Different styles of printers

Posted by pineapple

|

Different styles of printers March 02, 2015 10:54AM |

Registered: 9 years ago Posts: 17 |

Hello world,

My name is pineapple and I'm currently looking into creating a 3d printer. My initial research has shown that there are different types of printers (delta, Cartesian, polar) but I couldn't find a lot of information regarding the pros/cons for each type. I figured I could start a conversation on this topic and introduce myself to the community at the same time (if I've posted this in the wrong place, forgive). Anyways, I've gathered the following list so far:

Cartesian

Pro:

-Most common design

-Simple math

Con:

-Sloppier printing of circular objects (curve approximation isn't perfect in rectangular coordinates)

-More parts

Delta

Pro:

-Quick (can anybody explain why? All I've seen so far is the print head moves quicker because the filament motor isn't mounted on the print head but that seems arbitrary)

-Less parts

-Symmetric design

-Fixed print bed

-More accurate printing? (I will have to run the numbers on this)

Con:

-Most complex printing coordinates/trig

-Toughest to calibrate

Polar:

Pro:

-Best coordinates for printing circles

Con:

-Trouble printing rectangles

-Whole print bed has to rotate

Anybody have anything to add?

Edited 1 time(s). Last edit at 03/02/2015 02:51PM by pineapple.

My name is pineapple and I'm currently looking into creating a 3d printer. My initial research has shown that there are different types of printers (delta, Cartesian, polar) but I couldn't find a lot of information regarding the pros/cons for each type. I figured I could start a conversation on this topic and introduce myself to the community at the same time (if I've posted this in the wrong place, forgive). Anyways, I've gathered the following list so far:

Cartesian

Pro:

-Most common design

-Simple math

Con:

-Sloppier printing of circular objects (curve approximation isn't perfect in rectangular coordinates)

-More parts

Delta

Pro:

-Quick (can anybody explain why? All I've seen so far is the print head moves quicker because the filament motor isn't mounted on the print head but that seems arbitrary)

-Less parts

-Symmetric design

-Fixed print bed

-More accurate printing? (I will have to run the numbers on this)

Con:

-Most complex printing coordinates/trig

-Toughest to calibrate

Polar:

Pro:

-Best coordinates for printing circles

Con:

-Trouble printing rectangles

-Whole print bed has to rotate

Anybody have anything to add?

Edited 1 time(s). Last edit at 03/02/2015 02:51PM by pineapple.

|

Re: Different styles of printers March 02, 2015 11:14AM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Different styles of printers March 02, 2015 11:22AM |

Registered: 9 years ago Posts: 1,011 |

Scara of course and CoreXY.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Different styles of printers March 02, 2015 11:27AM |

Registered: 9 years ago Posts: 17 |

Quote

ggherbaz

You are forgetting the new breed of scara printers that seems to combine the best of both worlds, but still to young and with some math and backslashes issues.

I've seen mention of SCARA in a few places but to me it seems more complicated and less sturdy. Can you elaborate on why it's the best of both worlds?

Quote

Zavashier

Scara of course and CoreXY.

CoreXY just looks to be a fancier way of Cartesian control.

|

Re: Different styles of printers March 02, 2015 11:53AM |

Registered: 9 years ago Posts: 1,011 |

It isn't, a printer's architecture is different as long as the math to control it is different.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Different styles of printers March 02, 2015 12:38PM |

Registered: 10 years ago Posts: 14,672 |

Don't worry about the math, that's taken care of by the firmware. The delta has some more advantages over Cartesian printers:

* More regular construction. You build 3 identical towers and carriage assembles, instead of building 3 different axes. Get one of them right and you get them all right.

* No issues with bed levelling, because the bed is fixed. Once you have done the delta calibration (which takes less than an hour even if you don't have a Z probe and a good auto calibration facility in the firmware), the machine is stable. It's much more difficult to keep the bed of a Cartesian printer level and stable because it moves.

* Smaller footprint for the same build area, because of the non moving bed. The delta needs more height, but that isn't usually an issue.

I have a Cartesian printer (Ormerod) and a delta (Mini Kossel, about to be enlarged). Based on my experience with them, I recommend the delta for its easier build, smaller footprint and faster print speed for the same print quality. I have no experience with CoreXY or Scara.

