don't tell that to the guy who has to design something and input them into 3D modelling software. I guess once you have one it might not be too bad to copy and alter.

Edited 1 time(s). Last edit at 05/20/2010 06:42AM by KeithSloan.

Don't tell that to the guy who has to design something and input them into 3D modelling software. I guess once you have one it might not be too bad to copy and alter.

Edited 1 time(s). Last edit at 05/20/2010 06:42AM by KeithSloan.

|

Re: Tear Drop Holes. May 20, 2010 07:06AM |

Registered: 15 years ago Posts: 376 |

For small holes (about 7mm or below in diameter) you dont actually need them as ABS is capable of bridging the top of the hole. My machine is capable of bridging 7mm easily without any sagging. You can set the bridging speed higher in skeinforge so that you get a decent shaped hole. You occasionally get a filament drop in the hole but its easily cleaned with a drill.

You can also truncate the top of the hole so you dont get the sharp stress raiser pointed form. I normally go up at 60 degrees not 45 and then truncate the top so that the theoretical diameter touches horizontal.

Perhaps if this is adopted you could ask Adrian to change the logo!

You can also truncate the top of the hole so you dont get the sharp stress raiser pointed form. I normally go up at 60 degrees not 45 and then truncate the top so that the theoretical diameter touches horizontal.

Perhaps if this is adopted you could ask Adrian to change the logo!

|

Re: Tear Drop Holes. May 20, 2010 08:16AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes you can get away with nothing below M8 and truncated tear drops on bigger holes with Skeinforge, but the RepRap host still needs full teardrops I think.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.