pellet extruder??

Posted by fatesalign

|

pellet extruder?? April 23, 2015 07:21PM |

Registered: 9 years ago Posts: 158 |

Hello everyone. I was wondering if anyone tried this: [3dprintingindustry.com] I was looking at buying a filament extruder, but then I came across this. I don't want to get it and everyone switch to this type of extrusion. Any ideas? Thanks.

|

Re: pellet extruder?? April 23, 2015 08:09PM |

Registered: 9 years ago Posts: 6 |

|

Re: pellet extruder?? April 23, 2015 09:07PM |

Registered: 11 years ago Posts: 973 |

Granular or pellet extruder on a printer isn't a graveyard topic it's a ongoing project for some. It's prob next step as it's cheaper to buy pellet than filiment also gives you more colour mixing capabilities and like everything in reprap takes development to get a project working correctly

Edited 1 time(s). Last edit at 04/23/2015 09:11PM by chris33.

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Edited 1 time(s). Last edit at 04/23/2015 09:11PM by chris33.

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: pellet extruder?? April 23, 2015 09:37PM |

Registered: 9 years ago Posts: 6 |

|

Re: pellet extruder?? April 23, 2015 09:37PM |

Registered: 9 years ago Posts: 978 |

The pellets being used in that example were 25Euro for 1.2kg.... not really cheaper than (cheap) PLA filament from China at about US$20/kg. Cheap PLA pellets from China go from about $2/kg in 25kg+ lots up to about $10 per kg in 1kg lots. So not a huge saving, unless you're doing a *lot* of printing.

|

Re: pellet extruder?? April 23, 2015 09:57PM |

Registered: 9 years ago Posts: 6 |

|

Re: pellet extruder?? April 23, 2015 11:23PM |

Registered: 9 years ago Posts: 978 |

Quote

senior_eduardo

Quote

frankvdh

The pellets being used in that example were 25Euro for 1.2kg

Bologna. There's obviously a HUGE cost advantage in printing pellets. They're not turning pellets into filament for free. I can get PLA for <$5/lbs.

I'm not doubting that you *can* get cheap pellets. But the pellets being used in that example were 25Euro for 1.2kg

Incidentally, $5/lb is about $11/kg, which is at the expensive end of the cheap Chinese pellets.

So pellets are about half to a third the price of filament. That's only HUGE if you use a lot of filament.

|

Re: pellet extruder?? April 23, 2015 11:35PM |

Registered: 9 years ago Posts: 6 |

|

Re: pellet extruder?? April 24, 2015 02:48AM |

Registered: 11 years ago Posts: 973 |

well the idea is out there by the means of richrap and to be honest it takes the likes of us to develope it further there is also a advantage to of being able to feed the printer by pellet or chopped pieces and that is recycling scrap prints or other plastics so senior_eduardo your in a wrong place if you cant really understand what open source and reprap is all about

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: pellet extruder?? April 25, 2015 11:33AM |

Registered: 9 years ago Posts: 158 |

|

Re: pellet extruder?? May 02, 2015 07:08PM |

Registered: 8 years ago Posts: 10 |

Hello! Too I am interested in this extruder, I will surely unpack and I will test, join. Maybe who has an experience of the press on this extruder, the photo in work and that turns out would be desirable to look. All responses about it muffled or bad though in practice nobody checked. If a detail then to process and paint - this extruder that that is necessary =)

|

Re: pellet extruder?? June 19, 2015 04:06PM |

Registered: 8 years ago Posts: 1 |

I'm currently in the process of testing the RichRap U.P.E device for pellet extrusion. If anyone is interested I'll be keeping a running log of my observations. The first thing I seem to notice is that the bearings are not 606 as mentioned in the blog post. They're closer to 626 bearings. It's a tight fit, but I'm removing excess material with a file to make the fit.