If you choose a delta then I strongly recommend you choose a 32-bit controller board for it. The 8-bit boards have barely enough power to do the delta calculations in spite of the approximations that firmware for 8-bity boards uses. Both my printers use 32-bit Duet electronics.

Edited 1 time(s). Last edit at 03/02/2015 12:39PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

* More regular construction. You build 3 identical towers and carriage assembles, instead of building 3 different axes. Get one of them right and you get them all right.

* No issues with bed levelling, because the bed is fixed. Once you have done the delta calibration (which takes less than an hour even if you don't have a Z probe and a good auto calibration facility in the firmware), the machine is stable. It's much more difficult to keep the bed of a Cartesian printer level and stable because it moves.

* Smaller footprint for the same build area, because of the non moving bed. The delta needs more height, but that isn't usually an issue.

I have a Cartesian printer (Ormerod) and a delta (Mini Kossel, about to be enlarged). Based on my experience with them, I recommend the delta for its easier build, smaller footprint and faster print speed for the same print quality. I have no experience with CoreXY or Scara.

If you choose a delta then I strongly recommend you choose a 32-bit controller board for it. The 8-bit boards have barely enough power to do the delta calculations in spite of the approximations that firmware for 8-bity boards uses. Both my printers use 32-bit Duet electronics.

Edited 1 time(s). Last edit at 03/02/2015 12:39PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Different styles of printers March 02, 2015 01:44PM |

Registered: 9 years ago Posts: 17 |

Quote

Zavashier

It isn't, a printer's architecture is different as long as the math to control it is different.

Fair enough!

Quote

dc42

Don't worry about the math, that's taken care of by the firmware. The delta has some more advantages over Cartesian printers:

* More regular construction. You build 3 identical towers and carriage assembles, instead of building 3 different axes. Get one of them right and you get them all right.

* No issues with bed levelling, because the bed is fixed. Once you have done the delta calibration (which takes less than an hour even if you don't have a Z probe and a good auto calibration facility in the firmware), the machine is stable. It's much more difficult to keep the bed of a Cartesian printer level and stable because it moves.

* Smaller footprint for the same build area, because of the non moving bed. The delta needs more height, but that isn't usually an issue.

I have a Cartesian printer (Ormerod) and a delta (Mini Kossel, about to be enlarged). Based on my experience with them, I recommend the delta for its easier build, smaller footprint and faster print speed for the same print quality. I have no experience with CoreXY or Scara.

If you choose a delta then I strongly recommend you choose a 32-bit controller board for it. The 8-bit boards have barely enough power to do the delta calculations in spite of the approximations that firmware for 8-bity boards uses. Both my printers use 32-bit Duet electronics.

That makes a lot of sense. I noticed the symmetry in the Delta style printers but I didn't link it to easier manufacturing.

So then two follow up questions (if you don't mind). Why would someone choose a Cartesian printer over a delta? Is there a reason polar isn't as popular as Cartesian? Polar and Cartesian would appear to be almost the same complexity to me, but then again I'm just a noob here.

Edited 1 time(s). Last edit at 03/02/2015 02:50PM by pineapple.

|

Re: Different styles of printers March 02, 2015 03:09PM |

Registered: 11 years ago Posts: 335 |

None of the methods are intrinsically more or less accurate for particular geometries. Any form of approximation made in software is orders of magnitude smaller than the physical resolution of the printer. By your logic (polar being bad at lines, cartesian being bad at curves), delta should suck at everything because any motion requires approximation using all three motors.

Polar can immediately be dumped because any system that relies on rotational axes for positioning has too many disadvantages in our price range (amplification of error, backlash, inertia).

There are plenty of existing discussions about cartesian vs delta. I think delta has a niche, but isn't great for large printers because the build volume is not efficient. It also has problems with loads that need a lot of space (multiple extruders).

The main source of faster print speeds in delta printers is the bowden+fixed bed. This can be emulated in cartesian printers, such as the ultimaker.

A delta printer will generally have much lower inertia than a cartesian printer because the arms can be very light. They do not undergo bending loads and are therefore extremely rigid in practice. Most consumers like deltas because they look cool.

The CoreXY is a variation of the H-Bot designed to compensate for poor rigidity, and uses a rather inelegant belt path. There are no high-end commercial implementations of the CoreXY- everyone uses h-bots (ex: stratasys).

