Nichrome Wire Questions

Posted by HSRepProject

|

Nichrome Wire Questions June 09, 2010 12:25PM |

Registered: 14 years ago Posts: 16 |

So, we got our extruder's firmware working, and our thermistor appears to be working properly, and the stepper motor is running as it should, but the nichrome doesn't appear to be heating up.

We checked the voltage as the reprap was running and the nichrome is getting about 12v

We tried connecting a 6 olm length of nichrome into the controller and it glowed a majestic shade of orange and put off a bunch of smoke before we managed to disconnect the power.

We tried a strand of thicker nichrome and got similar results. (smoke, no pretty orange glow :-()

I'm guessing that either there's too much voltage from the extruder, or we need nichrome that is rated to a higher voltage.

Edit: I did a little checking, and 12v is the normal voltage from the extruder, so it must be a problem with the nichrome

Edited 1 time(s). Last edit at 06/09/2010 12:49PM by HSRepProject.

We checked the voltage as the reprap was running and the nichrome is getting about 12v

We tried connecting a 6 olm length of nichrome into the controller and it glowed a majestic shade of orange and put off a bunch of smoke before we managed to disconnect the power.

We tried a strand of thicker nichrome and got similar results. (smoke, no pretty orange glow :-()

Edit: I did a little checking, and 12v is the normal voltage from the extruder, so it must be a problem with the nichrome

Edited 1 time(s). Last edit at 06/09/2010 12:49PM by HSRepProject.

|

Re: Nichrome Wire Questions June 09, 2010 01:26PM |

Registered: 16 years ago Posts: 106 |

If you have nichrome in air without wrapping it around the barrel, it will usually burn out. The barrel (should) sink heat away from the wire and keep it from melting, and you probably won't see any color change.

The main problem I've had is disconnects or shorts. When wrapped around the barrel, make sure you don't have any shorts to the barrel or to the nichrome, it won't work properly if you have shorts. Are you using coated nichrome or bare wire? If bare wire, be sure to insulate it using either kapton tape around the barrel or some sort of fireplace cement.

Also be sure you have a good circuit back to the board. You can clip the crimp ends off of spade terminals to use as new crimp connectors if you don't have any.

----

[www.binaryconstruct.com]

The main problem I've had is disconnects or shorts. When wrapped around the barrel, make sure you don't have any shorts to the barrel or to the nichrome, it won't work properly if you have shorts. Are you using coated nichrome or bare wire? If bare wire, be sure to insulate it using either kapton tape around the barrel or some sort of fireplace cement.

Also be sure you have a good circuit back to the board. You can clip the crimp ends off of spade terminals to use as new crimp connectors if you don't have any.

----

[www.binaryconstruct.com]

|

Re: Nichrome Wire Questions June 09, 2010 02:41PM |

Registered: 14 years ago Posts: 16 |

Well, we just put together another extruder, and we had the same problem as with the exposed nichrome to the air. We think the problem might be that the wire we are using is not insulated, and also possibly of low quality. We're going to try and order some insulated wire off of makerbot and try that. If we're still having problems after that, we'll post here again.

|

Re: Nichrome Wire Questions June 09, 2010 05:22PM |

Registered: 15 years ago Posts: 376 |

I always insulate my nichrome wire between kapton tape (usually two layers) before winding it around the extruder barrel. That way you can be confident that you wont get any shorts. I then tape over the assembly again with kapton. Nichrome with silk or enamel insulation I have found to be no use at all, so stick with wrapping kapton tape around it anyway. Its a little more fiddly to get it around but is much better.

The best method I have found is to tape the nichrome wire to a board in a straight line (tape it down at each end) then put your kapton tape along it (I use 7mm wide tape). Gently lift one end of the tape and pinch the kapton tape around the nichrome as you go along. You now have the wire neatly surrounded by kapton. Repeat again if you want for a double layer.

The best method I have found is to tape the nichrome wire to a board in a straight line (tape it down at each end) then put your kapton tape along it (I use 7mm wide tape). Gently lift one end of the tape and pinch the kapton tape around the nichrome as you go along. You now have the wire neatly surrounded by kapton. Repeat again if you want for a double layer.

|

Re: Nichrome Wire Questions June 09, 2010 06:21PM |

Registered: 13 years ago Posts: 7,616 |

> Well, we just put together another extruder, and

> we had the same problem as with the exposed

> nichrome to the air.