Regards

-------------------

Abbas Ahsan

Intern : R&D Engineer

re:3D

Think Big, Print HUGE, Your Gigabot

Austin, TX : Houston, TX

www.re3D.org

abbas.ahsan@re3d.org

Regards

-------------------

Abbas Ahsan

Intern : R&D Engineer

re:3D

Think Big, Print HUGE, Your Gigabot

Austin, TX : Houston, TX

www.re3D.org

abbas.ahsan@re3d.org

|

Re: pellet extruder?? August 26, 2015 02:21PM |

Registered: 9 years ago Posts: 4 |

|

Re: pellet extruder?? August 26, 2015 04:20PM |

Registered: 8 years ago Posts: 396 |

Quote

senior_eduardo

I don't see a 3/8" auger bit on a .4mm nozzle achieving retraction on par with a standard filament extruder. All the development in the world won't change that. I tend to believe that something this simple hasn't been done yet because it's impossible.

2008 - printing 3d objects from plastic line is impossible!

|

Re: pellet extruder?? August 28, 2015 03:40PM |

Registered: 11 years ago Posts: 210 |

Quote

thetazzbot

Quote

senior_eduardo

I don't see a 3/8" auger bit on a .4mm nozzle achieving retraction on par with a standard filament extruder. All the development in the world won't change that. I tend to believe that something this simple hasn't been done yet because it's impossible.

2008 - printing 3d objects from plastic line is impossible!

Actually printing objects from plastic filament was done 30 years ago, its nothing new.

|

Re: pellet extruder?? November 21, 2015 10:01AM |

Registered: 8 years ago Posts: 69 |

Ciao,

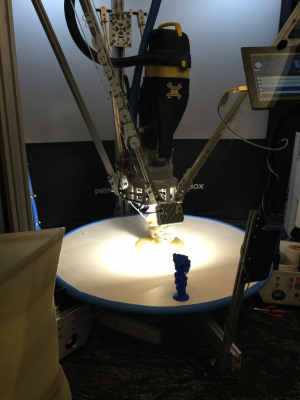

I am in the process of building a pellet extruder similar to this one: [upe3d.blogspot.it]

Will build it in steel since I will need to print carbon fiber as main material.

I already build an extruder with one motor, 2 servos for 4 materials. It works fine but maintenance is a pain.

Will do a post as soon as I get the pieces and will start to assemble it.

Alessandro

I am in the process of building a pellet extruder similar to this one: [upe3d.blogspot.it]

Will build it in steel since I will need to print carbon fiber as main material.

I already build an extruder with one motor, 2 servos for 4 materials. It works fine but maintenance is a pain.

Will do a post as soon as I get the pieces and will start to assemble it.

Alessandro

|

Re: pellet extruder?? November 21, 2015 01:50PM |

Registered: 10 years ago Posts: 580 |

It's an interesting Idea.

I was at the World 3d Printer Expo in Burbank this year (exhibiting my printer with my Makerspace) and was next to the See-me-cnc booth. They had their huge pellet fed delta there.

So I got to watch that thing attempt to print for the weekend, it left a lasting impression. It was painful to watch, not one good print, but it did get on the news, a shame really.

I hope you succeed, and find some ways around these pitfalls:

- Pellet extruders are heavier. Ugh. The one at the show made the entire machine shake as it moved ponderously around. Travel speed and acceleration will be affected.

- Can't retract! Up to now, no way to retract. It's not gonna be pretty.

- Much less control of changes in print volume than a normal extruder.

- Have to be restocked with pellets during a big job. They had 55 gallon barrels of PLA, and a vacuum arrangement to re-fill the hopper

IMHO, if cost is the issue, then it would be better to invest in a reliable filament bot and produce consistent filament. That would pay for itself. Your time is more valuable.

What I'd like to have seen at the show was them using a filament bot to make some 6mm filament, and feed that to the big delta. If they'd done that (and made the frame stiffer) it would have been awesome. .

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I was at the World 3d Printer Expo in Burbank this year (exhibiting my printer with my Makerspace) and was next to the See-me-cnc booth. They had their huge pellet fed delta there.

So I got to watch that thing attempt to print for the weekend, it left a lasting impression. It was painful to watch, not one good print, but it did get on the news, a shame really.