Edited 2 time(s). Last edit at 03/02/2015 03:10PM by 691175002.

Polar can immediately be dumped because any system that relies on rotational axes for positioning has too many disadvantages in our price range (amplification of error, backlash, inertia).

There are plenty of existing discussions about cartesian vs delta. I think delta has a niche, but isn't great for large printers because the build volume is not efficient. It also has problems with loads that need a lot of space (multiple extruders).

The main source of faster print speeds in delta printers is the bowden+fixed bed. This can be emulated in cartesian printers, such as the ultimaker.

A delta printer will generally have much lower inertia than a cartesian printer because the arms can be very light. They do not undergo bending loads and are therefore extremely rigid in practice. Most consumers like deltas because they look cool.

The CoreXY is a variation of the H-Bot designed to compensate for poor rigidity, and uses a rather inelegant belt path. There are no high-end commercial implementations of the CoreXY- everyone uses h-bots (ex: stratasys).

Edited 2 time(s). Last edit at 03/02/2015 03:10PM by 691175002.

|

Re: Different styles of printers March 02, 2015 03:35PM |

Registered: 9 years ago Posts: 17 |

Quote

691175002

None of the methods are intrinsically more or less accurate for particular geometries. Any form of approximation made in software is orders of magnitude smaller than the physical resolution of the printer. By your logic (polar being bad at lines, cartesian being bad at curves), delta should suck at everything because any motion requires approximation using all three motors.

Polar can immediately be dumped because any system that relies on rotational axes for positioning has too many disadvantages in our price range (amplification of error, backlash, inertia).

There are plenty of existing discussions about cartesian vs delta. I think delta has a niche, but isn't great for large printers because the build volume is not efficient. It also has problems with loads that need a lot of space (multiple extruders).

The main source of faster print speeds in delta printers is the bowden+fixed bed. This can be emulated in cartesian printers, such as the ultimaker.

A delta printer will generally have much lower inertia than a cartesian printer because the arms can be very light. They do not undergo bending loads and are therefore extremely rigid in practice. Most consumers like deltas because they look cool.

The CoreXY is a variation of the H-Bot designed to compensate for poor rigidity, and uses a rather inelegant belt path. There are no high-end commercial implementations of the CoreXY- everyone uses h-bots (ex: stratasys).

Good point on the Cartesian/polar differences that I called out in my original post. I'm used to dealing with these coordinate systems by hand so I didn't consider that the software would be more accurate than the hardware.

What do you mean by delta's not having an efficient build volume?

|

Re: Different styles of printers March 02, 2015 04:35PM |

Registered: 9 years ago Posts: 1,011 |

Well that's my humble opinion (and facts) about deltas :

1. This can be an extremely fast machine, initialy used for pick and place applications. The FDM technology limits the max speed anyways. When you build a delta 3D printer, you use only 25% of the speed that architecture can provide.

2. On a delta, the footprint looks a bit smaller. Honnestly, it's only smaller compared to mobile bed printers. Scara or CoreXY can have a comparable footprint. Throught, the delta needs height. The overall volume is bigger on a delta.

3. Some says the delta print volume is a cylinder while carthesian is a parallepiped. It's not exactly a cylindre* but who cares ? Except if you're printing vases or lamps once at a time only, it will be easyer to manage multiple parts on a carthesian build area.

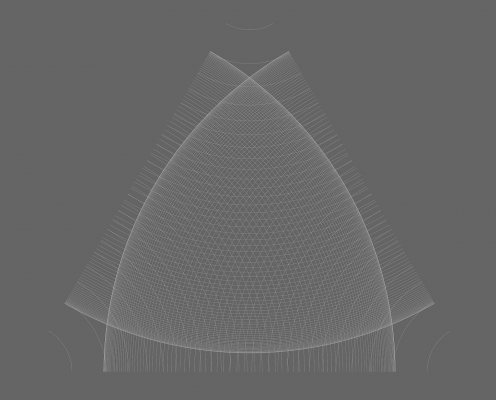

4. Unlike carthesian printers, on a delta the resolution is not constant on the build plate. You've got less resolution on the centre, and more at the edges.*

*see the picture above.

5. The build is more simple on a delta, but the arms must be cutted accurately, and the build ask for a better precision.

