Deformable printed objects

Posted by OliveOyl

|

Deformable printed objects May 05, 2015 04:31AM |

Registered: 8 years ago Posts: 4 |

As a foreword, please bear with me as I am completely novice in 3D printing -- but I have an extensive experience in the mechanics of deformable objects and of liquids.

I believe that many useful 3D printed parts are made of relatively soft material, and this deformability can be used for a practical purpose : as a simple example, think of tablecloth clips:

It seems to me that this type of structure is not widely used yet in 3D printing, or is it ?

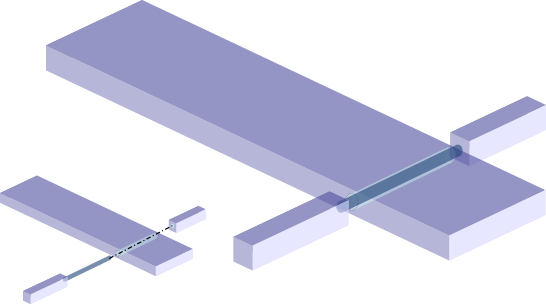

I think it could simplify the design of small-scale objects performing a mechanical task, as it seems to me also that it is easier to print a single connected but deformable part acting as a micro-machine, rather than several parts that you have to assemble into a machine. E.g., if you need a lever, one solution is this :

There are 3 parts to assemble, at least, including a thin one which may have to be metal (axle). And you probably need a spring somewhere so that the lever has some well defined rest position.

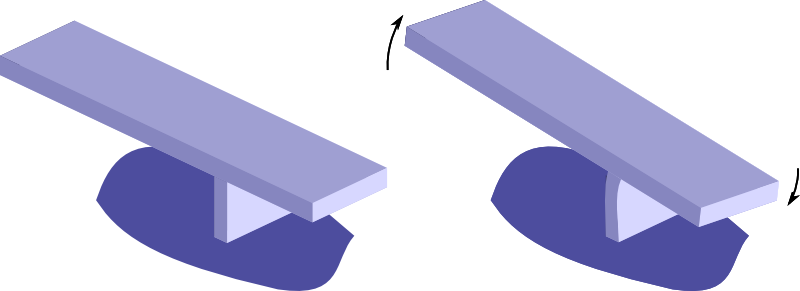

A one-piece lever using material flexibility could be this:

Can you point me to designs using that sort of concept, and possibly issues about it (material wear, design reliability, ...) ? I think I can provide useful design tools for this type of mechanical device.

I believe that many useful 3D printed parts are made of relatively soft material, and this deformability can be used for a practical purpose : as a simple example, think of tablecloth clips:

It seems to me that this type of structure is not widely used yet in 3D printing, or is it ?

I think it could simplify the design of small-scale objects performing a mechanical task, as it seems to me also that it is easier to print a single connected but deformable part acting as a micro-machine, rather than several parts that you have to assemble into a machine. E.g., if you need a lever, one solution is this :

There are 3 parts to assemble, at least, including a thin one which may have to be metal (axle). And you probably need a spring somewhere so that the lever has some well defined rest position.

A one-piece lever using material flexibility could be this:

Can you point me to designs using that sort of concept, and possibly issues about it (material wear, design reliability, ...) ? I think I can provide useful design tools for this type of mechanical device.

|

Re: Deformable printed objects May 05, 2015 05:01AM |

Registered: 12 years ago Posts: 375 |

|

Re: Deformable printed objects May 05, 2015 05:07AM |

Registered: 12 years ago Posts: 375 |

You'll also find a lot with ''laser cut" as key words in thingiverse or elsewhere ;

like

[www.thingiverse.com]

for exemple

like

[www.thingiverse.com]

for exemple

|

Re: Deformable printed objects May 05, 2015 05:22AM |

Registered: 8 years ago Posts: 4 |

Thanks tchitchou. I was thinking of cases where the flexibility is not just a feature but accomplishes a mechanical purpose.

The S-Carabiner is somewhat like this (your first link), meaning that elasticity is a possibility for designing objects with a mechanical purpose. Now is it used in more complex mini-machines (I've seen ones with cogwheels, etc.) and if not, what are the issues ? I think I may help solve some, or identify them.

The S-Carabiner is somewhat like this (your first link), meaning that elasticity is a possibility for designing objects with a mechanical purpose. Now is it used in more complex mini-machines (I've seen ones with cogwheels, etc.) and if not, what are the issues ? I think I may help solve some, or identify them.

|

Re: Deformable printed objects May 05, 2015 05:51AM |

Registered: 12 years ago Posts: 375 |

There is a 3D printed spring on the eggbot, two.

See [www.thingiverse.com]

The first file.

Some ratchets, two ?

[www.thingiverse.com]

See [www.thingiverse.com]

The first file.

Some ratchets, two ?

[www.thingiverse.com]

|

Re: Deformable printed objects May 05, 2015 08:38AM |

Registered: 10 years ago Posts: 869 |

Depending on the material as well as the design, you may have an issue where the plastic can't handle the fatigue or other mechanical stresses of repeated flexing. Your lever for example likely wouldn't bend as shown on the vertical "post". What is more likely is that the horizontal "beam" would flex until the point where the yield strength at the T is reached and then it snaps.

|

Re: Deformable printed objects May 05, 2015 11:10AM |

Registered: 8 years ago Posts: 4 |

Thanks for both answers.

The spring structure in the eggbot is interesting for me, it may well be a better example rather than the lever of what type of elastic structures are currently possible using 3D printing:

It seems that currently such parts are created according to pure know-how and intuition of the maker, aren't they?