What's the problem with the wire becoming colored? It's the most normal state of affairs for metal becoming colored when heated and exposed to air (oxygen). There are even color tables which allow you to estimate the actual temperature of the metal by comparing the metal color with the color in the table. See for example on page 8 in this paper: [aba-fachverband.org]

> We think the problem might be

> that the wire we are using is not insulated

As the insulation holds the oxygen away from the metal, yes, the wire will stay blank for a longer time. But an additional insulation will also reduce the flow of temperature to where you probably want it: towards the nozzle.

> and also possibly of low quality.

As long as the wire reaches the desired temperature the quality is just fine for this purpose.

Markus

> we had the same problem as with the exposed

> nichrome to the air.

What's the problem with the wire becoming colored? It's the most normal state of affairs for metal becoming colored when heated and exposed to air (oxygen). There are even color tables which allow you to estimate the actual temperature of the metal by comparing the metal color with the color in the table. See for example on page 8 in this paper: [aba-fachverband.org]

> We think the problem might be

> that the wire we are using is not insulated

As the insulation holds the oxygen away from the metal, yes, the wire will stay blank for a longer time. But an additional insulation will also reduce the flow of temperature to where you probably want it: towards the nozzle.

> and also possibly of low quality.

As long as the wire reaches the desired temperature the quality is just fine for this purpose.

Markus

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Nichrome Wire Questions June 14, 2010 01:30PM |

Registered: 14 years ago Posts: 16 |

We received our fiberglass insulated wire from makerbot, and it still began to smoke when we ran the machine. We also tried wrapping our old wire in kapton tape, and the same thing happened, it looks like we actually burned through the kapton tape, we recorded a temperature of 90C using an infrared thermometer and kapton is not supposed to melt until 260C according to makerbot. After about 10 seconds, the wire stopped working altogether and just started cooling down.

The temperature that nichrome reaches is determined according to wattage, correct? If everything is getting to hot, the problem might be that our length of wire is slightly to short. We've been using a length that is ~6 olms,so might it be worthwhile to use a ~7 or 8 olm length?

Edit: We tried a 8 ohm length, and it still burnt up the kapton. We did a little research, and according to wikipedia, 32 gauge wire at 2 amps gets between 1000-2000 degrees F! That's way over the kapton tape's max temperature!

Edited 1 time(s). Last edit at 06/14/2010 03:48PM by HSRepProject.

The temperature that nichrome reaches is determined according to wattage, correct? If everything is getting to hot, the problem might be that our length of wire is slightly to short. We've been using a length that is ~6 olms,

Edit: We tried a 8 ohm length, and it still burnt up the kapton. We did a little research, and according to wikipedia, 32 gauge wire at 2 amps gets between 1000-2000 degrees F! That's way over the kapton tape's max temperature!

Edited 1 time(s). Last edit at 06/14/2010 03:48PM by HSRepProject.

|

Re: Nichrome Wire Questions June 15, 2010 04:57AM |

Registered: 13 years ago Posts: 7,616 |

Quote

The temperature that nichrome reaches is determined according to wattage, correct?

The temperature reached is determined by the wattage put into (by electricity) vs. the wattage going out (by thermal radiation and thermal convection). The more you insulate the wire, the hotter it will get.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Nichrome Wire Questions June 15, 2010 11:21PM |

Registered: 14 years ago Posts: 16 |

|

Re: Nichrome Wire Questions June 16, 2010 09:21AM |

Registered: 15 years ago Posts: 199 |

HSRepProject Wrote:

-------------------------------------------------------

> The temperature that nichrome reaches is

> determined according to wattage, correct?

The temperature depends on power density, not just power (Watts). If you have a 6-Ohm piece of fine gage nichrome that is 3 cm long it will get hotter than a 6-Ohm piece of heavier nichrome that is 30 cm long, even though both are dissipating 24 Watts at 12 Volts. (12 Volts through 6 Ohms = 2 Amps, 2 Amps at 12 Volts = 24 Watts)

If your nichrome is too fine a gage and is getting too hot you can decrease the power density by using two 12-Ohm strands in parallel. Each will draw half the current (1 Amp) and each will be twice as long (12 Ohm instead of 6).

-------------------------------------------------------

> The temperature that nichrome reaches is

> determined according to wattage, correct?