6. Except if you build a well documented kit, the calibration of the machine can be a nightmare ! Especialy when you scalled up or down your delta.

7. The delta needs a bowden, so you probably won't be able to print exotic filaments, like filaflex.

8. The dela's head has a limited space, and that head is limited by weight too. So you probably won't be able to add a lot of features to your printer, like multiple extruders, a laser head, fans...

The delta have some advantages too, like a supported and fixed bed.

Edited 1 time(s). Last edit at 03/02/2015 04:36PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

1. This can be an extremely fast machine, initialy used for pick and place applications. The FDM technology limits the max speed anyways. When you build a delta 3D printer, you use only 25% of the speed that architecture can provide.

2. On a delta, the footprint looks a bit smaller. Honnestly, it's only smaller compared to mobile bed printers. Scara or CoreXY can have a comparable footprint. Throught, the delta needs height. The overall volume is bigger on a delta.

3. Some says the delta print volume is a cylinder while carthesian is a parallepiped. It's not exactly a cylindre* but who cares ? Except if you're printing vases or lamps once at a time only, it will be easyer to manage multiple parts on a carthesian build area.

4. Unlike carthesian printers, on a delta the resolution is not constant on the build plate. You've got less resolution on the centre, and more at the edges.*

*see the picture above.

5. The build is more simple on a delta, but the arms must be cutted accurately, and the build ask for a better precision.

6. Except if you build a well documented kit, the calibration of the machine can be a nightmare ! Especialy when you scalled up or down your delta.

7. The delta needs a bowden, so you probably won't be able to print exotic filaments, like filaflex.

8. The dela's head has a limited space, and that head is limited by weight too. So you probably won't be able to add a lot of features to your printer, like multiple extruders, a laser head, fans...

The delta have some advantages too, like a supported and fixed bed.

Edited 1 time(s). Last edit at 03/02/2015 04:36PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Different styles of printers March 02, 2015 04:42PM |

Registered: 11 years ago Posts: 335 |

Quote

pineapple

What do you mean by delta's not having an efficient build volume?

Just the ratio of build volume to overall printer size isn't particularly great. They are more space efficient than a moving (x and/or y) bed printer, but worse than a fixed or Z-bed cartesian. Delta printers also become ridiculously tall as build volume increases.

I'd also consider a rectangular working area more useful than the circular area of a delta printer. If you are desgining functional prototypes, it is much easier to know the exact x and y limits availaible instead of needing trigonometry to figure out what will fit in a circle. Ditto for printing large parts in segments.

On a cartesian printer you have the option of printing diagonally, so an 8"x8" bed can actually print >11" long if the part is thin enough.

|

Re: Different styles of printers March 02, 2015 05:30PM |

Registered: 9 years ago Posts: 98 |

|

Re: Different styles of printers March 03, 2015 03:38AM |

Registered: 9 years ago Posts: 1,011 |

You'd rather use a 32 bit controler with a delta.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Different styles of printers March 03, 2015 09:51AM |

Registered: 9 years ago Posts: 17 |

So what I'm gathering so far is this:

Polar:

-Rotating bed=nonononoohgodno

Cartesian:

-More complex build/more parts

-Even distribution of print resolution over the surface area of the print bed

-Better build volume per printer overall size

Delta:

-Simpler assembly (more symmetry in design)

-Can be tougher to calibrate (depending on your software)

-Needs more processing power

-Cool factor>9000

-Print resolution isn't even over the print bed

-Prints quicker (because of Bowden)

-Prints only one material (because of Bowden)

Polar:

-Rotating bed=nonononoohgodno

Cartesian:

-More complex build/more parts

-Even distribution of print resolution over the surface area of the print bed

-Better build volume per printer overall size

Delta:

-Simpler assembly (more symmetry in design)

-Can be tougher to calibrate (depending on your software)

-Needs more processing power

-Cool factor>9000

-Print resolution isn't even over the print bed

-Prints quicker (because of Bowden)

-Prints only one material (because of Bowden)

|

Re: Different styles of printers March 03, 2015 10:27AM |

Registered: 9 years ago Posts: 98 |

The ultimaker 1/2 printers can reach extremely fast speeds. The motors are strong and the head is lightweight. It uses a bowden style extruder. The twoup 3d printer is a cheap printer that has bad gantry sag as one side of the gantry isnt supported. With my bowden e3d v6 printhead, is is so light that it doesnt even matter and I can do up to 100mm/s on that thing. Not super fast but not too bad. Does anyone know what a basic delta controller costs?

