Converting 3mm filament bowden system to 1.75mm...

Posted by mr.sneezy

|

Converting 3mm filament bowden system to 1.75mm... March 21, 2015 09:29AM |

Registered: 9 years ago Posts: 59 |

I have a new 3D printer at work that's based on Ultimaker, and was setup for 3mm filament originally. I've converted the feeder drive for 1.75mm filament (ABS), and the main bowden line has been changed to a tube with 2mm ID (approx) to suit the smaller diameter filament. What has not been changed is the original PTFE tube inside the extruder, it's still 3mm right from the entry on the extruder body to the nozzle. I'm finding I'm having trouble with the feeder binding up, by wrapping filament around the hobbed drive roller. I think this is happening because of back pressure in the extruder when using 1.75mm ABS(cause and effect...).

As I have not converted an extruder like this before, I'm wondering if the throat of the extruder needs to be matched to filament diameter (1.75mm or 3mm), or if that doesn't matter normally ?

Anybody got experience with converting extruders from 3mm to 1.75mm ?

Martin

Edited 1 time(s). Last edit at 03/21/2015 09:29AM by mr.sneezy.

As I have not converted an extruder like this before, I'm wondering if the throat of the extruder needs to be matched to filament diameter (1.75mm or 3mm), or if that doesn't matter normally ?

Anybody got experience with converting extruders from 3mm to 1.75mm ?

Martin

Edited 1 time(s). Last edit at 03/21/2015 09:29AM by mr.sneezy.

|

Re: Converting 3mm filament bowden system to 1.75mm... March 21, 2015 10:16AM |

Admin Registered: 11 years ago Posts: 3,096 |

Most hotends are specifically designed to print with 3mm or 1.75mm filament. Not only should you change the inner PTFE tube, but the melt-chamber of the hotend is in most cases also different. My advise would be to replace the hotend completely to a 1.75mm spec hotend.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Converting 3mm filament bowden system to 1.75mm... March 21, 2015 07:42PM |

Registered: 9 years ago Posts: 59 |

Thanks Marinus.

Maybe others here have also got experiences on converting extruder's,and could confirm that we'd be better off with a new extruder and hotend than trying to reuse the old one ?

Baring that I'll see if the vendor has a 1.75mm option, or else convert back to 3mm and see how it goes with that filament.

The original conversion to 1.75mm was to be filament compatible with other local machines that use that size.

Maybe others here have also got experiences on converting extruder's,and could confirm that we'd be better off with a new extruder and hotend than trying to reuse the old one ?

Baring that I'll see if the vendor has a 1.75mm option, or else convert back to 3mm and see how it goes with that filament.

The original conversion to 1.75mm was to be filament compatible with other local machines that use that size.

|

Re: Converting 3mm filament bowden system to 1.75mm... March 21, 2015 08:43PM |

Admin Registered: 11 years ago Posts: 3,096 |

With the J-head that I had, the throat of the heating block was also drilled to a specific size. I've understood that if the diameter of the inner PTFE tube is 3mm when printing with 1.75 you will get the effect of the molten plastic being pushed up through that PTFE tube. This results in the plastic forming a big plug in the PTFE tube in the insulator zone and you will have no or low extrusion pressure in the melt chamber resulting in poor extrusion.

I could get a 1.75mm spec heater block at that time, and this worked well for me when I converted the J-head. The only thing that I could keep was the PEEK insulator part.

What kind of hotend do you use?

http://www.marinusdebeer.nl/

I could get a 1.75mm spec heater block at that time, and this worked well for me when I converted the J-head. The only thing that I could keep was the PEEK insulator part.

What kind of hotend do you use?

http://www.marinusdebeer.nl/

|

Re: Converting 3mm filament bowden system to 1.75mm... March 22, 2015 08:34AM |

Registered: 9 years ago Posts: 59 |

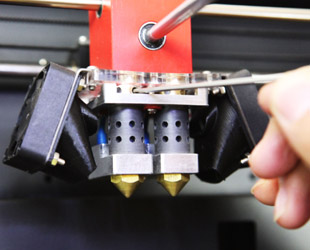

I don't know the name of the dual hotend, it's what was supplied with the Ultimaker style machine, which runs Marlin firmware. I'm only using one side at the moment, given the trouble I'm having I've not had time to setup the other side yet.

Here's an image though of the whole hotend.

When I've had a block up, I have pulled out a 15mm long 3mm diameter plug of 1.75mm filament from the hotend...

Edited 2 time(s). Last edit at 03/22/2015 08:38AM by mr.sneezy.

Here's an image though of the whole hotend.

When I've had a block up, I have pulled out a 15mm long 3mm diameter plug of 1.75mm filament from the hotend...

Edited 2 time(s). Last edit at 03/22/2015 08:38AM by mr.sneezy.

Sorry, only registered users may post in this forum.