The temperature depends on power density, not just power (Watts). If you have a 6-Ohm piece of fine gage nichrome that is 3 cm long it will get hotter than a 6-Ohm piece of heavier nichrome that is 30 cm long, even though both are dissipating 24 Watts at 12 Volts. (12 Volts through 6 Ohms = 2 Amps, 2 Amps at 12 Volts = 24 Watts)

If your nichrome is too fine a gage and is getting too hot you can decrease the power density by using two 12-Ohm strands in parallel. Each will draw half the current (1 Amp) and each will be twice as long (12 Ohm instead of 6).

|

DB

Re: Nichrome Wire Questions June 16, 2010 06:32PM |

|

Re: Nichrome Wire Questions June 25, 2010 11:31PM |

Registered: 14 years ago Posts: 16 |

We have figured out that part of the problem was the heater wire touching itself, we have fixed that and the wire still melts right through the kapton tape. We are using the techzone boards. The extruder controller was giving 12 volts DC and 1.7amps DC to the nichrome wire. We are using a 6ohm length of nichrome wire. We have tried bare wire surrounded by Kapton tape, and the fiberglass insulated wire from makerbot.

Thanks in advance for any advice.

~Ryan

Thanks in advance for any advice.

~Ryan

|

Re: Nichrome Wire Questions June 26, 2010 04:54AM |

Admin Registered: 17 years ago Posts: 7,879 |

Did you get your Kapton tape from Deal Extreme? You may have some fake Kapton that melts at low temperatures. Try testing it with a soldering iron.

[casainho-emcrepstrap.blogspot.com]

[www.hydraraptor.blogspot.com]

[casainho-emcrepstrap.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Nichrome Wire Questions June 27, 2010 12:30AM |

Registered: 14 years ago Posts: 380 |

I would also check the heater controller. It sounds like the driver for the nicrome is stuck on, so that no matter how hot the wire is, it keeps sending more power. You should be able to change the set point in the software so that it will turn off at a lower temperature. Try setting the heater controller for a temperature of 90C or less. Disconnect the nicrome altogether. Connect the heater output to a voltmeter. Power everything up and the meter should read 12 volts. Dip the thermistor into boiling water and the meter should read 0 volts. If you can not get the heater controller to switch on and off by heating and cooling the thermistor, then it will either do nothing, or burn the nicrome and melt the tape. If you bought the kapton tape from McMaster-Carr with the silicone based adhesive, it should be good for 500C. If you are melting that then you have a runaway heater system!

Mike

Mike

|

Re: Nichrome Wire Questions July 08, 2010 01:22PM |

Registered: 14 years ago Posts: 16 |

We tried running our extruder again with our new thermistor, and new Kapton tape. We are still using fiberglass insulated wire from makerbot. Aside from a little smoke, we thought everything was working fine, but then after around 60 seconds, we noticed large globs of melted goop around the extruder. There are pictures at the links below.

In addition we checked to make sure the controller switches off when it has reached its target temperature.

Also our thermal barrier is nylon, not teflon, will that make a difference?

Any help would be greatly appreciated.

[img820.imageshack.us]

Edit: Further testing has indicated that we have indeed melted the nylon we used to make the thermal barrier. If we can't fix it we've got some other materials on hand we think would work well.

Edited 1 time(s). Last edit at 07/08/2010 02:48PM by HSRepProject.

In addition we checked to make sure the controller switches off when it has reached its target temperature.

Also our thermal barrier is nylon, not teflon, will that make a difference?

Any help would be greatly appreciated.

[img820.imageshack.us]

Edit: Further testing has indicated that we have indeed melted the nylon we used to make the thermal barrier. If we can't fix it we've got some other materials on hand we think would work well.

Edited 1 time(s). Last edit at 07/08/2010 02:48PM by HSRepProject.

|

Re: Nichrome Wire Questions July 08, 2010 02:43PM |

Registered: 13 years ago Posts: 7,616 |

Nylon (PA 6) has a melting temperature of 220 C, Teflon (PTFE) one of 327 C.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Nichrome Wire Questions September 25, 2010 12:20AM |

|

Re: Nichrome Wire Questions March 25, 2013 02:49AM |

|

Re: Nichrome Wire Questions September 05, 2015 09:39PM |

Registered: 8 years ago Posts: 1 |

|

Re: Nichrome Wire Questions September 08, 2015 09:45PM |

Registered: 10 years ago Posts: 39 |

Quote

photografr7

If Nichrome wire is heated in a vacuum to 300-400C, what color will it glow?