|

Re: Different styles of printers March 03, 2015 10:29AM |

Registered: 10 years ago Posts: 14,672 |

Print resolution isn't an issue with delta printers. It's true that the XY resolution of a delta varies across the bed, but it's better everywhere on the bed than a Cartesian printer of similar design (i.e. same stepper motor pulley radius). But all good 3D printer designs have a resolution much better than the width of the nozzle, so I suggest you ignore print resolution in your deliberations.

The quicker printing of a delta compared to Cartesian is because the head is liightweight and there is no heavy bed to move. It may be possible to achieve the same result with a CoreXY design if the head bearings can be made light enough.

I think printing with 2 nozzles on a delta should be entirely possible, if you go for a dual nozzle hot end design such as the E3D Chimera. I'm planning to try this on my Mini Kossel some time.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The quicker printing of a delta compared to Cartesian is because the head is liightweight and there is no heavy bed to move. It may be possible to achieve the same result with a CoreXY design if the head bearings can be made light enough.

I think printing with 2 nozzles on a delta should be entirely possible, if you go for a dual nozzle hot end design such as the E3D Chimera. I'm planning to try this on my Mini Kossel some time.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Different styles of printers March 03, 2015 11:29AM |

Registered: 9 years ago Posts: 17 |

Thanks to everyone who has contributed to the conversation so far. I've learned a lot and I hope other people have as well.

I wanted to share a little bit of the research I've been doing on SCARA. The Wikipedia article on this has some helpful gif's and this great paragraph:

"SCARAs are generally faster and cleaner than comparable Cartesian robot systems. Their single pedestal mount requires a small footprint and provides an easy, unhindered form of mounting. On the other hand, SCARAs can be more expensive than comparable Cartesian systems and the controlling software requires inverse kinematics for linear interpolated moves. This software typically comes with the SCARA though and is usually transparent to the end-user."

I'm guessing the parts needed for a SCARA are a little more expensive (my guess is that it would be whatever is that elbow joint). The software doesn't seem too complicated (I've done similar calculations by hand and they're more tedious than tough: perfect for software) but I'm concluding it's just not as widespread as delta/Cartesian software. Anybody have any experience building/operating a SCARA printer?

I wanted to share a little bit of the research I've been doing on SCARA. The Wikipedia article on this has some helpful gif's and this great paragraph:

"SCARAs are generally faster and cleaner than comparable Cartesian robot systems. Their single pedestal mount requires a small footprint and provides an easy, unhindered form of mounting. On the other hand, SCARAs can be more expensive than comparable Cartesian systems and the controlling software requires inverse kinematics for linear interpolated moves. This software typically comes with the SCARA though and is usually transparent to the end-user."

I'm guessing the parts needed for a SCARA are a little more expensive (my guess is that it would be whatever is that elbow joint). The software doesn't seem too complicated (I've done similar calculations by hand and they're more tedious than tough: perfect for software) but I'm concluding it's just not as widespread as delta/Cartesian software. Anybody have any experience building/operating a SCARA printer?

|

Re: Different styles of printers March 03, 2015 11:50AM |

Registered: 10 years ago Posts: 14,672 |

I suggest you post in forum "Polar bots and robot arns" for more info on Scara printers - that's where they are discussed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Different styles of printers March 03, 2015 01:16PM |

Registered: 10 years ago Posts: 1,401 |

Pineapple,

I'm developing a scara printer, and like I posted at the beginning, they are quite simple in construction, a lot more sturdier than Cartesian and delta printers and with less moving parts.

The one I'm building is just for kids at school to see how vast and diverse 3d printing can be, it is fully 3d printed with exception of bearings, bolts and electronics. I don't care too much right now about its accuracy (kids don't mind) but it gives me a platform to work on. The main problem is gear backlash, which I'm reducing with plain opposite springs at the elbows and timing belts for power transmission.

The kind of gears and bearings used by real scara robots are expensive at this time, but if this type of printer progress, the costs will be reduced as it happened with cartesian ones and I think they will gain a lot more popularity than deltas or cartesian combined.