I hope you succeed, and find some ways around these pitfalls:

- Pellet extruders are heavier. Ugh. The one at the show made the entire machine shake as it moved ponderously around. Travel speed and acceleration will be affected.

- Can't retract! Up to now, no way to retract. It's not gonna be pretty.

- Much less control of changes in print volume than a normal extruder.

- Have to be restocked with pellets during a big job. They had 55 gallon barrels of PLA, and a vacuum arrangement to re-fill the hopper

IMHO, if cost is the issue, then it would be better to invest in a reliable filament bot and produce consistent filament. That would pay for itself. Your time is more valuable.

What I'd like to have seen at the show was them using a filament bot to make some 6mm filament, and feed that to the big delta. If they'd done that (and made the frame stiffer) it would have been awesome. .

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: pellet extruder?? November 21, 2015 02:17PM |

Registered: 8 years ago Posts: 69 |

Ciao,

here more videos from those guys.

The results seems decent.

About your point:

1 - weight, it depends on implementation, pellets holder should not be on the extruder

2 - retraction is a problem

3 - not sure what you mean, pls explain

4 - since my print job is huge, filaments are an issue, that's why want to try pellets, you fill 3 or 4kg and forget it

My extruder design is 180mm height including motor and btw my printer is huge, 1200x600x600mm with dual extruder at the moment.

Will be all stainless steel including nozzles. Will try to post some pictures next week when I get the steel pieces.

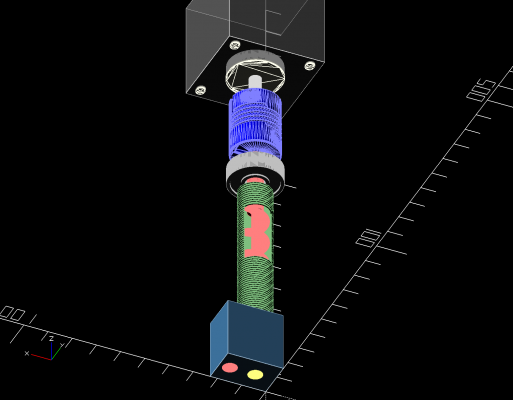

Here is a design:

Alessandro

Edited 4 time(s). Last edit at 11/21/2015 02:46PM by biskero.

here more videos from those guys.

The results seems decent.

About your point:

1 - weight, it depends on implementation, pellets holder should not be on the extruder

2 - retraction is a problem

3 - not sure what you mean, pls explain

4 - since my print job is huge, filaments are an issue, that's why want to try pellets, you fill 3 or 4kg and forget it

My extruder design is 180mm height including motor and btw my printer is huge, 1200x600x600mm with dual extruder at the moment.

Will be all stainless steel including nozzles. Will try to post some pictures next week when I get the steel pieces.

Here is a design:

Alessandro

Edited 4 time(s). Last edit at 11/21/2015 02:46PM by biskero.

|

Re: pellet extruder?? November 21, 2015 04:04PM |

Registered: 8 years ago Posts: 69 |

|

Re: pellet extruder?? November 21, 2015 05:36PM |

Registered: 10 years ago Posts: 580 |

Quote

biskero

Much less control of changes in print volume than a normal extruder.

- not sure what you mean, pls explain

Sorry, I meant to say "less control of extrusion rate".

In a regular extruder the output mm3/second is linearly related to the pressure applied, and combined with retraction, the output extrusion rate can be precisely and (nearly) instantly controlled over a large range. So you can print an outside perimeter or "small perimeter" at a lower speed and low extrusion rate, then go directly to a high extrusion rate for infill or inside perimeters or bridging, then back to a low rate. *

If a pellet extruder is extruding at a high rate, can it slow down to a slower rate quickly, and go back to a higher rate quickly? Will it get air bubbles if the screw is reversed? I don't think there can be as much pressure control as you get using a filament that is directly driven. It may not matter depending on the resolution you need, but it could also slow down your print a lot, and make certain kinds of operations difficult. I hope I'm wrong, their videos showed some pretty rough stuff. Not being able to retract would be a deal breaker for me.