In the case of the lever, as cdru writes, the intuition is that there'll be a high tensile stress just under the branching of the T, this will cause fatigue of the material and eventually rupture. But the design can be improved, e.g. with rounded junctions. Then another issue is to determine the relative thickness (and/or density of the filling structure) in the vertical post of the T relative to the one of the horizontal beam so that you get the behaviour you're after.

So I believe that this amounts to two questions for the maker:

EDIT: Additionally, I believe my idea is useful only if one wants to test relatively complex designs, especially ones you'll get if you minimize the number of separate parts : that was the idea behind the one-piece lever, you do not have to assemble it compared to a traditional axle technique. Do I over estimate the time spent in assembly, or is it really an issue ?

Edited 1 time(s). Last edit at 05/05/2015 11:24AM by OliveOyl.

The spring structure in the eggbot is interesting for me, it may well be a better example rather than the lever of what type of elastic structures are currently possible using 3D printing:

It seems that currently such parts are created according to pure know-how and intuition of the maker, aren't they?

In the case of the lever, as cdru writes, the intuition is that there'll be a high tensile stress just under the branching of the T, this will cause fatigue of the material and eventually rupture. But the design can be improved, e.g. with rounded junctions. Then another issue is to determine the relative thickness (and/or density of the filling structure) in the vertical post of the T relative to the one of the horizontal beam so that you get the behaviour you're after.

So I believe that this amounts to two questions for the maker:

- Will it work? Will I get the displacements I expect from the different parts.

- Will it last? Is the material strong enough to resist these displacements, where will failure likely occur.

EDIT: Additionally, I believe my idea is useful only if one wants to test relatively complex designs, especially ones you'll get if you minimize the number of separate parts : that was the idea behind the one-piece lever, you do not have to assemble it compared to a traditional axle technique. Do I over estimate the time spent in assembly, or is it really an issue ?

Edited 1 time(s). Last edit at 05/05/2015 11:24AM by OliveOyl.

|

Re: Deformable printed objects May 05, 2015 12:14PM |

Registered: 10 years ago Posts: 869 |

I don't want to sound discouraging. Really I think something like what you are envisioning could be useful. But I think you're really underestimating the complexity of the issue. Different materials and different printers printing with different settings in different orientations are going to have drastically different results. Even different batches of the same material could have pretty different characteristics depend on age, moisture content, uv exposure, etc.Quote

OliveOyl

So I believe that this amounts to two questions for the maker:

I believe I can develop the software to address these questions. And possibly to help makers improve their designs. Then my next question is, will it be of use?

- Will it work? Will I get the displacements I expect from the different parts.

- Will it last? Is the material strong enough to resist these displacements, where will failure likely occur.

To answer your question if current parts are designed pure know-how and intuition, I wouldn't say exclusively, but a lot of it is just that, plus a lot of trial and error, trying out different designs, and an iterative approach. Try this design. Print it out. See if it works. See how it broke. See how you can design it so it doesn't break. Reprint. Break it a different way. Rinse. Repeat. FDM printing makes such things much more convenient as if you had to machine a new mold for each iteration your development costs for a simple part could be enormous. There are also commercial software packages are are meant to model and simulate stresses in a component, but they are going to be prohibitively expensive for the hobbyist.

|

Re: Deformable printed objects May 05, 2015 05:26PM |

Registered: 9 years ago Posts: 978 |

My own design in this space

Also try searching Thingiverse for "mesostructure" e.g.

Edited 1 time(s). Last edit at 05/05/2015 05:29PM by frankvdh.

Also try searching Thingiverse for "mesostructure" e.g.

Edited 1 time(s). Last edit at 05/05/2015 05:29PM by frankvdh.

|

Re: Deformable printed objects May 05, 2015 06:04PM |

Admin Registered: 13 years ago Posts: 730 |

There is a page on the wiki that includes examples, links to other projects, and some basic analysis: Compliant Linear Motion Mechanism.

Delgir made an entire 3D printer using deformable objects. It is described in this thread: Parallel flexure test.

Delgir made an entire 3D printer using deformable objects. It is described in this thread: Parallel flexure test.

|

Re: Deformable printed objects May 06, 2015 03:49AM |

Registered: 8 years ago Posts: 4 |

Thanks for all these thoughts and links. I think what I need now is mainly to hang around the nearest fablab for a while, and try out a few things.

depend on how many variables you need (e.g. all orientation couples...). But I believe some simplifying assumptions can help a lot (e.g. a piece with

no shape variations and no deformations along z, as the spring or lever above)

Of course, testing fatigue under repeated strain would necessitate to apply repeated strain in a sample... But you have stepper motors, don't you?

Though I believe the people in this forum would quite easily overcome that with just a bit of guidance -- if anyone wants to give it a try, I'm willing to help.

Yes, I have alsot that in mind. A calibration test would be necessary, but I guess you can just... print it! Then of course the complexity of doing so willQuote

cdru

Different materials and different printers printing with different settings in different orientations are going to have drastically different results

depend on how many variables you need (e.g. all orientation couples...). But I believe some simplifying assumptions can help a lot (e.g. a piece with

no shape variations and no deformations along z, as the spring or lever above)

Of course, testing fatigue under repeated strain would necessitate to apply repeated strain in a sample... But you have stepper motors, don't you?

There's free software around with which you can solve elasticity in 3D (such as freefem 3d, rheolef, ...) but it's true that they are rather meant for a research-level usage.Quote

cdru

There are also commercial software packages are are meant to model and simulate stresses in a component, but they are going to be prohibitively expensive for the hobbyist.

Though I believe the people in this forum would quite easily overcome that with just a bit of guidance -- if anyone wants to give it a try, I'm willing to help.

|

Re: Deformable printed objects May 06, 2015 11:56AM |

Registered: 12 years ago Posts: 375 |

Sorry, only registered users may post in this forum.