I'm developing a scara printer, and like I posted at the beginning, they are quite simple in construction, a lot more sturdier than Cartesian and delta printers and with less moving parts.

The one I'm building is just for kids at school to see how vast and diverse 3d printing can be, it is fully 3d printed with exception of bearings, bolts and electronics. I don't care too much right now about its accuracy (kids don't mind) but it gives me a platform to work on. The main problem is gear backlash, which I'm reducing with plain opposite springs at the elbows and timing belts for power transmission.

The kind of gears and bearings used by real scara robots are expensive at this time, but if this type of printer progress, the costs will be reduced as it happened with cartesian ones and I think they will gain a lot more popularity than deltas or cartesian combined.

|

Re: Different styles of printers March 03, 2015 01:52PM |

Registered: 10 years ago Posts: 469 |

Quote

Zavashier

7. The delta needs a bowden, so you probably won't be able to print exotic filaments, like filaflex.

8. The dela's head has a limited space, and that head is limited by weight too. So you probably won't be able to add a lot of features to your printer, like multiple extruders, a laser head, fans...

The delta have some advantages too, like a supported and fixed bed.

I Disagree on the multiple extruders sentiment. You can design a delta with multiple extruders and it will function properly. Each extruder will have to be bowden fed.

I also disagree on the flexible filament sentiment. That is more of a function of the extruder than anything else. A proper extruder would not have issues pushing flexible filament down a bowden tube, unless the filament is sticky by nature. I am fairly sure that with a proper extruder you can push a wet noodle through a bowden tube.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Different styles of printers March 03, 2015 03:24PM |

Registered: 9 years ago Posts: 17 |

Quote

ggherbaz

Pineapple,

I'm developing a scara printer, and like I posted at the beginning, they are quite simple in construction, a lot more sturdier than Cartesian and delta printers and with less moving parts.

The one I'm building is just for kids at school to see how vast and diverse 3d printing can be, it is fully 3d printed with exception of bearings, bolts and electronics. I don't care too much right now about its accuracy (kids don't mind) but it gives me a platform to work on. The main problem is gear backlash, which I'm reducing with plain opposite springs at the elbows and timing belts for power transmission.

The kind of gears and bearings used by real scara robots are expensive at this time, but if this type of printer progress, the costs will be reduced as it happened with cartesian ones and I think they will gain a lot more popularity than deltas or cartesian combined.

May I ask why the gears/bearings are more expensive? Are they made to a higher tolerance? Are they unique?

|

Re: Different styles of printers March 03, 2015 03:55PM |

Registered: 9 years ago Posts: 1,011 |

Well I'm not a noodle expert, what about a review ?Quote

jaguarking11

Quote

Zavashier

7. The delta needs a bowden, so you probably won't be able to print exotic filaments, like filaflex.

8. The dela's head has a limited space, and that head is limited by weight too. So you probably won't be able to add a lot of features to your printer, like multiple extruders, a laser head, fans...

The delta have some advantages too, like a supported and fixed bed.

I Disagree on the multiple extruders sentiment. You can design a delta with multiple extruders and it will function properly. Each extruder will have to be bowden fed.

I also disagree on the flexible filament sentiment. That is more of a function of the extruder than anything else. A proper extruder would not have issues pushing flexible filament down a bowden tube, unless the filament is sticky by nature. I am fairly sure that with a proper extruder you can push a wet noodle through a bowden tube.

Some people says you can't extrude with enough precision flexible filaments on a bowden extruder, because of the compression applied to the filament. I must confess that seems logical to me too. That's why I did not tryed flexible filaments on my bowden setting yet. I also don't need flexible prints very often. Honnestly, I just give my spool some trys, then it's on the shelve since 4 months now.

Some people says you can't extrude with enough precision flexible filaments on a bowden extruder, because of the compression applied to the filament. I must confess that seems logical to me too. That's why I did not tryed flexible filaments on my bowden setting yet. I also don't need flexible prints very often. Honnestly, I just give my spool some trys, then it's on the shelve since 4 months now.In absolute... you're right for the multiple extruder. BUT, read well, I said "So you probably won't be able to". I meant, it's not impossible, it just won't be easy, you'll probably need to start over a reworked design, and arrange maths/configuration which can be tricky on a delta. The huge majority of deltas kits and/or BOM/plans are engineered for a single extruder plate, with limited space to install multiple hotends side by side. Even the Chimaera takes a piece of space. My opinion can sounds distinct to your ears. At last, appreciate that on other machine types, it's much more simple.