Note that the See-me-cnc delta appears to only be printing at about 30mm/sec in that video, and was doing a very simple continuously rounded shape. At the show it appeared to be only using one extrusion width also, and it would hop up to try to break the blob before going to the next location, which didn't work well. Perhaps you could put a valve on the nozzle.

You'll want to make sure that the extrusion rate of the pellet fed extruder is actually high enough for the large prints you want to do, and reliable enough.

BTW, you can buy 3kg rolls of filament now.

Good luck with your project!

* I realize these large changes in extrude rate are not always handled properly with current slicers. With bowden extruders there is a small time delay required when starting a high-rate extrude while pressure builds, and extra pressure is needed to begin at that rate, which needs to be removed later, etc. However the hardware is capable of full pressure control if it is commanded properly. I'm working on a project to do this: Coast while Retracting, First Segment Acceleration, and Pressure Compensation.

|

Re: pellet extruder?? November 21, 2015 05:50PM |

Registered: 8 years ago Posts: 69 |

Ciao,

very good points.

"If a pellet extruder is extruding at a high rate, can it slow down to a slower rate quickly, and go back to a higher rate quickly?"

Thats a good point which is fundamental for high quality and high definition prints.

Will certainly need to do a lot of testing and also tweaking in the Marlin firmware.

I am going to use a wood drill bit which will "eat" more pellets so that there will be more pressure given by the pellets.

Also the nozzles are 0.6/0.8 and 1.0mm and they are similar to the one used from Volcano E3D hotends, which means that are toll enough so that it re-creates a short "filament" while we melt the pellets.

At least is the idea but will need to see it in action.

If you have links to pellets resellers please let me know, looking for HIPS and Carbon Fiber.

Alessandro

very good points.

"If a pellet extruder is extruding at a high rate, can it slow down to a slower rate quickly, and go back to a higher rate quickly?"

Thats a good point which is fundamental for high quality and high definition prints.

Will certainly need to do a lot of testing and also tweaking in the Marlin firmware.

I am going to use a wood drill bit which will "eat" more pellets so that there will be more pressure given by the pellets.

Also the nozzles are 0.6/0.8 and 1.0mm and they are similar to the one used from Volcano E3D hotends, which means that are toll enough so that it re-creates a short "filament" while we melt the pellets.

At least is the idea but will need to see it in action.

If you have links to pellets resellers please let me know, looking for HIPS and Carbon Fiber.

Alessandro

|

Re: pellet extruder?? November 23, 2015 11:32AM |

Registered: 8 years ago Posts: 3,525 |

How about essentially a pellet fed filament-extruder i.e. a filament maker being fed pellets outside of the printer and the filament generated being fed to the printer and extruded in the normal way. You might conceive of a system which requests to slow down the printer if the pellet based filament maker is struggling to produce the filament fast enough.

Yeah you could buy a filament extruder and pellets and make your own filament, but then there are spools, winding, storage, the time it takes etc...

This way you pour your pellets in, then print with them in the same way as you do with regular filament provided the filament extruder and printer can synchronise consumption to output. There is no excess weight on the printer, and retraction can be done normally assuming some slack in the filament between the pellet fed filament-extruder and the printer.

Edited 1 time(s). Last edit at 11/23/2015 11:33AM by DjDemonD.

Yeah you could buy a filament extruder and pellets and make your own filament, but then there are spools, winding, storage, the time it takes etc...

This way you pour your pellets in, then print with them in the same way as you do with regular filament provided the filament extruder and printer can synchronise consumption to output. There is no excess weight on the printer, and retraction can be done normally assuming some slack in the filament between the pellet fed filament-extruder and the printer.

Edited 1 time(s). Last edit at 11/23/2015 11:33AM by DjDemonD.

|

Re: pellet extruder?? November 23, 2015 11:42AM |

Registered: 8 years ago Posts: 69 |

Ciao,

The idea of creating you own filaments is in any case pretty cool.

I though about that but it complicates the system for my project.

I might need to pause the printing process to have inserts inside the print.