Black body radiation color is independent of material. 400C looks dimly red in the dark. Temperature chart

|

Re: Nichrome Wire Questions September 09, 2015 04:51PM |

Registered: 10 years ago Posts: 580 |

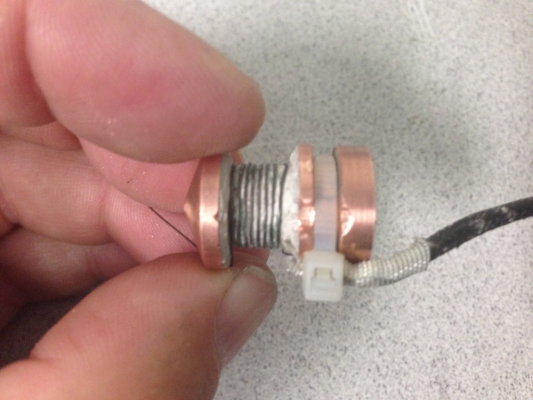

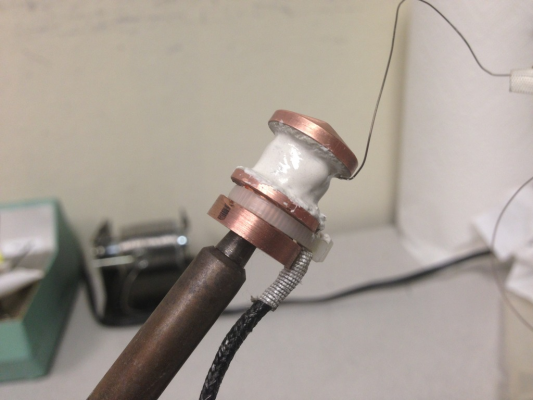

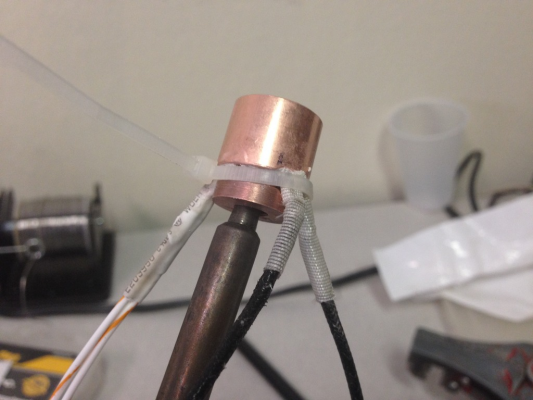

Instead of Kapton you could use Autocrete Hi-Temp Ceramic Adhesive.

When mixed with water it forms a paste that can be brushed on.

I got the nichrome from a fishtank heater. It took 33 inches for 17.42 ohms. I was shooting for a maximum of 45 watts at 28 volts (although I run it a lower voltage than that).

When I made my hot end I brushed on a layer of Autocrete and stuck the hot-end on a soldering iron to cure. Then I wrapped layers of nichrome carefully so they did not touch - that's the hardest part. You could try using thread between each, and then removing it.

Then I brushed Autocrete over each layer and let it cure before winding the next layer.

And I finished it off with more autocrete and part of a pipe fitting, and let it cure.

My only issue with it is I wish I had made the nozzle come to more of a point. Still working great tho.

BTW the copper I used is Tellurium Copper, it machines just about as well as brass.

Make sure you are calculating the wattage correctly (what wattage are you aiming for?)

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

When mixed with water it forms a paste that can be brushed on.

I got the nichrome from a fishtank heater. It took 33 inches for 17.42 ohms. I was shooting for a maximum of 45 watts at 28 volts (although I run it a lower voltage than that).

When I made my hot end I brushed on a layer of Autocrete and stuck the hot-end on a soldering iron to cure. Then I wrapped layers of nichrome carefully so they did not touch - that's the hardest part. You could try using thread between each, and then removing it.

Then I brushed Autocrete over each layer and let it cure before winding the next layer.

And I finished it off with more autocrete and part of a pipe fitting, and let it cure.

My only issue with it is I wish I had made the nozzle come to more of a point. Still working great tho.

BTW the copper I used is Tellurium Copper, it machines just about as well as brass.

Make sure you are calculating the wattage correctly (what wattage are you aiming for?)

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Sorry, only registered users may post in this forum.