Edited 1 time(s). Last edit at 03/03/2015 04:02PM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Different styles of printers March 03, 2015 06:38PM |

Registered: 10 years ago Posts: 1,401 |

Pineapple,

You just answered the question.

The scara robot I have seen, moves thousands of times in a day, they need to be extremely precise and efficient, usually gear reductions from 50:1 or more packet in small sizes requires high tolerances and special alloys to prevent backlash, high precision and speed bearings that allows the arms moves without wobble millions of times in their life span.

Electronics manufacturers count their rejects in 1 per millon or less, the only way to achieve that is with extreme precision and advanced materials.

You just answered the question.

The scara robot I have seen, moves thousands of times in a day, they need to be extremely precise and efficient, usually gear reductions from 50:1 or more packet in small sizes requires high tolerances and special alloys to prevent backlash, high precision and speed bearings that allows the arms moves without wobble millions of times in their life span.

Electronics manufacturers count their rejects in 1 per millon or less, the only way to achieve that is with extreme precision and advanced materials.

|

Re: Different styles of printers March 04, 2015 06:25AM |

Registered: 13 years ago Posts: 7,616 |

Quote

691175002

Polar can immediately be dumped because any system that relies on rotational axes for positioning has too many disadvantages in our price range (amplification of error, backlash, inertia).

I'd strongly disagree here. Actually I think a Morgan-like design is the next step beyond Deltas. The main reasons is, you get away with only one linear axis and rotating axes are much easier to make sturdy and precise. Instead of expensive hardened rods and linear bearings you simply put a plain bolt in and that's it.

Quote

dc42

But all good 3D printer designs have a resolution much better than the width of the nozzle, so I suggest you ignore print resolution in your deliberations.

Size of the nozzle gives approx. the width of the path laid down, resolution gives the dimensional accuracy of the part. It certainly makes sense to have a < 0.1 mm resolution when printing with a 1.0 mm nozzle.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Different styles of printers March 04, 2015 07:16AM |

Registered: 9 years ago Posts: 1,011 |

I agree with Traumflug on each point. The problem with scara is to make good arms with minimal play. It's not that easy with printed arms. Through, some people disapprove math used in actual scara repraps. Are they right ? For print resolution, the fused filament itself is one of the most important error source, so precision is limited anyways. But print artefacts depends of both mecanical and control issues.

Edited 1 time(s). Last edit at 03/04/2015 07:17AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Edited 1 time(s). Last edit at 03/04/2015 07:17AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Different styles of printers March 04, 2015 10:49AM |

Registered: 9 years ago Posts: 17 |

Quote

ggherbaz

Pineapple,

You just answered the question.

The scara robot I have seen, moves thousands of times in a day, they need to be extremely precise and efficient, usually gear reductions from 50:1 or more packet in small sizes requires high tolerances and special alloys to prevent backlash, high precision and speed bearings that allows the arms moves without wobble millions of times in their life span.

Electronics manufacturers count their rejects in 1 per millon or less, the only way to achieve that is with extreme precision and advanced materials.

Well wouldn't any 3D printer that was running all the day be in the same situation? I understand you would need precise gears, but one in a million rejects is not only five standard deviations. A lot of companies today try and get at least six sigma (one in 506,797,346). Do you have to use a special type of gear? I would imagine they would just be spur gears with some kind of bearings for the last plane.

|

Re: Different styles of printers March 04, 2015 10:52AM |

Registered: 9 years ago Posts: 44 |

|

Re: Different styles of printers March 04, 2015 11:12AM |

Registered: 11 years ago Posts: 335 |

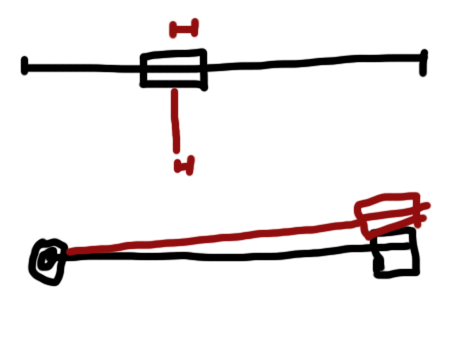

The problem with rotational axes are very simple.