Also I might be able to speed up the printing which than will need to sync with the filament extruder.

Also if for any reasons the filament breaks it will stop the print.

In any case I will need to make a pellet machine to recycle all support materials and failed prints for sure.

I am getting the pellet extruders this week and ordered 25kg of HIPS.

Still need to get CF pellets, alibaba seems only choice for now.

Will post extruder pics if anyone is interested. BTW this is the printer.

Alessandro

Edited 1 time(s). Last edit at 11/23/2015 11:44AM by biskero.

The idea of creating you own filaments is in any case pretty cool.

I though about that but it complicates the system for my project.

I might need to pause the printing process to have inserts inside the print.

Also I might be able to speed up the printing which than will need to sync with the filament extruder.

Also if for any reasons the filament breaks it will stop the print.

In any case I will need to make a pellet machine to recycle all support materials and failed prints for sure.

I am getting the pellet extruders this week and ordered 25kg of HIPS.

Still need to get CF pellets, alibaba seems only choice for now.

Will post extruder pics if anyone is interested. BTW this is the printer.

Alessandro

Edited 1 time(s). Last edit at 11/23/2015 11:44AM by biskero.

|

Re: pellet extruder?? November 27, 2015 08:58AM |

Registered: 8 years ago Posts: 69 |

Ciao,

just received all the pieces for the stainless steel pellet extruder.

Waiting for other components to finish the build.

Alessandro

just received all the pieces for the stainless steel pellet extruder.

Waiting for other components to finish the build.

Alessandro

|

Re: pellet extruder?? December 04, 2015 11:10PM |

Registered: 10 years ago Posts: 118 |

Quote

biskero

Ciao,

here more videos from those guys.

The results seems decent.

About your point:

1 - weight, it depends on implementation, pellets holder should not be on the extruder

2 - retraction is a problem

3 - not sure what you mean, pls explain

4 - since my print job is huge, filaments are an issue, that's why want to try pellets, you fill 3 or 4kg and forget it

My extruder design is 180mm height including motor and btw my printer is huge, 1200x600x600mm with dual extruder at the moment.

Will be all stainless steel including nozzles. Will try to post some pictures next week when I get the steel pieces.

Here is a design:

Alessandro

Any more info on your huge printer?

I'm running into same issue - filament lasting. I guess i just have to make my own super large pools and use filastruder continuously for few days straight to fill them up

As for straight pellet extruder hotends -> I see a need for somekind of fast acting valve, magnetic perhaps, a ball in there to stop extrusion where retract would be needed.

Solve that and you are good to go. Something like a engine fuel injector but what actually works on 300-400C temps to allow any material to be used.

I can't wait when some engineering materials arrive - that stuff will require something like 390C to print!

|

Re: pellet extruder?? December 05, 2015 04:27AM |

Registered: 8 years ago Posts: 69 |

Ciao,

I have some pictures on the facebook project page.

You can follow the project on Twitter too Hackebike

Basically the printer is 1200x600x600mm for a print of almost 1m and at the moment will last 44hrs.

I already got 25Kg HIPS pellets for the support and in the process of purchasing 25Kg of PA6+30% Carbon Fiber pellets.

Getting a lot of Kg because I am sure will need to do some good testing before trying the big print.

Calibration will be the main issue since all firmware are based on filaments measurements.

I do not see retraction as a huge issue, at least for my case, maybe I am wrong but will see during tests.

Another issue I see is speed of print which needs to be in sync withe the melting of the pellets and so to the speed of the drill bit. A tricky problem.

But from what I have seen from the videos looks like is ok.

Alessandro

I have some pictures on the facebook project page.

You can follow the project on Twitter too Hackebike

Basically the printer is 1200x600x600mm for a print of almost 1m and at the moment will last 44hrs.

I already got 25Kg HIPS pellets for the support and in the process of purchasing 25Kg of PA6+30% Carbon Fiber pellets.

Getting a lot of Kg because I am sure will need to do some good testing before trying the big print.

Calibration will be the main issue since all firmware are based on filaments measurements.