In a linear system, mechanical errors are directly reflected in the position of the extruder. If the belt is out by 0.1mm, the extruder will also be out by 0.1mm.

In a rotational system, any mechanical errors are multiplied by the length of the arm. A tiny error at the motor shaft becomes a major problem 6 or 12 inches from center. I have attached a crude drawing to illustrate this problem.

Note that amplification of error goes two ways: any torque applied to the end of the lever gets multiplied by its length. With a linear system, a 200g extruder is just a 200g extruder. On a rotary system that 200g is suddenly on the end of a 12" lever and might be applying ten times that force to the bearing.

So you have two major problems - you need more accuracy and more rigidity. Both requirements scale multiplicatively with build area.

This already sounds pretty bad, but to fully understand the implications you have to realize that rotational accuracy is harder to achieve than linear accuracy. The only viable option for a hobbyist is timing belts, but you run into rigidity/stretch problems due to the huge torques involved and it is difficult to get sufficient mechanical reduction in one stage. Most people end up with a servobelt clone.

This problem isn't new and has plauged the CNC and telescope mount guys for a very long time.

For an example of "budget" rotary stage construction you can look at the pocketnc. Note the dual stepper motors and massive 200+ tooth pulley (not an off-the-shelf part). If you dig through the rest of their posts you can also spot the massive 60mm tapered roller bearings. Their current design may still be insufficient for milling. They started with a single motor and smaller bearings and have progressively added to the design with each revision.

Ironically, 3d printing might actually be the best way to achieve accurate rotary positioning (at least with low loads) since you can easily print geometries that are otherwise impractical. A differential planetary gearbox using spring-loaded tapered planets could provide zero backlash reduction, and with 6-8 planets any geometrical errors in the print will be averaged out.

In a linear system, mechanical errors are directly reflected in the position of the extruder. If the belt is out by 0.1mm, the extruder will also be out by 0.1mm.

In a rotational system, any mechanical errors are multiplied by the length of the arm. A tiny error at the motor shaft becomes a major problem 6 or 12 inches from center. I have attached a crude drawing to illustrate this problem.

Note that amplification of error goes two ways: any torque applied to the end of the lever gets multiplied by its length. With a linear system, a 200g extruder is just a 200g extruder. On a rotary system that 200g is suddenly on the end of a 12" lever and might be applying ten times that force to the bearing.

So you have two major problems - you need more accuracy and more rigidity. Both requirements scale multiplicatively with build area.

This already sounds pretty bad, but to fully understand the implications you have to realize that rotational accuracy is harder to achieve than linear accuracy. The only viable option for a hobbyist is timing belts, but you run into rigidity/stretch problems due to the huge torques involved and it is difficult to get sufficient mechanical reduction in one stage. Most people end up with a servobelt clone.

This problem isn't new and has plauged the CNC and telescope mount guys for a very long time.

For an example of "budget" rotary stage construction you can look at the pocketnc. Note the dual stepper motors and massive 200+ tooth pulley (not an off-the-shelf part). If you dig through the rest of their posts you can also spot the massive 60mm tapered roller bearings. Their current design may still be insufficient for milling. They started with a single motor and smaller bearings and have progressively added to the design with each revision.

Ironically, 3d printing might actually be the best way to achieve accurate rotary positioning (at least with low loads) since you can easily print geometries that are otherwise impractical. A differential planetary gearbox using spring-loaded tapered planets could provide zero backlash reduction, and with 6-8 planets any geometrical errors in the print will be averaged out.

|

Re: Different styles of printers March 04, 2015 12:14PM |

Registered: 11 years ago Posts: 335 |

|

Re: Different styles of printers March 04, 2015 01:47PM |

Registered: 9 years ago Posts: 17 |

Quote

691175002

Also note that print quality requires repeatability much better than the nozzle diameter.

The human eye can perceive inconsistencies well below 0.01mm. For good looking prints you must be able to perfectly line up successive layers.

So repeatability is really the key parameter for any build/printer. You could be accurate to the atomic level but if you can't reduce and/or prevent deviations then it's meaningless. Other than choosing a more "sound" design and buying low tolerance parts, is there any other way of increasing repeatability?

Sorry, only registered users may post in this forum.