I do not see retraction as a huge issue, at least for my case, maybe I am wrong but will see during tests.

Another issue I see is speed of print which needs to be in sync withe the melting of the pellets and so to the speed of the drill bit. A tricky problem.

But from what I have seen from the videos looks like is ok.

Alessandro

|

Re: pellet extruder?? December 05, 2015 10:01AM |

Registered: 10 years ago Posts: 128 |

|

Re: pellet extruder?? December 05, 2015 10:12AM |

Registered: 10 years ago Posts: 118 |

Nice! Where do you get that PA6+30% CF and how much does it cost?

Any chance of good overall pictures of the machine? I'm working on a large machine as well and would like to make comparisons.

You need really strong motor to push pellets thru extruder at exactly the pace you need, capable of doing probably like 2-4Nm @ 120RPM or something of the sort, but it also needs to be able to go quick for retract and then going back into position.

A wiredrive train might come in handy to lower the weight.

TBH, i would just make some very large diameter filament, like 6mm and modify a wade for larger gearing ratio to regain accuracy, perhaps add a 1:4 planetary gearbox you see on thingiverse on the nema 17 and it might be that easy!

Especially if you print the gearbox from PA6+30% CF it will last forever!

Any chance of good overall pictures of the machine? I'm working on a large machine as well and would like to make comparisons.

You need really strong motor to push pellets thru extruder at exactly the pace you need, capable of doing probably like 2-4Nm @ 120RPM or something of the sort, but it also needs to be able to go quick for retract and then going back into position.

A wiredrive train might come in handy to lower the weight.

TBH, i would just make some very large diameter filament, like 6mm and modify a wade for larger gearing ratio to regain accuracy, perhaps add a 1:4 planetary gearbox you see on thingiverse on the nema 17 and it might be that easy!

Especially if you print the gearbox from PA6+30% CF it will last forever!

|

Re: pellet extruder?? December 05, 2015 12:07PM |

Registered: 8 years ago Posts: 69 |

Ciao,

check the facebook page has a lot of pictures about the build of the printer.

I am getting the PA6+30% CF from China manufacturer specialized on these type of compounds and it's about $10/kg for the small amount I am getting.

If you get more cost less obviously. I doing prototypes so that I can evaluable both the compound and company relations!

The motors on the extruder are Nema 17 at 59Nm but I have stronger ones too.

I will post some pictures as soon as I start to do some tests on the extruder, probably after the holidays since I am waiting for the CF and other components to do some upgrades.

Backup is always filaments! But I am pretty confident pellets will work.

Consider I will print with a 1mm nozzle or maybe 0.8mm and the print will last 44hrs at the moment.

I am optimizing the design too to reduce both print time and make a better design of the ebike frame.

I found pretty much all the software I am using have issues with big prints design!

If you want you can follow progress on facebook project page or on Twitter Hackebike

Alessandro

Edited 2 time(s). Last edit at 12/05/2015 12:09PM by biskero.

check the facebook page has a lot of pictures about the build of the printer.

I am getting the PA6+30% CF from China manufacturer specialized on these type of compounds and it's about $10/kg for the small amount I am getting.

If you get more cost less obviously. I doing prototypes so that I can evaluable both the compound and company relations!

The motors on the extruder are Nema 17 at 59Nm but I have stronger ones too.

I will post some pictures as soon as I start to do some tests on the extruder, probably after the holidays since I am waiting for the CF and other components to do some upgrades.

Backup is always filaments! But I am pretty confident pellets will work.

Consider I will print with a 1mm nozzle or maybe 0.8mm and the print will last 44hrs at the moment.

I am optimizing the design too to reduce both print time and make a better design of the ebike frame.

I found pretty much all the software I am using have issues with big prints design!

If you want you can follow progress on facebook project page or on Twitter Hackebike

Alessandro

Edited 2 time(s). Last edit at 12/05/2015 12:09PM by biskero.

|

Re: pellet extruder?? December 07, 2015 12:14AM |

Registered: 10 years ago Posts: 118 |

Sorry, only registered users may post in this forum.